CNC PCB milling

-

@neverdie for er11 fastening you should use two wrenches.

if you loose steps during the milling, then with the given feed rate / depth / spindle speed combination the cnc / spindle / steppers are not powerful enough.

if you wood milling depth is not constant then:

- the wood is not flat

- the cnc bad is not flat

- the cnc x axis is not horizontal

my availability for the next couple of days will be quite limited, so I wish you good luck for experiencing the router and for the first PCBs!

Have a Merry Christmas!

Also, I'm not going to dwell on etching wood . It was just my first attempt at etching anything, and I thought wood might be a little softer.

I suppose the next step is to have a go at auto-leveling on a PCB rather than perfect the machine's etching of plywood. Indeed, PCB's may turn out to be easier, as the resistance to downward motion (especially after auto-levelling) should be more uniform.

-

Meh, I think I know what happened now. If the z-axis ever skips a step in downward motion--for whatever reason--then the rest of the etching is screwed from that point forward, because the higher height then becomes the new "zero" for the entire remainder of the etching since the depth control is completely open loop. So, the first spot in the sequence that isn't at proper depth would be where the error occurred, creating a persistence of the error from that point forward in the etching sequence.

-

Meh, I think I know what happened now. If the z-axis ever skips a step in downward motion--for whatever reason--then the rest of the etching is screwed from that point forward, because the higher height then becomes the new "zero" for the entire remainder of the etching since the depth control is completely open loop. So, the first spot in the sequence that isn't at proper depth would be where the error occurred, creating a persistence of the error from that point forward in the etching sequence.

@neverdie If the material is parallel to the cutting plane, the cut depth should be constant. Might I suggest doing same experiment using auto-level.... Wood is easier on the bits, plywood less so but still less abrasive than FR4...

-

@neverdie If the material is parallel to the cutting plane, the cut depth should be constant. Might I suggest doing same experiment using auto-level.... Wood is easier on the bits, plywood less so but still less abrasive than FR4...

@zboblamont said in CNC PCB milling:

Might I suggest doing same experiment using auto-level....

Is there an auto-level that works on wood? I thought it assumed a conductive surface, like on a blank copper PCB, to facilitate the auto-leveling mapping process, so that it knows when contact is made and therefore the height at each touch point.

-

@zboblamont said in CNC PCB milling:

Might I suggest doing same experiment using auto-level....

Is there an auto-level that works on wood? I thought it assumed a conductive surface, like on a blank copper PCB, to facilitate the auto-leveling mapping process, so that it knows when contact is made and therefore the height at each touch point.

@neverdie Tinfoil?

-

@zboblamont said in CNC PCB milling:

Might I suggest doing same experiment using auto-level....

Is there an auto-level that works on wood? I thought it assumed a conductive surface, like on a blank copper PCB, to facilitate the auto-leveling mapping process, so that it knows when contact is made and therefore the height at each touch point.

@neverdie I should explain my thinking... I do not think your wood experiment made sense. You assume your sensors and the wood are parallel, this need not be true. Plywood is generally less than 0.3mm out of true, even if you could zero the 4 corners with foil or similar it would give you a plane on which to see if the original trial was misleading.

-

@neverdie Tinfoil?

@zboblamont said in CNC PCB milling:

@neverdie Tinfoil?

You get an A+ for creative thinking. I suppose extra wide foil tape might work.

-

@zboblamont said in CNC PCB milling:

@neverdie Tinfoil?

You get an A+ for creative thinking. I suppose extra wide foil tape might work.

@neverdie I was thinking kitchen foil pressed flat as possible to the block surface, whatever works...

-

This is a good video for how to auto level in ChiliPeppr:

https://www.youtube.com/watch?v=6WNE3E1ZZYYSo, with that as inspiration, I plan to connect the probe to A5 on the woodpecker, and the PCB surface to GND. He soldered his ground wire to the PCB, so I guess I'll do the same, at least for now.

I'll use tape to secure the PCB to the sacrificial board underneath.

