💬 Easy/Newbie PCB for MySensors

-

Resistors can be soldered either way, but if you read 0v on that capacitor pin it mean you have a problem between the battery and the capacitor, so you have to backtrack the connection that is missing

@gohan said in 💬 Easy/Newbie PCB for MySensors:

Resistors can be soldered either way, but if you read 0v on that capacitor pin it mean you have a problem between the battery and the capacitor, so you have to backtrack the connection that is missing

I measured the capacitor again and get a 0,10 output.

-

Capacitor value does not change the voltage. The resistors does... I would double check that you use the right resistors. For example it's easy to use a resistor marked 1k instead of 1M. With 3.3v you should have around 1v on the capacitor.

-

@gohan said in 💬 Easy/Newbie PCB for MySensors:

you are also missing the capacitor on the booster output for better stability

Ok, I assumed it was not needed when using a battery. Which one to use there?

@mr_sensor a advice is to measure the resistance again over the resistors.

-

@mr_sensor a advice is to measure the resistance again over the resistors.

@sundberg84 Well I tried that but did not get the measurement straight from the pcb si I decided t solder a new board using the right capacitor this time (0,1uf instead of 1uf) made sure using the right resistors as well and adding a capacitor after the booster. Than with the same mini pro from the other board tested again and wow it is working as intended.

Child ID 2Battery Voltage: 3.44 V Battery Percent: 102 % 2930 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:102 2938 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 2945 TSF:TDI:TSL 2947 MCO:SLP:WUP=-1 2949 TSF:TRI:TSB 3065 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 3178 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 957 Child ID 2Battery Voltage: 3.22 V Battery Percent: 95 % 3690 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:95 3698 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 3704 TSF:TDI:TSL 3706 MCO:SLP:WUP=-1 3708 TSF:TRI:TSB 3815 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 3932 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 955 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 4442 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 4452 TSF:TDI:TSL 4454 MCO:SLP:WUP=-1 4456 TSF:TRI:TSB 4560 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 4673 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 953 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 5185 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 5193 TSF:TDI:TSL 5195 MCO:SLP:WUP=-1 5197 TSF:TRI:TSB 5304 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 5416 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 5926 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 5935 TSF:TDI:TSL 5939 MCO:SLP:WUP=-1 5941 TSF:TRI:TSB 6045 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 6158 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 6670 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 6678 TSF:TDI:TSL 6680 MCO:SLP:WUP=-1 6682 TSF:TRI:TSB 6789 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 6901 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 7411 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 7419 TSF:TDI:TSL 7424 MCO:SLP:WUP=-1 7426 TSF:TRI:TSB 7530 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 7643 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 8155 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 8163 TSF:TDI:TSL 8165 MCO:SLP:WUP=-1 8167 TSF:TRI:TSB 8273 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 8388 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 955 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 8898 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 8908 TSF:TDI:TSL 8910 MCO:SLP:WUP=-1 8912 TSF:TRI:TSB 9021 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 9132 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 948 Child ID 2Battery Voltage: 3.19 V Battery Percent: 94 % 9646 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:94 9654 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 9660 TSF:TDI:TSL 9662 MCO:SLP:WUP=-1 9664 TSF:TRI:TSB 9771 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 9881 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 10395 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:95 10403 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 10409 TSF:TDI:TSL 10412 MCO:SLP:WUP=-1 10414 TSF:TRI:TSB 10520 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 10635 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 953 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 11147 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 11155 TSF:TDI:TSLNow in mqtt I can see the percentage as:

95 qos : 0, retain : false, cmd : publish, dup : false, topic : **mygateway1-out/2/255/3/0/0**, messageId : , length : 30, Raw payload : 5753``` But not the voltage? -

@sundberg84 Well I tried that but did not get the measurement straight from the pcb si I decided t solder a new board using the right capacitor this time (0,1uf instead of 1uf) made sure using the right resistors as well and adding a capacitor after the booster. Than with the same mini pro from the other board tested again and wow it is working as intended.

