Your workshop :)

-

@gohan That looks very much like the one that @AWI posted previously in the thread only with a nice case and a color display. The one he posted is quite a bit cheaper. I may get one myself and just 3D print a case for it. I can use your link for the 3D case design.

http://s.click.aliexpress.com/deep_link.htm?dl_target_url=http%3A%2F%2Fwww.aliexpress.com%2Fitem%2FNew-2016-12864-LCD-Transistor-Tester-Capacitance-ESR-Meter-Diode-Triode-MOS-NPN-LCR-Mega328%2F32579390679.html&aff_short_key=e2Vzr3v -

Just looked on ebay, and here is one a bit cheaper that comes with a basic case.

http://www.ebay.com/itm/LCR-T4-Mega328-Transistor-Tester-Diode-Triode-Capacitance-ESR-Meter-MOS-NPN-PNP-/222247985900?var=&hash=item33bf0322ec:m:mLakYynk0RqdZT62qrYQfdw -

if you want the case it costs 10$. The one I posted it seems to have pretty much the same specs, but it can detect also IR and probably some more components. It also comes with a lithium battery instead of the classic 9V, color screen and the case looks much better :)

-

if you want the case it costs 10$. The one I posted it seems to have pretty much the same specs, but it can detect also IR and probably some more components. It also comes with a lithium battery instead of the classic 9V, color screen and the case looks much better :)

@gohan You are right. I just ordered the thing. With the case and the builtin battery it looks like a real tool. The price seems to be a promotion. Normal price is >30$.

You shoult by the way fix the link. Makes it easier for others to order it.I am looking for a soldering vise. Has anyone tested this one: https://www.amazon.de/dp/B00196RV9C/ref=wl_it_dp_o_pC_S_ttl?_encoding=UTF8&colid=2COJS1QZ6SUVJ&coliid=IQEGMI1GM2R46 ?

-

Fixed the link; anyway it is a recurring promotion because I have seen that price for quite a while :)

@gohan Then you can safely lean back and wait for my review. ;)

-

@gohan You are right. I just ordered the thing. With the case and the builtin battery it looks like a real tool. The price seems to be a promotion. Normal price is >30$.

You shoult by the way fix the link. Makes it easier for others to order it.I am looking for a soldering vise. Has anyone tested this one: https://www.amazon.de/dp/B00196RV9C/ref=wl_it_dp_o_pC_S_ttl?_encoding=UTF8&colid=2COJS1QZ6SUVJ&coliid=IQEGMI1GM2R46 ?

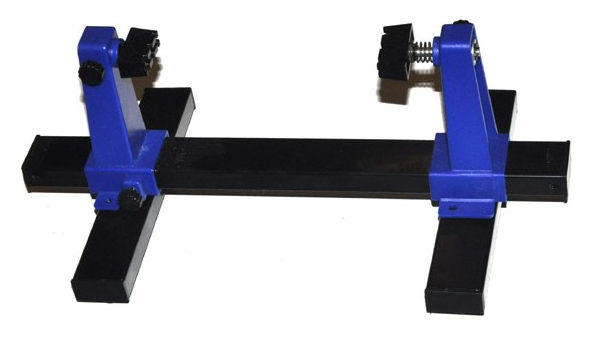

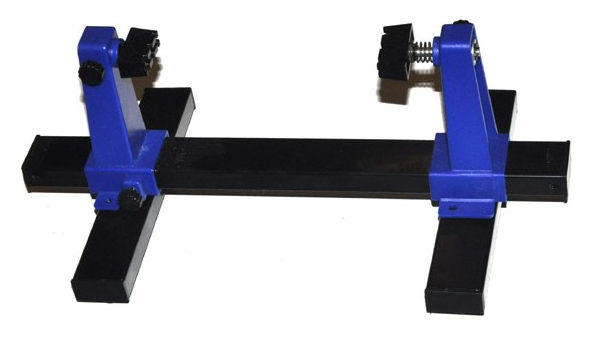

@Jan-Gatzke I have this one:

It's able to hold all kinds of PCB sizes and can rotate easily.

Tip for soldering through-hole components from the back without them falling out:

Place all components on the top of the PCB and put a sponge or scotch-brite on top of them. Fix to the PCB with some rubber bands and swap the PCB to solder! -

@Jan-Gatzke I have this one:

It's able to hold all kinds of PCB sizes and can rotate easily.

Tip for soldering through-hole components from the back without them falling out:

Place all components on the top of the PCB and put a sponge or scotch-brite on top of them. Fix to the PCB with some rubber bands and swap the PCB to solder!@Yveaux I saw that thing on Amazon. There was a review saying the brackets would melt easily when using hot air. Did you use this with hot air?

