💬 NModule

-

Hey @Nca78 I received the boards and components (yay!)

But... I connected three modules, and none of them works :(

They all have transport (radio?) fail like32 TSM:INIT

49 TSF:WUR:MS=0

81 !TSM:INIT:TSP FAIL

98 TSM:FAIL:CNT=1

114 TSM:FAIL:PDTI tried connecting radios from two different batches, I tried connecting only the radio and arduino, I tried powering it from separate powersupply and only debug via serial. I tried provided sketch and also tried dummy sketch from the examples. I tried using the CR battery, node works fine except that the radio doesn't start communicating.

I do measure 3V on the radio pins. I tried with and without radio cap.I am using chinese silicon mat to solder components on, I read somewhere that you use something similar *(not that I am spying on you :) ) but could it be that I am frying all the radios with static electricity?

I have used the mat before and it works fine with regular radios, nothing fried so far, but there is something preventing nodes from working :(Do you have any suggestions on how I can debug them and see what seems to be the problem?

-

Hey @Nca78 I received the boards and components (yay!)

But... I connected three modules, and none of them works :(

They all have transport (radio?) fail like32 TSM:INIT

49 TSF:WUR:MS=0

81 !TSM:INIT:TSP FAIL

98 TSM:FAIL:CNT=1

114 TSM:FAIL:PDTI tried connecting radios from two different batches, I tried connecting only the radio and arduino, I tried powering it from separate powersupply and only debug via serial. I tried provided sketch and also tried dummy sketch from the examples. I tried using the CR battery, node works fine except that the radio doesn't start communicating.

I do measure 3V on the radio pins. I tried with and without radio cap.I am using chinese silicon mat to solder components on, I read somewhere that you use something similar *(not that I am spying on you :) ) but could it be that I am frying all the radios with static electricity?

I have used the mat before and it works fine with regular radios, nothing fried so far, but there is something preventing nodes from working :(Do you have any suggestions on how I can debug them and see what seems to be the problem?

Hello, @dakipro, can you show a picture of one of the board ?

Did you short the jumpers (JPOWER and JRDIO) if you're not using any regulators ?Yes I use a cheap silicon mat because it's so convenient, and I never had any problems with it all my radio worked.

-

Hey @Nca78 I received the boards and components (yay!)

But... I connected three modules, and none of them works :(

They all have transport (radio?) fail like32 TSM:INIT

49 TSF:WUR:MS=0

81 !TSM:INIT:TSP FAIL

98 TSM:FAIL:CNT=1

114 TSM:FAIL:PDTI tried connecting radios from two different batches, I tried connecting only the radio and arduino, I tried powering it from separate powersupply and only debug via serial. I tried provided sketch and also tried dummy sketch from the examples. I tried using the CR battery, node works fine except that the radio doesn't start communicating.

I do measure 3V on the radio pins. I tried with and without radio cap.I am using chinese silicon mat to solder components on, I read somewhere that you use something similar *(not that I am spying on you :) ) but could it be that I am frying all the radios with static electricity?

I have used the mat before and it works fine with regular radios, nothing fried so far, but there is something preventing nodes from working :(Do you have any suggestions on how I can debug them and see what seems to be the problem?

-

-

Looks as though the PA/LNA part of the silkscreen warning got largely obliterated by the solder pads.

-

Must I have a radio cap?

I connected the jumpers now quickly for a test (missed the part that I need them), but still same error49 TSF:WUR:MS=0

