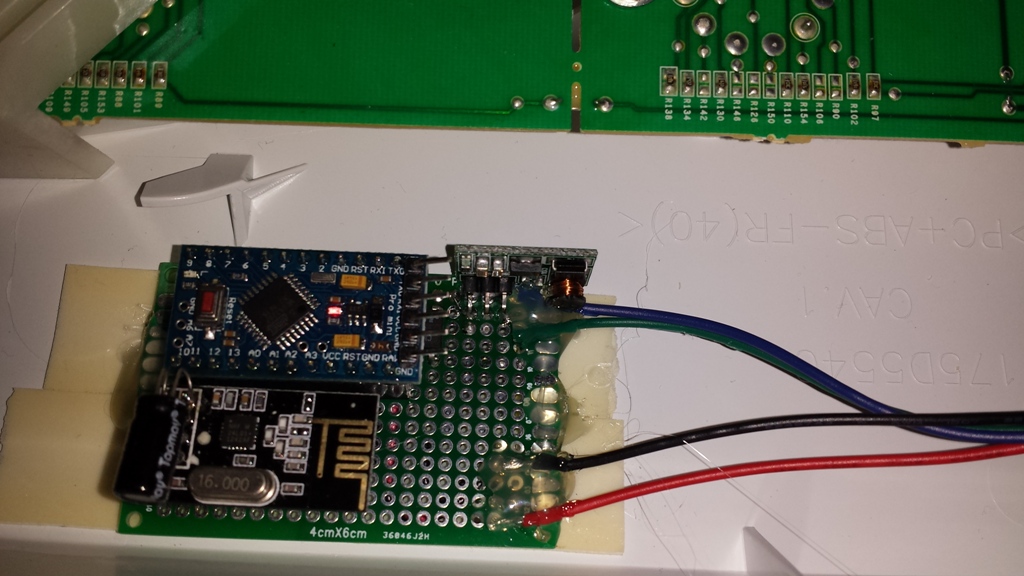

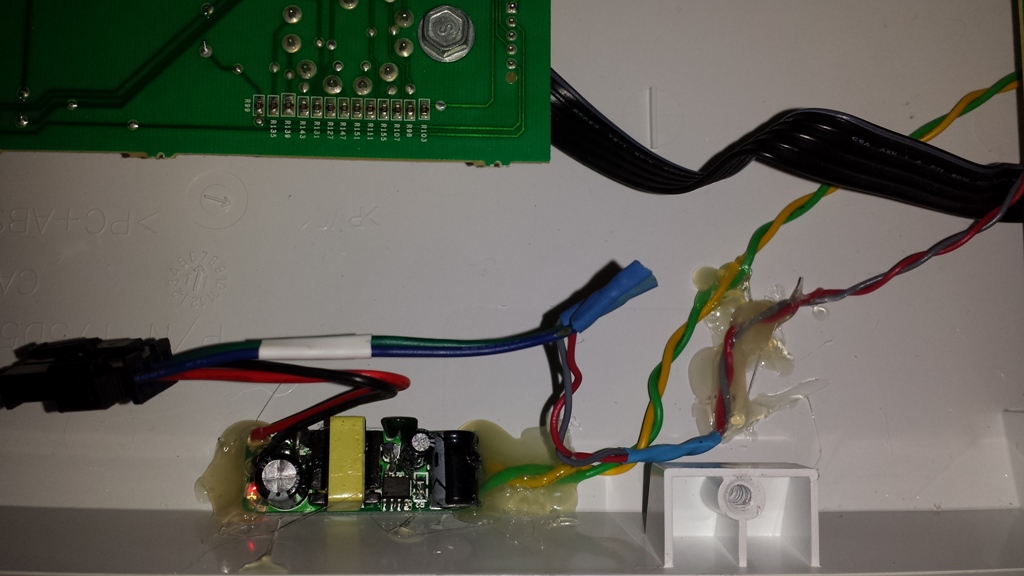

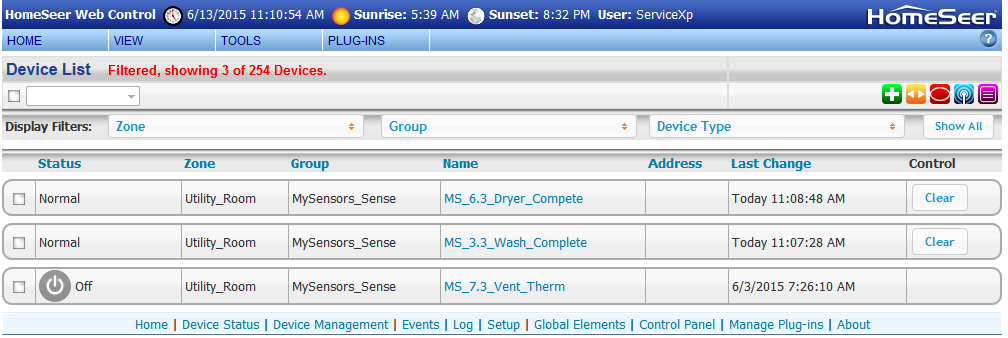

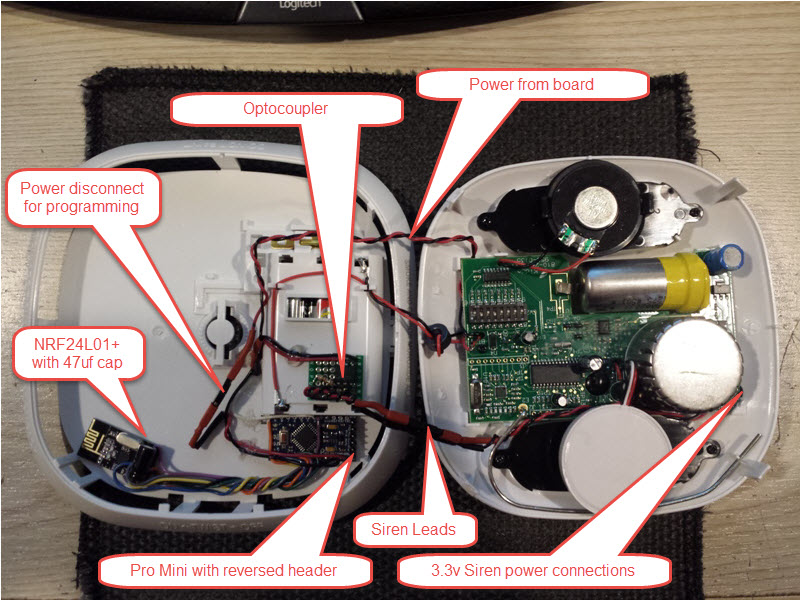

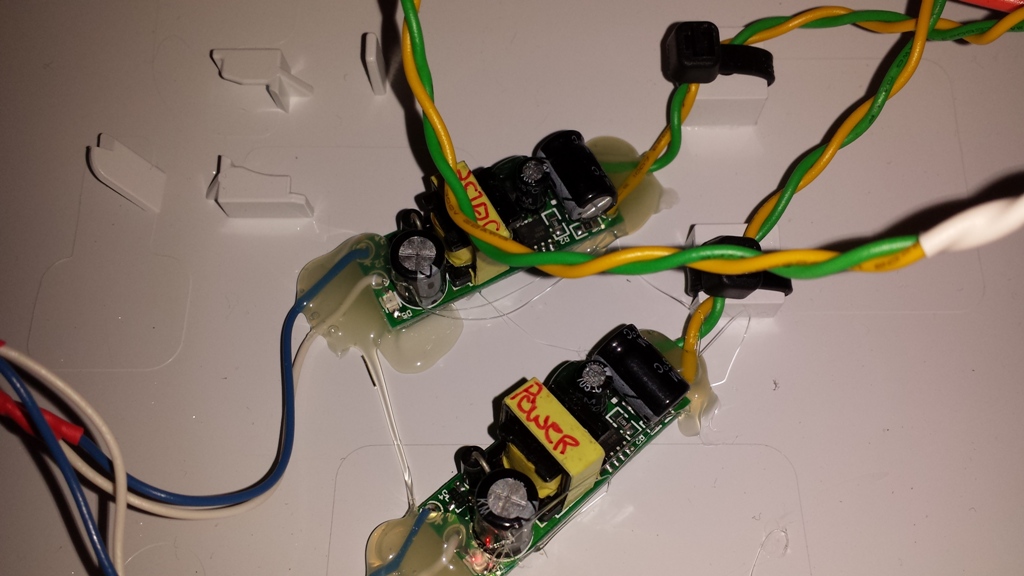

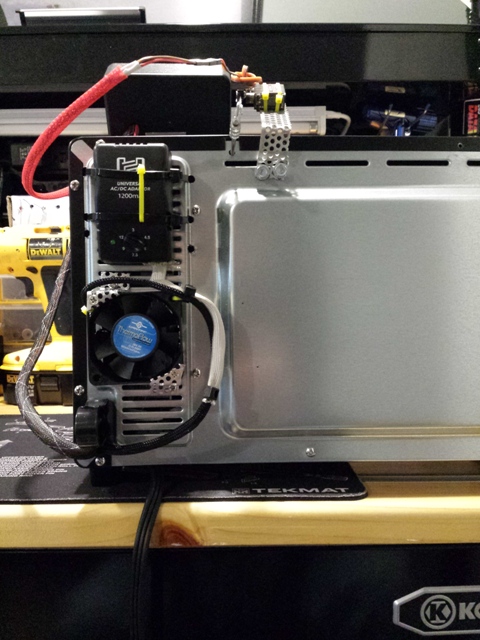

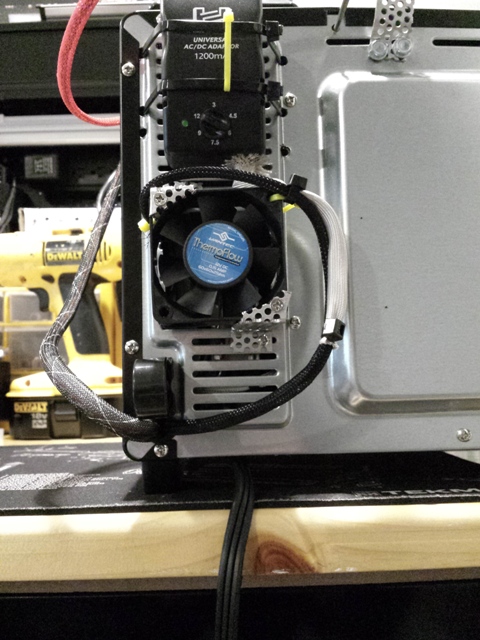

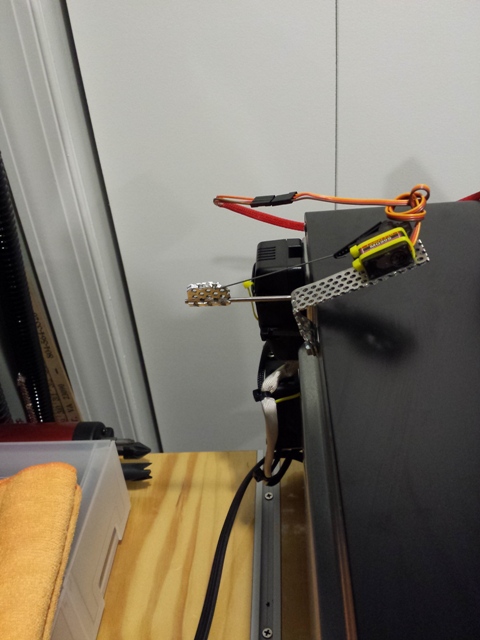

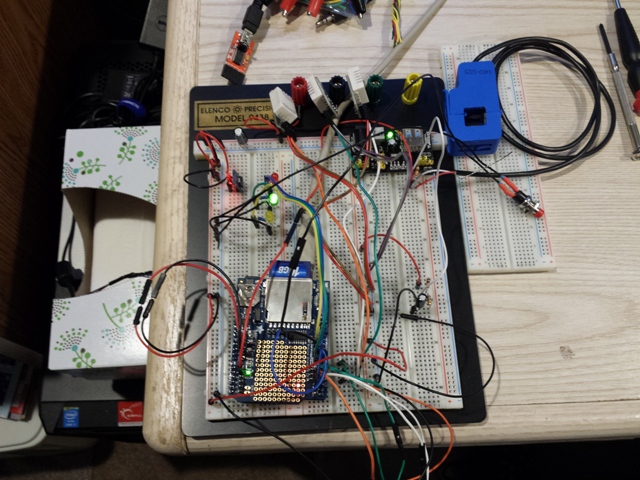

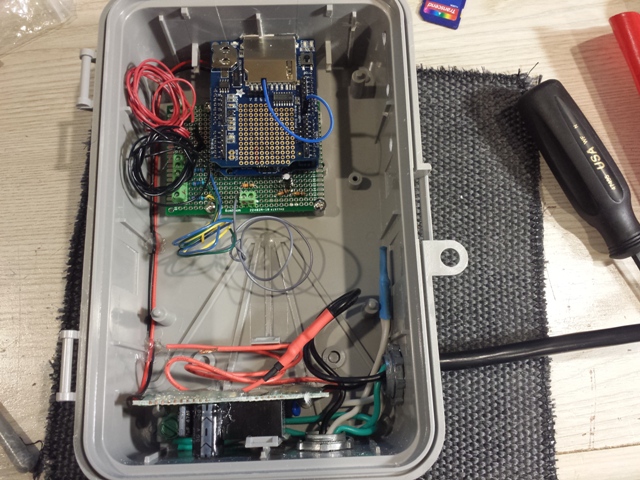

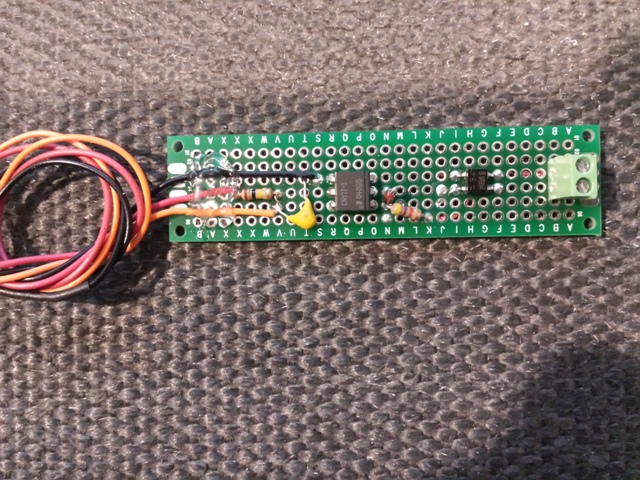

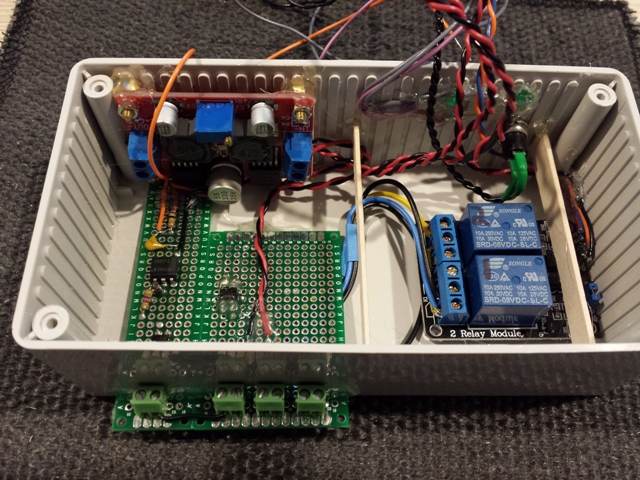

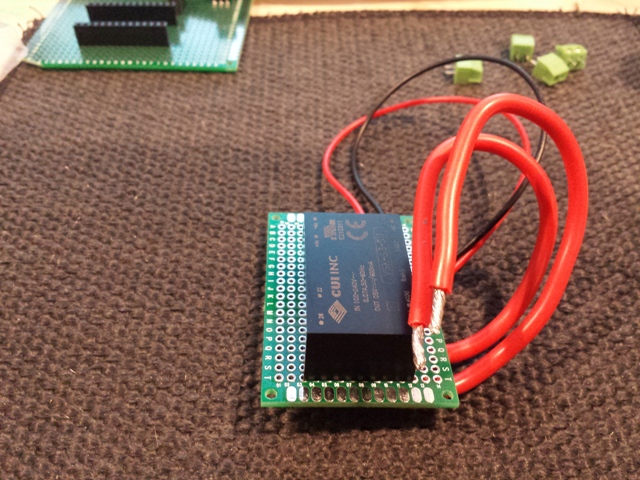

This is another very simple "Wash Cycle Completed" sensor. It's design uses the same Optocoupler sensing design I used in the Kiddie Smoke Detector project. The only difference is that I'm using 1 AC to DC transformer, and a boost module to boost the washer speaker power to fire the Optocoupler.