Child ID 2Battery Voltage: 3.44 V Battery Percent: 102 % 2930 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:102 2938 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 2945 TSF:TDI:TSL 2947 MCO:SLP:WUP=-1 2949 TSF:TRI:TSB 3065 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 3178 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 957 Child ID 2Battery Voltage: 3.22 V Battery Percent: 95 % 3690 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:95 3698 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 3704 TSF:TDI:TSL 3706 MCO:SLP:WUP=-1 3708 TSF:TRI:TSB 3815 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 3932 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 955 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 4442 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 4452 TSF:TDI:TSL 4454 MCO:SLP:WUP=-1 4456 TSF:TRI:TSB 4560 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 4673 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 953 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 5185 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 5193 TSF:TDI:TSL 5195 MCO:SLP:WUP=-1 5197 TSF:TRI:TSB 5304 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 5416 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 5926 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 5935 TSF:TDI:TSL 5939 MCO:SLP:WUP=-1 5941 TSF:TRI:TSB 6045 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 6158 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 6670 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 6678 TSF:TDI:TSL 6680 MCO:SLP:WUP=-1 6682 TSF:TRI:TSB 6789 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 6901 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 7411 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 7419 TSF:TDI:TSL 7424 MCO:SLP:WUP=-1 7426 TSF:TRI:TSB 7530 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 7643 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 8155 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 8163 TSF:TDI:TSL 8165 MCO:SLP:WUP=-1 8167 TSF:TRI:TSB 8273 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 8388 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 955 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 8898 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 8908 TSF:TDI:TSL 8910 MCO:SLP:WUP=-1 8912 TSF:TRI:TSB 9021 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 9132 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 948 Child ID 2Battery Voltage: 3.19 V Battery Percent: 94 % 9646 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:94 9654 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 9660 TSF:TDI:TSL 9662 MCO:SLP:WUP=-1 9664 TSF:TRI:TSB 9771 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 9881 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 952 Child ID 2Battery Voltage: 3.20 V Battery Percent: 95 % 10395 TSF:MSG:SEND,2-2-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:95 10403 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 10409 TSF:TDI:TSL 10412 MCO:SLP:WUP=-1 10414 TSF:TRI:TSB 10520 TSF:MSG:SEND,2-2-0-0,s=1,c=1,t=0,pt=7,l=5,sg=0,ft=0,st=OK:998.0 T: 998.00 10635 TSF:MSG:SEND,2-2-0-0,s=0,c=1,t=1,pt=7,l=5,sg=0,ft=0,st=OK:998.0 H: 998.00 953 Child ID 2Battery Voltage: 3.21 V Battery Percent: 95 % 11147 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255 11155 TSF:TDI:TSLNow in mqtt I can see the percentage as:

95 qos : 0, retain : false, cmd : publish, dup : false, topic : **mygateway1-out/2/255/3/0/0**, messageId : , length : 30, Raw payload : 5753``` But not the voltage?@mr_sensor good to hear its working.

It looks like you are only sending the % and not the voltage? -

@Mr_sensor It happened to me once that capacitor was just shortening the circuit, it was a smd, but when I removed it and tested it it was constantly making shortage, thus the circuit was never working and luckily my power supply had a low enough protection.

I examined cap very closely, all looked fine, but internally it was not working fine.Since most of us (well, me at least) are buying cheap components I made it a habit now to always measure every passive component before installation, partly eliminates one variable

-

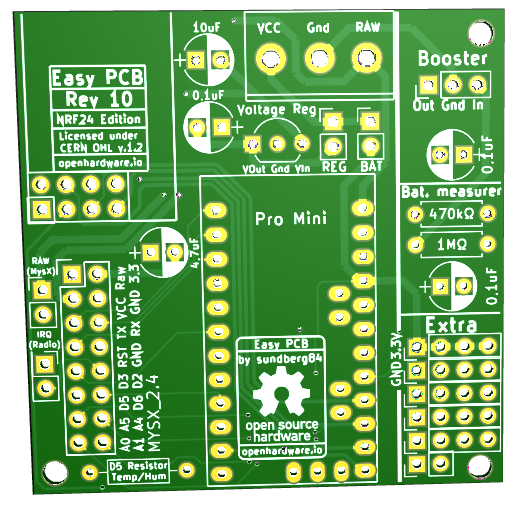

A short sneak-peak on the upcoming revision...