81 !TSM:INIT:TSP FAIL

98 TSM:FAIL:CNT=1

114 TSM:FAIL:PDT

10158 TSM:FAIL:RE-INIT

10174 TSM:INIT

10207 !TSM:INIT:TSP FAIL

10240 TSM:FAIL:CNT=2

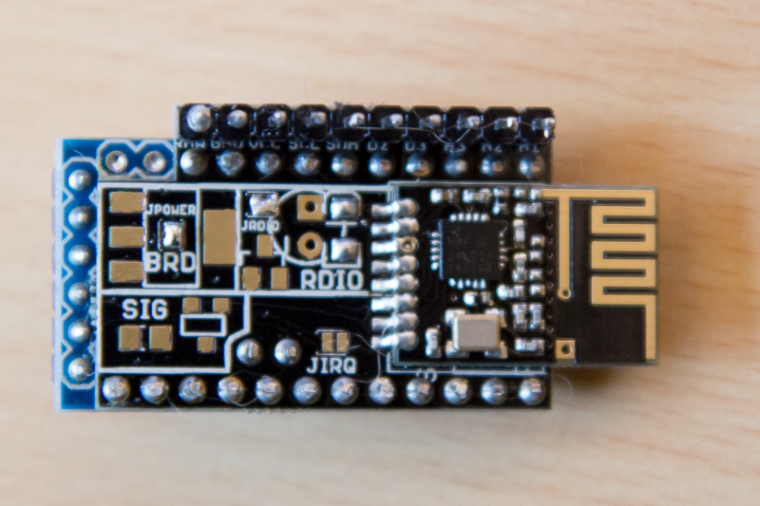

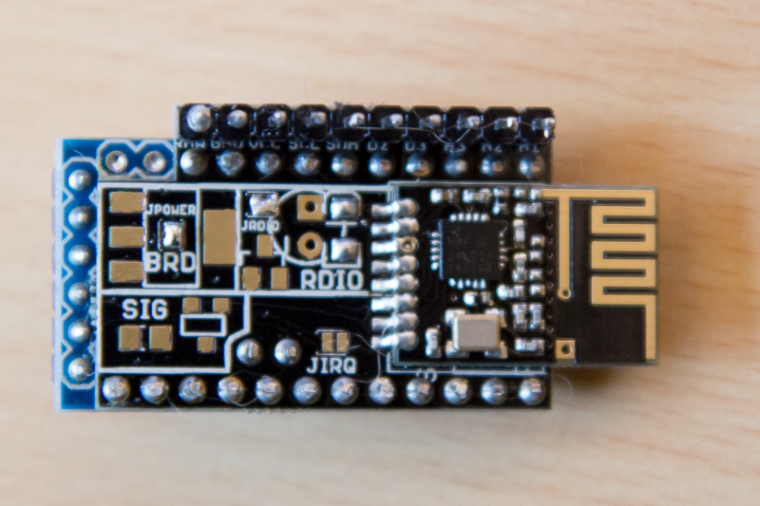

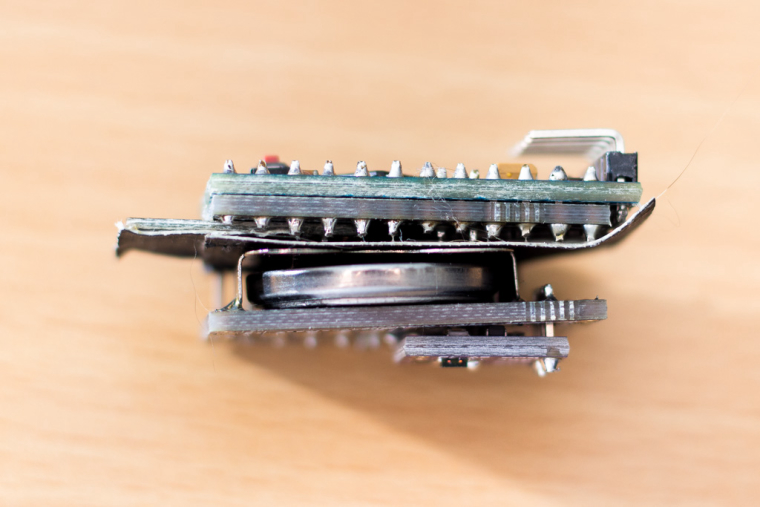

10256 TSM:FAIL:PDTHere is the photo of the board (a bit blurry, I can take it again if it helps)

I am missing the radio cap as I was testing lest night without them, but I can solder them in a few hours and test again if you think it will help.

I connect power to the vcc pin of the "connection pins" right?

Radio is the one linked in the BOM from aliexpress

-

Must I have a radio cap?

I connected the jumpers now quickly for a test (missed the part that I need them), but still same error49 TSF:WUR:MS=0

81 !TSM:INIT:TSP FAIL

98 TSM:FAIL:CNT=1

114 TSM:FAIL:PDT

10158 TSM:FAIL:RE-INIT

10174 TSM:INIT

10207 !TSM:INIT:TSP FAIL

10240 TSM:FAIL:CNT=2

10256 TSM:FAIL:PDTHere is the photo of the board (a bit blurry, I can take it again if it helps)

I am missing the radio cap as I was testing lest night without them, but I can solder them in a few hours and test again if you think it will help.

I connect power to the vcc pin of the "connection pins" right?

Radio is the one linked in the BOM from aliexpress

-

checked between the pins, no radio pins are touching each other. Those hairs er most likely from the cat, got them cleaned after the photo.

I will try to make one more module in a few days and test.But to confirm, for the simplest module I need >4.7uF cap, pro mini and the radio, two jumpers (jpower and jrdio) and some mock sketch, and it should all work?

Have I missed some other jumper or resistor or some other component maybe? -

checked between the pins, no radio pins are touching each other. Those hairs er most likely from the cat, got them cleaned after the photo.