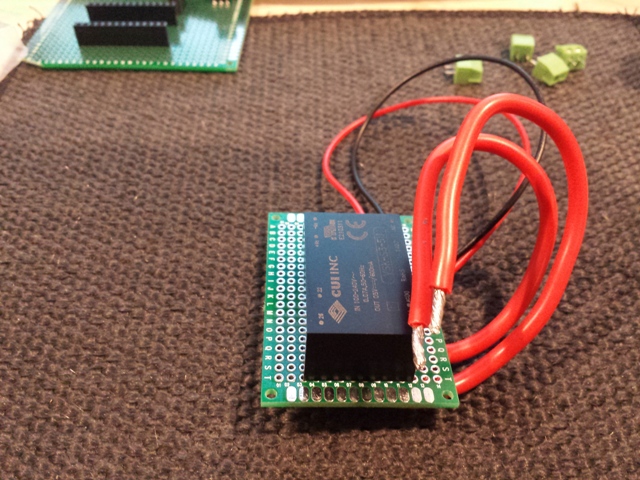

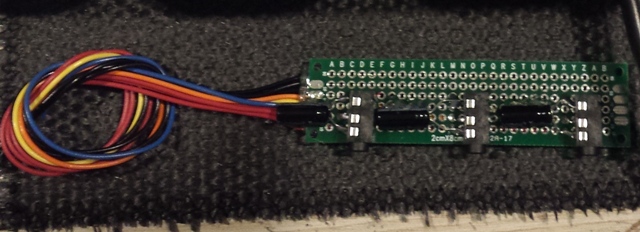

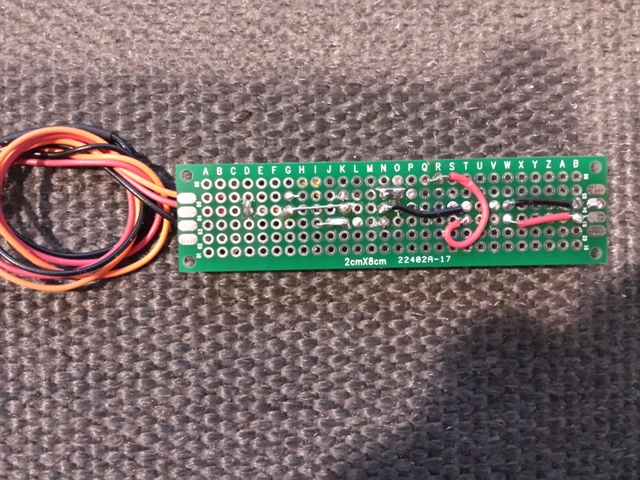

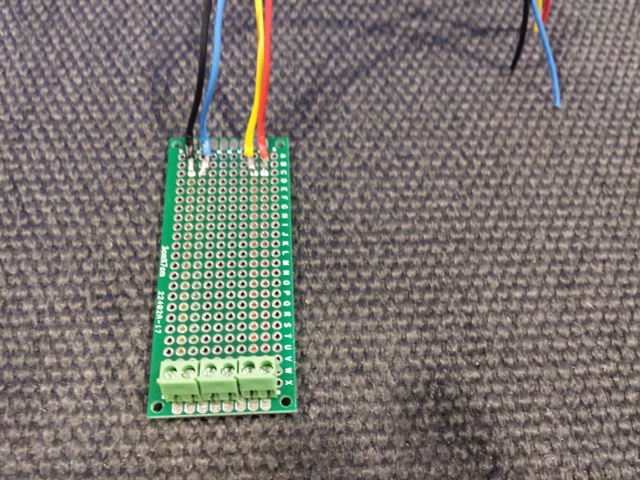

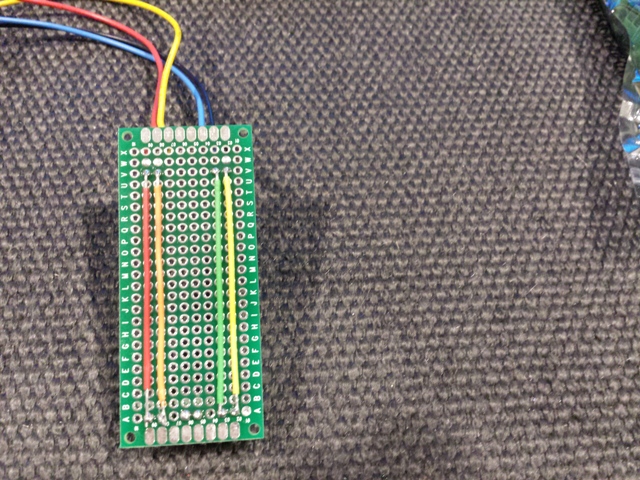

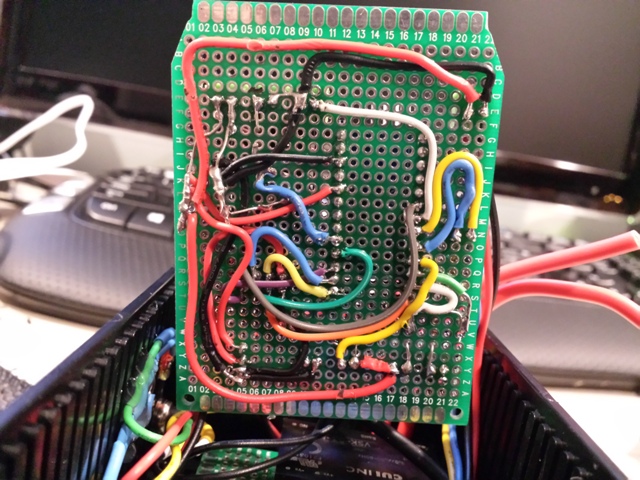

Parts:

- 1 Cheap AC/DC converter

- 1 Optocoupler

- 1 Step up Regulator

- 1 Small Proto Board.

- Some wire

Highlights:

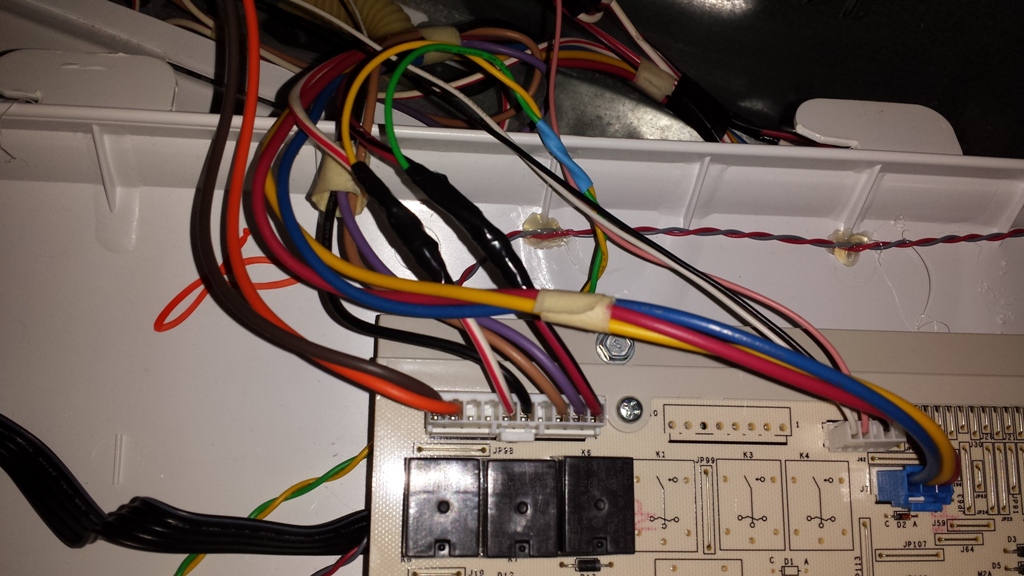

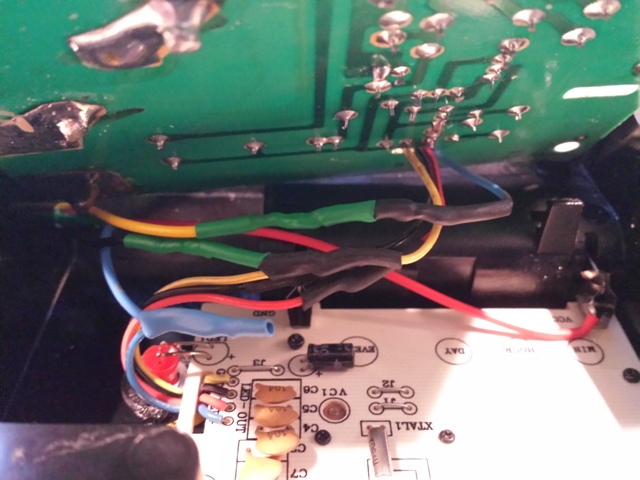

Use the Washers .5vdc Signal Piezo to interface with the Pro-Mini. The voltage to the Piezo is to low to drive the Optocoupler so I had to use a boost module to boost the voltage to the Optocoupler. I'm not sure what the long term effect will be on washers control board Piezo drive circuit, so I will follow up if I encounter a problem.