-

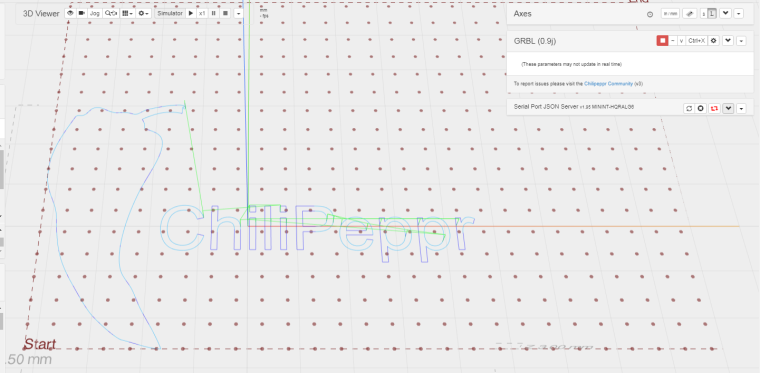

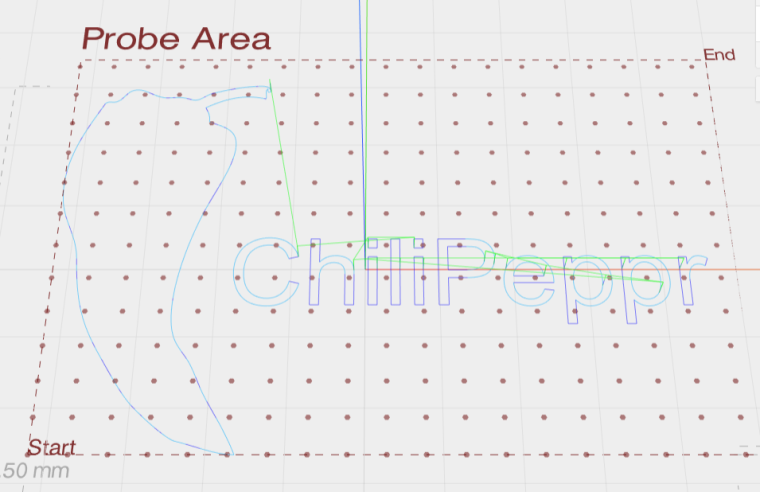

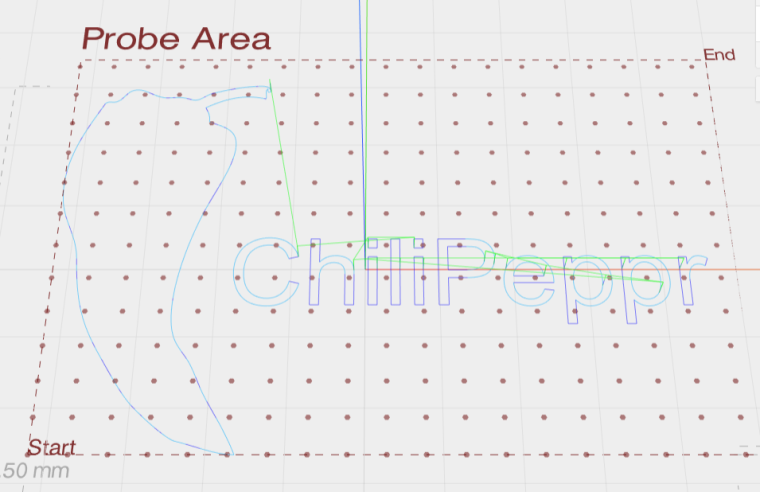

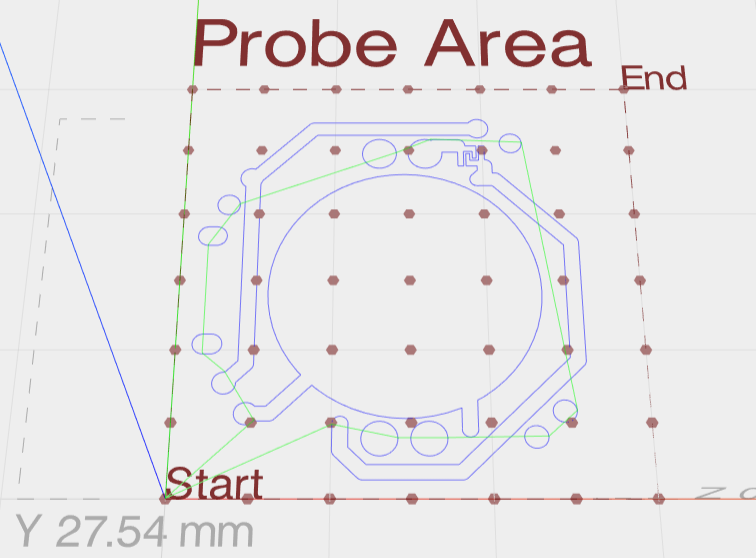

I've confirmed that A5 and GND work correctly for the auto-leveling.

However, Chillipeppr strangely defaults to probe a much larger area than is needed for auto-leveling, so I need to figure out how to reduce the upper and right-hand boundaries of the probing area:

Otherwise, it runs the risk of not even hitting the PCB if it gets too far out.

-

Nailed it!

Well, further progress will have to wait until I can move the CNC to the garage or outdoors, so that I don't fill the house with toxic fiberglass particles (Thank you @executivul for pointing that out, and sorry I butchered your name earlier. I didn't mean to.)

-

Nailed it!