I will try to make one more module in a few days and test.But to confirm, for the simplest module I need >4.7uF cap, pro mini and the radio, two jumpers (jpower and jrdio) and some mock sketch, and it should all work?

Have I missed some other jumper or resistor or some other component maybe?@dakipro no you're not missing anything now.

Cap is not even necessary at the moment don't worry about it.Problem is connection with radio so you have to make sure :

- VCC and GND pins of radio are correctly connected (seems it's done)

- SPI pins are correctly connected to the radio, check the "connecting the radio" page for the pinout on the pro mini, and radio module pinout. Then check continuity from radio connector to matching pin on radio side, you might have a soldering problem.

-

@dakipro you can also check the continuity between adjacents pins of the radio modules, it should be in MOmhs, if lower that could be a reason for failing communication too.

@dakipro you can also check the continuity between adjacents pins of the radio modules, it should be in MOmhs, if lower that could be a reason for failing communication too.

Just reading on computer instead of phone and I see you did it already, so except a connection problem with the SPI pins I don't see any reason for failure...

-

Thanks :)

Then I guess all that is left is to motivate you to start OTA and improve it (finetune) it to nmodule :)

I used it for regular modules and it is really practical, but I never had much luck with optimizing modules for battery performance. I would get a half year/year with 2 AA batteries, which is not that good comparing with your tweaks for CR battery.Keep us updated on other modules, people are waiting for your tests to start ordering :)

Thanks :)

Then I guess all that is left is to motivate you to start OTA and improve it (finetune) it to nmodule :)Just did OTA on a main powered NModule with MYSBootloader and it worked like a charm.

I will test with a battery (CR123) module at 1MHz now, and post a tutorial later. -

Thanks :)

Then I guess all that is left is to motivate you to start OTA and improve it (finetune) it to nmodule :)Just did OTA on a main powered NModule with MYSBootloader and it worked like a charm.

I will test with a battery (CR123) module at 1MHz now, and post a tutorial later. -

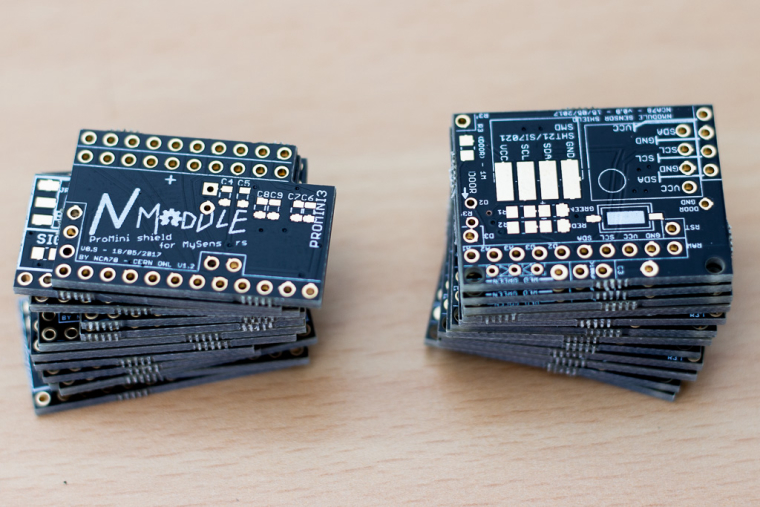

IT WORKS!! Life is worth living again...

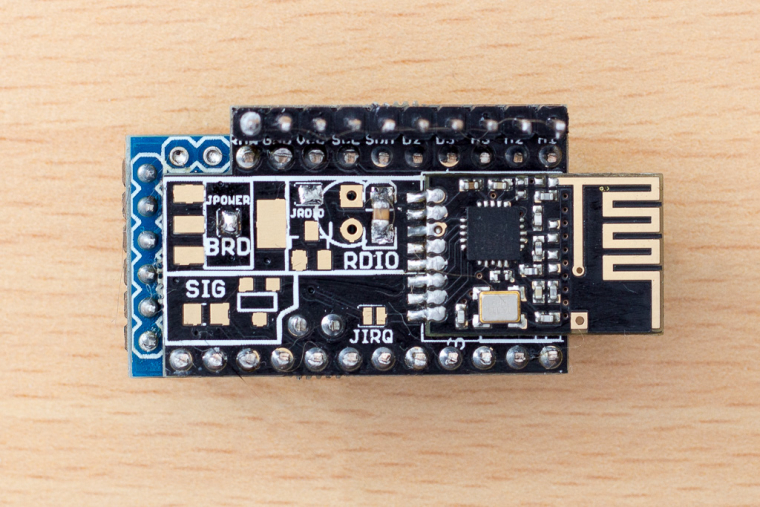

I've assembled now fourth module and it works, only different thing I did is that I have soldered the radio and power jumpers before connecting the module together. It could be that without jumpers essential component of all electronics (white smoke) gets out of the radio, not sure what happened. But it works!I was struggling a bit to figure out all components needed and all the steps, it might be helpful to have a "short guide", this is for my own reference of what I did in order to get CR2032 module for using with TempHumDoor shield:

Components needed [nModule]: pro mini, radio, nmodule board, 1 capacitor for radio larger then 4.7uf (I har only 10uf, I have ordered 47uf for future modules).

Assembling process

- Burn 1mhz bootloader on pro mini

- solder two jumpers for jpower and jrdio

- solder the radio to the board

- Control that there is no connection between the radio pins, resistance is at least above 200Kohm (don't skip this part thinking it cannot happen to you, it will happen)

- Solder >4.7uf (f.eks. 10ud) smd.

- Solder all legs to arduino (except last two RXI and TX0, you will see them missing when you align nModule)

- Take off the plastic from the legs, before you solder it to the radio (do this BEFORE you solder it to the board)

- Solder arduino to nModule board

- Since the capacitor is very small, just check if there is no short between plus and minus (vcc and gnd) pins, as somehow I managed to short them on one module, it turned out that one of the caps was shorting it, probably by overhitting or something.

Upload mockMySensors sketch and check that node works properly (spare yourself a trouble, no point continuing further if this doesn't work) By this point you should have node looking like (better then) this:

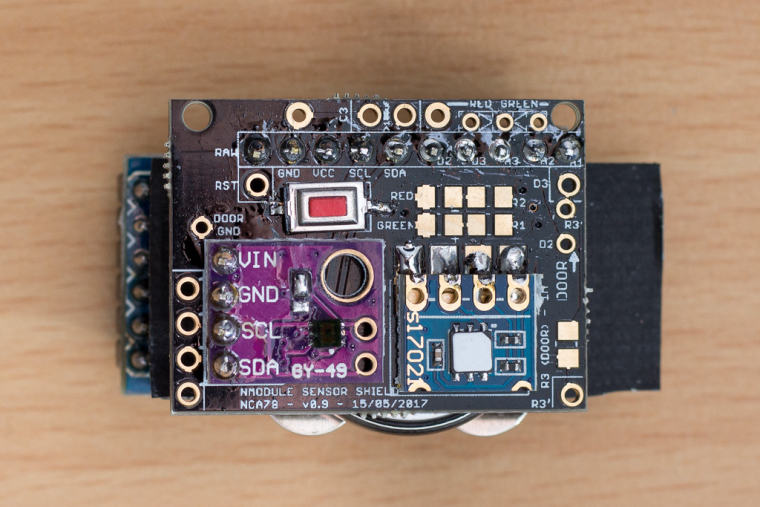

TempHumidityLightDoor shield components: SMD SI7021 for temperature and humidity and a MAX44009 for light, two capacitors larger then 100uf (I used two of 100uf, waiting for 220 to come). And the work so far.

You basically solder these three/four components and the battery holder as described on the shield here https://www.openhardware.io/view/398/NModule-Temperature-Humidity-Light-Door-sensor-shield

I didn't yet solder LEDs, but they are accessible after assembling the module.

Then it looks like this:

Now that nModule #1 is completed, you continue with other modules

-

If the "power" board is used, shall I keep the voltage regulator on Arduino? Without it, i think powering the board from RAW pin will not work.

-

If the "power" board is used, shall I keep the voltage regulator on Arduino? Without it, i think powering the board from RAW pin will not work.

@Haozhi-Wang it will depend how you connect things on the "power" board and/or what regulators you use on the NModule board.

There are 2 reasons to remove the regulator :- save energy if you are running on battery, it's not a big waste so if you are using CR123 or AAA you can keep it so it's possible for you to power from RAW with a higher voltage

- when powering from main, allow higher RAW voltage with a better voltage regulator on the NModule or the "power" board (on promini clones usually the maximum voltage is usually 9V)

There is a connection between the RAW pin of the promini (on the long side) and the RAW on the "power board", so whether it will work if you use a regulator on the "power" board and remove regulator on the promini will depend on the promini you use, if there is a track betwenn the 2 RAW pins or if it goes through the regulator.

I hope it answers your question, if not please describe more clearly what sensor you are building, with what power source and why you want to power it from RAW.

-

I love those shields... to bad they dont use MysX connector ;) Any thoughts about 2.0 rev?