What did you build today (Pictures) ?

-

@sundberg84 If I'm honest some of those sensors seem 'old' to me.

- I usually go for the BEM280 instead of the BMP085 and DHT22. It's so cheap now.

- I never use pulse soil sensors, only the capacitive kind, as they last much longer and don't pollute the soil.

In fact, I always make all my sensors with the Nano Wireless Expansion Board, which is about $2. You can simply plug in the NRF24 into it.

https://www.aliexpress.com/item/Free-shipping-Nano-328P-IO-wireless-sensor-expansion-board-for-XBEE-and-NRF24L01-Socket-for-arduino/32264665470.html -

@sundberg84 If I'm honest some of those sensors seem 'old' to me.

- I usually go for the BEM280 instead of the BMP085 and DHT22. It's so cheap now.

- I never use pulse soil sensors, only the capacitive kind, as they last much longer and don't pollute the soil.

In fact, I always make all my sensors with the Nano Wireless Expansion Board, which is about $2. You can simply plug in the NRF24 into it.

https://www.aliexpress.com/item/Free-shipping-Nano-328P-IO-wireless-sensor-expansion-board-for-XBEE-and-NRF24L01-Socket-for-arduino/32264665470.html@alowhum thanks for the reply!

I used the sensor in MySensors build section, i somehow believe that is whats used the most. But that does not stop me from adding your suggestion for BEM280. That Wireless board looks great, but Im working with the MysX connector so thats why im making this board. -

@sundberg84 If I'm honest some of those sensors seem 'old' to me.

- I usually go for the BEM280 instead of the BMP085 and DHT22. It's so cheap now.

- I never use pulse soil sensors, only the capacitive kind, as they last much longer and don't pollute the soil.

In fact, I always make all my sensors with the Nano Wireless Expansion Board, which is about $2. You can simply plug in the NRF24 into it.

https://www.aliexpress.com/item/Free-shipping-Nano-328P-IO-wireless-sensor-expansion-board-for-XBEE-and-NRF24L01-Socket-for-arduino/32264665470.html@alowhum said in What did you build today (Pictures) ?:

- I usually go for the BEM280 instead of the BMP085 and DHT22. It's so cheap now.

Unfortunately most of the cheap breakout boards found on AliExpress use clones with much worse specs than the original version

In fact, I always make all my sensors with the Nano Wireless Expansion Board, which is about $2. You can simply plug in the NRF24 into it.

https://www.aliexpress.com/item/Free-shipping-Nano-328P-IO-wireless-sensor-expansion-board-for-XBEE-and-NRF24L01-Socket-for-arduino/32264665470.htmlBut you can't really make battery-powered sensors with those ? The regulators are AMS1117 with 5mA typical quiescent current.

-

@alowhum said in What did you build today (Pictures) ?:

- I usually go for the BEM280 instead of the BMP085 and DHT22. It's so cheap now.

Unfortunately most of the cheap breakout boards found on AliExpress use clones with much worse specs than the original version

In fact, I always make all my sensors with the Nano Wireless Expansion Board, which is about $2. You can simply plug in the NRF24 into it.

https://www.aliexpress.com/item/Free-shipping-Nano-328P-IO-wireless-sensor-expansion-board-for-XBEE-and-NRF24L01-Socket-for-arduino/32264665470.htmlBut you can't really make battery-powered sensors with those ? The regulators are AMS1117 with 5mA typical quiescent current.

@nca78 said in What did you build today (Pictures) ?:

Unfortunately most of the cheap breakout boards found on AliExpress use clones with much worse specs than the original version

Could you be more specific? How exactly worth specs does they have. Was going to buy a bunch of them. Maybe there is some comparison or tests?

-

@sundberg84 yes, sorry about that, I realised too late that it's an expansion board.

@Nca78 Thanks! That 5ma leak current was exactly the kind of info I needed about the board. I was wondering it if could be useful for battery powered things. None of my sensors are. Well, one - I used the BBC Micro:bit as a battery powered motion sensor.

I guess not having a regulator on board is what makes the Arduino Pro Micro so good at being battery powered.

Out of curiosity: if I attached the board to a Usb powerbank (say 10.000 Mah) to operate as an electricity led pulse sensor.. what would be an estimate for how long it would run?

-

@sundberg84 yes, sorry about that, I realised too late that it's an expansion board.

@Nca78 Thanks! That 5ma leak current was exactly the kind of info I needed about the board. I was wondering it if could be useful for battery powered things. None of my sensors are. Well, one - I used the BBC Micro:bit as a battery powered motion sensor.

I guess not having a regulator on board is what makes the Arduino Pro Micro so good at being battery powered.

Out of curiosity: if I attached the board to a Usb powerbank (say 10.000 Mah) to operate as an electricity led pulse sensor.. what would be an estimate for how long it would run?

-

@nca78 said in What did you build today (Pictures) ?:

Unfortunately most of the cheap breakout boards found on AliExpress use clones with much worse specs than the original version

Could you be more specific? How exactly worth specs does they have. Was going to buy a bunch of them. Maybe there is some comparison or tests?

-

@sundberg84 yes, sorry about that, I realised too late that it's an expansion board.

@Nca78 Thanks! That 5ma leak current was exactly the kind of info I needed about the board. I was wondering it if could be useful for battery powered things. None of my sensors are. Well, one - I used the BBC Micro:bit as a battery powered motion sensor.

I guess not having a regulator on board is what makes the Arduino Pro Micro so good at being battery powered.

Out of curiosity: if I attached the board to a Usb powerbank (say 10.000 Mah) to operate as an electricity led pulse sensor.. what would be an estimate for how long it would run?

@alowhum said in What did you build today (Pictures) ?:

I guess not having a regulator on board is what makes the Arduino Pro Micro so good at being battery powered.

actually the better solution is the pro mini at 3.3v with regulator and led removed, and you can use an LDO regulator to power it with a LiPo cell or no regulator at all if you use a LiFePO4 battery. Using the arduino at 3.3v allows you to use all radio modules and all the low power sensors.

-

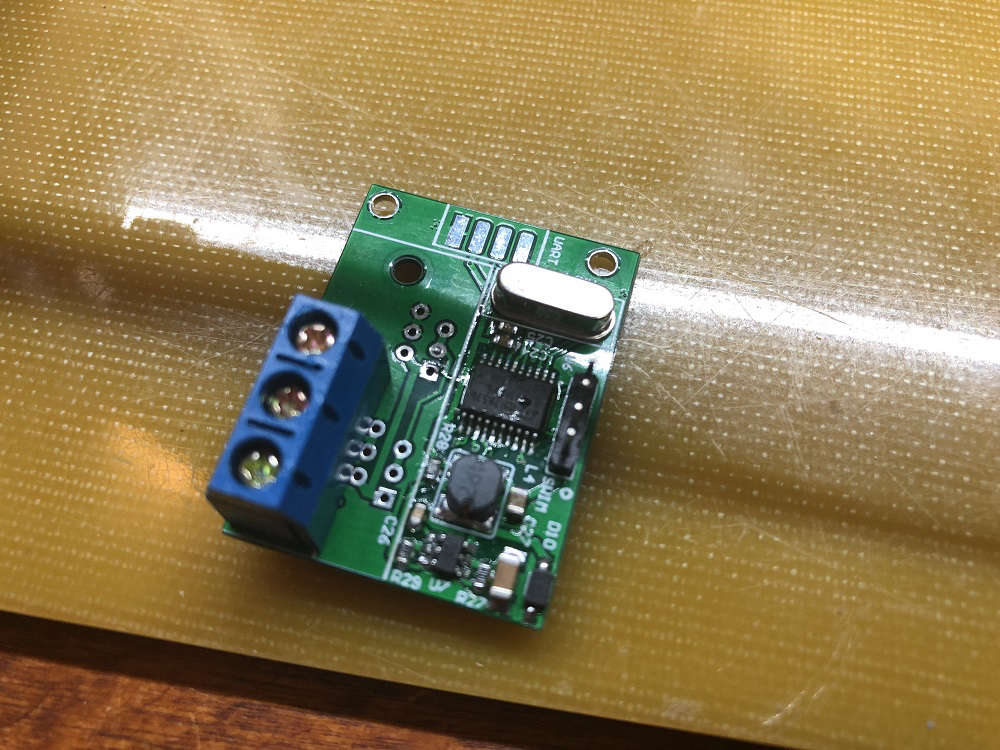

Something nice about those power supplies is that for very little extra money (maybe $1-3 extra) you can buy versions with UART and/or even bluetooth data output that you can send to a logger. I'd have to check, but it might even be controllable that way also.

-

Something nice about those power supplies is that for very little extra money (maybe $1-3 extra) you can buy versions with UART and/or even bluetooth data output that you can send to a logger. I'd have to check, but it might even be controllable that way also.

-

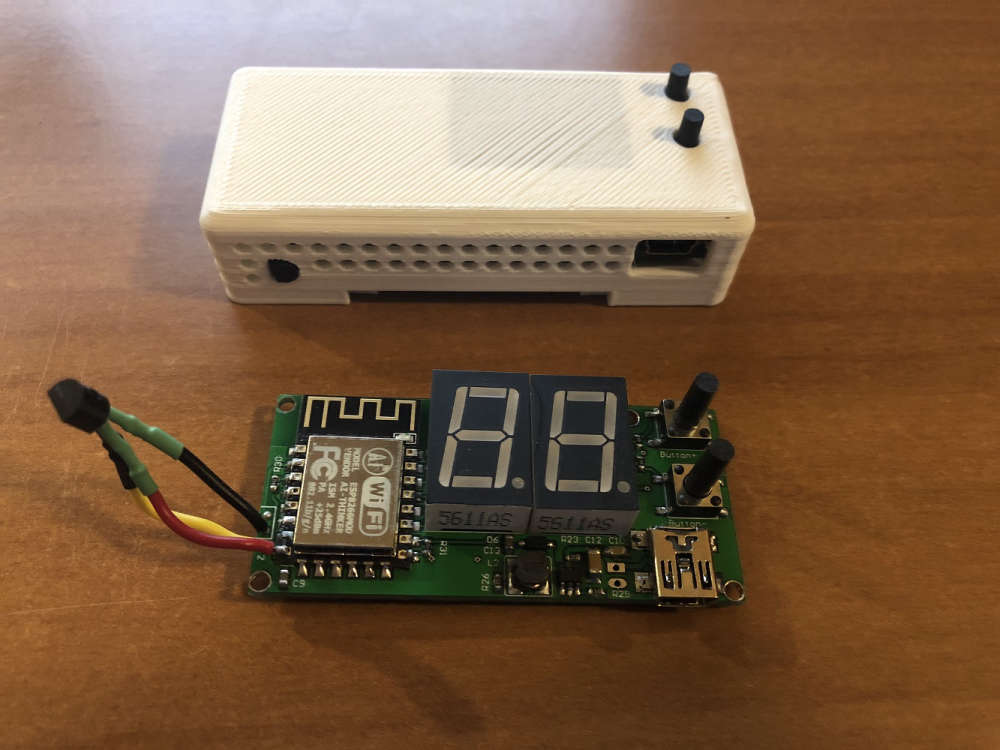

@alexsh1 very nice! Is the 3d-drawing online to be downloaded? I think I want one as well.

-

Saw that all other kids cool kids have one, so I installed one kitchen-pc as well.

It is Flytech K757 15'' POS terminal, windows 10 pro, touch screen, 300gb (soon to be ssd) 8gb ram dual core 2,2ghz. Purchased from local "ebay" for around 140 eur.

Now I can make that awesome dinner, once in a full moon, without having to carry and unlock my phone all the time...

-

@alexsh1 very nice! Is the 3d-drawing online to be downloaded? I think I want one as well.

Yes, you can downloads STLs from here: https://www.thingiverse.com/thing:2250644

There another one https://www.thingiverse.com/thing:1816188