What did you build today (Pictures) ?

-

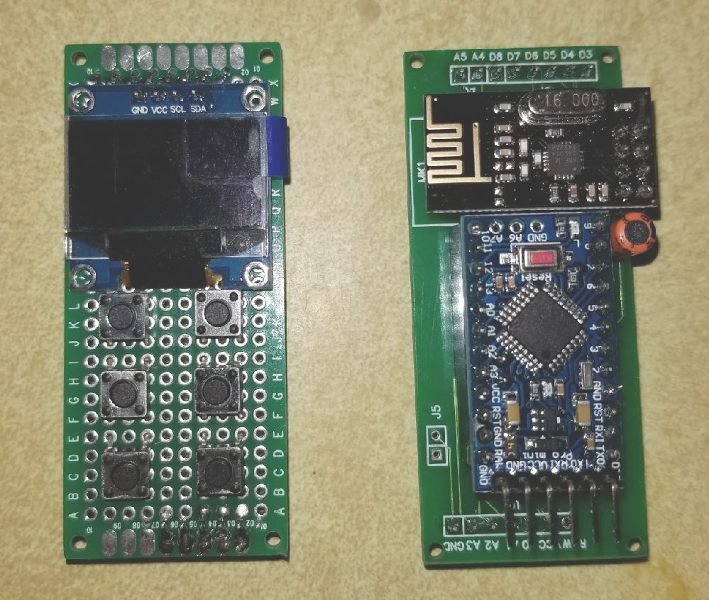

Finally got the PCBs from AllPCB.com (cost 5 Euros and took a total of 7 days from order submission to free DHL delivery to Europe!!!) for my own MySensors Arduino Pro Mini prototyping board. Unfortunately the soldering iron broke during my assembly, so it's not fully finished and I couldn't test it yet, either...

This board is inspired by the Nano IO shields that are offered on AliExpress and improves it further for my needs (and switched to the Pro Mini instead of the Nano).

- Each analog and digital pin of the Pro Mini has its own VCC and GND pins,

- the board also provides its own voltage regulator, solder pins for by NRF24L01+ and RFM69H are provided (plus the 5V->3.3V XC6206 regulator),

- either a tiny 55-pin breadboard or three I²C connectors can be placed on the board.

- One can also use PogoPins instead of soldering the Pro Mini (or headers for it) to burn the bootloader or change fuses on the Pro Mini via the ICSP connector.

All design files are available on GitHub: https://www.openhardware.io/view/538/Arduino-Pro-Mini-IO-Shield

