@bjornhallberg said:

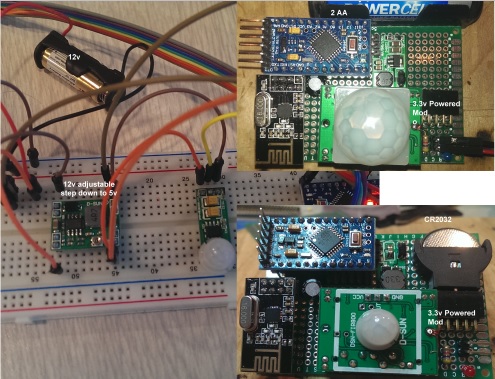

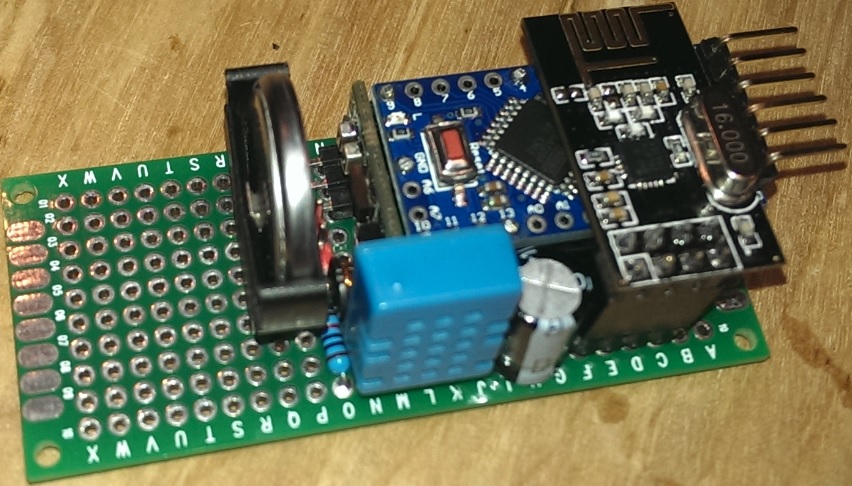

I have no step-up in the circuit, just 2xAA that powers the NRF24 directly and then the HC-SR501 is powered from the Arduino Pro Mini, not grounded next to the RAW pin but it seems to work anyway. No idea at what voltage the HC-SR501 will start to experience problems but I guess we'll find out as the battery level drops.

Are the 2xAA that power the NRF24 also powering the Pro Mini or are you using another power source?

Are you running the HC-SR501 in its 4.5v mode or the 3.3v modification?

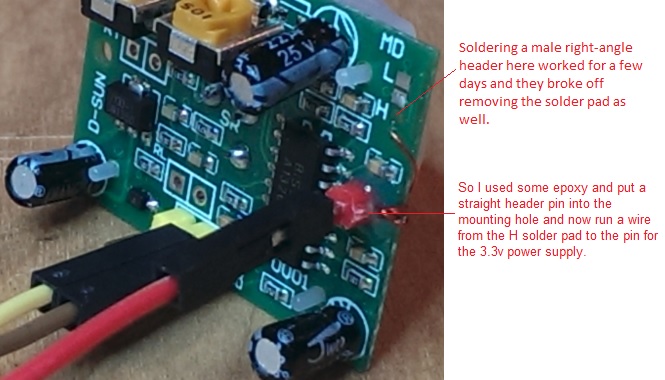

I believe it was the step up converter in my case as it has been 3 days, working fine, and the 2-AA's still report 3.3v when not connected to the sensor.

Thanks