Still a long way to go...

Rev 10 - Nrf24l01+ ed.

- Completley redesigned in KiCad.

- MysX location changed to accept more MysX boards and align like RFM version.

- Optional signing added

- Optional SPI flash added.

- Extra pins aligned to 2.45 vertical & horisontal

- Relocated Extra + Bat Measurer some to allow more space to booster

- Changed pull-up resistor from D3 to D5 to have one more pin for Interrupt

- Relocated D5 pullup, MysX and IRQ jumper some.

- Changed footprint (silk-screen) on capacitor to easier show Gnd/Pos side.

Need to change footprint on voltage regulator on both nrf and rfm edition back to a square and not a liniar one. (rev 9 change). Not intended to revert back.

Also a bit worried the 4,7uF cap os to far away from radio.

-

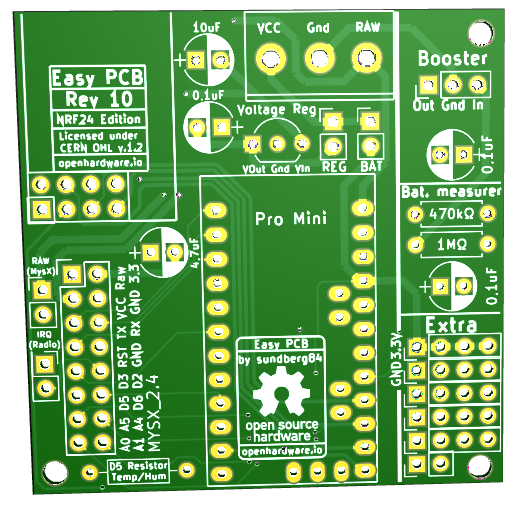

A short sneak-peak on the upcoming revision...

Still a long way to go...

Rev 10 - Nrf24l01+ ed.

- Completley redesigned in KiCad.

- MysX location changed to accept more MysX boards and align like RFM version.

- Optional signing added

- Optional SPI flash added.

- Extra pins aligned to 2.45 vertical & horisontal

- Relocated Extra + Bat Measurer some to allow more space to booster

- Changed pull-up resistor from D3 to D5 to have one more pin for Interrupt

- Relocated D5 pullup, MysX and IRQ jumper some.

- Changed footprint (silk-screen) on capacitor to easier show Gnd/Pos side.

Need to change footprint on voltage regulator on both nrf and rfm edition back to a square and not a liniar one. (rev 9 change). Not intended to revert back.

Also a bit worried the 4,7uF cap os to far away from radio.

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

Also a bit worried the 4,7uF cap os to far away from radio.

Putting it underneath the nrf24 module? I know it is not a "clean solution" but there would be still be unused space under the radio module

-

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

Also a bit worried the 4,7uF cap os to far away from radio.

Putting it underneath the nrf24 module? I know it is not a "clean solution" but there would be still be unused space under the radio module

@gohan - thanks, not what I want to do - I have descided to have optional/more advanced on bottom side. This is the core idea of the PCB. I might revert back to Rev 9 footprint and squeeze it in like prev. revision.

-

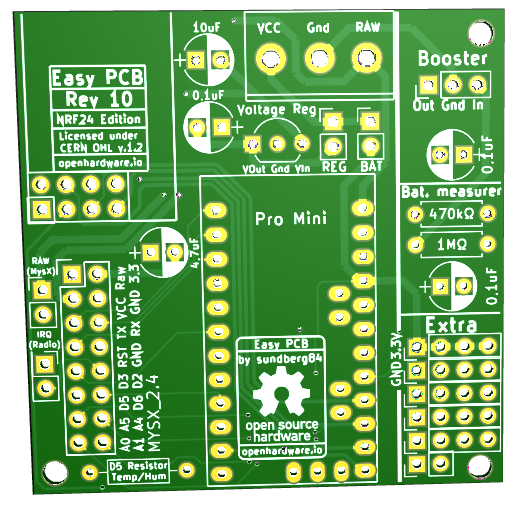

A short sneak-peak on the upcoming revision...

