CNC PCB milling

-

-

@sundberg84 see andrew's earlier post.

Freezing the motor axis makes it a bit smaller.

-

@sundberg84 And heating up the other part makes it expand and get bigger allowing the two to fit together easier. Has to do with tight tolerances.

-

@andrew

Since I probably have only one shot at this, how hot should I heat up the ER11 before trying to fit it onto the frozen spindle? Should it be burning hot, or is luke-warm enough?@neverdie unfortunately, as I mentioned, I don't have ER11 (yet), and I just read articles and vendor suggestions on the installation method, so I cannot provide experience based suggestions to that. as far as I remember nor concrete temperature was mentioned, so I would say you should not "overheat" it.

-

@neverdie unfortunately, as I mentioned, I don't have ER11 (yet), and I just read articles and vendor suggestions on the installation method, so I cannot provide experience based suggestions to that. as far as I remember nor concrete temperature was mentioned, so I would say you should not "overheat" it.

@andrew said in CNC PCB milling:

@neverdie unfortunately, as I mentioned, I don't have ER11 (yet), and I just read articles and vendor suggestions on the installation method, so I cannot provide experience based suggestions to that. as far as I remember nor concrete temperature was mentioned, so I would say you should not "overheat" it.

I slipped it on, no problem at all. After freezing the motor overnight, what I did was heat the ER11 with my wife's crafting hot air gun. I held it with an insulated glove as I warmed it up. When it started to become uncomfortable to hold with even the insulated glove, I slipped it on without any resistance.

Hopefully this info will help you when you receive yours.

-

@andrew said in CNC PCB milling:

@neverdie unfortunately, as I mentioned, I don't have ER11 (yet), and I just read articles and vendor suggestions on the installation method, so I cannot provide experience based suggestions to that. as far as I remember nor concrete temperature was mentioned, so I would say you should not "overheat" it.

I slipped it on, no problem at all. After freezing the motor overnight, what I did was heat the ER11 with my wife's crafting hot air gun. I held it with an insulated glove as I warmed it up. When it started to become uncomfortable to hold with even the insulated glove, I slipped it on without any resistance.

Hopefully this info will help you when you receive yours.

