Hi Folks,

Another update on this project

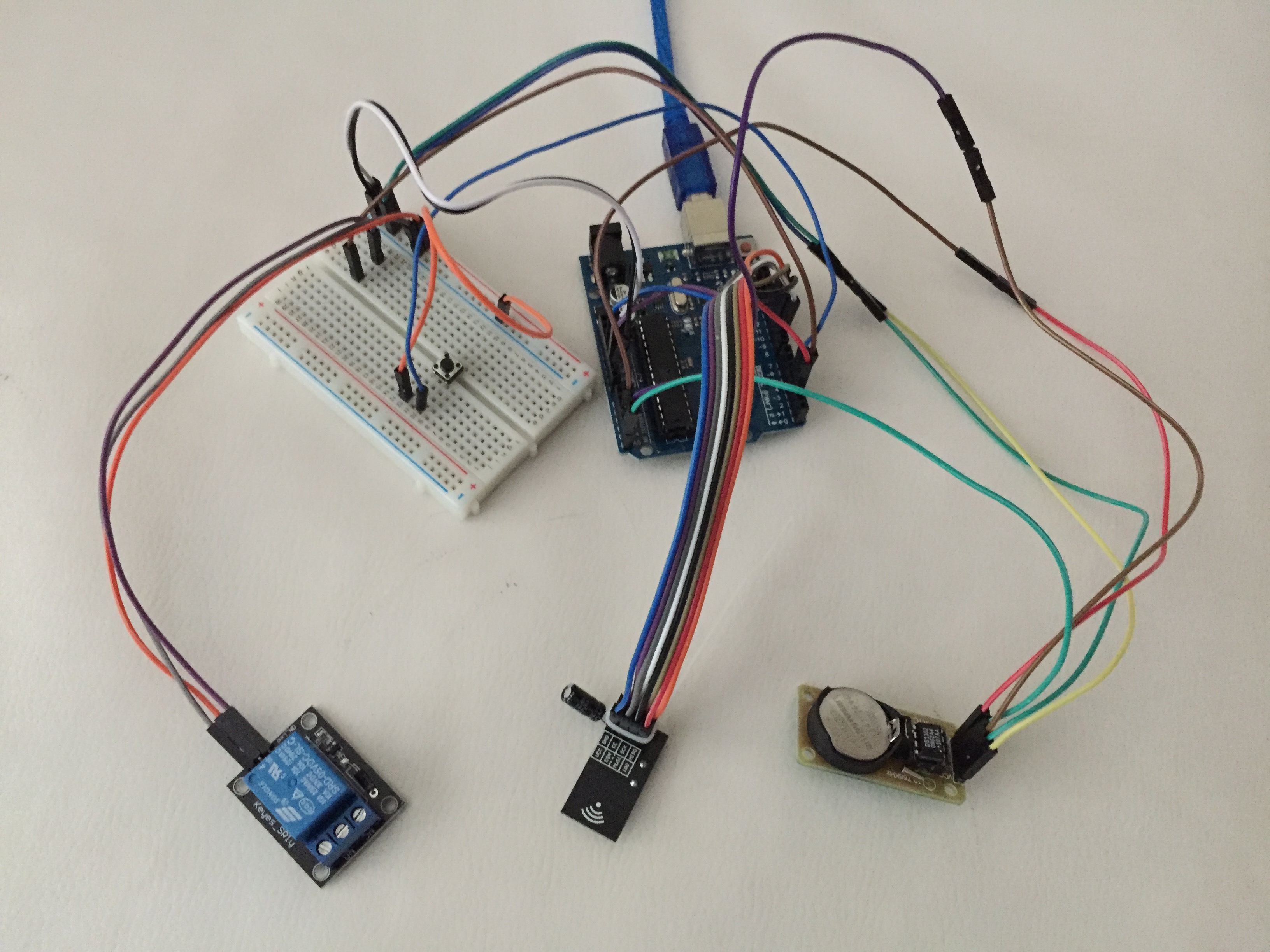

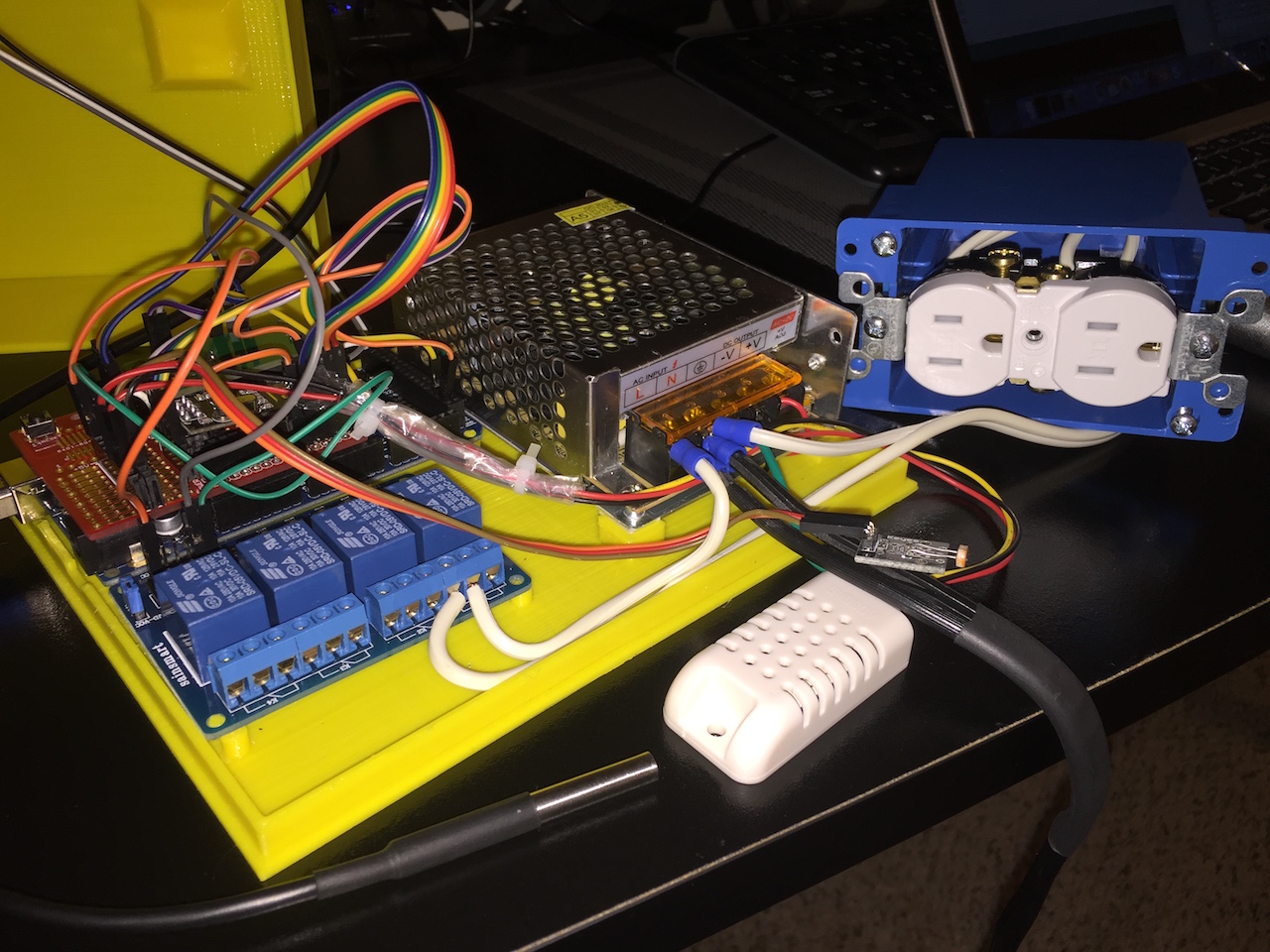

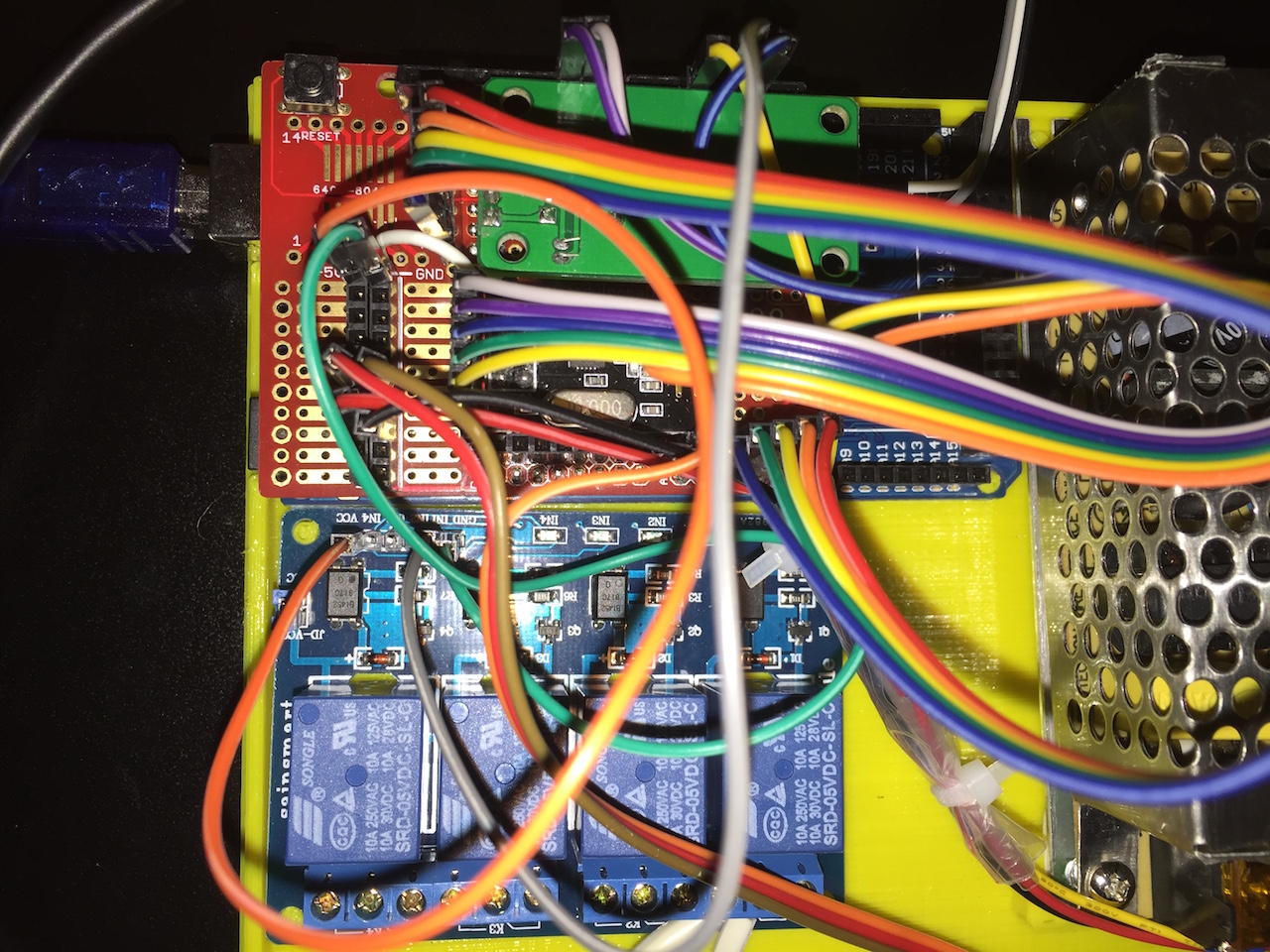

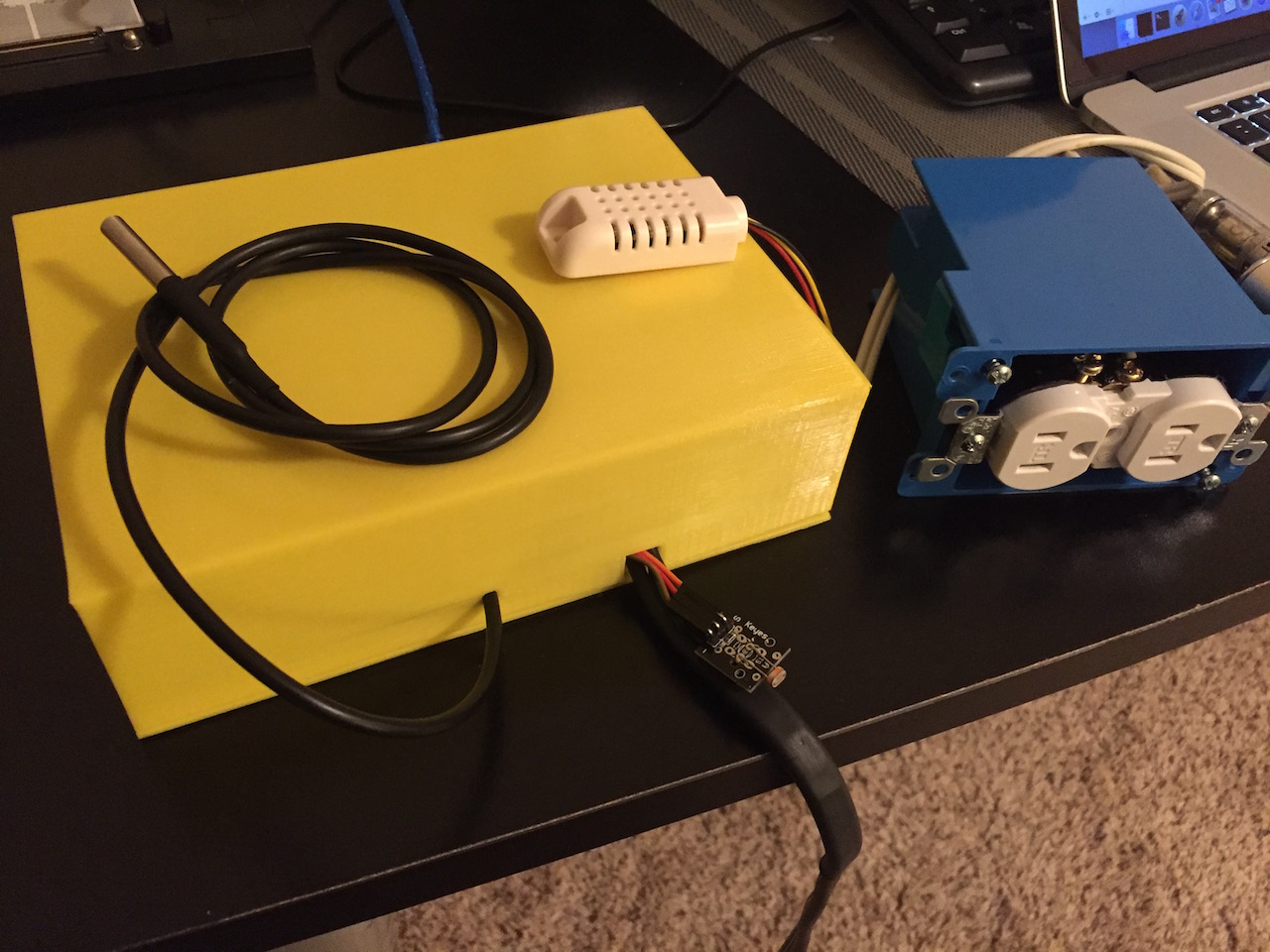

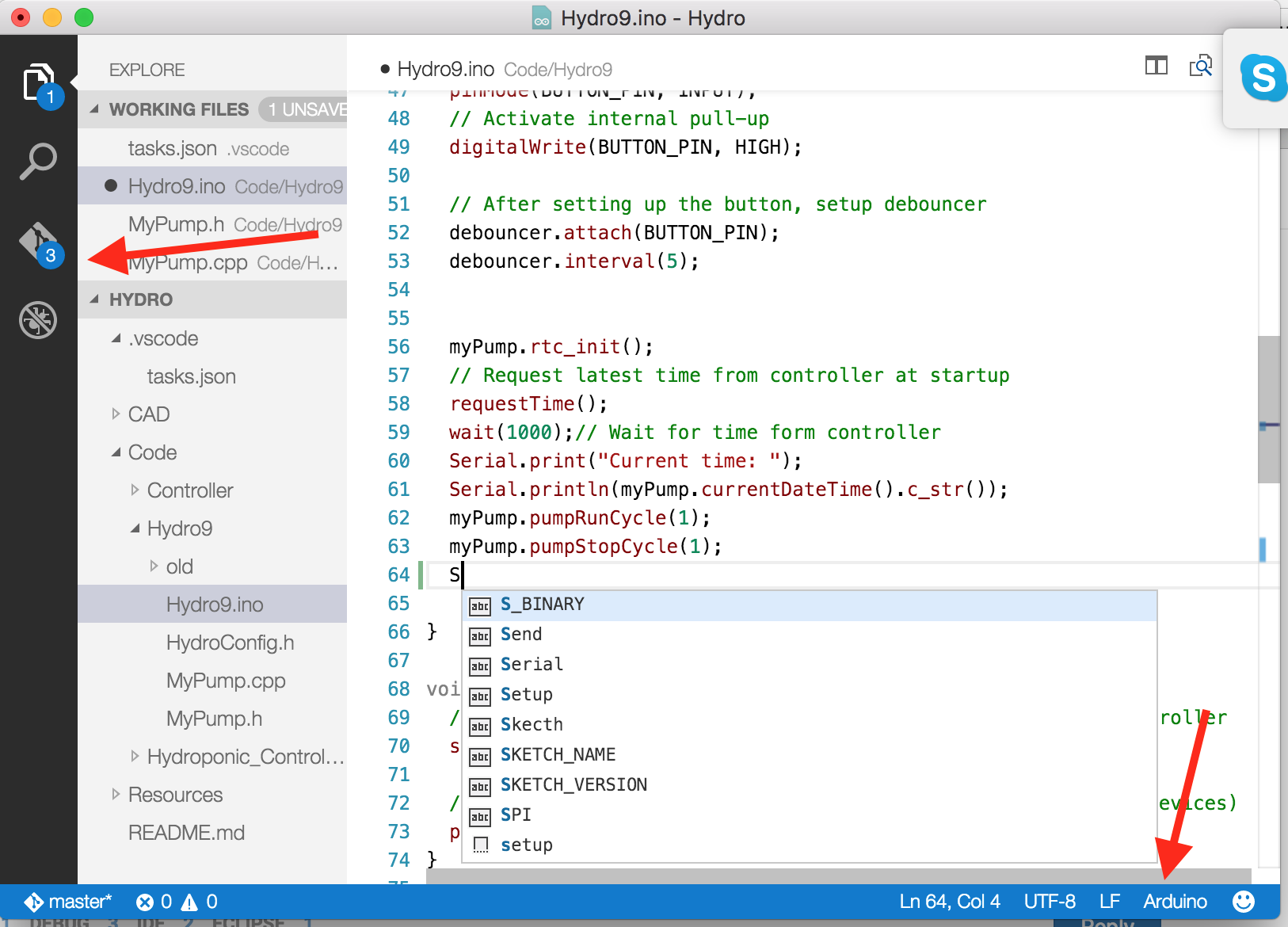

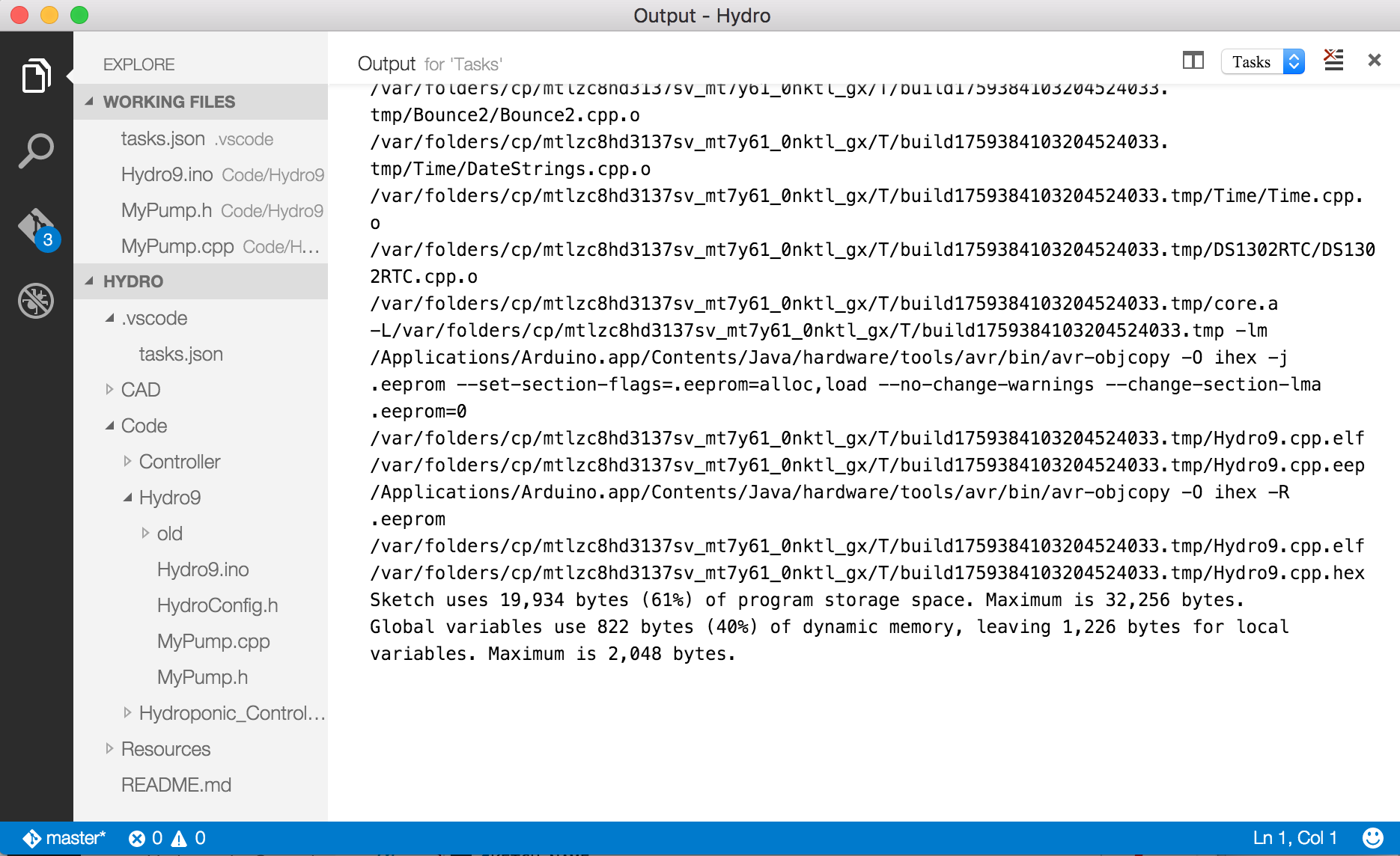

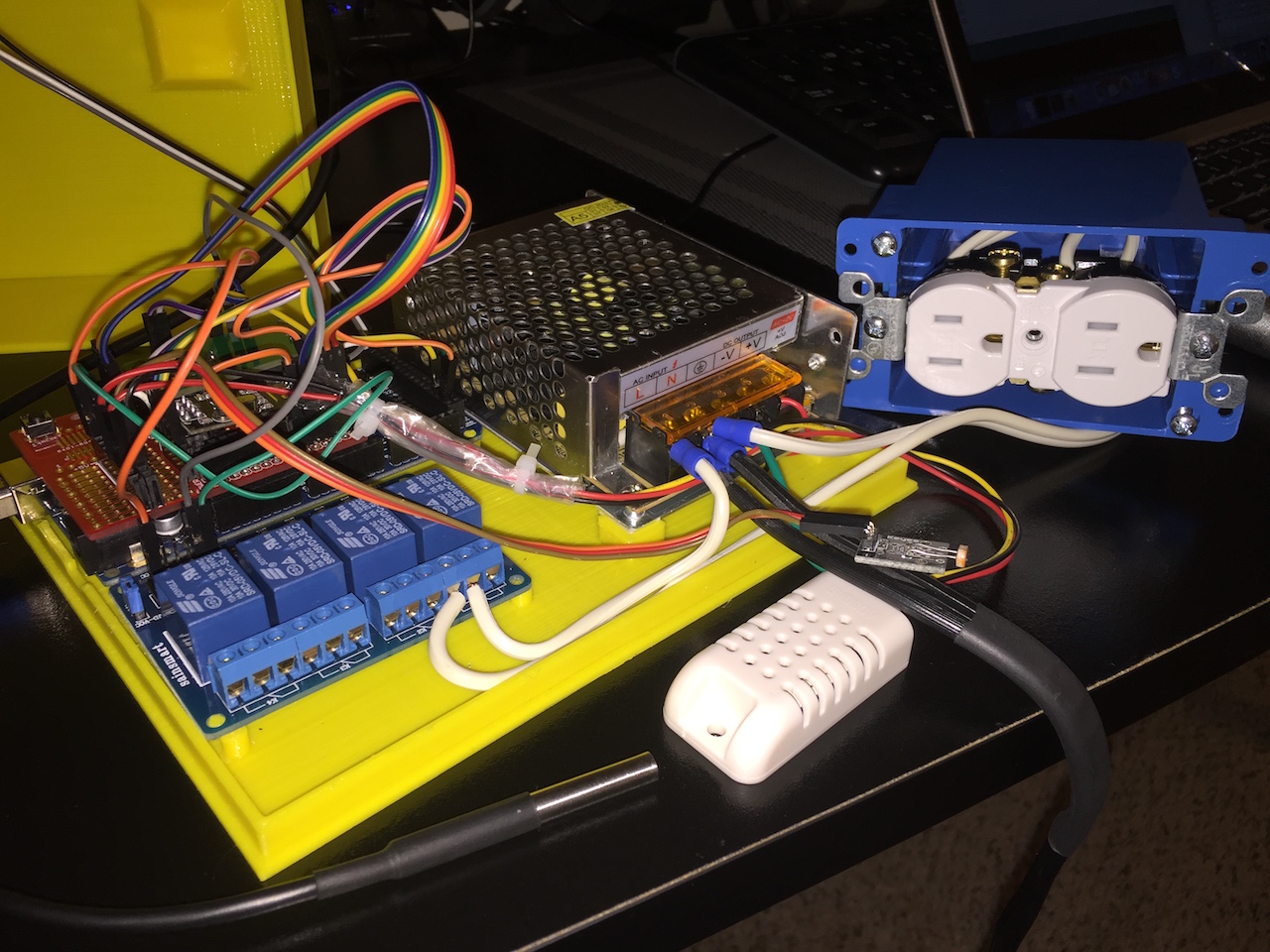

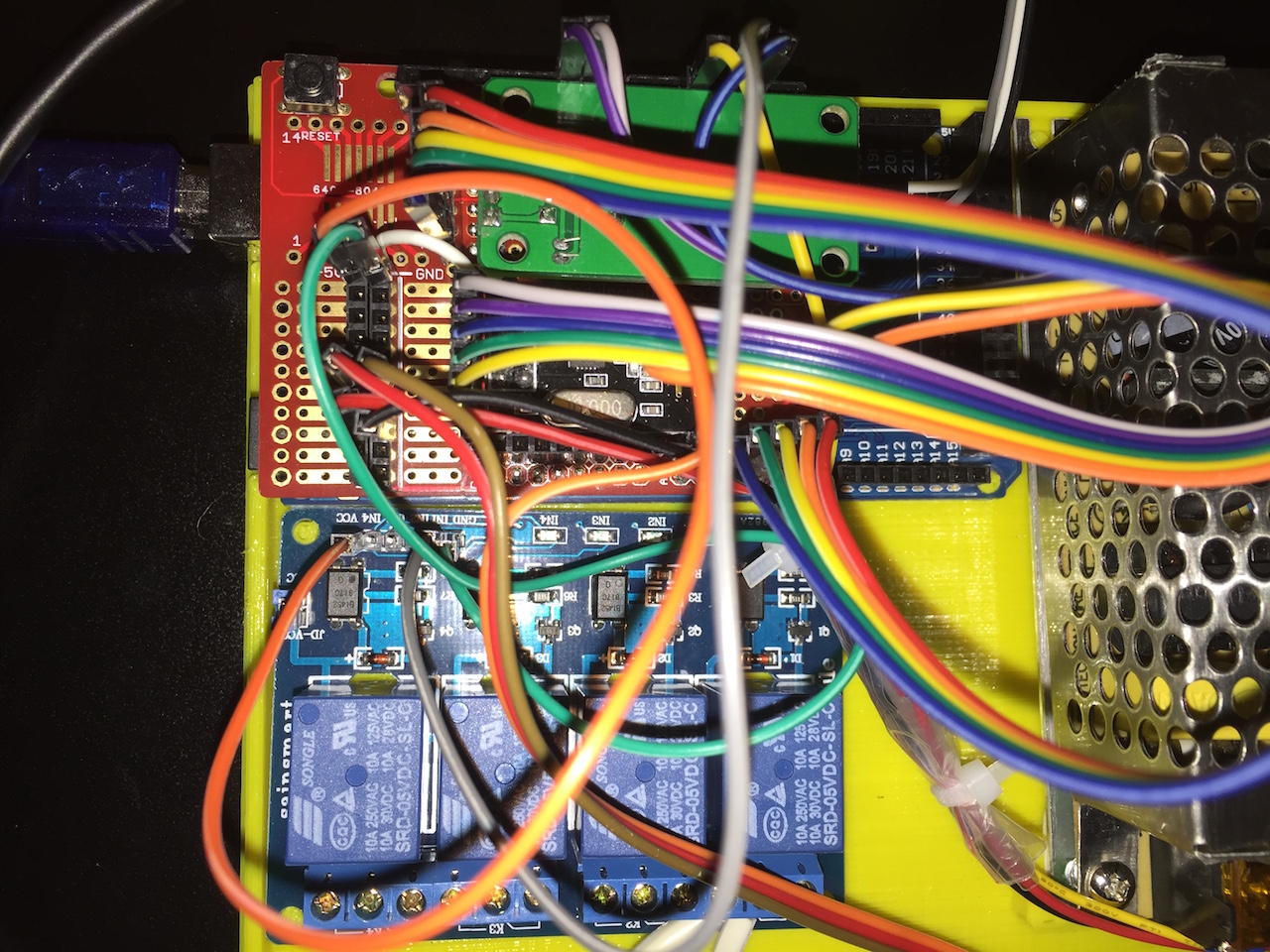

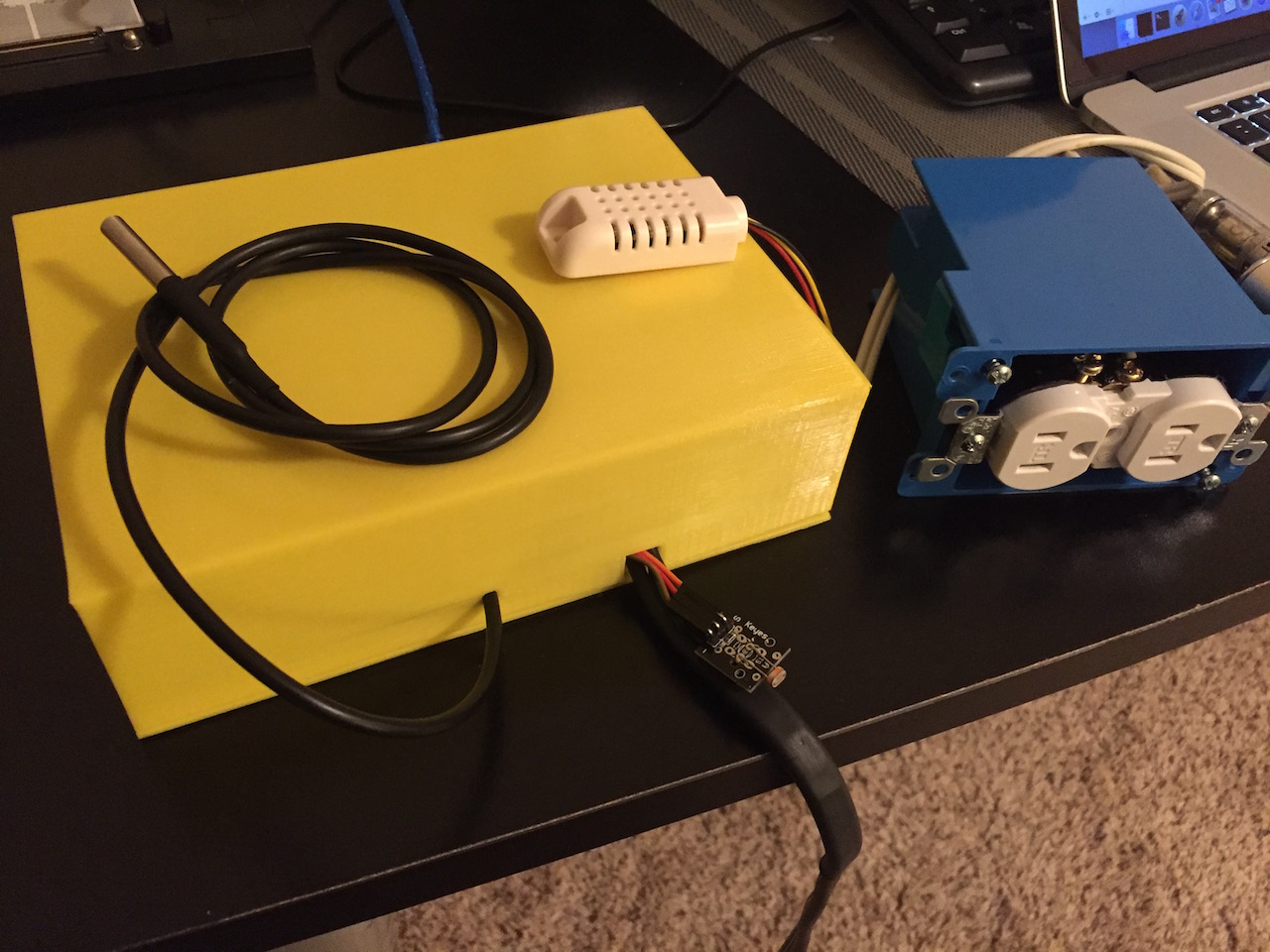

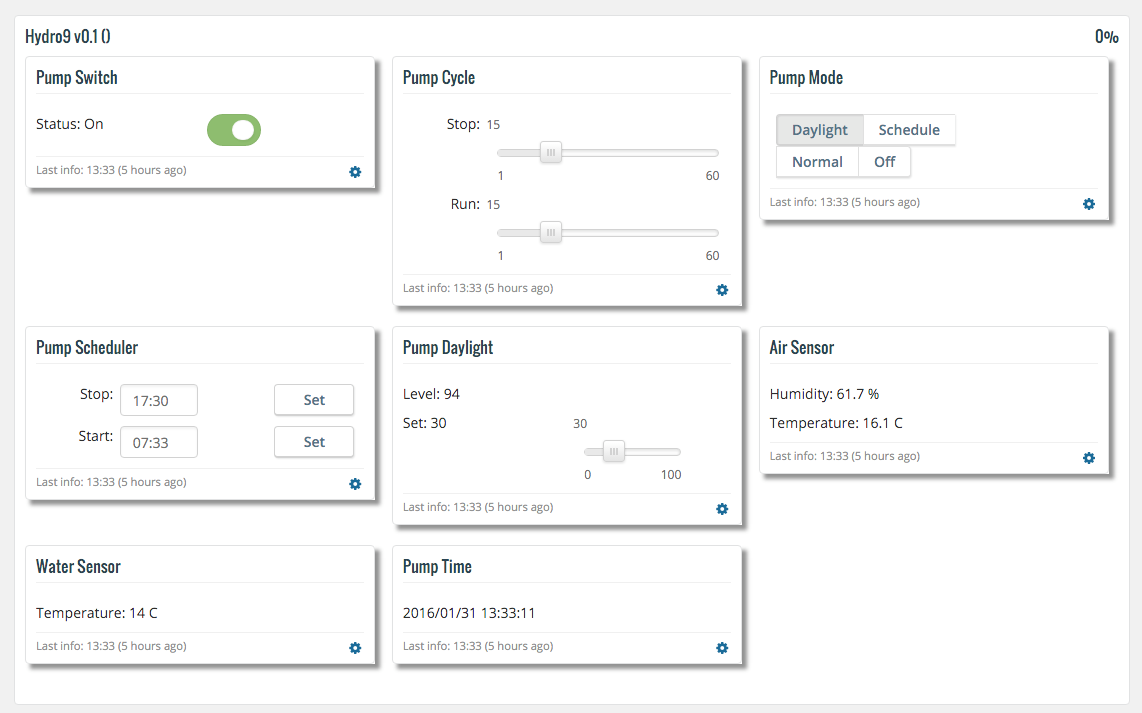

I've finally finished with the software. Added a DHT22 for air temperature and humidity and also a Dallas for the water temperature.

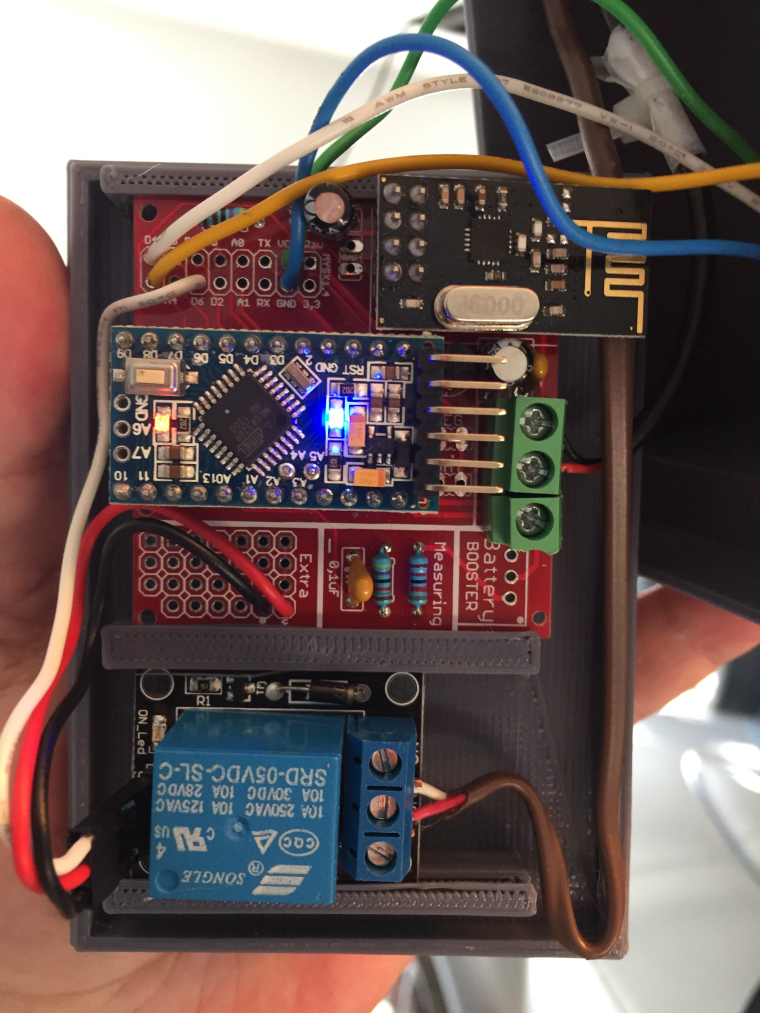

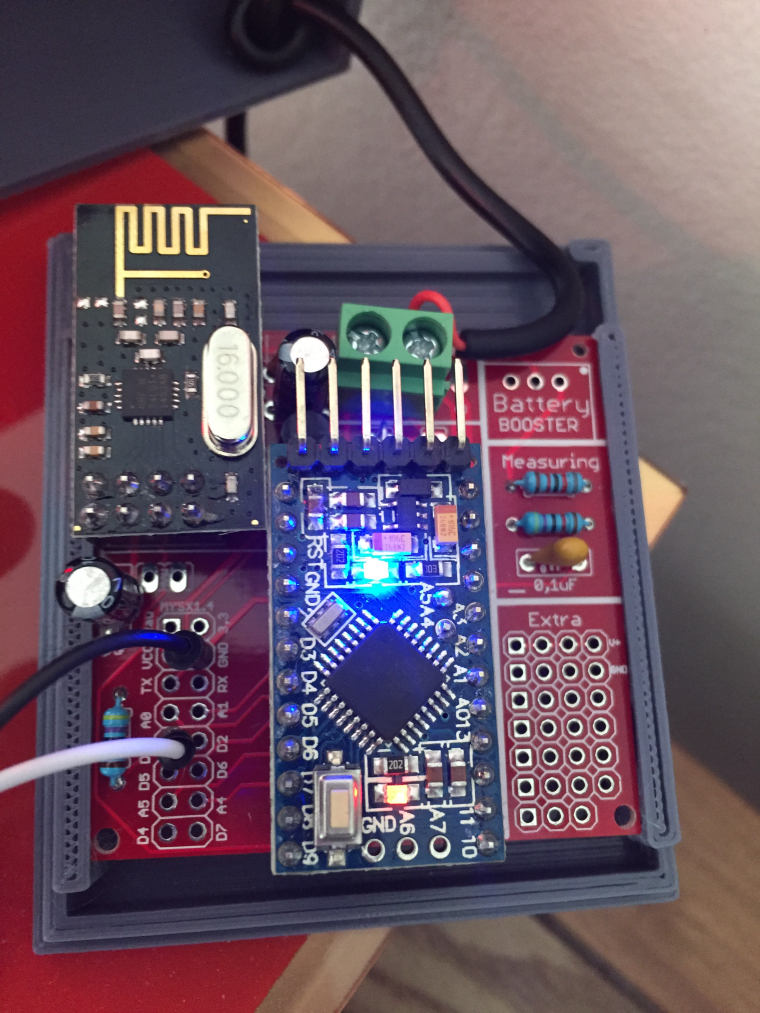

Assembling the hardware was a bit more challenging then anticipated, but with no PCB, i've decided to use a proto shield and maintain support/flexibility for both UNO and MEGA boards. Soon after I've realized the code does not fit a UNO (too much debug eventually)

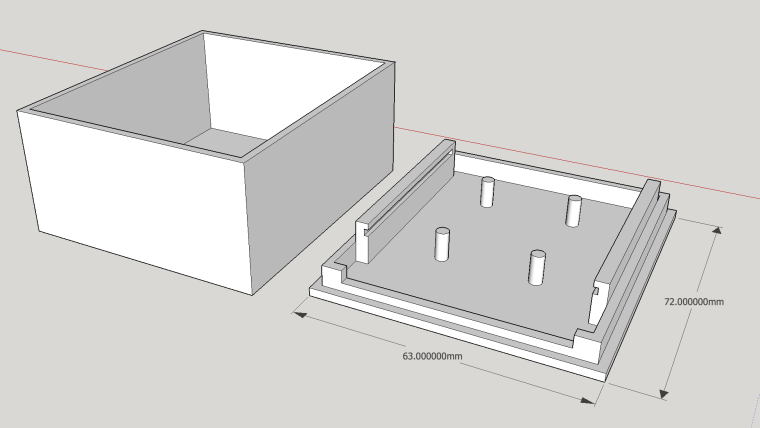

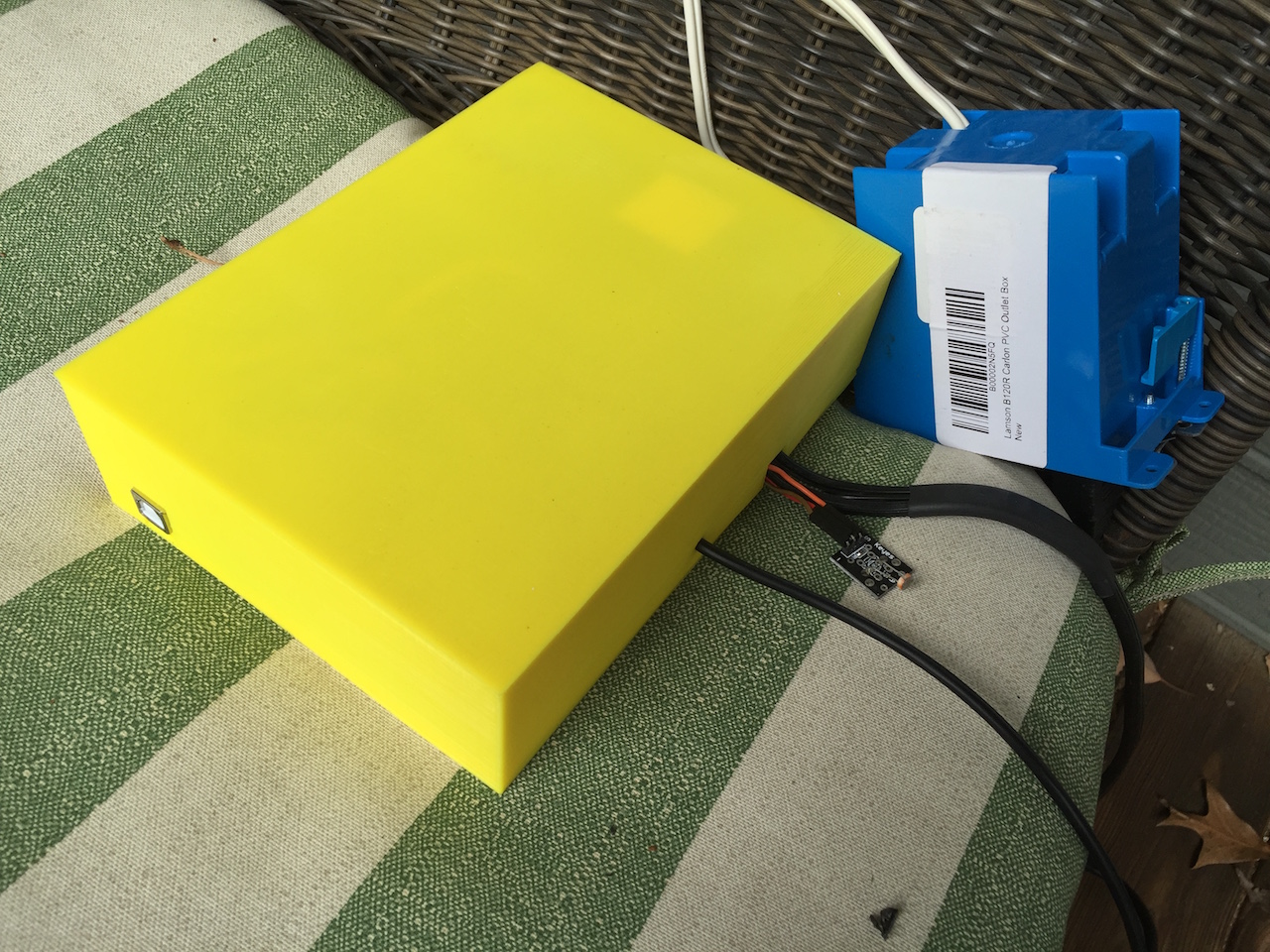

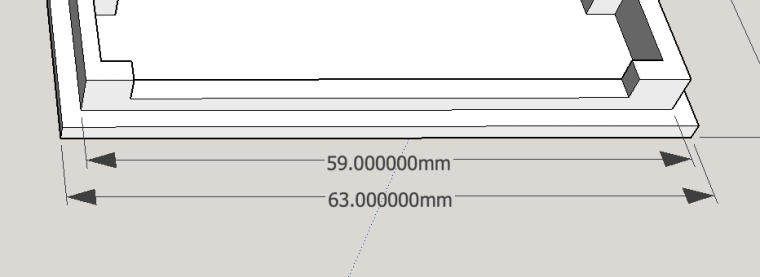

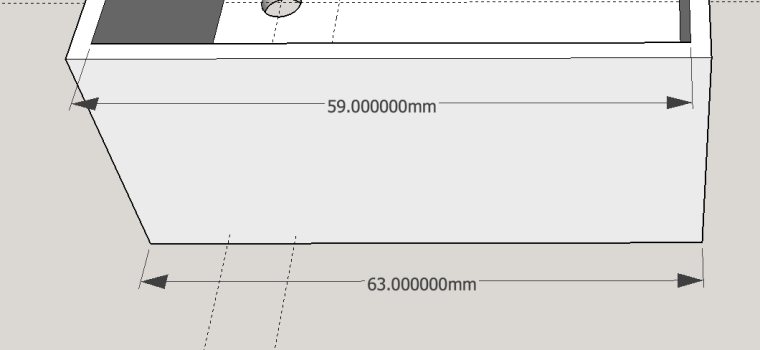

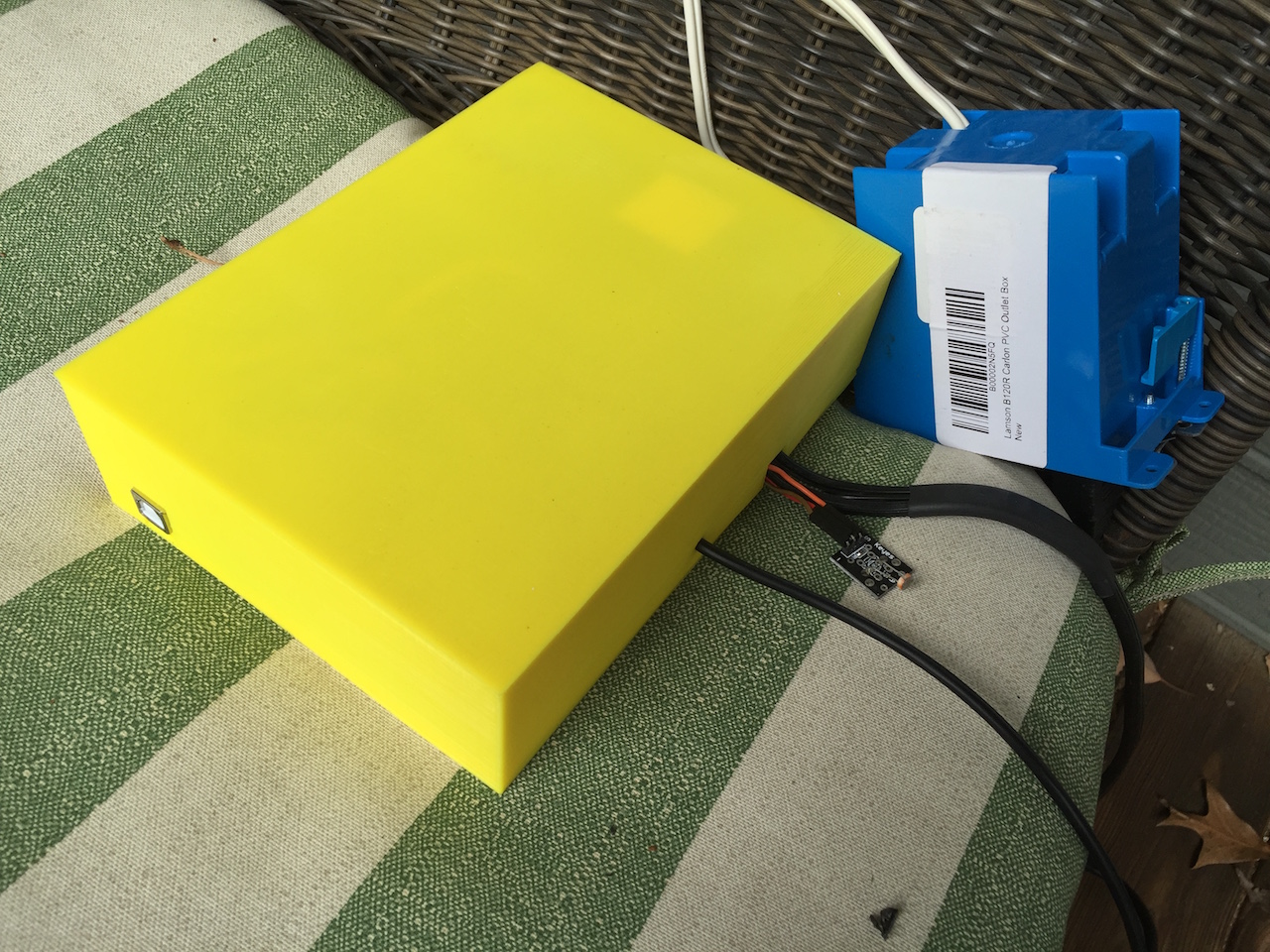

Also created a simple case to enclose it all.

The Column it self

If anyone would likr to take a look at the code, feed back is much appreciated!

Hydro9.zip

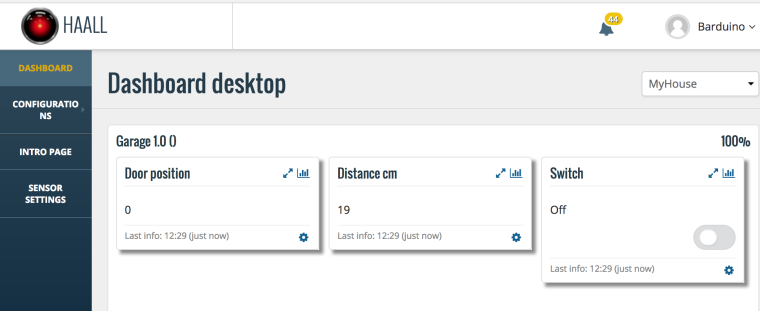

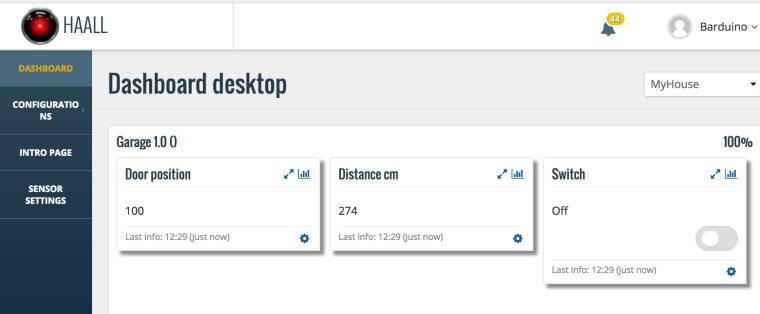

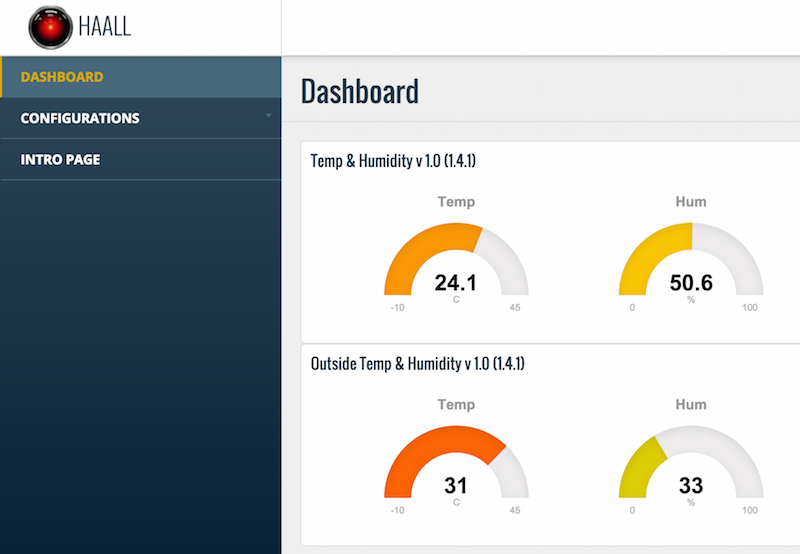

Finally the dashboard looks like this

Cheers

EDIT: Forgot to add the startup log

Starting sensor (RNNNA-, 1.6.0-beta)

Radio init successful.

Initializing DHT... Done!

Dallas Temperature IC Control Library Demo

Locating devices...Found 1 devices.

Parasite power is: OFF

Device 0 Address: 2817611D070000C3

Device 0 Resolution: 9

RTC module activated

The DS1302 is write protected. This normal.

RTC Sync TieStatus: 2 timeSet 2 Ok!

send: 7-7-0-0 s=255,c=3,t=1,pt=0,l=0,sg=0,st=ok:

read: 0-0-7 s=255,c=3,t=1,pt=0,l=10,sg=0:1454110229

Time value received: 1454110229

Pump Time:2016/01/29 23:30:28

send: 7-7-0-0 s=255,c=3,t=15,pt=1,l=1,sg=0,st=ok:0

send: 7-7-0-0 s=255,c=0,t=17,pt=0,l=10,sg=0,st=ok:1.6.0-beta

send: 7-7-0-0 s=255,c=3,t=6,pt=1,l=1,sg=0,st=ok:0

read: 0-0-7 s=255,c=3,t=6,pt=0,l=1,sg=0:M

Starting presentation

send: 7-7-0-0 s=255,c=3,t=11,pt=0,l=6,sg=0,st=ok:Hydro9

send: 7-7-0-0 s=255,c=3,t=12,pt=0,l=4,sg=0,st=ok:v0.1

send: 7-7-0-0 s=1,c=0,t=3,pt=0,l=11,sg=0,st=ok:Pump Switch

send: 7-7-0-0 s=2,c=0,t=23,pt=0,l=10,sg=0,st=ok:Pump Cycle

send: 7-7-0-0 s=3,c=0,t=25,pt=0,l=9,sg=0,st=ok:Pump Mode

send: 7-7-0-0 s=4,c=0,t=23,pt=0,l=14,sg=0,st=ok:Pump Scheduler

send: 7-7-0-0 s=5,c=0,t=23,pt=0,l=13,sg=0,st=ok:Pump Daylight

send: 7-7-0-0 s=6,c=0,t=6,pt=0,l=10,sg=0,st=ok:Air Sensor

send: 7-7-0-0 s=7,c=0,t=6,pt=0,l=12,sg=0,st=ok:Water Sensor

send: 7-7-0-0 s=10,c=0,t=23,pt=0,l=9,sg=0,st=ok:Pump Time

End presentation

Init complete, id=7, parent=0, distance=1

**************** PUMP STATUS ***********************

Pump Mode is: Daylight

Pump Cycle: On:15 Off:15

Pump Schedule: Start:07:33 Stop:17:30

Pump Daylight: Start:70 Current:59

Pump Time: 2016/01/29 23:30:34

****************************************************

************* ENVIRONMENT STATUS *******************

Air temperature:10.60 Air humidity:37.90

Water temperature:10.00

****************************************************

send: 7-7-0-0 s=1,c=1,t=2,pt=1,l=1,sg=0,st=ok:0

send: 7-7-0-0 s=3,c=1,t=19,pt=2,l=2,sg=0,st=ok:3

send: 7-7-0-0 s=4,c=1,t=24,pt=0,l=5,sg=0,st=ok:07:33

send: 7-7-0-0 s=4,c=1,t=25,pt=0,l=5,sg=0,st=ok:17:30

send: 7-7-0-0 s=5,c=1,t=37,pt=2,l=2,sg=0,st=ok:70

send: 7-7-0-0 s=5,c=1,t=35,pt=2,l=2,sg=0,st=ok:59

send: 7-7-0-0 s=2,c=1,t=37,pt=2,l=2,sg=0,st=ok:15

send: 7-7-0-0 s=2,c=1,t=35,pt=2,l=2,sg=0,st=ok:15

send: 7-7-0-0 s=10,c=1,t=24,pt=0,l=20,sg=0,st=ok:2016/01/29 23:30:34

send: 7-7-0-0 s=6,c=1,t=0,pt=7,l=5,sg=0,st=ok:10.6

send: 7-7-0-0 s=6,c=1,t=1,pt=7,l=5,sg=0,st=ok:37.9

send: 7-7-0-0 s=7,c=1,t=0,pt=7,l=5,sg=0,st=ok:10.0

2016/01/29 23:30:34 Light level: 59