-

@Yveaux I saw that thing on Amazon. There was a review saying the brackets would melt easily when using hot air. Did you use this with hot air?

@Jan-Gatzke said in Your workshop :):

There was a review saying the brackets would melt easily when using hot air.

When you clamp a PCB in it only the edges are held by the plastic brackets.

Unless you are blowing directly on the edge of the PCB where it is held I can imagine this could be a problem, but then, why don't you shift or rotate the PCB to get away from the brackets?Did you use this with hot air?

Yes

-

if you want the case it costs 10$. The one I posted it seems to have pretty much the same specs, but it can detect also IR and probably some more components. It also comes with a lithium battery instead of the classic 9V, color screen and the case looks much better :)

@gohan Be aware that there are quite a few different versions around. The one I posted has a rotary encoder to select and operate the pwm and frequency functions. The perspex casing fits well with the rest of the nerdy testboxes I own (dummy load, power supply, a few function generators, frequencycounter ) All a lot of functionality for very little..

-

I noticed the many of you have an oscilloscope on their desk. What exactly do you use these for? There seems to be nothing under 200$ and I wonder if it is worth it.

-

I noticed the many of you have an oscilloscope on their desk. What exactly do you use these for? There seems to be nothing under 200$ and I wonder if it is worth it.

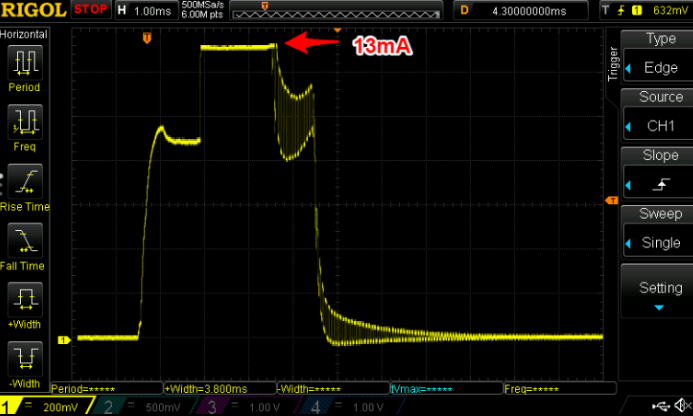

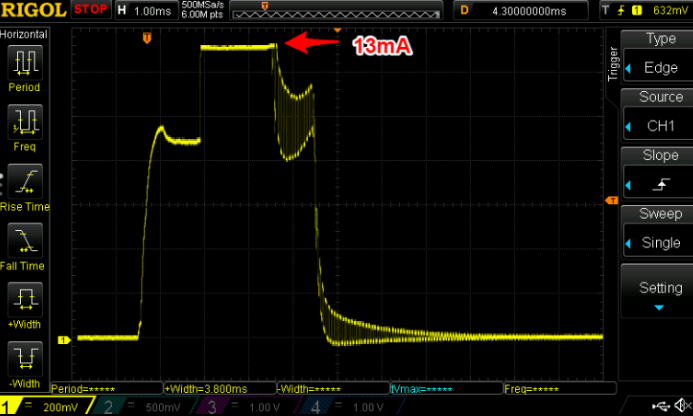

@Jan-Gatzke For MySensor I use it mostly for measuring response times and get a general idea of what is happening timewise. Especially if you have multiple event happening at the same time. Also for getting a grip on low power

it gives a lot of information which would be very hard to measure with any other instrument. (for my other hobby, analog audio design, I couldn't live without it. ;-))

A few considerations:

- It can be rather complicated using a scope in first instance. (a steep learning curve)

- Unless you are just curious and want to educate yourself I would strongly disencourage buying a cheap instrument. Better to study a few manuals of serious > €300 instruments, save a little and buy the thing you need (or can't resist). 10 years ago you had to put down > €1000 for something reasonable.

-

@Jan-Gatzke For MySensor I use it mostly for measuring response times and get a general idea of what is happening timewise. Especially if you have multiple event happening at the same time. Also for getting a grip on low power

it gives a lot of information which would be very hard to measure with any other instrument. (for my other hobby, analog audio design, I couldn't live without it. ;-))

A few considerations:

- It can be rather complicated using a scope in first instance. (a steep learning curve)

- Unless you are just curious and want to educate yourself I would strongly disencourage buying a cheap instrument. Better to study a few manuals of serious > €300 instruments, save a little and buy the thing you need (or can't resist). 10 years ago you had to put down > €1000 for something reasonable.

@AWI Troubleshooting power probolems with the nrf24 is a good example, thx. I think at the beginning it is more a nice to have than a must have. I am always curios for such things. Still I don't want to buy trash. I will read a bit and watch ebay for good offers. Thx for your explanation.