-

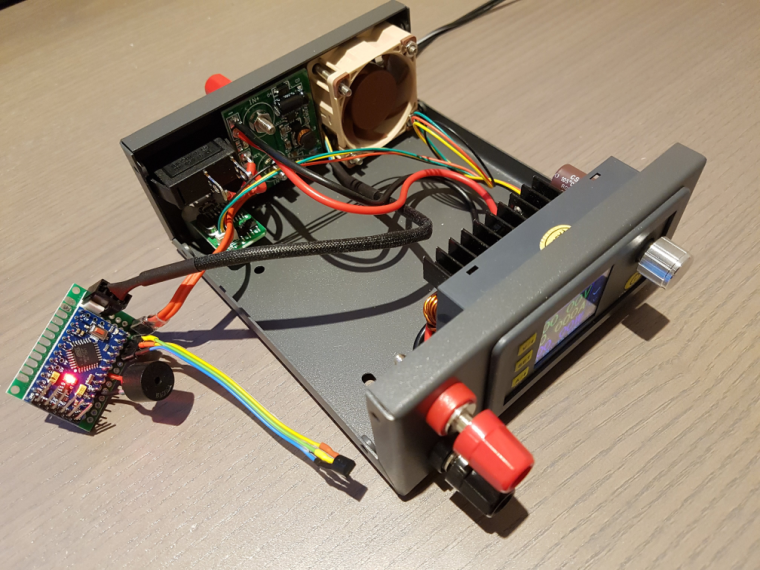

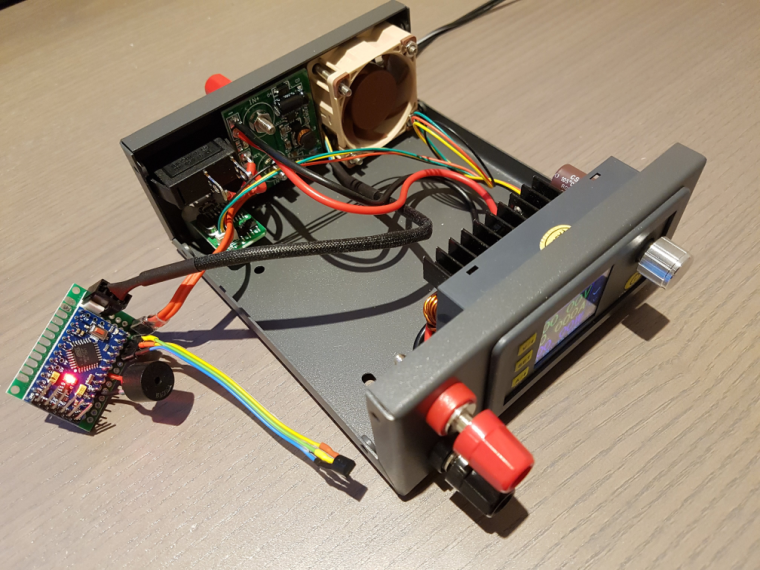

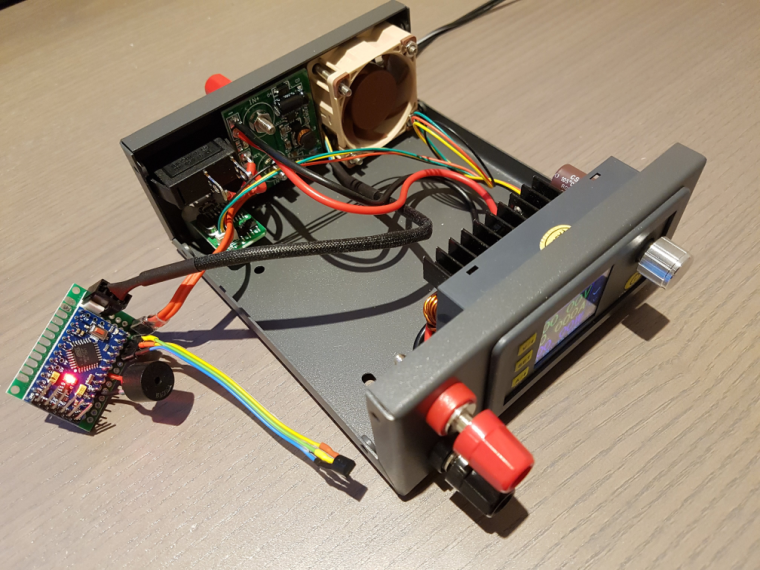

A temperature controlled PWM fan controller for my DPS5005 power supply!

The original 2-wire fan that came with the power supply casing made an incredible amount of noise.

Using PWM to reduce its velocity made it even more noisy :imp:So, I made a fresh start and ordered a quality fan (almost as expensive as the whole casing...)

Using nothing more than a 5V pro mini, piezo speaker, DS18B20 temperature sensor and a resistor I made a full fledged fan controller ;-)

It takes the current temp from the DS18B20 (which will be mounted on the heatsink) and ramps up the fan linearly in the 30..60 C range. Below 30 C, the fan is off.

If RPM readback indicates a stalled fan, or DS18B20 returns wrong values the buzzer will force me to invest what's wrong :muscle: -

A temperature controlled PWM fan controller for my DPS5005 power supply!

The original 2-wire fan that came with the power supply casing made an incredible amount of noise.

Using PWM to reduce its velocity made it even more noisy :imp:So, I made a fresh start and ordered a quality fan (almost as expensive as the whole casing...)

Using nothing more than a 5V pro mini, piezo speaker, DS18B20 temperature sensor and a resistor I made a full fledged fan controller ;-)

It takes the current temp from the DS18B20 (which will be mounted on the heatsink) and ramps up the fan linearly in the 30..60 C range. Below 30 C, the fan is off.

If RPM readback indicates a stalled fan, or DS18B20 returns wrong values the buzzer will force me to invest what's wrong :muscle: -

@mfalkvidd don't tempt me...

-

A temperature controlled PWM fan controller for my DPS5005 power supply!

The original 2-wire fan that came with the power supply casing made an incredible amount of noise.

Using PWM to reduce its velocity made it even more noisy :imp:So, I made a fresh start and ordered a quality fan (almost as expensive as the whole casing...)

Using nothing more than a 5V pro mini, piezo speaker, DS18B20 temperature sensor and a resistor I made a full fledged fan controller ;-)

It takes the current temp from the DS18B20 (which will be mounted on the heatsink) and ramps up the fan linearly in the 30..60 C range. Below 30 C, the fan is off.

If RPM readback indicates a stalled fan, or DS18B20 returns wrong values the buzzer will force me to invest what's wrong :muscle:@yveaux said in What did you build today (Pictures) ?:

The original 2-wire fan that came with the power supply casing made an incredible amount of noise.

Using PWM to reduce its velocity made it even more noisy :imp:Less funny that way but did you try to lower the PWM frequency of the atmega to it's minimum ? I had the same problem with the fan I put in my fridge cabinet and low PWM frequency solved it.

-

@yveaux said in What did you build today (Pictures) ?:

The original 2-wire fan that came with the power supply casing made an incredible amount of noise.

Using PWM to reduce its velocity made it even more noisy :imp:Less funny that way but did you try to lower the PWM frequency of the atmega to it's minimum ? I had the same problem with the fan I put in my fridge cabinet and low PWM frequency solved it.

-

An RC filter could probably also make wonders for the fan. I had to add one for the parts fan on my 3D printer. Couldn't control the speed with PWM without the RC filter..

Btw. probably a bit over the top of using an arduino as fan control? Unless you plan on adding a NRF radio, and report the temperature + PWM duty cycle to your mysensors system, and store the values in influxdb? ;)

-

An RC filter could probably also make wonders for the fan. I had to add one for the parts fan on my 3D printer. Couldn't control the speed with PWM without the RC filter..

Btw. probably a bit over the top of using an arduino as fan control? Unless you plan on adding a NRF radio, and report the temperature + PWM duty cycle to your mysensors system, and store the values in influxdb? ;)

@tbowmo said in What did you build today (Pictures) ?:

Btw. probably a bit over the top of using an arduino as fan control?

Really? How so? Seems like the end result will be as quiet as possible, yet avoids stalling.

-

@tbowmo said in What did you build today (Pictures) ?:

Btw. probably a bit over the top of using an arduino as fan control?

Really? How so? Seems like the end result will be as quiet as possible, yet avoids stalling.

@neverdie said in What did you build today (Pictures) ?:

@tbowmo said in What did you build today (Pictures) ?:

Btw. probably a bit over the top of using an arduino as fan control?

Really? How so? Seems like the end result will be as quiet as possible, yet avoids stalling.

Indeed! I thought of going the analog way, but the final solution would be more expensive, I didn't have the parts at hand, it wouldn't have as many features and it would have cost me a lot more time...

-

An RC filter could probably also make wonders for the fan. I had to add one for the parts fan on my 3D printer. Couldn't control the speed with PWM without the RC filter..

Btw. probably a bit over the top of using an arduino as fan control? Unless you plan on adding a NRF radio, and report the temperature + PWM duty cycle to your mysensors system, and store the values in influxdb? ;)

-

a 555 and a couple of resistors / capacitors.. ;)

https://electronics.stackexchange.com/questions/91102/555-temperature-controlled-pwm

But then again, I recon that most of us might have more atmega328 based boards, than 555's in the parts bin :)

about the RC for PWM, it was meant as a hint for others that might fight problems with a fan that they couldn't control properly with PWM..