Again Uses the same sketch as the Kiddie Smoke Project, with the only change being to CYCLE_INTERVAL (For my dryer 3 works well)

Sketch:

// Based on Author: Patrick 'Anticimex' Fallberg Interrupt driven binary switch example with dual interrupts

#include <MySensor.h>

#include <SPI.h>

#define SKETCH_NAME "Washer End Cycle"

#define SKETCH_MAJOR_VER "1"

#define SKETCH_MINOR_VER "1"

#define CHILD_ID 3

#define SIREN_SENSE_PIN 3 // Arduino Digital I/O pin for optocoupler for siren

unsigned int SLEEP_TIME = 32400; // Sleep time between reads (in seconds) 32400 = 9hrs?

long CYCLE_COUNTER = 3; // This is the number of times we want the Audio Counter to reach before triggering a signal to controller.

unsigned long CYCLE_INTERVAL = 3; // How long do we want to watch once first detected (in seconds)

//Adjust for your smoke detector, you want to pick up the siren signal at least 3 time to help stop false alarms.

unsigned long CYCLE_RATE = 90; // How fast do we want to move checking the Pin state in the Status Check (in Millis) Adjust for your smoke detector

//Adjust for your smoke detector, you want to pick up the siren signal at least 3 time to help stop false alarms.

unsigned long CYCLE_TIME_OKSTATUS = 8; // How long do we want to watch for "all clear" once we have confirmed an Alarm (in seconds)

unsigned long CYCLE_RATE_OKSTATUS = 500; // How fast do we want to move checking the Pin state when checking for an OK status (in Millis)

int oldValue=1;

int value=0;

MySensor sensor_node;

MyMessage msg(CHILD_ID, V_TRIPPED);

void setup()

{

sensor_node.begin();

// Setup the Siren Pin HIGH

pinMode(SIREN_SENSE_PIN, INPUT_PULLUP);

// Send the sketch version information to the gateway and Controller

sensor_node.sendSketchInfo(SKETCH_NAME, SKETCH_MAJOR_VER"."SKETCH_MINOR_VER);

sensor_node.present(CHILD_ID, S_SMOKE);

//Send the state -- Always send Alarm state on power up.

sensor_node.send(msg.setSensor(CHILD_ID).set("1"), true);

}

// Loop will iterate on changes on the BUTTON_PINs

void loop()

{

// Check to see if we have a alarm. I always want to check even if we are coming out of sleep for heartbeat.

AlarmStatus();

// Sleep until we get a audio power hit on the optocoupler or 9hrs

sensor_node.sleep(SIREN_SENSE_PIN-2,FALLING, SLEEP_TIME * 1000UL);

}

void AlarmStatus()

{

// We will check the status now, this could be called by an interrupt or heartbeat

int siren_audio_count =0;

long cycle_time =0;

unsigned long startedAt = millis();

Serial.println("Status Check");

//Read the Pin

value = digitalRead(SIREN_SENSE_PIN);

// If Pin return a 0 (LOW), then we have a Alarm Condition

if (value != 1) {

//We are only going to check for status for CYCLE_INTERVAL time I think this should help stabilize Siren Sensing

while(millis() - startedAt < CYCLE_INTERVAL * 1000)

{

//We are going to check CYCLE_RATE fast

if(millis() - cycle_time > CYCLE_RATE ) {

// save the last time you Checked

cycle_time = millis();

//We will count each time SIREN_SENSE_PIN is 0 (Alarm - LOW) for the above time and at the above rate.

value = digitalRead(SIREN_SENSE_PIN);

if (value != 1)

{

siren_audio_count++;

Serial.print("Audio Count: ");

Serial.println(siren_audio_count);

}

}

}

// Eval siren audio hit count against our limit. If we are => then CYCLE_COUNTER then lets start a loop for "All Clear" reset

// If we continue to return an audio power hit, then we will continue to send to the controller.

if (siren_audio_count>=CYCLE_COUNTER)

{

Serial.println("Alarm Detected");

do

{

//update gateway with bad news.

//sensor_node.send(msg.set("1"));

sensor_node.send(msg.setSensor(CHILD_ID).set("1"), true);

Serial.println("Alarm Detected Sent to gateway");

} while (IsAlarmAllClear()!=1);

}

}

//Pin returned a 1 (High) so there is no alarm.

else

{

IsAlarmAllClear();

}

}

int IsAlarmAllClear()

// We are looking for an gap in time that we no longer see an audio power hit to the optocoupler.

{

int alarmOn =0;

long cycle_time =0;

unsigned long startedAt = millis();

//We are only going to check for status for CYCLE_TIME_OKSTATUS time

while(millis() - startedAt < CYCLE_TIME_OKSTATUS * 1000)

{

//We are going to check CYCLE_RATE_OKSTATUS fast

if(millis() - cycle_time > CYCLE_RATE_OKSTATUS) {

// save the last time you Checked

cycle_time = millis();

int value = digitalRead(SIREN_SENSE_PIN);

if (value != 1) //We are still in an alarm state

{

alarmOn++;

}

}

}

if (alarmOn < 1)

{

// We don't have any sign that we are still in an alarm status

//Send all clear msg to controller

//sensor_node.send(msg.set("0"));

sensor_node.send(msg.setSensor(CHILD_ID).set("0"), true);

// Used to update the node - NOT used for battery check.

sensor_node.sendBatteryLevel(random(1, 100) );

Serial.println("All Clear");

return 1;

}

else

{

// We are still in an alarm status

//The calling function will handle sending NOT CLEAR to controller

Serial.println("NOT CLEAR");

return 0;

