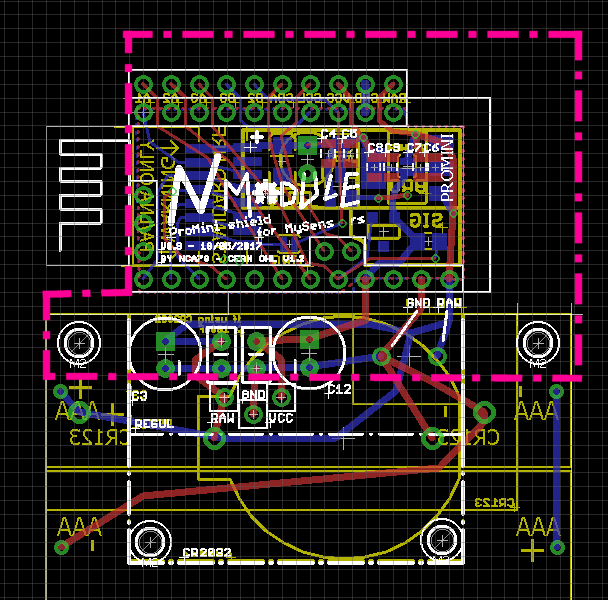

💬 NModule Temperature, Humidity, Light, Door sensor shield

-

Hey, do you have any experience with rechargable CR123, regarding the "capacity/voltage loss curve" or what the name is?

Meaning if rechargeable cr123 would hold enough voltage over time, as the lithium(?) ones doe?

I found these for a nice price, I have positive experience with Ultrafire http://www.dx.com/p/ultrafire-3-6v-880mah-lc-16340-protected-cr123a-battery-2-pack-3273@dakipro to complete the "use at your own risks" I found the disassembly page of some Ultrafire batteries from the same guy.

Not looking good...http://lygte-info.dk/info/batteryDisassemblyUltraFire UK.html

-

Ok, that certainly throws a new light on the matter :(

Thanks for the info, I will throw all ultrafire I have at home (before I get what their name suggests) and buy some from a trusted brand.

Cheers!@dakipro said in 💬 NModule Temperature, Humidity, Light, Door sensor shield:

Ok, that certainly throws a new light on the matter :(

Thanks for the info, I will throw all ultrafire I have at home (before I get what their name suggests) and buy some from a trusted brand.

Cheers!It should be fine with a good charger and if you avoid discharging them too low.

You can check the lygte website for other battery brands the guy tested a lot of them. Soshine brands seems ok. -

I just managed to fry the only working module I've build so far (life got some other plans for my spare time).

I just took it in a hand to show it to a friend, and logs show no activity since. The battery was 99%, and now it is 1V. I tried powering it from the power supply, but the voltage drops from 3V to 0.1V, indicating that something is shorting it out. Resistance between gnd and vcc is not 0, so it is not direct connection between them, but I guess static did its thing and some component died, leaving entire module non-functioning :(

So... when you build one, make sure you put it in the case and do not touch it with bare hands

(I remember holding it on the edges to avoid touching the circuits, but I still managed to fry it) -

Wow that's bad news and very strange, I manipulated a bunch of NModule boards without special precaution and never fried any.

It would be nice to investigate about what went wrong, maybe I can improve the design in some way.Did you cut the "power" part of the board ? Could be two cut traces too close to each others, or something similar.

You can contact me by private message if you want to discuss it. -

Speaking generally, the radio module tends to be the most likely component to fail.. Try replacing that and see if it works again. Or, more conservatively, just unsolder the radio module and then see if you can talk to the mpu again.

-

Good news, node works as expected after I removed the light sensor and changed the battery.

After removing MAX44009 light sensor and testing again, i realized that I was connecting both plus and minus to the same pin :cry: that is why power supply was showing shortage :(

Unfortunately, I am not very skilled at desoldering so light sensor is not usable anymore. I cannot tell if that sensor was actually the problem or not (most likely not).

But it looks like the battery has just depleted. After I took it out of the node, it was showing 1.3v then I tested with power supply (connecting it wrong) and that is why I assumed I have fried something. I changed the battery and module is working fine now. Strange is that it was reporting 100% battery level all the time, and while assembling I was changing voltage on the power supply down to 2.4V and it was reporting 40% as expected.

So... it is not impossible that something depleted the battery the day I touched the sensor, logs show exact time it stopped working (when I touched it).But I will consider it as a false alarm for now, and time will tell... I hope :)

Thanks everyone for assistance! -

Good news, node works as expected after I removed the light sensor and changed the battery.