-

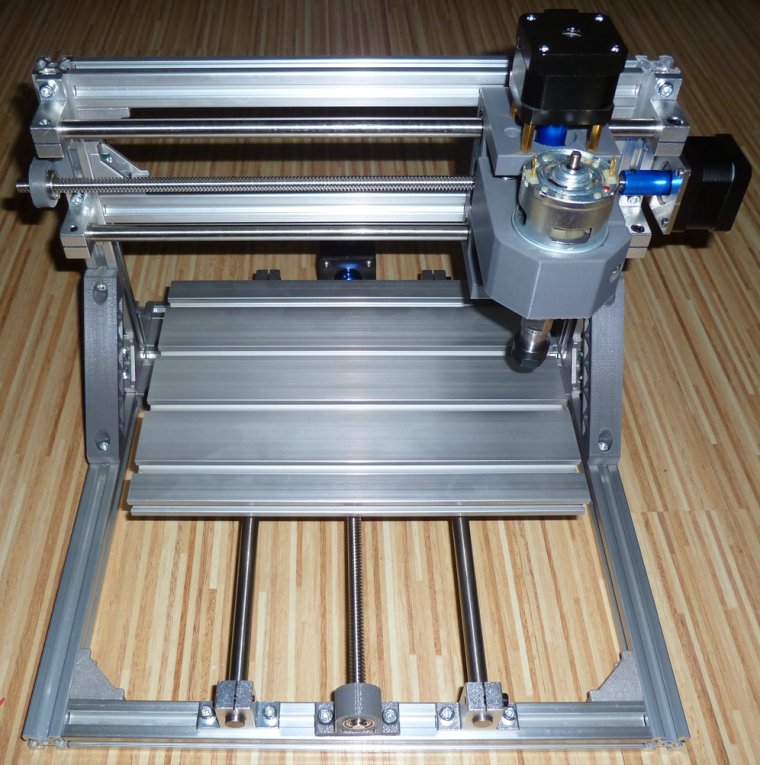

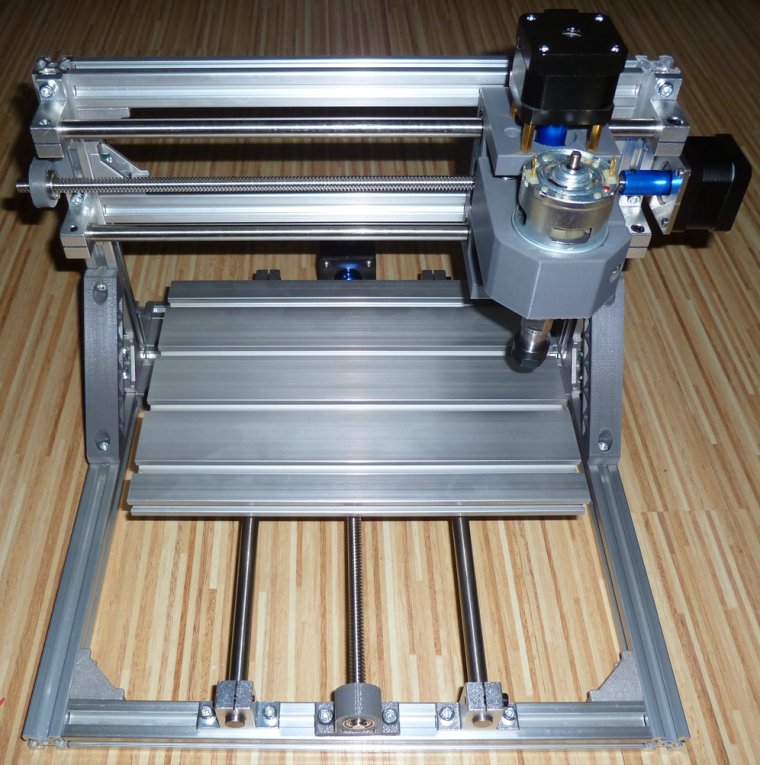

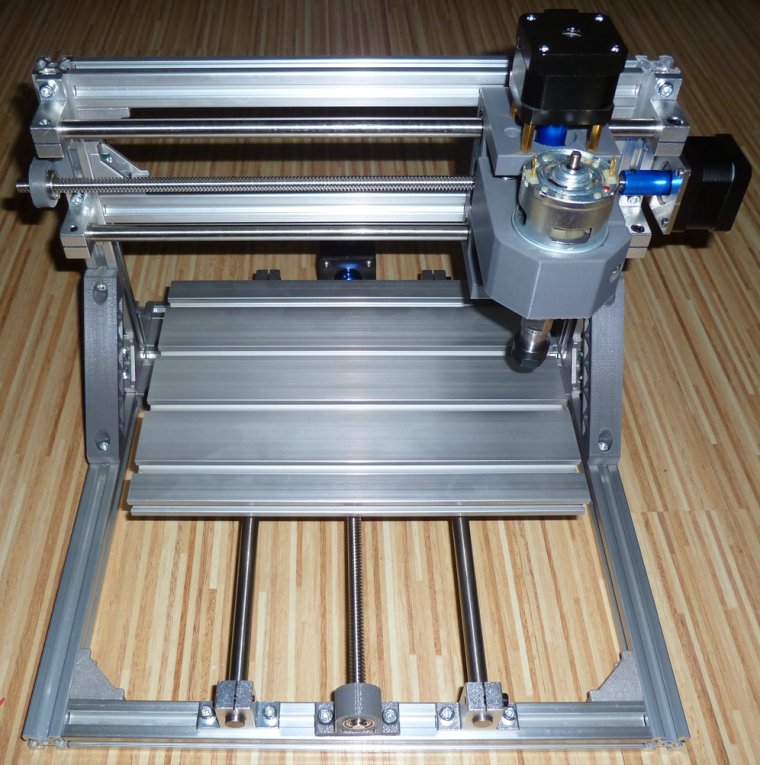

I seem to be finished with the mechanical assembly:

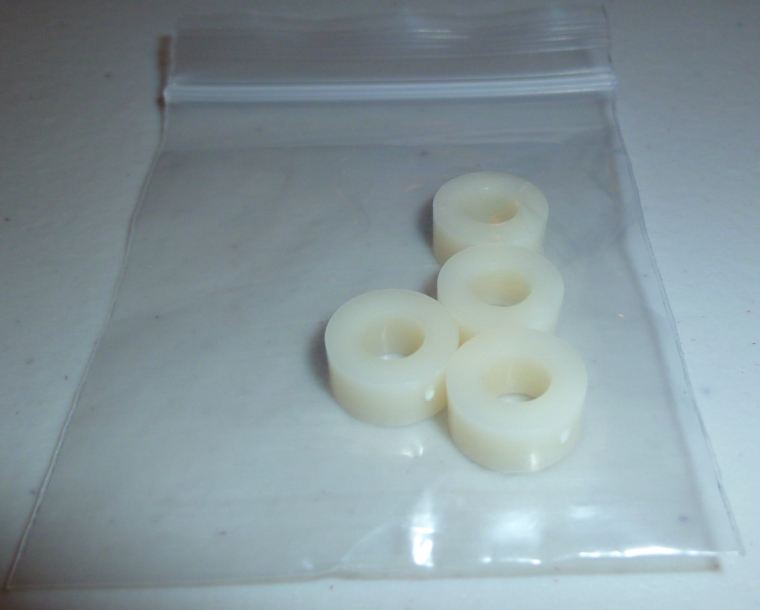

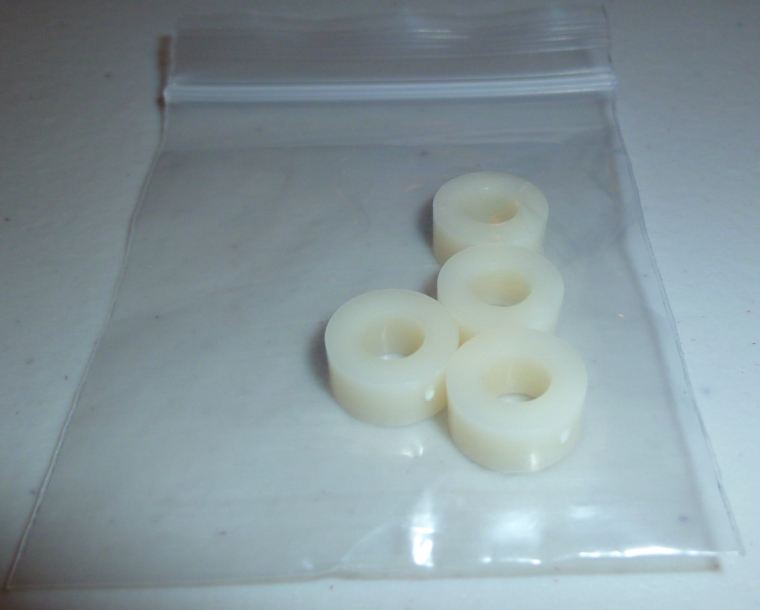

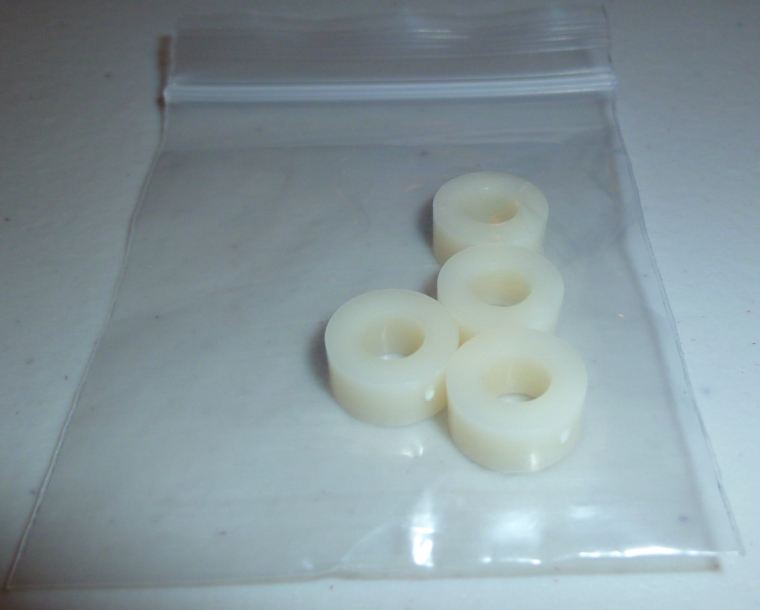

However, these washers came with the kit, and I'm not sure what they're for:

Anyone know? Are they for mounting the woodpecker board to the frame?Next I need to do the firmware upgrade and then wire things up.

-

I seem to be finished with the mechanical assembly:

However, these washers came with the kit, and I'm not sure what they're for:

Anyone know? Are they for mounting the woodpecker board to the frame?Next I need to do the firmware upgrade and then wire things up.

-

@andrew said in CNC PCB milling:

@neverdie unfortunately, as I mentioned, I don't have ER11 (yet), and I just read articles and vendor suggestions on the installation method, so I cannot provide experience based suggestions to that. as far as I remember nor concrete temperature was mentioned, so I would say you should not "overheat" it.

I slipped it on, no problem at all. After freezing the motor overnight, what I did was heat the ER11 with my wife's crafting hot air gun. I held it with an insulated glove as I warmed it up. When it started to become uncomfortable to hold with even the insulated glove, I slipped it on without any resistance.

Hopefully this info will help you when you receive yours.

@neverdie said in CNC PCB milling:

ER11

FYI - Was reading on another forum where the user was going to replace the ER11 with a larger version so he could use 8mm bits (fairly standard metric size for wood routing bits, but incredibly strong)...

Somebody pointed out to the guy that there are collets available for the ER11 specifically for 8mm shafted toolbits...

https://www.sorotec.de/shop/Spannzange-ER-11---8-00mm-DIN-6499B-4008E-Klasse-II.html -

I seem to be finished with the mechanical assembly:

However, these washers came with the kit, and I'm not sure what they're for:

Anyone know? Are they for mounting the woodpecker board to the frame?Next I need to do the firmware upgrade and then wire things up.

-

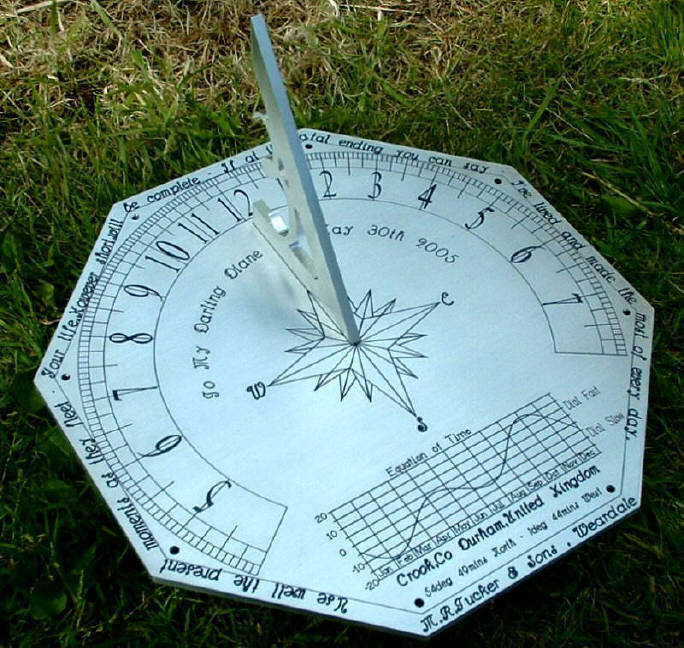

Carved this on my home made cnc router recently.

Bit off topic but good fun.

It is about 2ft diameter and 8" thick(old millstone)

-

@rmtucker said in CNC PCB milling:

@neverdie

You have gone quiet:relaxed:

Must be beavering away cutting pcb's?No, I've simply misplaced my Dragon AVR programmer for the firmware upgrade, so I need to hunt it down.