}

}

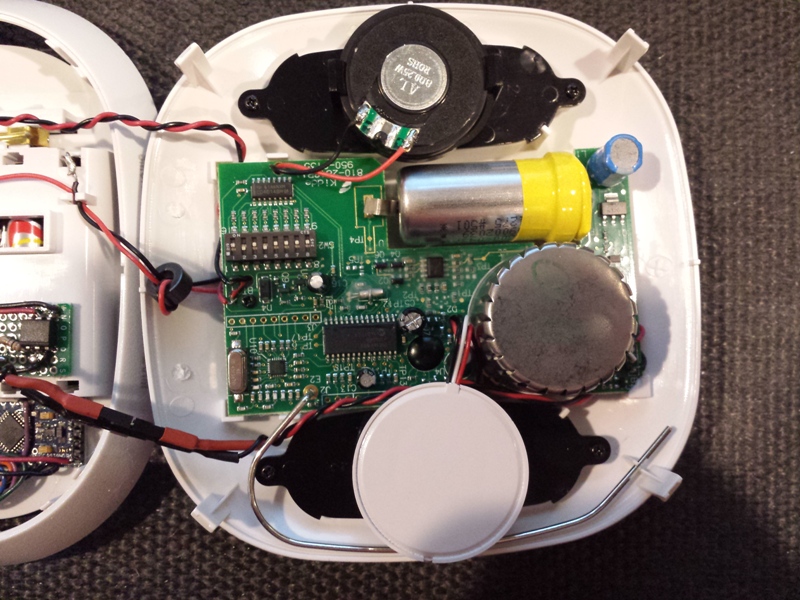

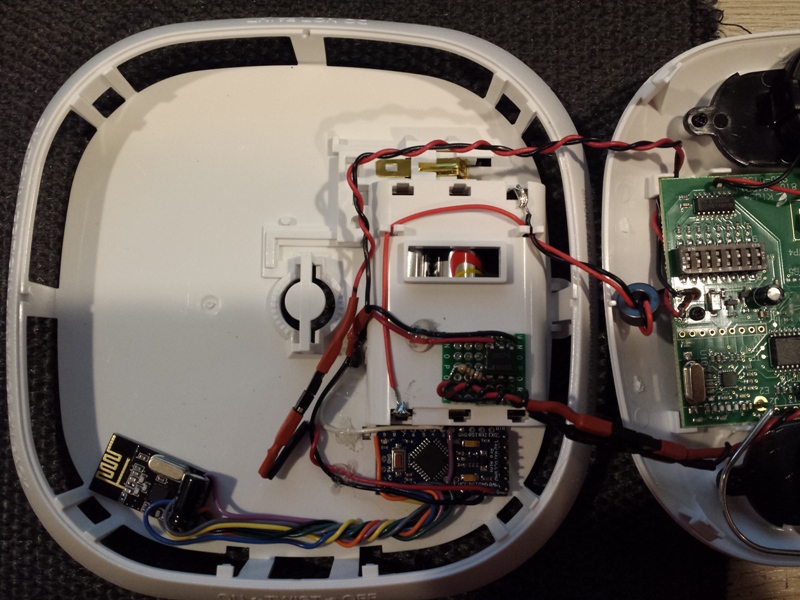

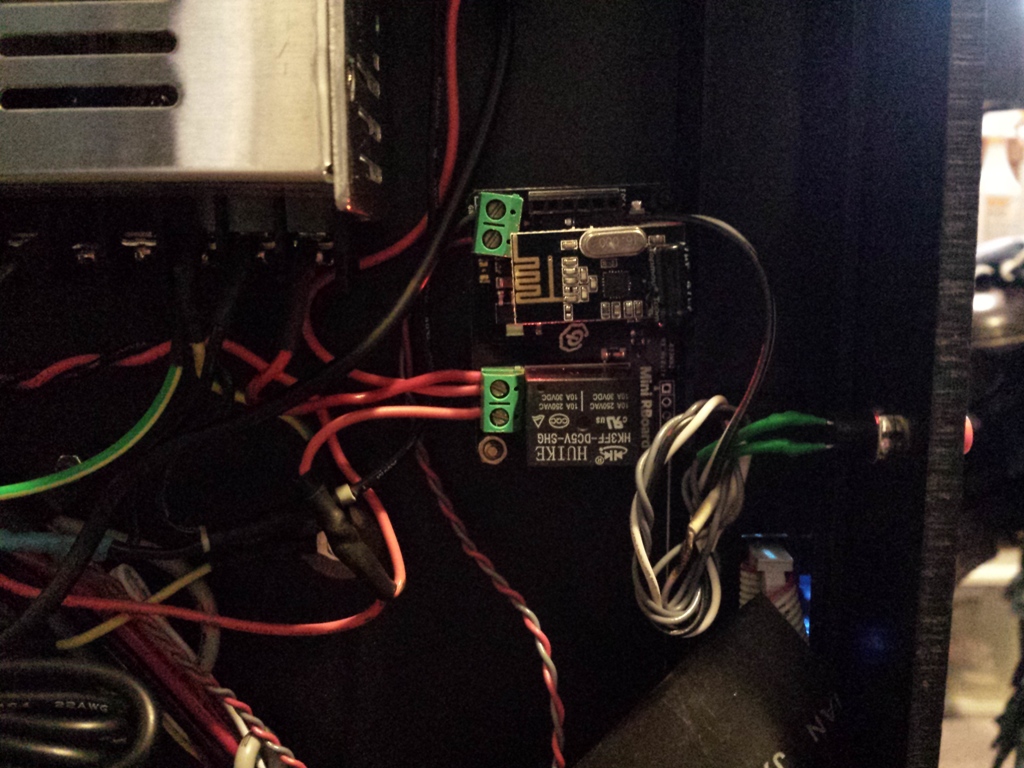

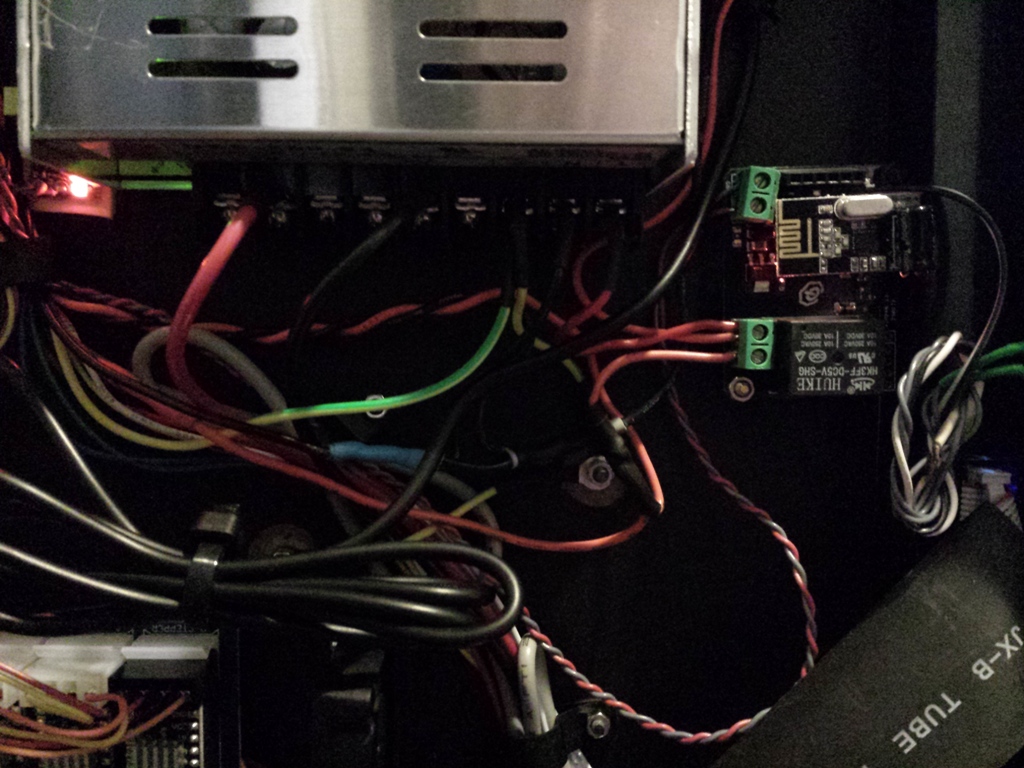

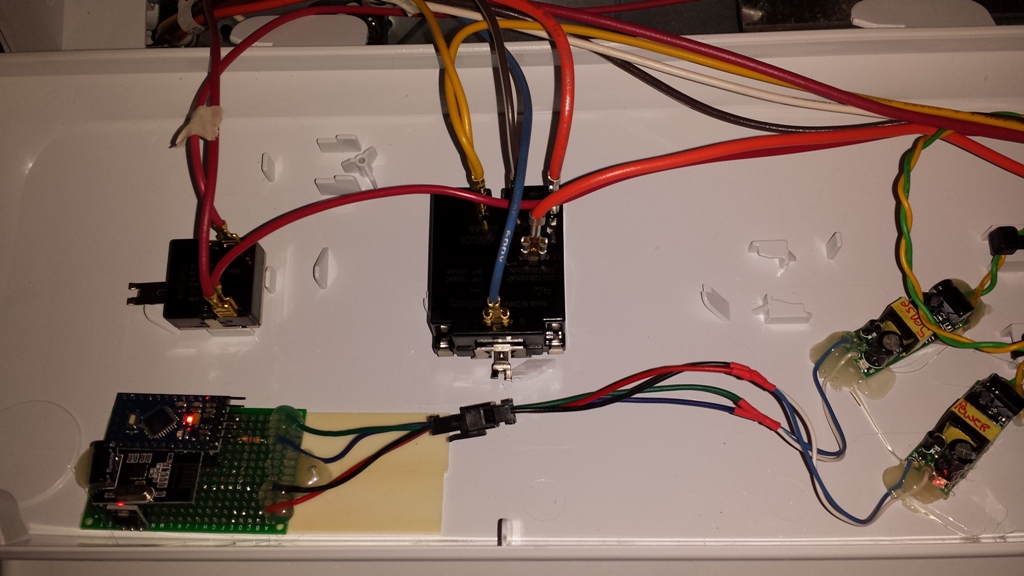

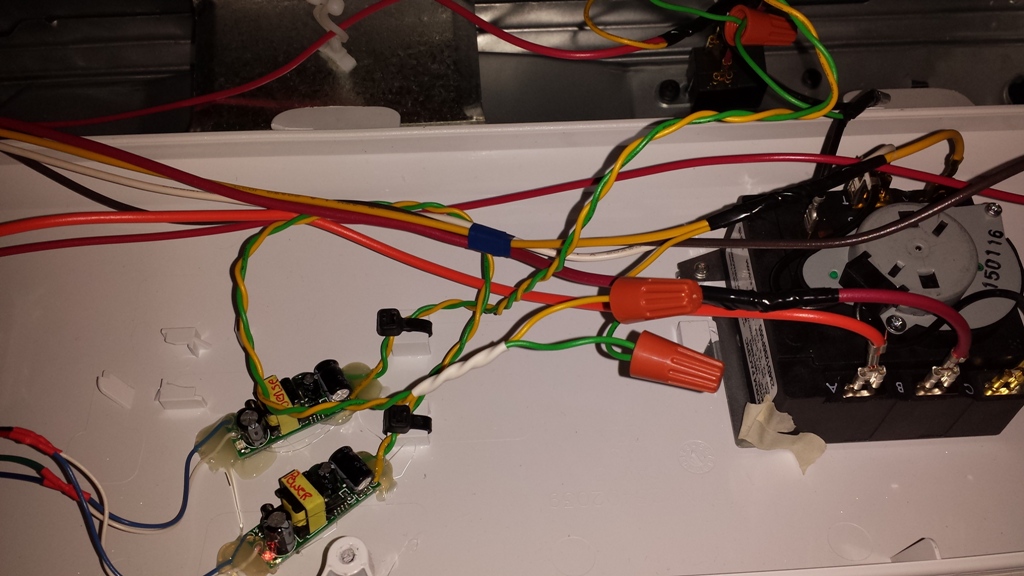

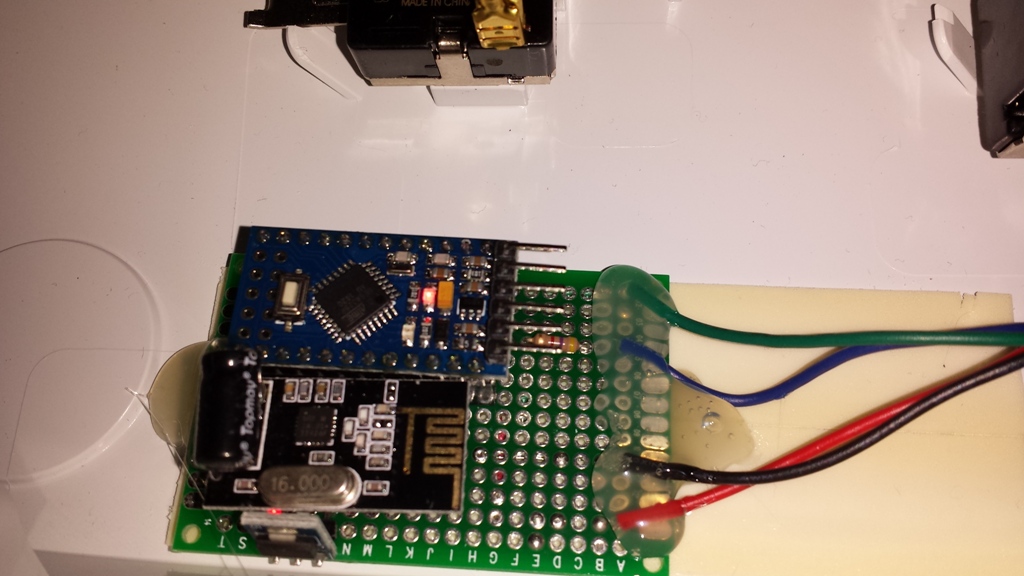

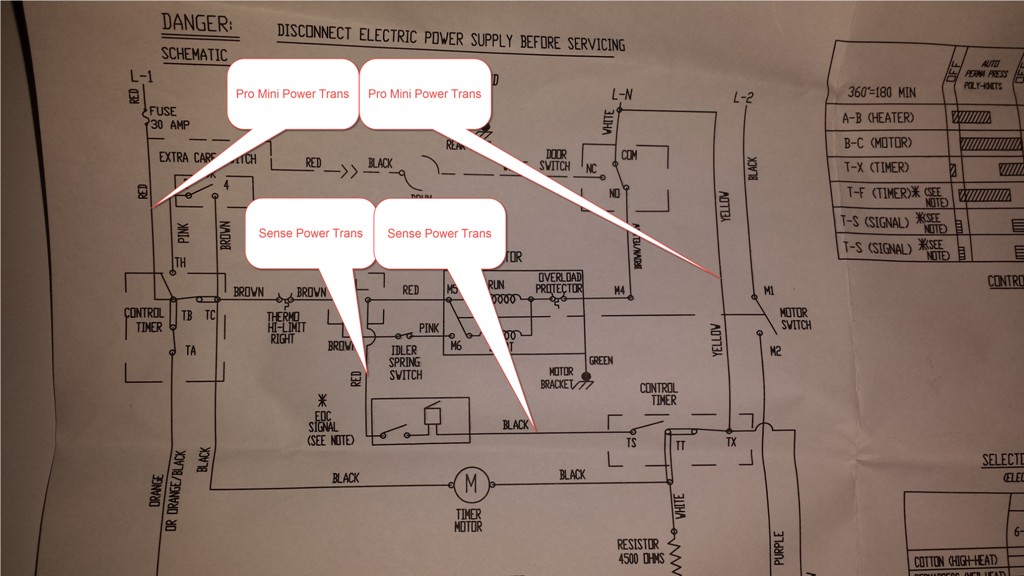

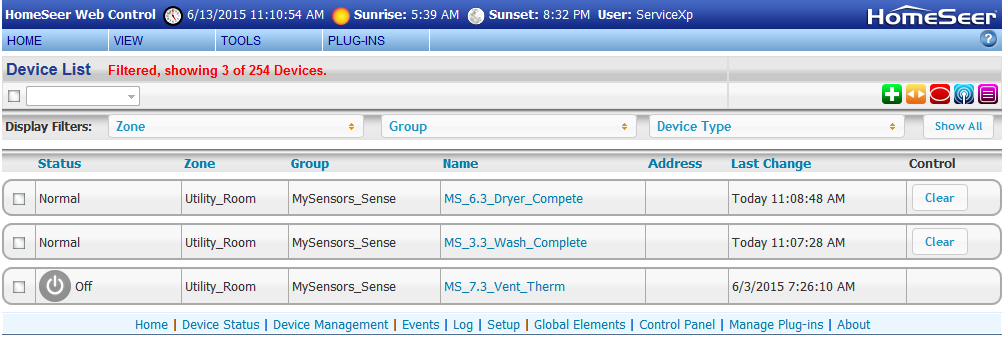

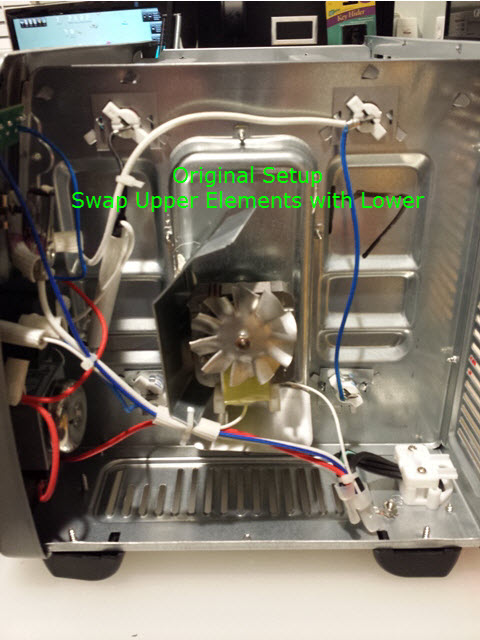

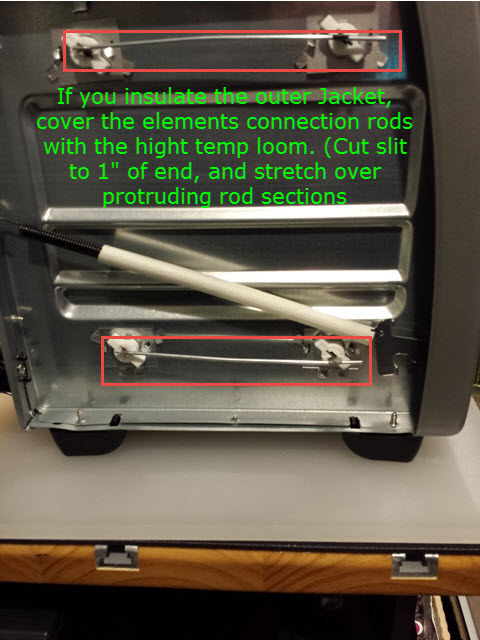