Still a long way to go...

Rev 10 - Nrf24l01+ ed.

- Completley redesigned in KiCad.

- MysX location changed to accept more MysX boards and align like RFM version.

- Optional signing added

- Optional SPI flash added.

- Extra pins aligned to 2.45 vertical & horisontal

- Relocated Extra + Bat Measurer some to allow more space to booster

- Changed pull-up resistor from D3 to D5 to have one more pin for Interrupt

- Relocated D5 pullup, MysX and IRQ jumper some.

- Changed footprint (silk-screen) on capacitor to easier show Gnd/Pos side.

Need to change footprint on voltage regulator on both nrf and rfm edition back to a square and not a liniar one. (rev 9 change). Not intended to revert back.

Also a bit worried the 4,7uF cap os to far away from radio.

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"Also a bit worried the 4,7uF cap os to far away from radio.

I agree especially with other traces to cross before reaching the radio.

-

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"Also a bit worried the 4,7uF cap os to far away from radio.

I agree especially with other traces to cross before reaching the radio.

@nca78 said in 💬 Easy/Newbie PCB for MySensors:

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"I actually had a long discussion with @Anticimex which is the designer of MysX and he said it is not wrong. Can you please explain why it's wrong ?

I was thinking pin 1 should go towards both vertical and horizontal edge of the pcb (that's why I asked him because I though It should go where the radio is) but he said the only rule is pin 1 should go towards the edge. I looked at the rules and that is what it said so I don't think I'm breaking any rules.

The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this. It should be oriented so that pin1 is always closest to the board edge parallel to the connector. This allows a daughter board designed using the same constraints to be facing back "inwards" over the motherboardEither way it has changed like less than 1mm

If we can somehow get Anticimex to recommend and we can agree on a better placement I'm happy to re-think my design.

If you thinks it's hard to create MysX boards for EasyPcb I have created a finished Kicad project with board outlines, connector and drill holes you can use as a template. Check it out on the project page.

-

@nca78 said in 💬 Easy/Newbie PCB for MySensors:

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"I actually had a long discussion with @Anticimex which is the designer of MysX and he said it is not wrong. Can you please explain why it's wrong ?

I was thinking pin 1 should go towards both vertical and horizontal edge of the pcb (that's why I asked him because I though It should go where the radio is) but he said the only rule is pin 1 should go towards the edge. I looked at the rules and that is what it said so I don't think I'm breaking any rules.

The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this. It should be oriented so that pin1 is always closest to the board edge parallel to the connector. This allows a daughter board designed using the same constraints to be facing back "inwards" over the motherboardEither way it has changed like less than 1mm

If we can somehow get Anticimex to recommend and we can agree on a better placement I'm happy to re-think my design.

If you thinks it's hard to create MysX boards for EasyPcb I have created a finished Kicad project with board outlines, connector and drill holes you can use as a template. Check it out on the project page.

@sundberg84 I cannot see anything wrong with the MYSX placement on that board.

If one could pick freely, ideal placement of the connector would be in the middle of the board side to allow daughter boards to extend both "upward" and "downward".

But the important rule is the one already cited, that pin1 is oriented to ensure daughterboard orientation relative to the motherboard and that there is spacing around the connector so that the daughterboard female connector does not come in contact with main board cirquitry.

Also that the daughterboard does not protrude outside of the mainboard at least along the edge the connector is aligned to.

Daughterboards in general should not be designed to be wider than the MYSX connector used for this reason (avoiding daughterboard protruding outside mainboard area) to allow a mainboard specific case to be reused with daughterboards mounted.Edit: if possible, try to move the components right next to the connector. (remember the 100mil spacing). The resistor below can probably be mounted on the reverse side.

-

@sundberg84 I will just go ahead and update the spec. Yes, it may cause some existing designs to violate the spec, but that will always be the case. We look forwards, not backwards :)

Spec is here.Back to the drawing desk! :)

Edit: MysX alignment changed so PCB needs to be redesigned.