-

a 555 and a couple of resistors / capacitors.. ;)

https://electronics.stackexchange.com/questions/91102/555-temperature-controlled-pwm

But then again, I recon that most of us might have more atmega328 based boards, than 555's in the parts bin :)

about the RC for PWM, it was meant as a hint for others that might fight problems with a fan that they couldn't control properly with PWM..

-

a 555 and a couple of resistors / capacitors.. ;)

https://electronics.stackexchange.com/questions/91102/555-temperature-controlled-pwm

But then again, I recon that most of us might have more atmega328 based boards, than 555's in the parts bin :)

about the RC for PWM, it was meant as a hint for others that might fight problems with a fan that they couldn't control properly with PWM..

@tbowmo said in What did you build today (Pictures) ?:

a 555 and a couple of resistors / capacitors..

https://electronics.stackexchange.com/questions/91102/555-temperature-controlled-pwmStill, no tacho readback to detect stalled fans, no temperature sensor verification or overtemperature warning, no initial fan spinup and little control over how the fans reacts to temperature changes....

-

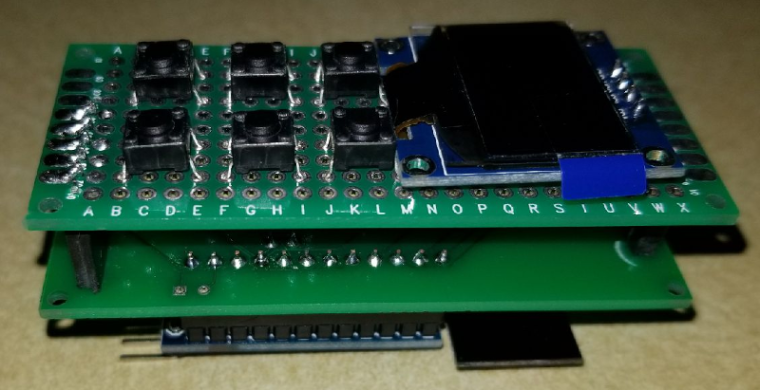

Though not fully finished, I am prototyping a new in-wall switch/scene controller with an integrated 128x64 OLED display. The design is made to fit my decora wall switch design that I had posted a while back. Here is a mock up of how I think the keypad and screen will be layed out.

!

For the screen, I am hoping to display the current room temperature and possibly the outside temp. I can also scroll messages across the screen if needed. I can also do some custom graphics and icons.

I have tested the display connected to my uno with the Adafruit sample code and think it does a nice job. This is not my video, but it is the same sample code that I used to test it.

https://www.youtube.com/watch?v=ldq0-IXl_GMI'll post more as I get further along.