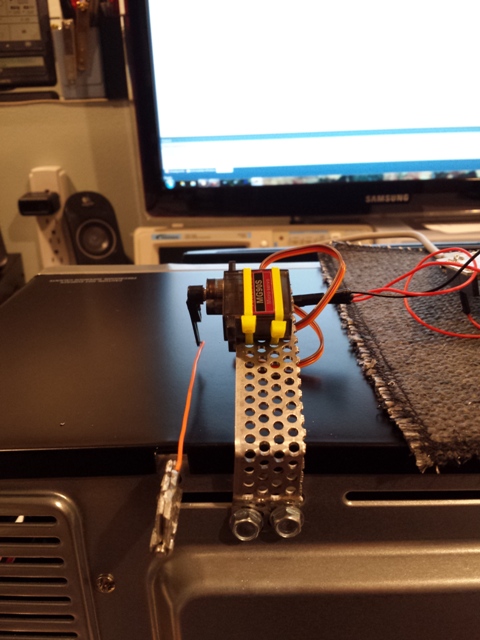

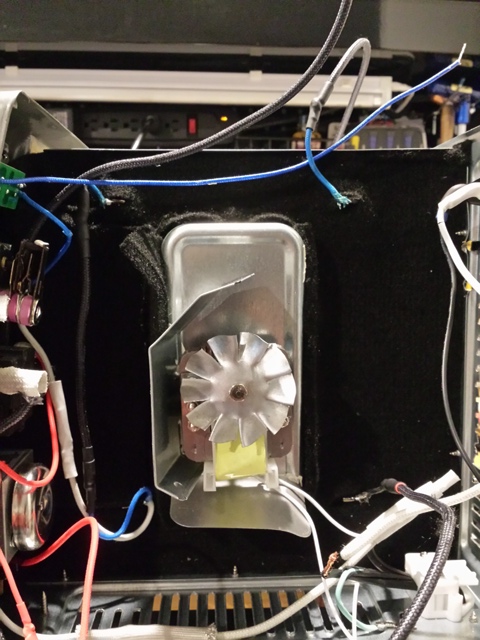

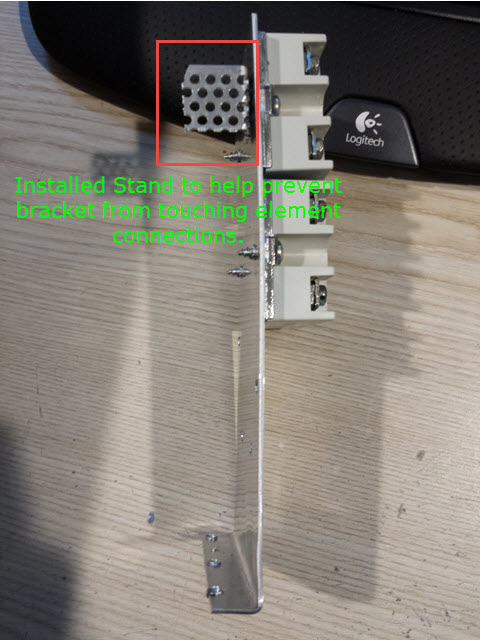

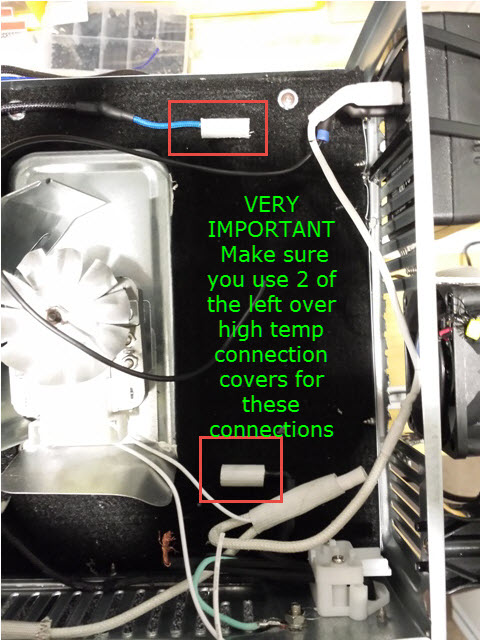

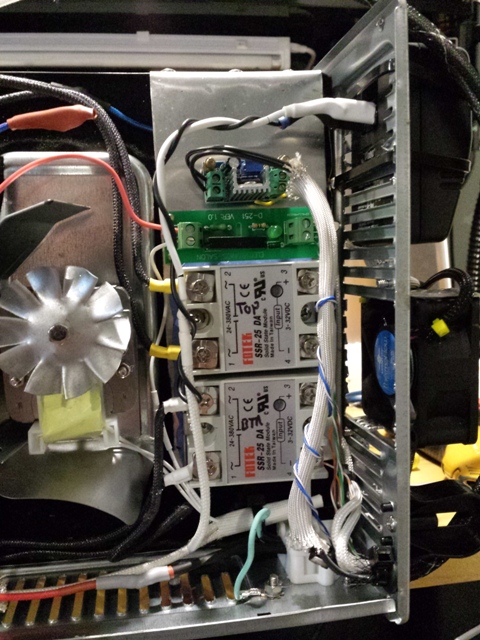

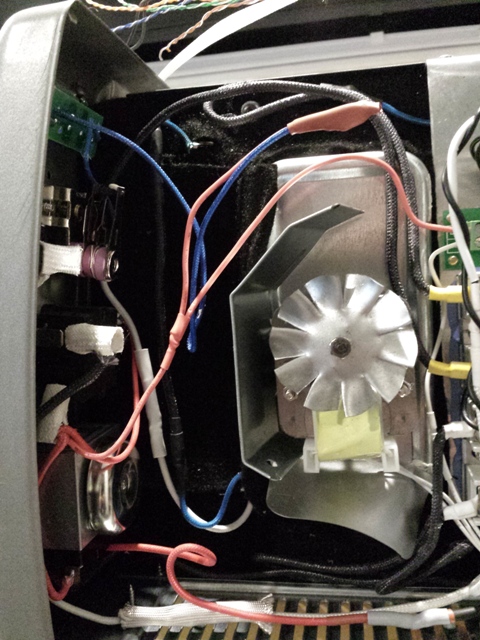

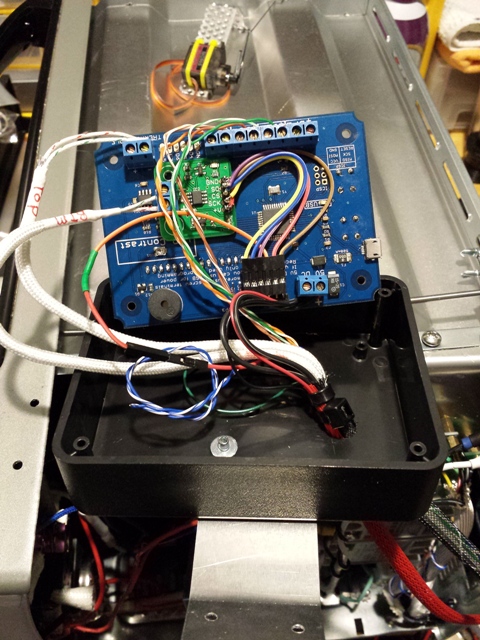

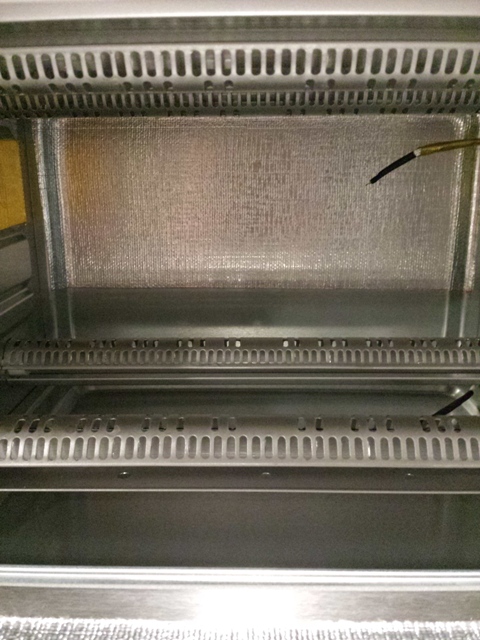

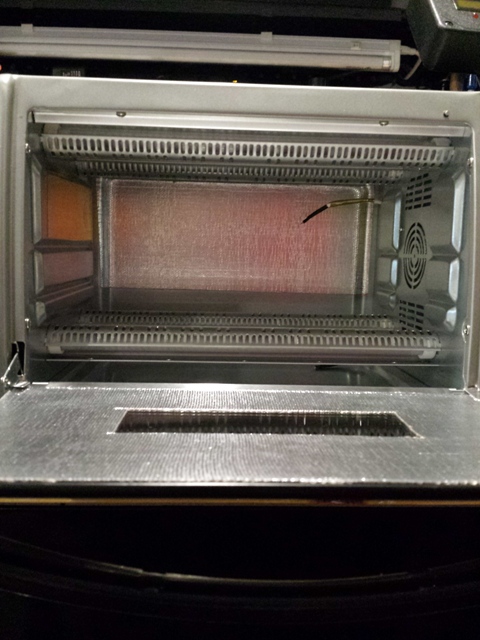

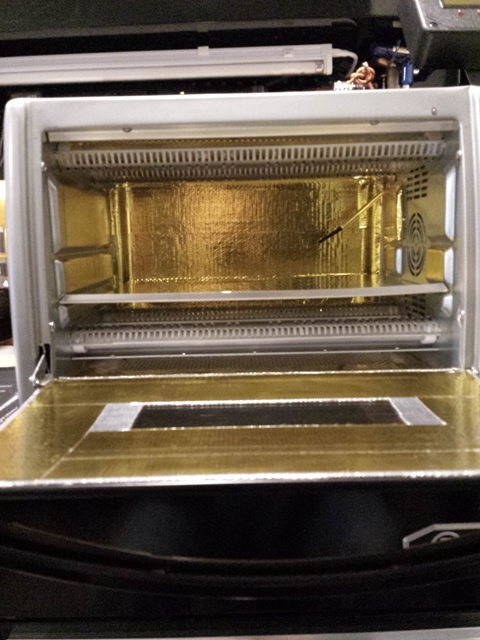

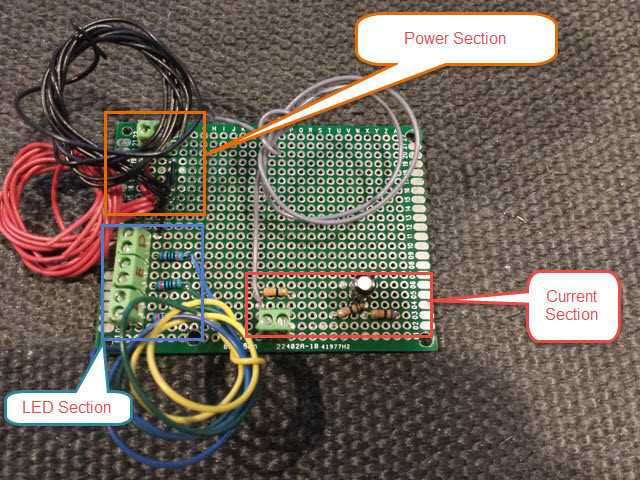

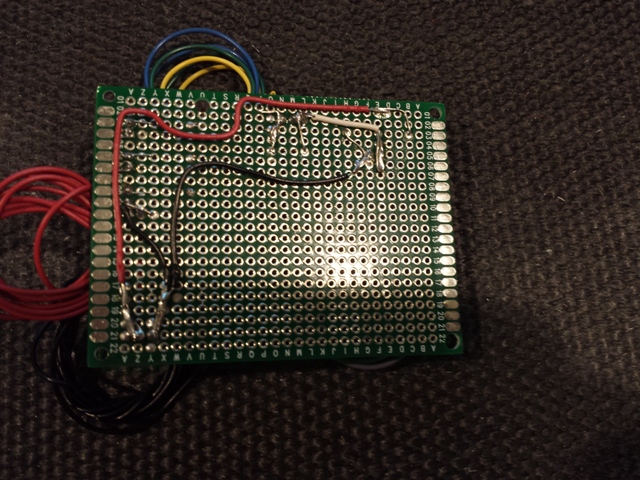