Well, further progress will have to wait until I can move the CNC to the garage or outdoors, so that I don't fill the house with toxic fiberglass particles (Thank you @executivul for pointing that out, and sorry I butchered your name earlier. I didn't mean to.)

@neverdie no problem, I got used to it since I'm using such a weird nickname, the good part is it's always free to register on any forum so all I have to remember is the pass.

I'm really excited about wet milling, it's freezing down here and not having to have windows open for the modded vacuum cleaner it's a treat. The trick is to use a solution with higher surface tension then water, but not too thick or it will gather around the mill as a small tornado and start splashing everywhere. You can use soap, shampoo, dishwash, carwash, etc. Start at 1:1 water mix and add more water if it tends to gather around the spinning bit. It's better to pour it slowly on the board and spread with your finger (use a syringe) than to spray it as not to make foam. Also try using a clear shampoo to better see what's milling below the liquid. A piece of flat plastic, acrylic, lexan, plexiglas, whatever, doublesided taped to the wood spoilboard is a must unless you leave a large margin between the actual milling and pcb edge liquid will spill and will swell the wood. Have a roll of paper sheets nearby and a garbage bag open. Always use glasses when operating the machine. I made a "fence" out of some polycarbonate sheet to contain any eventual splashes which occur mostly when drilling through the board, normal engraving behaves and doesn't splash at all.

-

Given that the goal is to get 6mil isolatioin routing, what cutting depth should I set in flatcam? 0.05mm?

-

Given that the goal is to get 6mil isolatioin routing, what cutting depth should I set in flatcam? 0.05mm?

-

@neverdie I have been kind of following this topic, but don't have a CNC mill, but wouldn't the thickness of the copper clad on the board be your depth?

@dbemowsk said in CNC PCB milling:

@neverdie I have been kind of following this topic, but don't have a CNC mill, but wouldn't the thickness of the copper clad on the board be your depth?

Makes sense to me. Well, doing that it would be 0.01mm. But since this isn't a perfect process, it likely needs some added depth to guarantee it's removed. The effective tool width gets wider the deeper you cut, so in some sense I suppose there's that as an added constraint on how deep you can cut before it becomes more than 6 mil isolation. We could try to arrive at an answer analytically from first principles only, but I thought it might be easier to just ask what depth others who are doing this successfully are using.

-

@dbemowsk said in CNC PCB milling:

@neverdie I have been kind of following this topic, but don't have a CNC mill, but wouldn't the thickness of the copper clad on the board be your depth?

Makes sense to me. Well, doing that it would be 0.01mm. But since this isn't a perfect process, it likely needs some added depth to guarantee it's removed. The effective tool width gets wider the deeper you cut, so in some sense I suppose there's that as an added constraint on how deep you can cut before it becomes more than 6 mil isolation. We could try to arrive at an answer analytically from first principles only, but I thought it might be easier to just ask what depth others who are doing this successfully are using.

-

@dbemowsk said in CNC PCB milling:

@neverdie I have been kind of following this topic, but don't have a CNC mill, but wouldn't the thickness of the copper clad on the board be your depth?

Makes sense to me. Well, doing that it would be 0.01mm. But since this isn't a perfect process, it likely needs some added depth to guarantee it's removed. The effective tool width gets wider the deeper you cut, so in some sense I suppose there's that as an added constraint on how deep you can cut before it becomes more than 6 mil isolation. We could try to arrive at an answer analytically from first principles only, but I thought it might be easier to just ask what depth others who are doing this successfully are using.

@neverdie you should use one depth, regardless of the trace width. for me 0.05mm worked, see my shared settings above. you should decide the isolation width, this is the main property for the given config, but you should stick for one milling depth only. if the requires isolation width is bigger than the tool width at a given depth, then it will use multiple rounds to reach the given width, but still, with one milling depth.