-

Anyway, once I do get the firmware upgraded and it wired up, what's the best way to start testing it? Do I need to learn GRBL as execuval seems to imply, or are there some simple tests I can run? I imagine some kind of calibration would be the need step, but I haven't read that far ahead because there's nothing to read (well, haven't googled it out yet either).

-

Anyway, once I do get the firmware upgraded and it wired up, what's the best way to start testing it? Do I need to learn GRBL as execuval seems to imply, or are there some simple tests I can run? I imagine some kind of calibration would be the need step, but I haven't read that far ahead because there's nothing to read (well, haven't googled it out yet either).

-

@neverdie said in CNC PCB milling:

ER11

FYI - Was reading on another forum where the user was going to replace the ER11 with a larger version so he could use 8mm bits (fairly standard metric size for wood routing bits, but incredibly strong)...

Somebody pointed out to the guy that there are collets available for the ER11 specifically for 8mm shafted toolbits...

https://www.sorotec.de/shop/Spannzange-ER-11---8-00mm-DIN-6499B-4008E-Klasse-II.html@zboblamont said in CNC PCB milling:

was going to replace the ER11 with a larger version

Given how it's installed, I don't see how you can get it off. I would assume it's permanent.

-

@zboblamont said in CNC PCB milling:

was going to replace the ER11 with a larger version

Given how it's installed, I don't see how you can get it off. I would assume it's permanent.

@neverdie From memory the guy got it off with a hub-puller, and a persuader, but the point I was trying to make was that there is a collet assembly for the ER11which takes 8mm...

-

Anyway, once I do get the firmware upgraded and it wired up, what's the best way to start testing it? Do I need to learn GRBL as execuval seems to imply, or are there some simple tests I can run? I imagine some kind of calibration would be the need step, but I haven't read that far ahead because there's nothing to read (well, haven't googled it out yet either).

@neverdie said in CNC PCB milling:

Anyway, once I do get the firmware upgraded and it wired up, what's the best way to start testing it? Do I need to learn GRBL as execuval seems to imply, or are there some simple tests I can run? I imagine some kind of calibration would be the need step, but I haven't read that far ahead because there's nothing to read (well, haven't googled it out yet either).

First watch the video (now I can't get it out of my head :man-bowing: )

https://www.youtube.com/watch?v=UOk6echpeqQThen, after you update to grbl 0.9j go to chilipeppr.com/grbl, download the SPJS, start it and start playing.

-

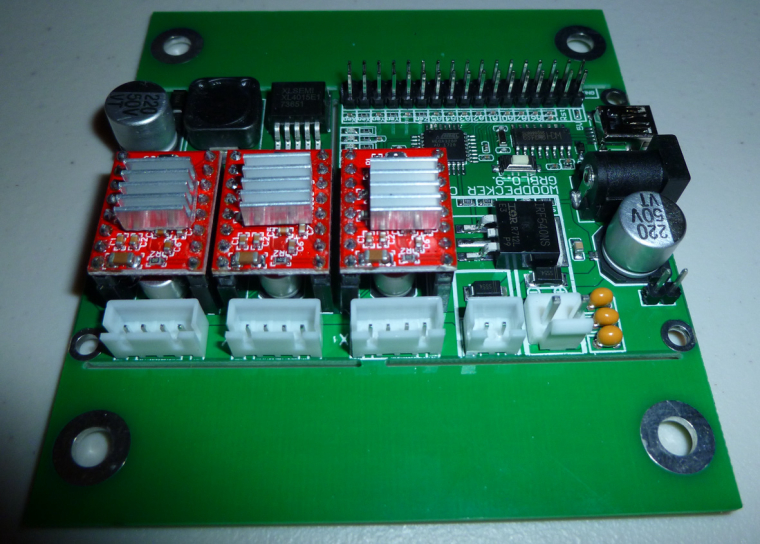

I hope these heatsinks that came with the kit don't short things out. Seems rather dicey.

In any case, until I can find my Dragon, I'm going to limp along with GRBL 0.9j so I can finish up the build. I'll upgrade later after I find it.