-

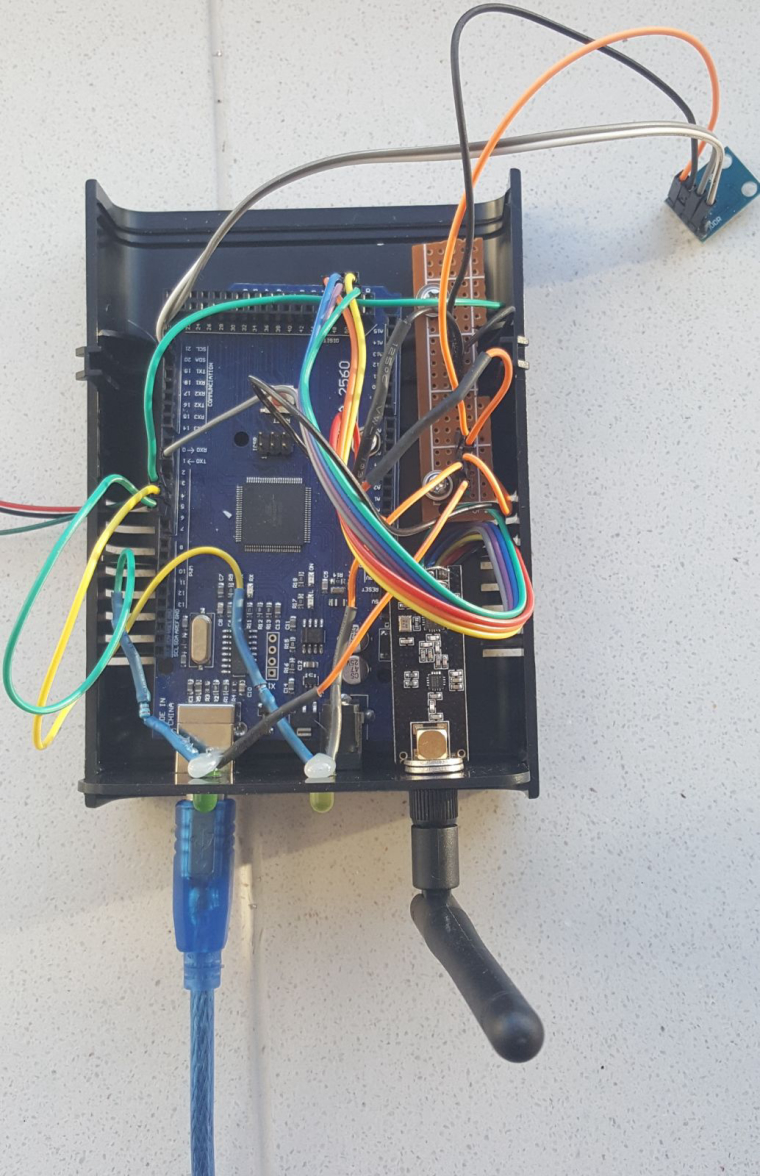

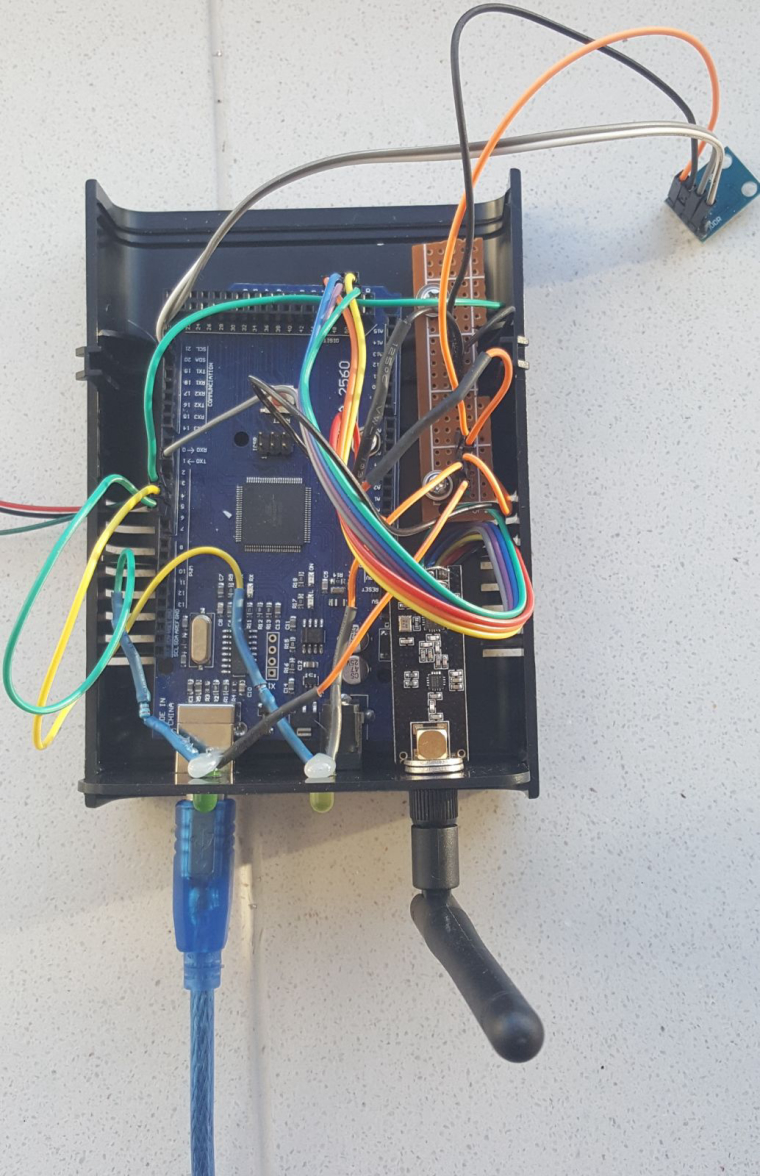

Well as you can see, my prototyping skills are not at the level of @dbemowsk (always interested in the under side of the boards, mine look .. yeah a mess?), however I managed to create this enclosure (once closed looks nice enough).