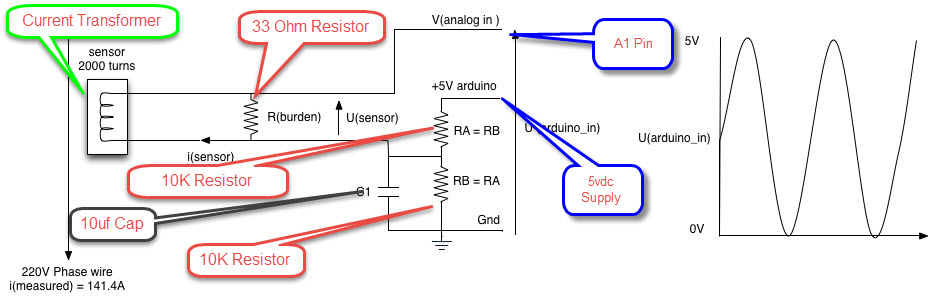

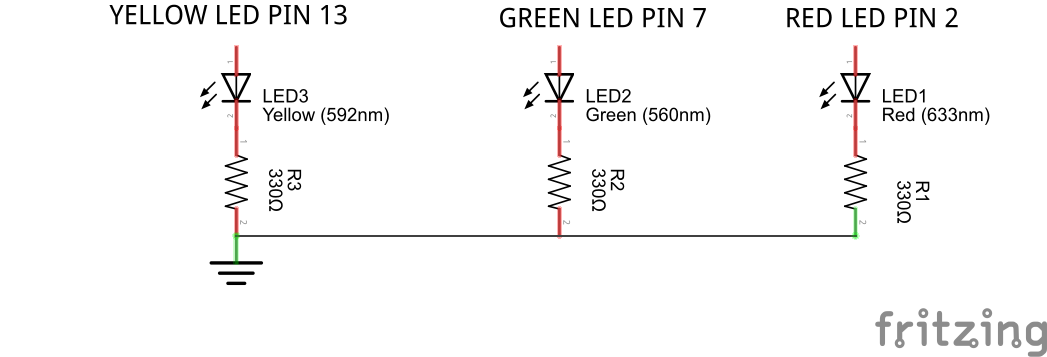

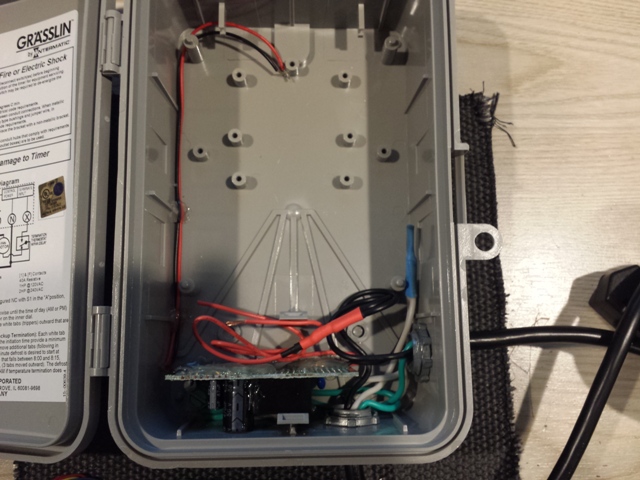

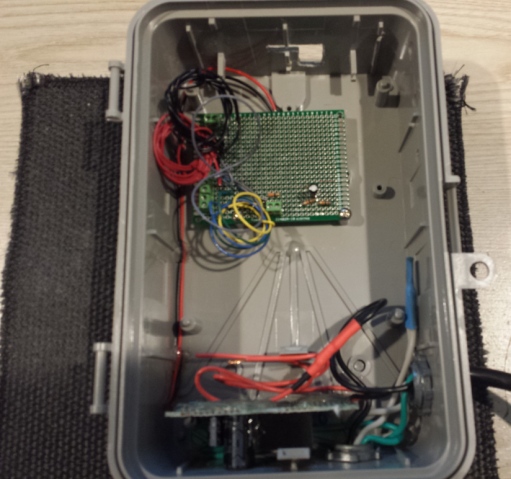

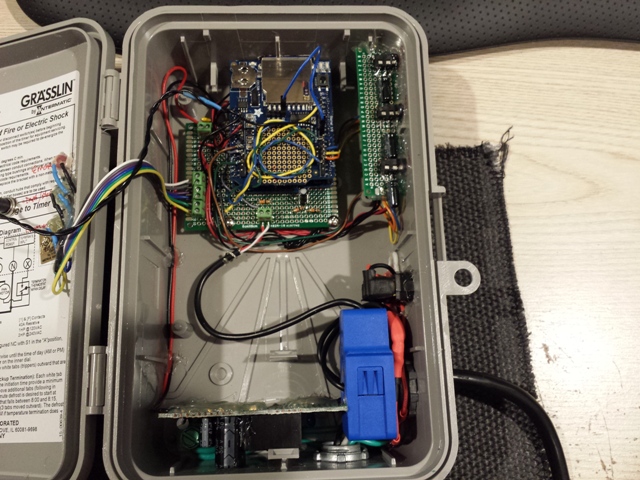

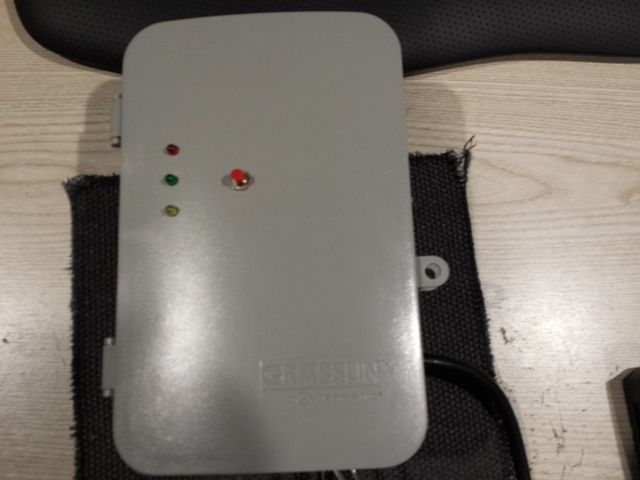

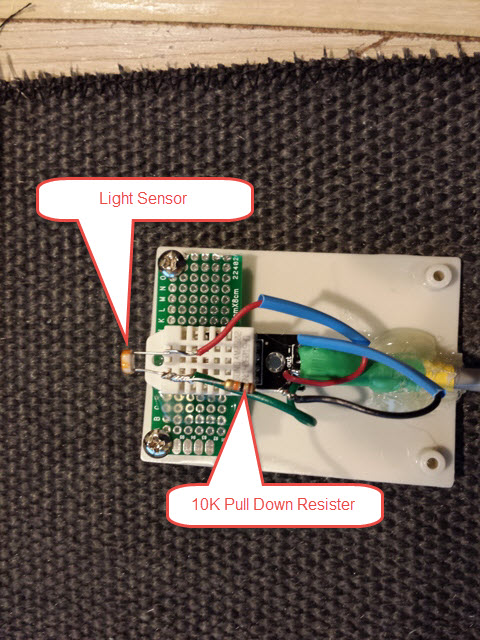

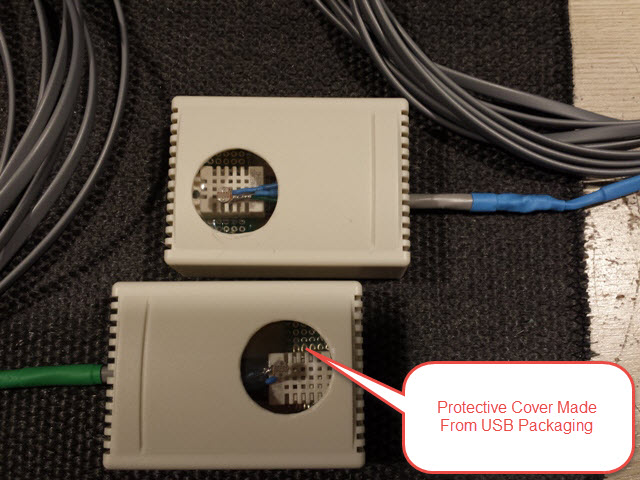

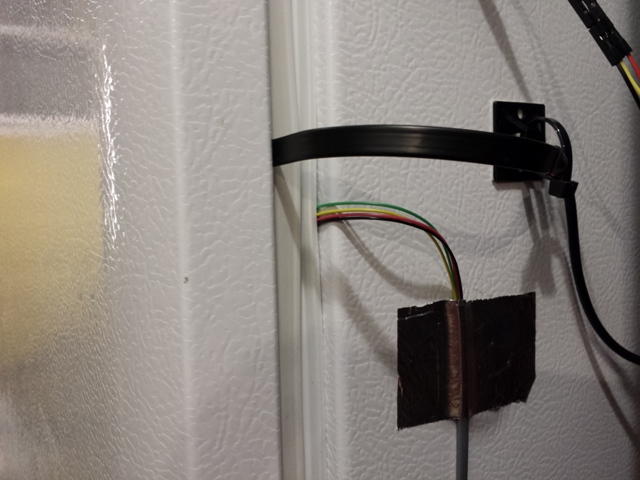

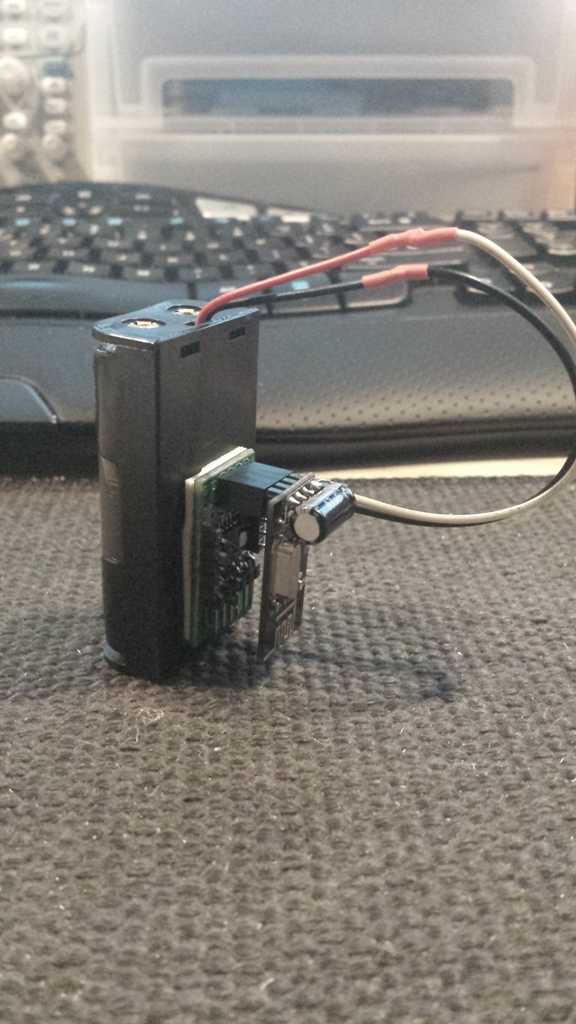

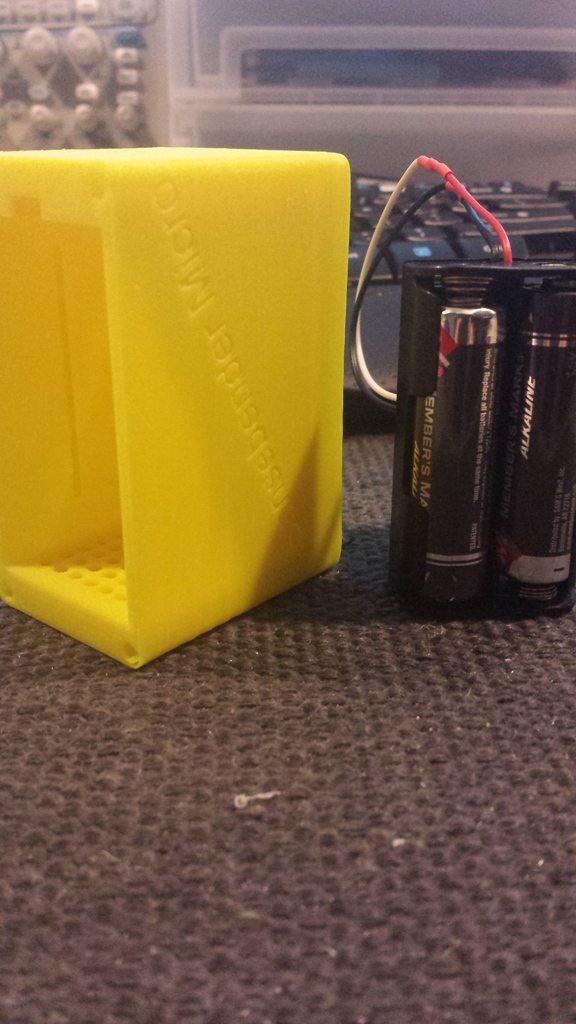