After removing MAX44009 light sensor and testing again, i realized that I was connecting both plus and minus to the same pin :cry: that is why power supply was showing shortage :(

Unfortunately, I am not very skilled at desoldering so light sensor is not usable anymore. I cannot tell if that sensor was actually the problem or not (most likely not).

But it looks like the battery has just depleted. After I took it out of the node, it was showing 1.3v then I tested with power supply (connecting it wrong) and that is why I assumed I have fried something. I changed the battery and module is working fine now. Strange is that it was reporting 100% battery level all the time, and while assembling I was changing voltage on the power supply down to 2.4V and it was reporting 40% as expected.

So... it is not impossible that something depleted the battery the day I touched the sensor, logs show exact time it stopped working (when I touched it).But I will consider it as a false alarm for now, and time will tell... I hope :)

Thanks everyone for assistance!@dakipro that's good news, it's not expensive to replace a max44009.

That case (shortcut with CR2032 leading to quick death of the battery) happened to me so I would bet the light sensor was not the culprit ;)Did you use a desoldering pump ? With some extra solder to keep the soldering joint hot longer, high iron temperature and a quick suck with a desoldering pump, it's not that difficult to unsolder.

-

It happened again, my wife moved the sensor (which was, you guessed it, without enclosure) and it stopped working due to empty battery. And of course, to make debugging more difficult, this happened with similar 2-3 months period since it happened last time. Since you have some nodes whose battery lasts more then a few months, it has to be something mechanical that happens and shortens the battery, or that another combination of circumstances empties the battery and that the node doesn't manage to report correct voltage/capacity.

Doesn't have to mean anything significant, except the "motivation" for people to make a housing for the nodes :)

-

It happened again, my wife moved the sensor (which was, you guessed it, without enclosure) and it stopped working due to empty battery. And of course, to make debugging more difficult, this happened with similar 2-3 months period since it happened last time. Since you have some nodes whose battery lasts more then a few months, it has to be something mechanical that happens and shortens the battery, or that another combination of circumstances empties the battery and that the node doesn't manage to report correct voltage/capacity.

Doesn't have to mean anything significant, except the "motivation" for people to make a housing for the nodes :)

@dakipro and was it working before ?

Which script are you using ? Maybe it lost radio link because of the moving and the script went into an endless loop, killing the battery ?Sounds very strange to me to generate a shortcut just by touching/moving the sensor...

-

No idea to be honest... It is the same node that was working fine, then something killed the battery (in the same timeframe when it was touched), then I removed light sensor MAX44009 and it worked fine with new battery, but then again similar thing happened just recently.

It sounds reasonable that it could be that radio gets stuck when being touched and then never connects again. Node was actually moved closer to the gateway, so I don't think it is the range issue.

The code is the one you provided (somewhere), I just modified few lines about interval if I remember correctly (I changed it to 5min i think).

Just reporting if someone else experiences the similar behavior

-

Hello,

I'm thinking about upgrading this board to include pinout for LIS3DH breakout board, like this one :

https://www.aliexpress.com/item/LIS3DH-Three-Converters-Motion-Accelerometer-Triaxial-Acceleration-Temperature-Sensor-Module-Development-Board-Replace-ADXL345/32840326778.htmland ditch the ADXL shield as it's not a good solution, it has either the ADXL345 which uses too much power, or the ADXL362 which is ultra low power but lacks advanced functionality like tap/double tap detection.

I would like to have feedback of users on this (do it sound useful ?), and also know if anyone uses the SMD footprints on the board, for leds and for reserve capacitors, as it could be a cleaner board without those footprints.

I would make the following changes :

- put footprint for LIS3DH accelerometer along the "NModule connector" as it has too many pins to put elsewhere

- keep only one I2C footprint on the side, for "GY-49" MAX44009 light sensor breakout board: https://www.aliexpress.com/item/GY-49-MAX44009-Ambient-Light-Sensor-Module-for-Arduino-with-4P-Pin-Header-Module/32828654450.html

- temperature/humidity would be via the existing "SMD" footprint, it's not through hole but very easy to solder as it's 2.54mm pad spacing

- remove SMD footprints for LED, add footprint for through hole reserve capacitor, keep SMD footprints for reserve capacitors only if I have space for them

- shield would be a bit extended to go over the 2 M2 holes in the "power" part of the NModule, so it could be fitted with spacers and nylon screws and have stable/reliable mechanical connection between NModule and Shield. Basically this would be the footprint of the shield :

So in the end it would make one shield to have Temperature/Humidity/Light/Acceleration or Temperature/Humidity/Light/Door.