It should control the programmable LED lights in my livingroom (900 pieces).The board is powered 5v from the same power supply as the LED's. In addition it needs to measure the lux in the livingroom to decide if it is dark enough to turn on the lights.

Initial tests looked okay, however after finding 56 effects in the Doll House of @Yveaux I decided to use that FX library as well. However the Arduino Mega is out of RAM to accomodate a full controll of the 900 LEDS. It will only control around 650 LEDS with that FX library.

After being in contact with @Yveaux we decided to use an ESP solution. I have a spare NodeMCU v3 that can house the ESP gateway sketch and will have enough memory to controll the LEDs. Well now I have to look for a nice prototyping thing/case for the NodeMCU and add a level shifter as well. The LED's control line wants to be controlled by at least 3,7v.

This is the nice thing about these kind of projects.. "There is always something to do"

-

Well as you can see, my prototyping skills are not at the level of @dbemowsk (always interested in the under side of the boards, mine look .. yeah a mess?), however I managed to create this enclosure (once closed looks nice enough).

It should control the programmable LED lights in my livingroom (900 pieces).The board is powered 5v from the same power supply as the LED's. In addition it needs to measure the lux in the livingroom to decide if it is dark enough to turn on the lights.

Initial tests looked okay, however after finding 56 effects in the Doll House of @Yveaux I decided to use that FX library as well. However the Arduino Mega is out of RAM to accomodate a full controll of the 900 LEDS. It will only control around 650 LEDS with that FX library.

After being in contact with @Yveaux we decided to use an ESP solution. I have a spare NodeMCU v3 that can house the ESP gateway sketch and will have enough memory to controll the LEDs. Well now I have to look for a nice prototyping thing/case for the NodeMCU and add a level shifter as well. The LED's control line wants to be controlled by at least 3,7v.

This is the nice thing about these kind of projects.. "There is always something to do"

-

@sincze I've done and seen a lot worse than this. Good job. Any particular reason you chose to use a Arduino Mega?

@dbemowsk Well first I started with my all time favourite... the Nano, as I have prototyping boards available.;-) but even with some simple light shows it did not have enough memory to hold de states of each individual 900 LEDs.

I moved to the Mega. as it has more memory. My sketch worked fine so I started to build the node in its box. I also looked at the Github for the Doll House inspiration. I found the library that had 56 effects. So I thought why not use that one... Migrated my sketch, did a few tests with 300 LEDS, completed the enclosure and only than found out It could not controll all the 900 leds, due to memory issue. Insufficient RAM.

But as this forum is a learning curve for me please feel free to share your thoughts. I always look at examples from others and see what I can do with it myself. I don't have fancy PCB equipment, justs a soldering iron and my own Aliexpress wearhouse with components ;-)

-

@dbemowsk Well first I started with my all time favourite... the Nano, as I have prototyping boards available.;-) but even with some simple light shows it did not have enough memory to hold de states of each individual 900 LEDs.

I moved to the Mega. as it has more memory. My sketch worked fine so I started to build the node in its box. I also looked at the Github for the Doll House inspiration. I found the library that had 56 effects. So I thought why not use that one... Migrated my sketch, did a few tests with 300 LEDS, completed the enclosure and only than found out It could not controll all the 900 leds, due to memory issue. Insufficient RAM.

But as this forum is a learning curve for me please feel free to share your thoughts. I always look at examples from others and see what I can do with it myself. I don't have fancy PCB equipment, justs a soldering iron and my own Aliexpress wearhouse with components ;-)