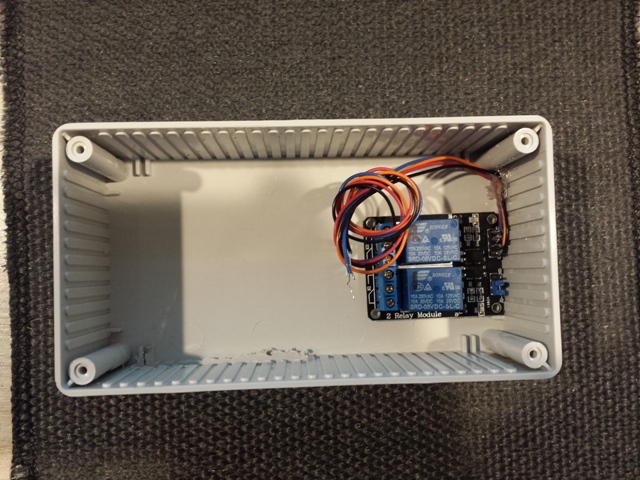

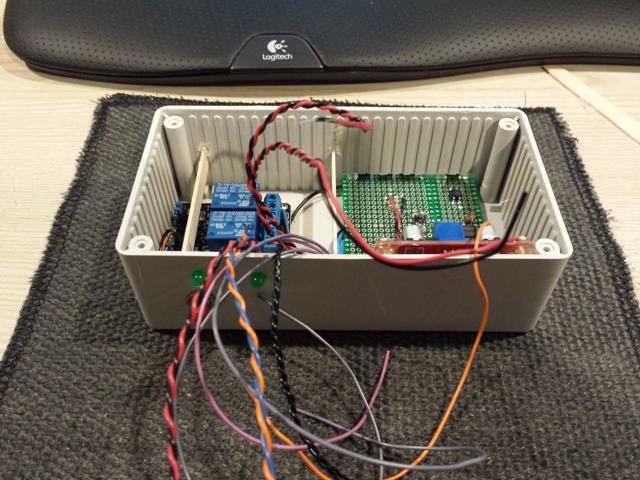

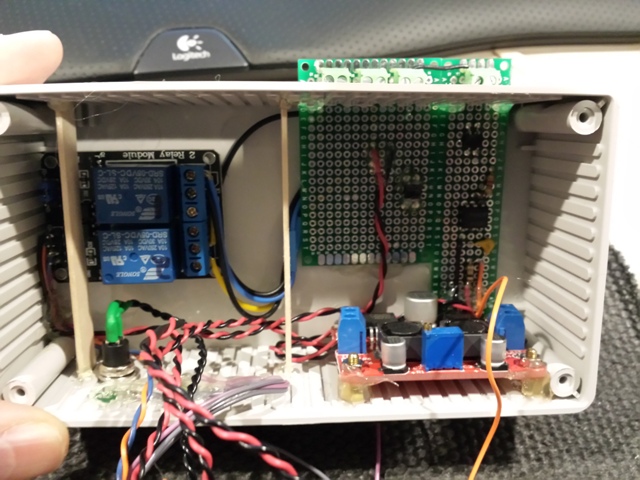

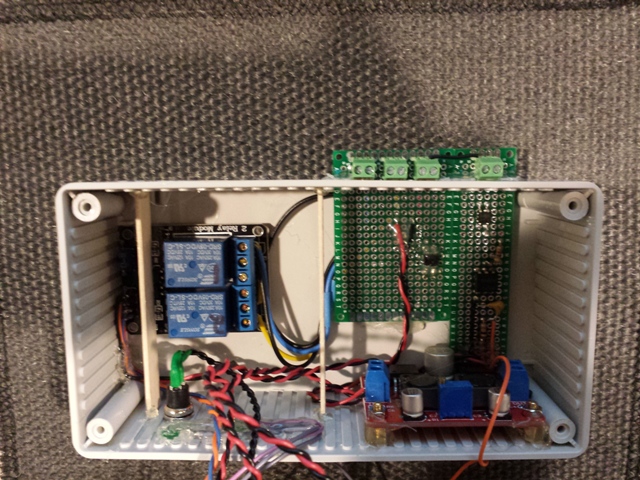

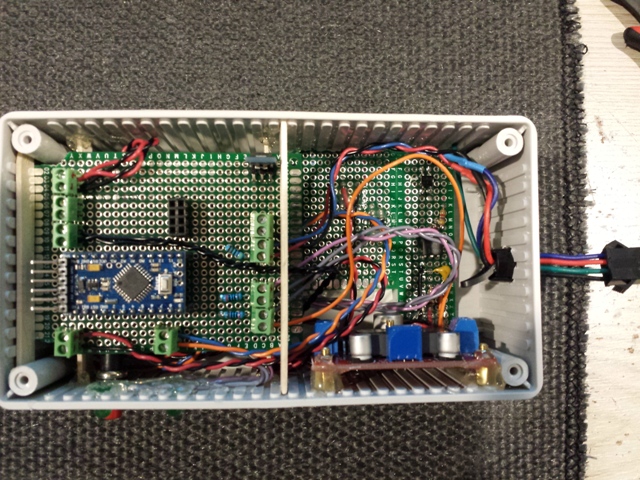

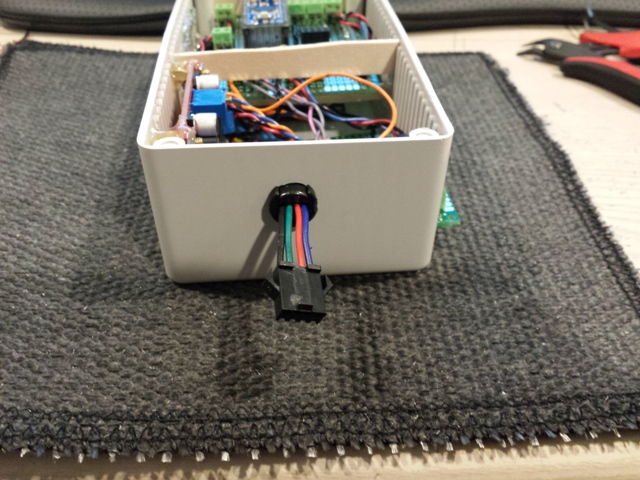

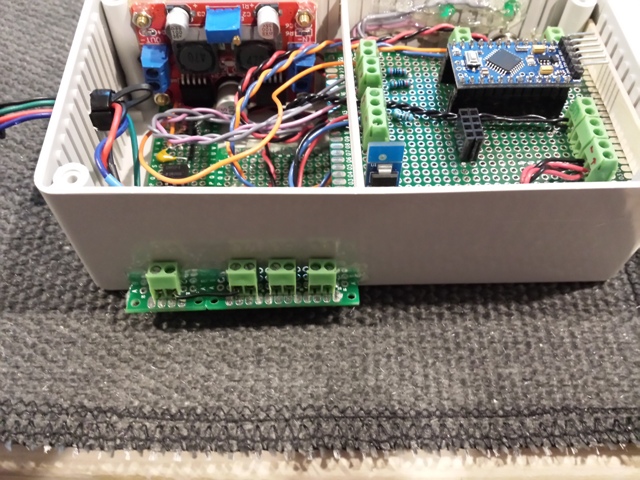

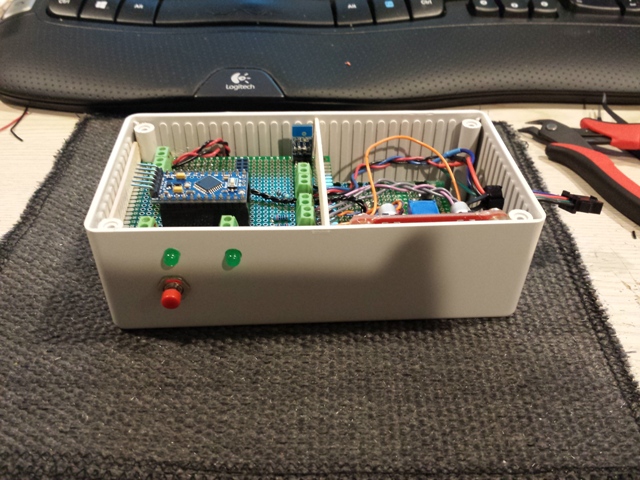

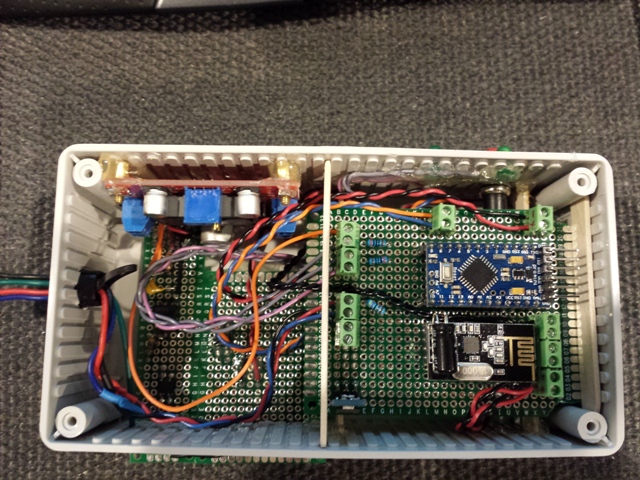

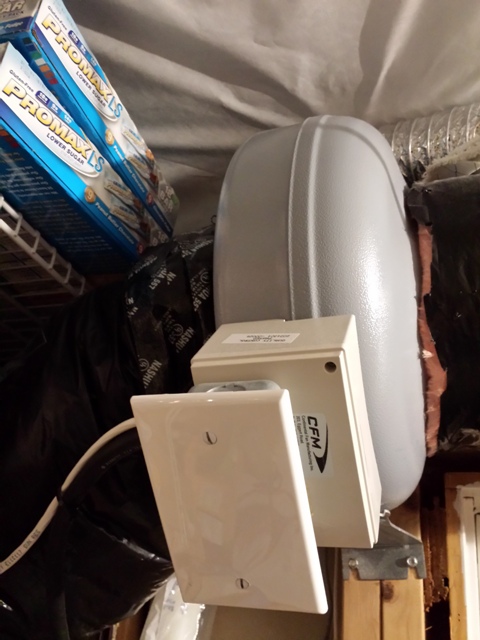

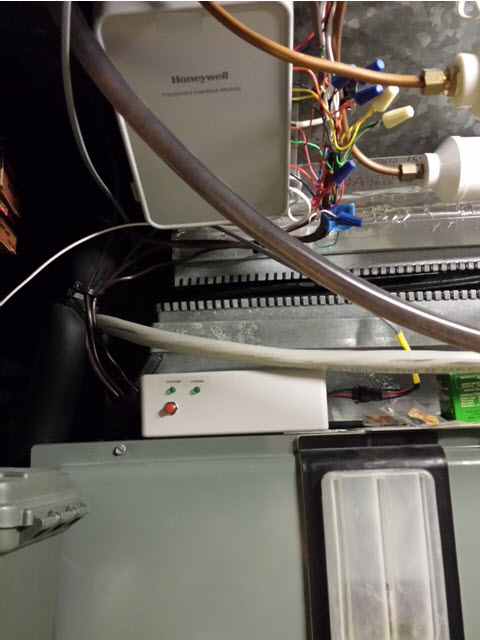

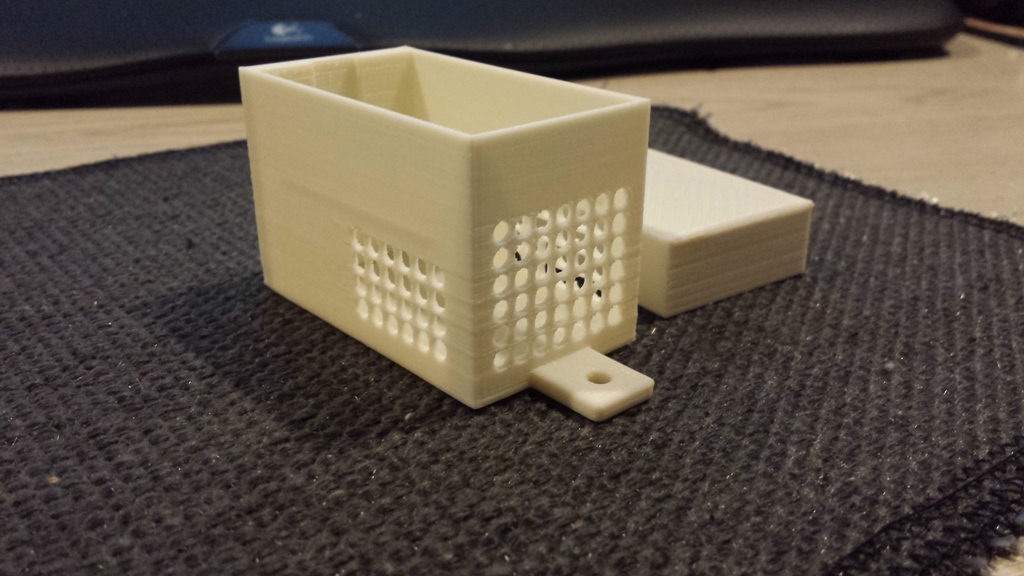