-

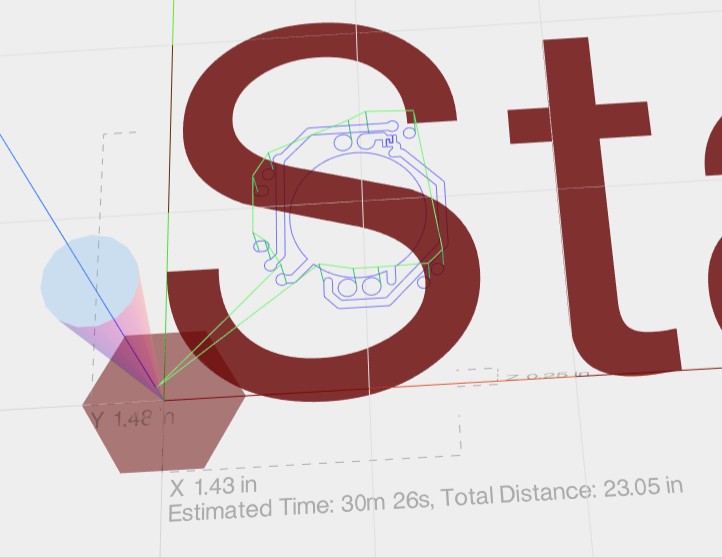

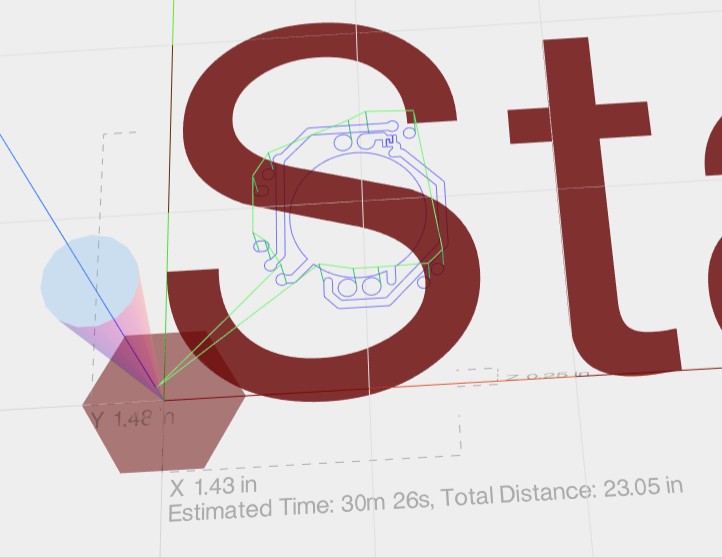

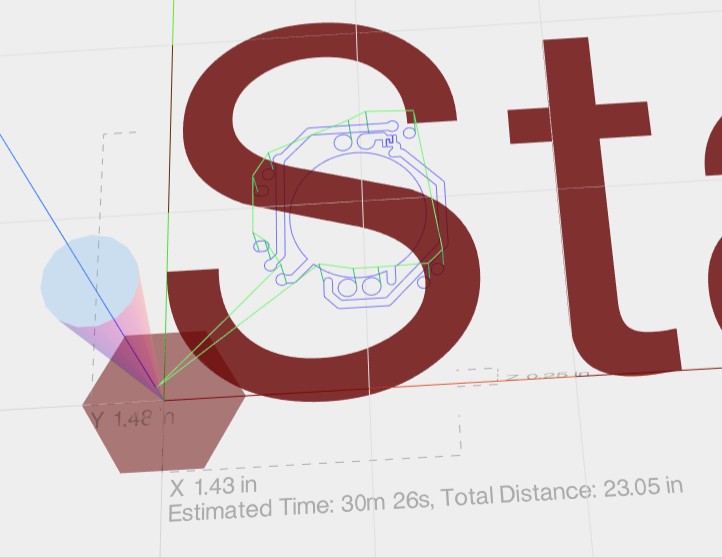

I'm stuck. I converted my gerber to gcode using flatcam, and imported it into Chilipeppr:

On the one hand, it seems to have gotten the dimensioning right, as indicated by the Y1.48in and X1.43in. However, the grid that it's showing is out of sync with that. Each square on the grid is 5mm. It's as though Chilipeppr thinks the entire design fits easily inside a 5mm square, and so when I attempt to do the autoleveling, it comes out completely wrong. -

I'm stuck. I converted my gerber to gcode using flatcam, and imported it into Chilipeppr:

On the one hand, it seems to have gotten the dimensioning right, as indicated by the Y1.48in and X1.43in. However, the grid that it's showing is out of sync with that. Each square on the grid is 5mm. It's as though Chilipeppr thinks the entire design fits easily inside a 5mm square, and so when I attempt to do the autoleveling, it comes out completely wrong.@neverdie said in CNC PCB milling:

I'm stuck. I converted my gerber to gcode using flatcam, and imported it into Chilipeppr:

On the one hand, it seems to have gotten the dimensioning right, as indicated by the Y1.48in and X1.43in. However, the grid that it's showing is out of sync with that. Each square on the grid is 5mm. It's as though Chilipeppr thinks the entire design fits easily inside a 5mm square, and so when I attempt to do the autoleveling, it comes out completely wrong.you can mark the zero point in the pcb designer tool before you export the gergbel, or in flatcam, during the post processing. if you do not define it, then maybe the given zero point could have some "offset" to the effective design. it is not problem, but it could make your life easier if your zero is e.g. at the pcb's corner.

if you don't want to update the files, then in chilipeppr you can update the probe area to not start from 0,0 but from a given offset. -

Thanks! I don't know why, but somehow that fixed the problem:

:)