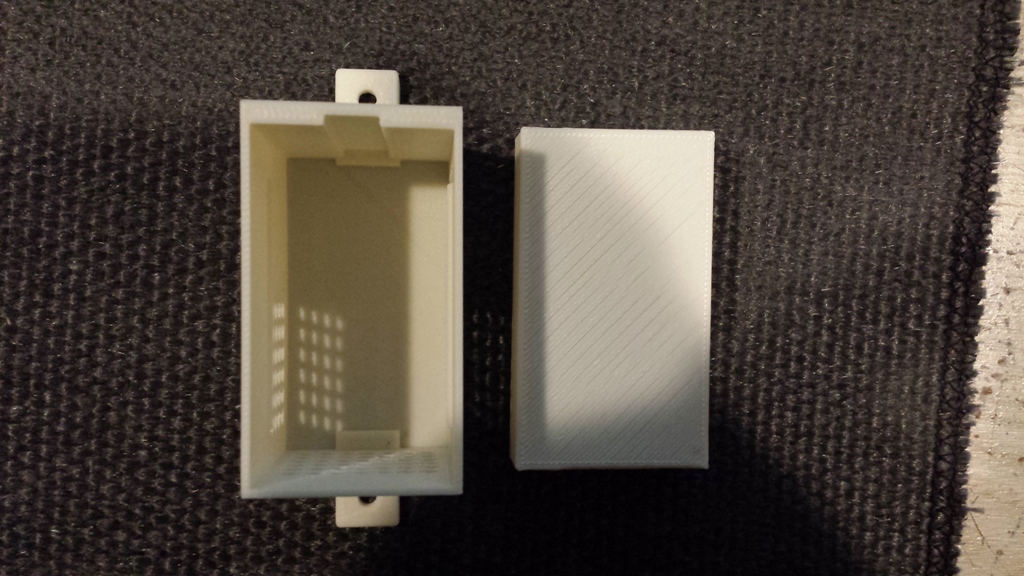

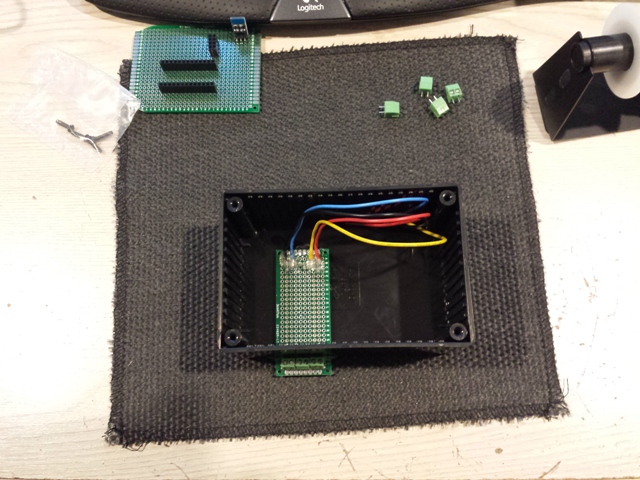

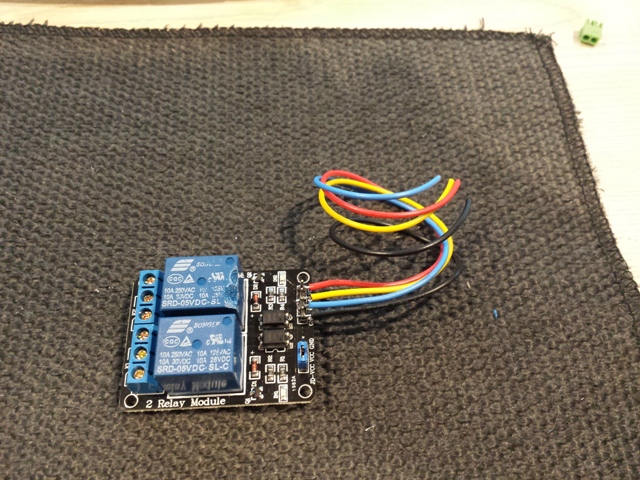

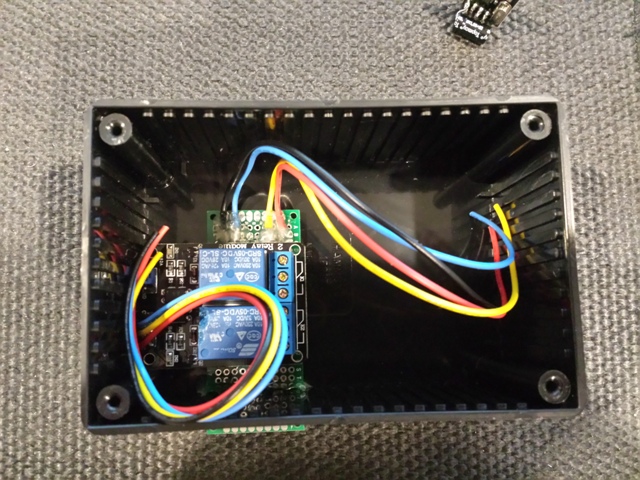

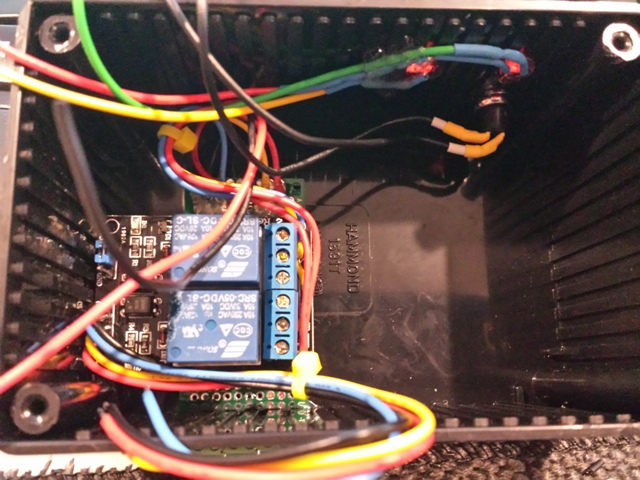

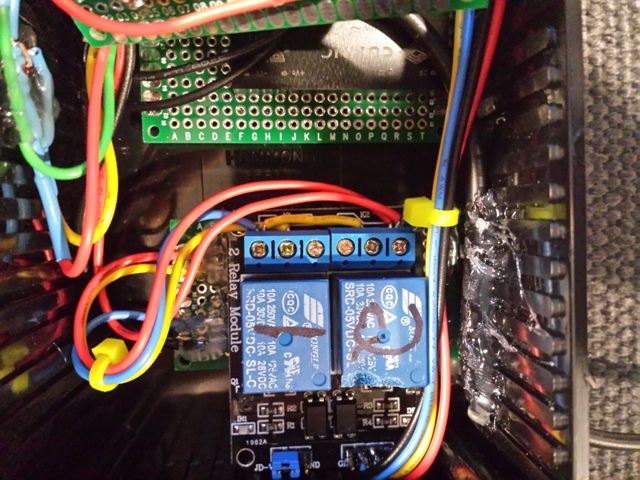

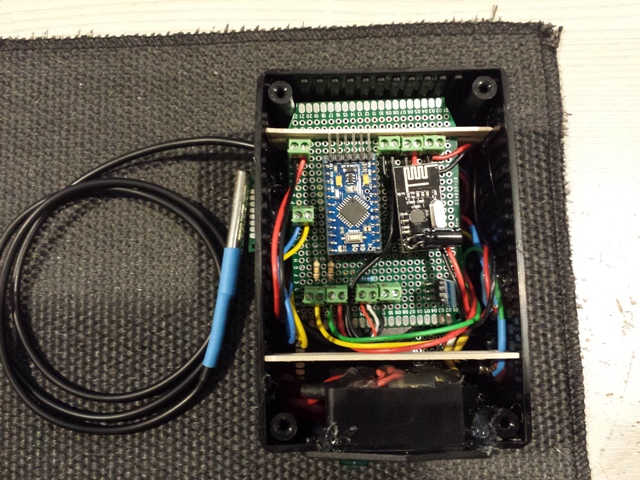

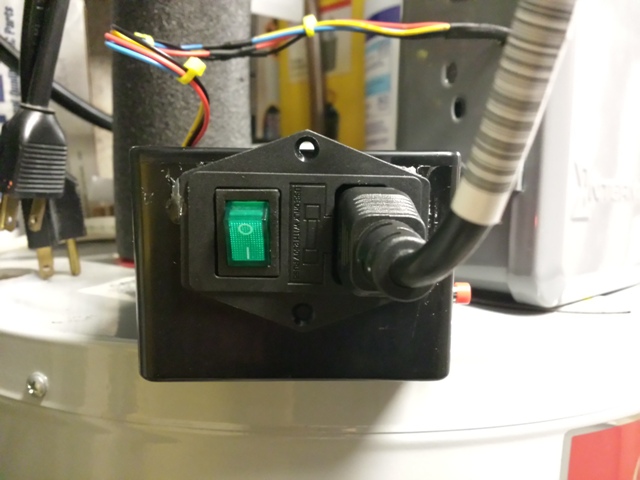

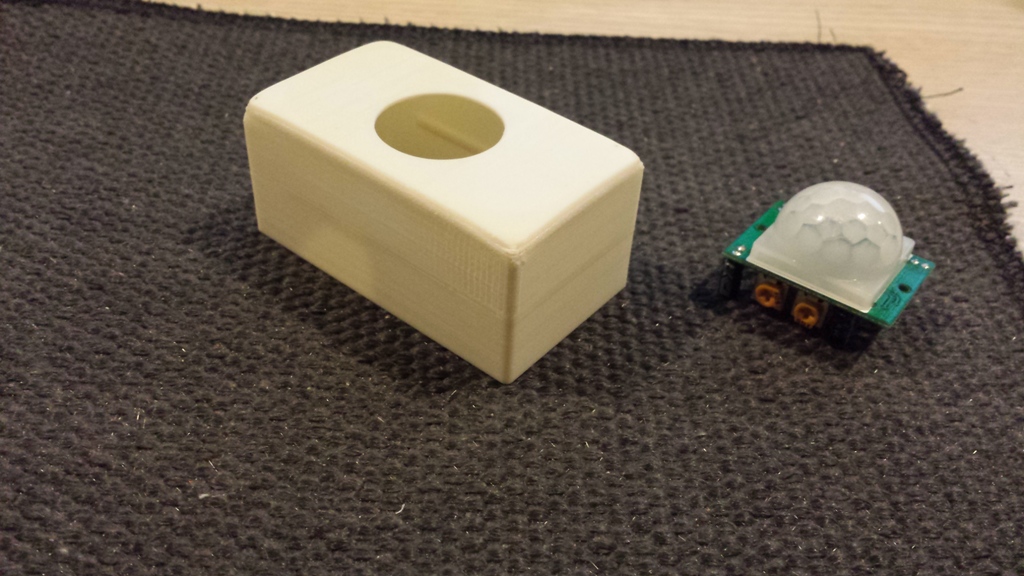

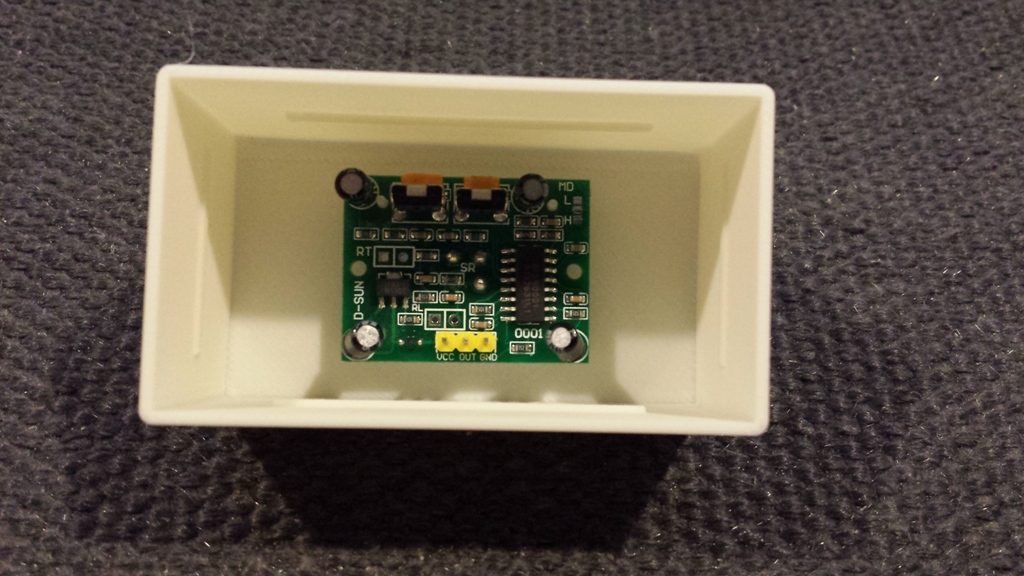

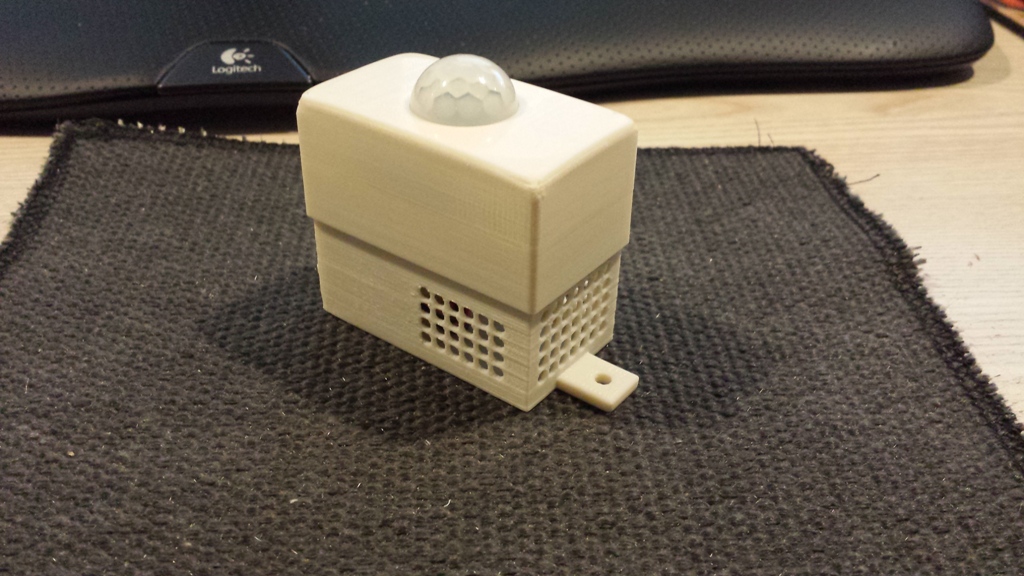

Here a some Pictures: