So in the early 2000's, 2002 2003 somewhere in there, I had started working on an idea for making a robotic lawn mower. I had worked on the project for a few years and kept having recurring problems with the electronics. The project ended up getting put in storage for around 15 years. I saw it rusting away in my basement and said, "I really need to bring that back to life."

THE ORIGINAL DESIGN

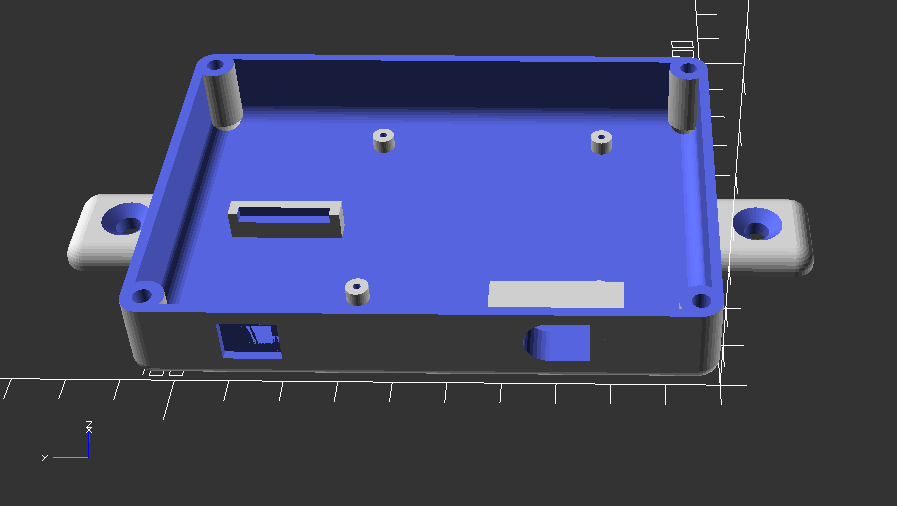

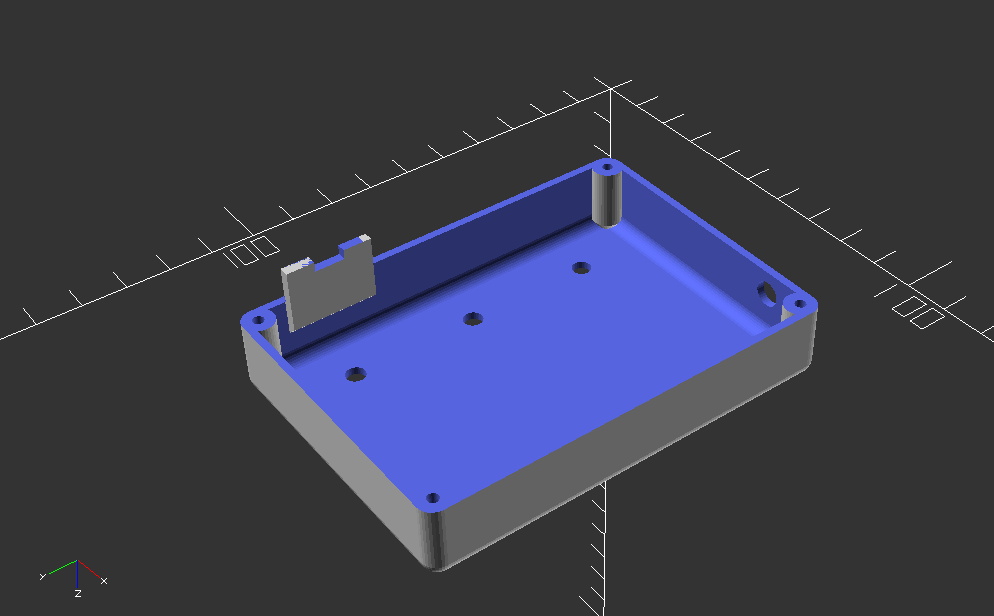

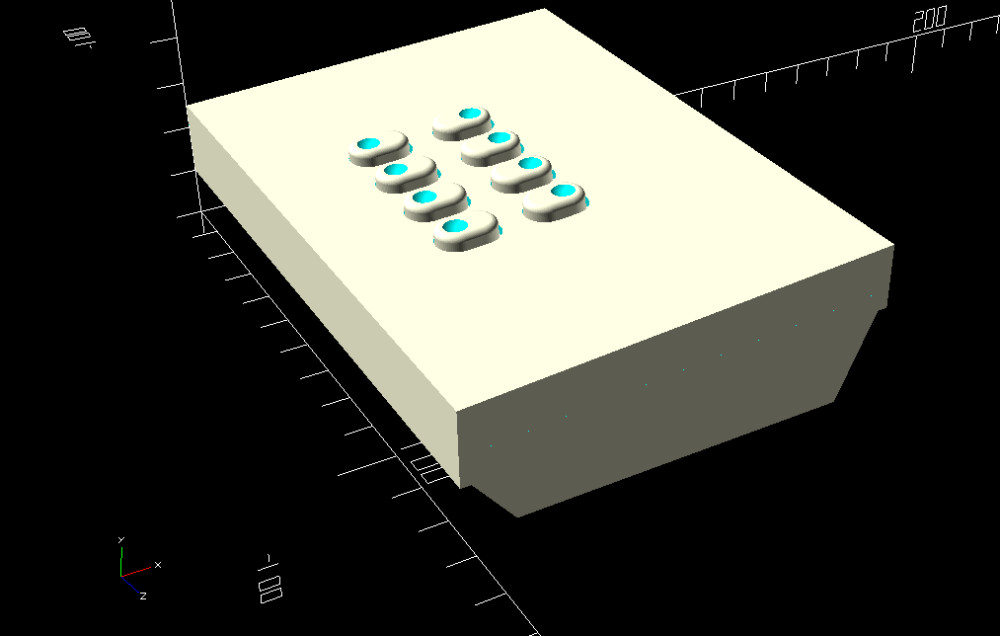

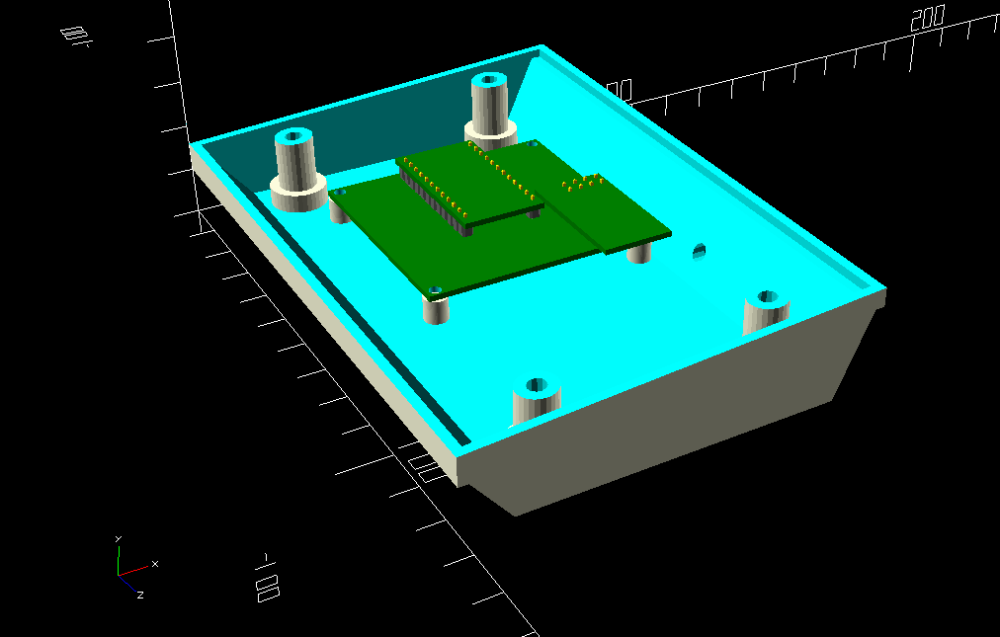

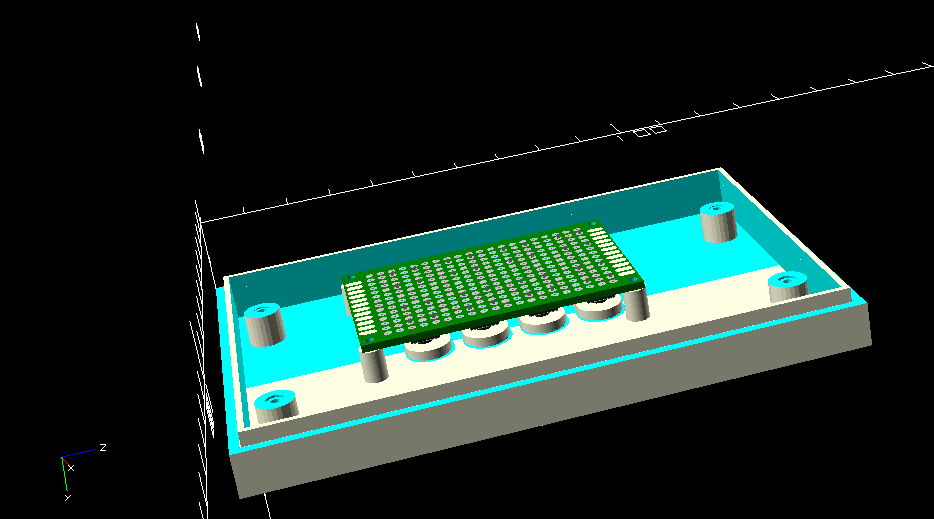

All the major hardware was designed by me. The main frame is a custom welded steel frame. The main deck was fabricated from a piece of acrylic that I had gotten from someone who had used it originally for a science fair computer display. The blade motor carriage was designed to fit at 3 different levels for different blade cut heights.

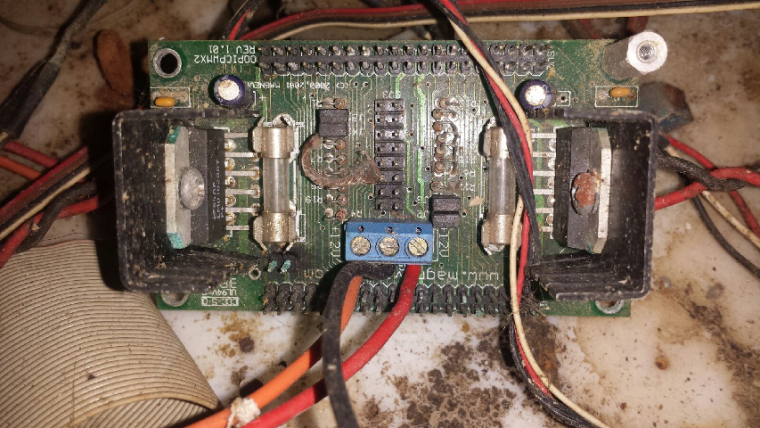

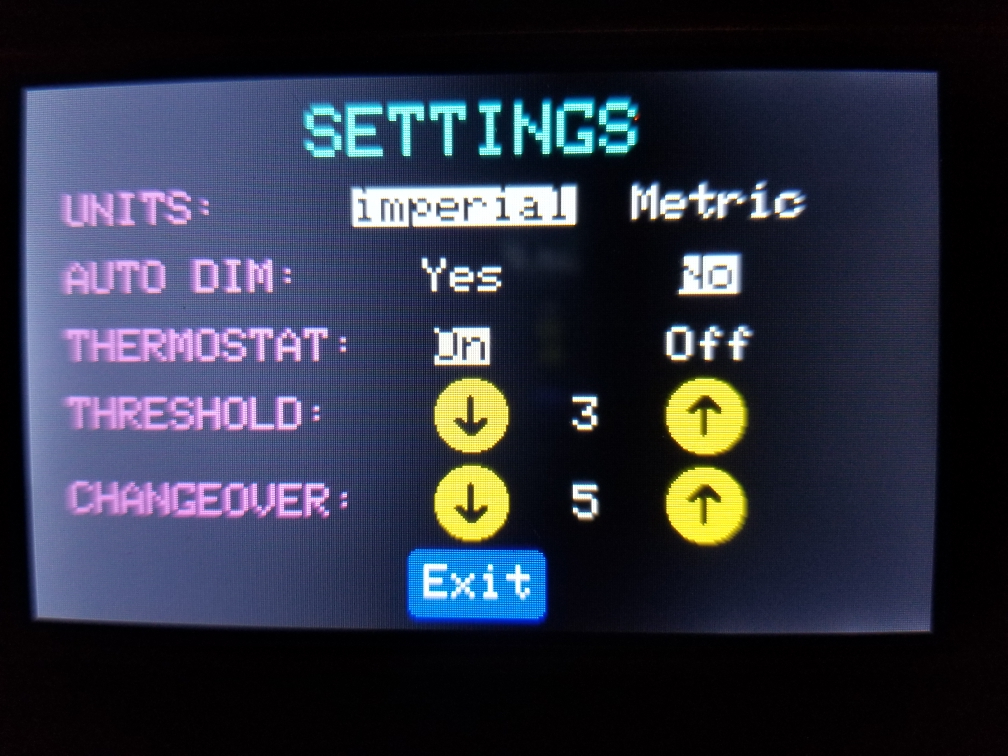

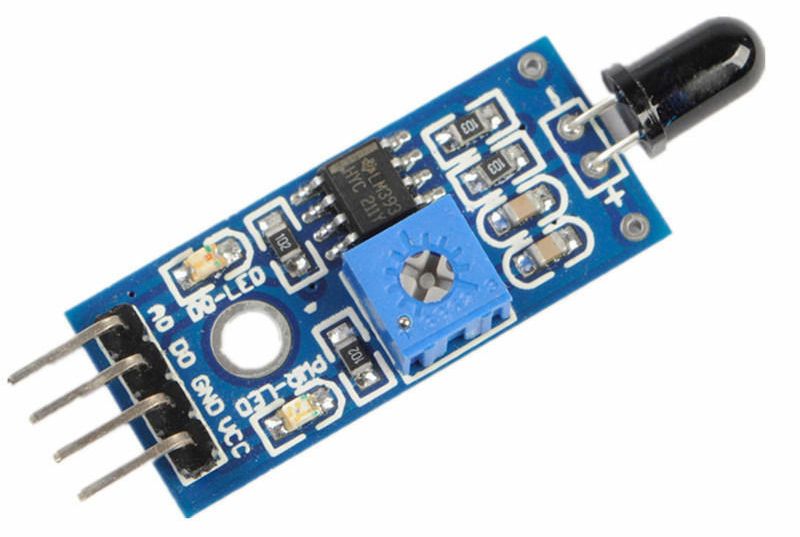

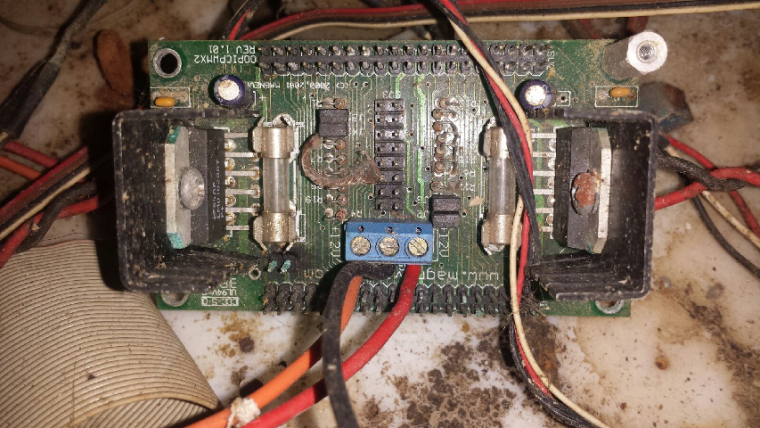

For the electronics, I had started using an old robotics micro-controller called OOPic. With it, I had a dual H bridge motor controller to give it differential steering. The front and rear both had custom bent aluminum bumpers which could detect directional contact with the use of micro-switches around the edge. I had side looking IR distance sensors for short range side sensing, with a front mounted ultrasonic distance sensor for longer range of vision.

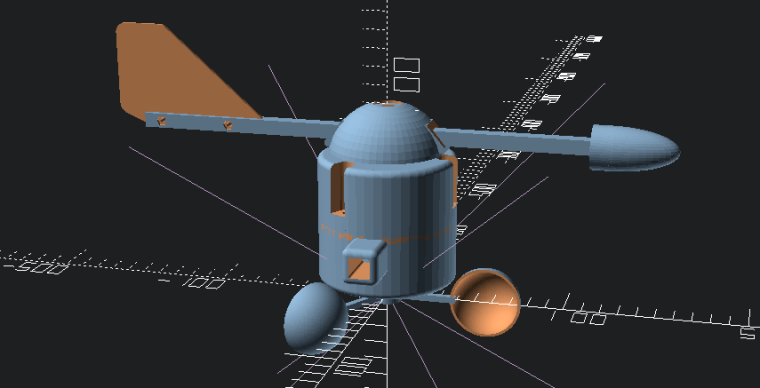

I had gotten so far as to start designing an outer shell for it that I was going to make out of fiberglass. In some of the pics you will see the styrofoam shell mold I had started building.

AFTER PULLING IT OUT OF STORAGE

I didn't have it covered or protected, so in the time it has been in storage, the frame has rusted, motors and electronics are corroded, deck is dirty, the front of the acrylic platform broke off and the front part broke in two pieces. WHEW, that was a mouthful. Looking at this picture, you can see that it is in rough shape. This is before any cleanup work so I have a before and after view when it is done.

I edited that picture in gimp to give an idea of what the full deck somewhat looked like.

THE GOAL

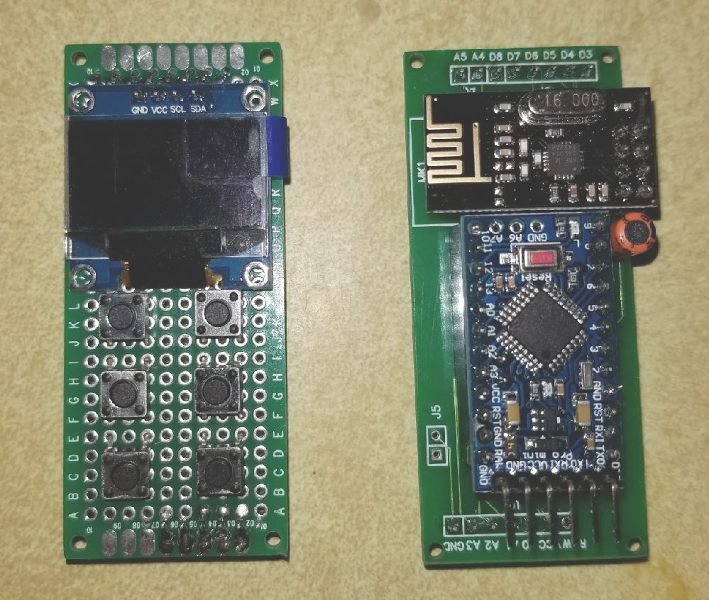

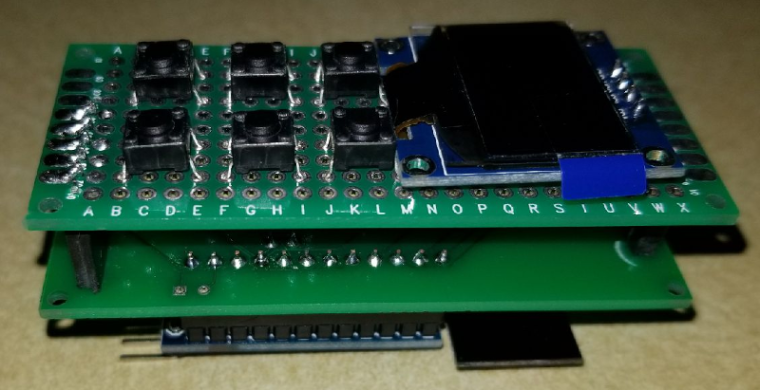

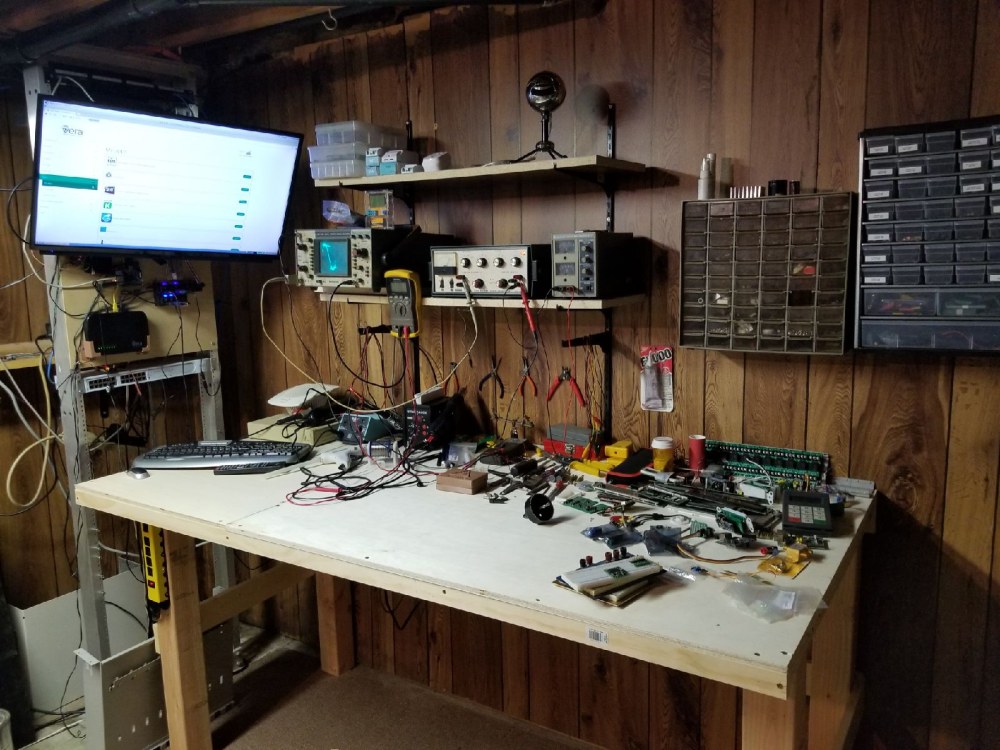

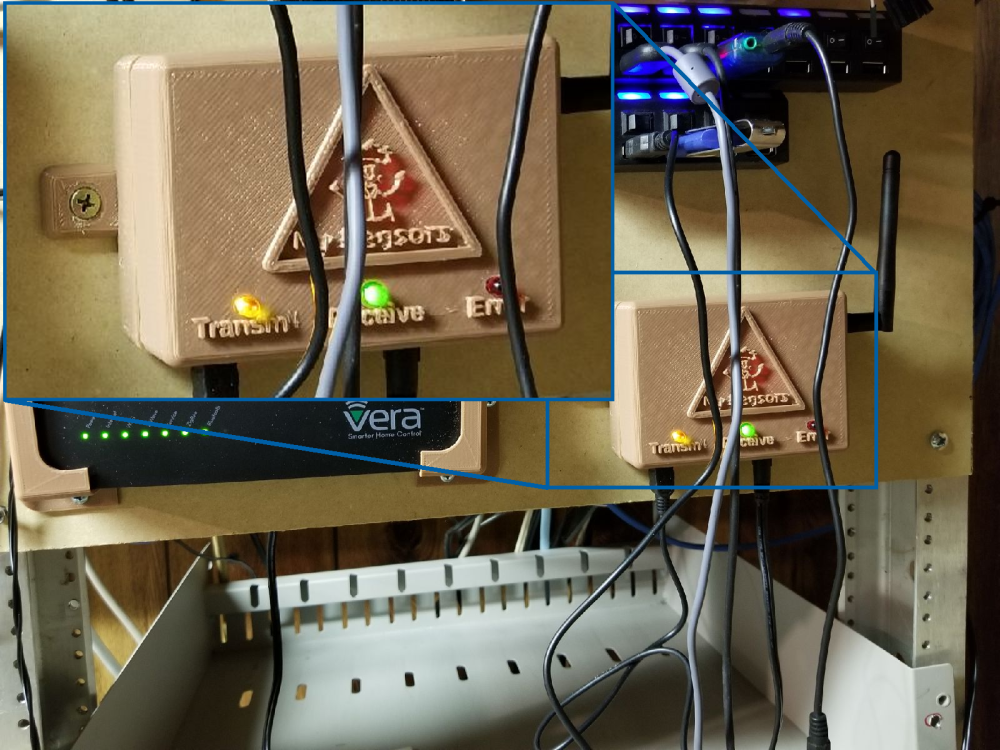

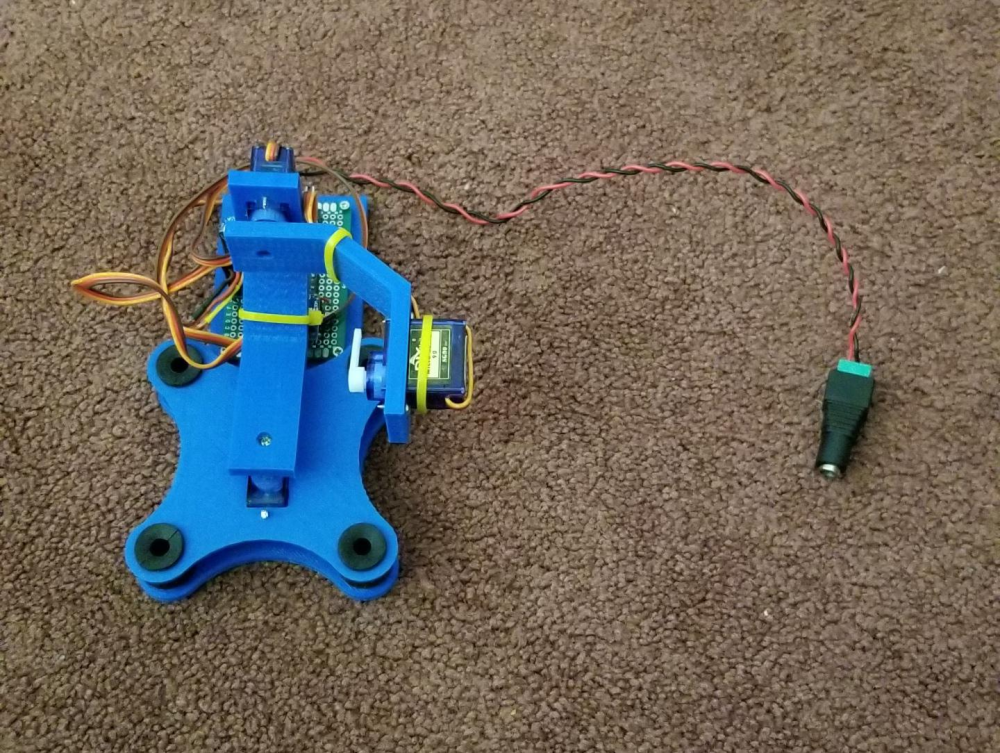

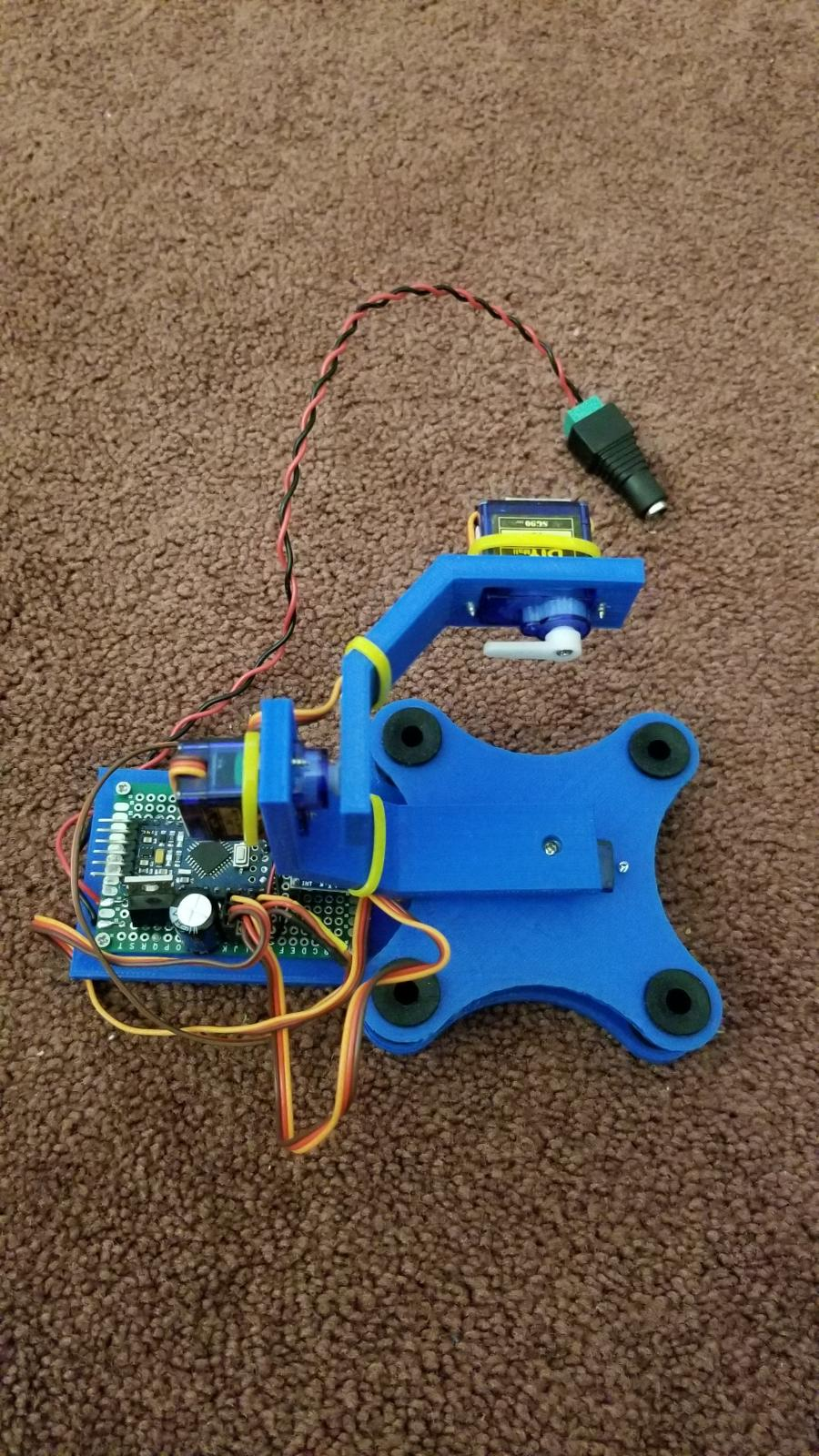

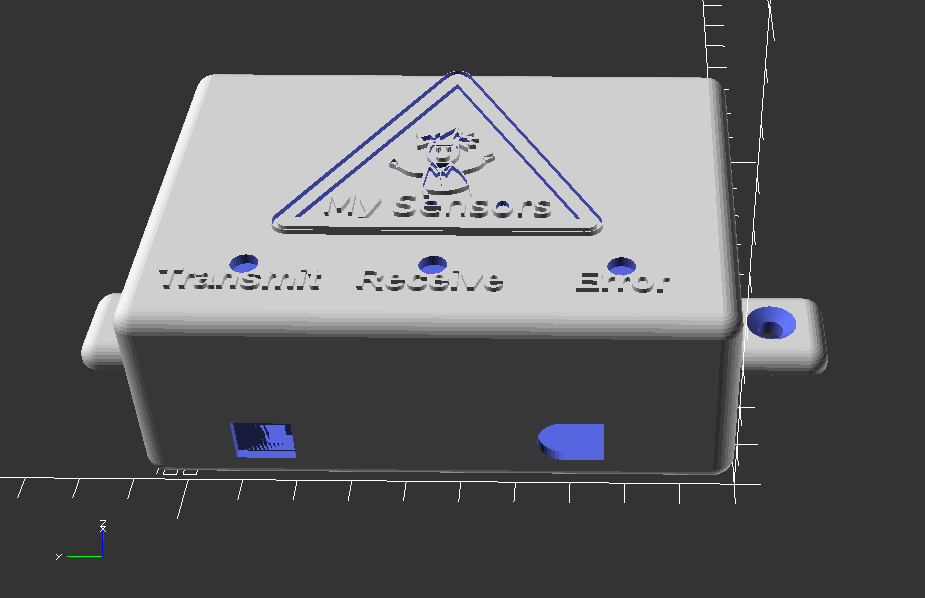

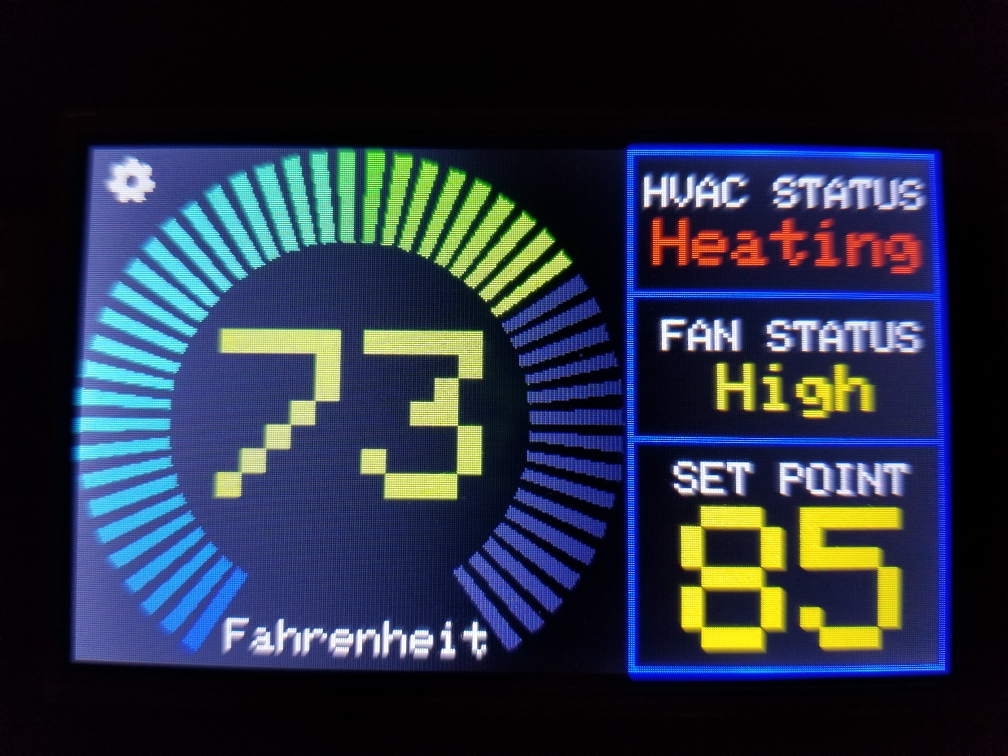

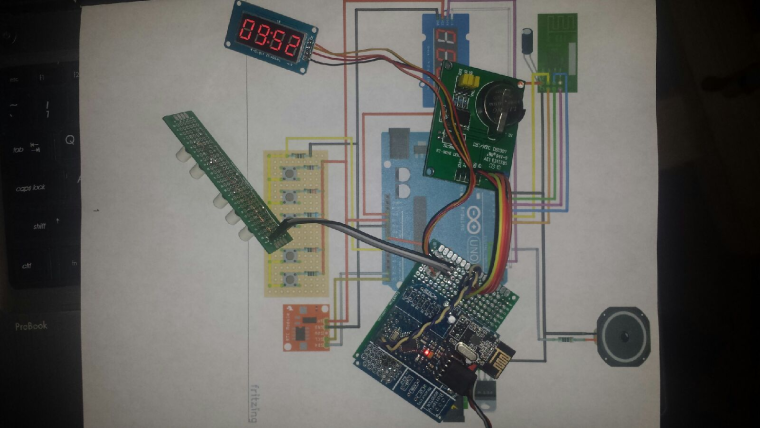

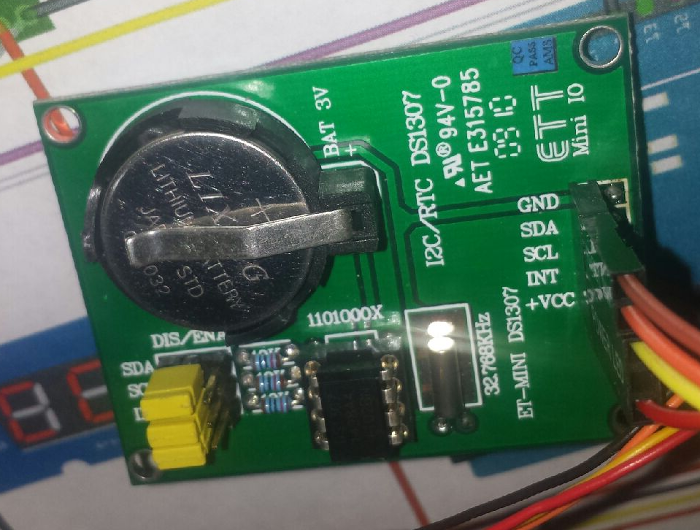

The end goal of the whole thing is to hopefully get this thing operational. I would like to MySensorize some parts of it, though I haven't thought out exactly what parts yet. First thing is going to be to take it all apart, clean all of the parts, and then start rebuilding. I need to re-figure all of the electronics. I figure I can get better vision and control with newer and cheaper electronics.

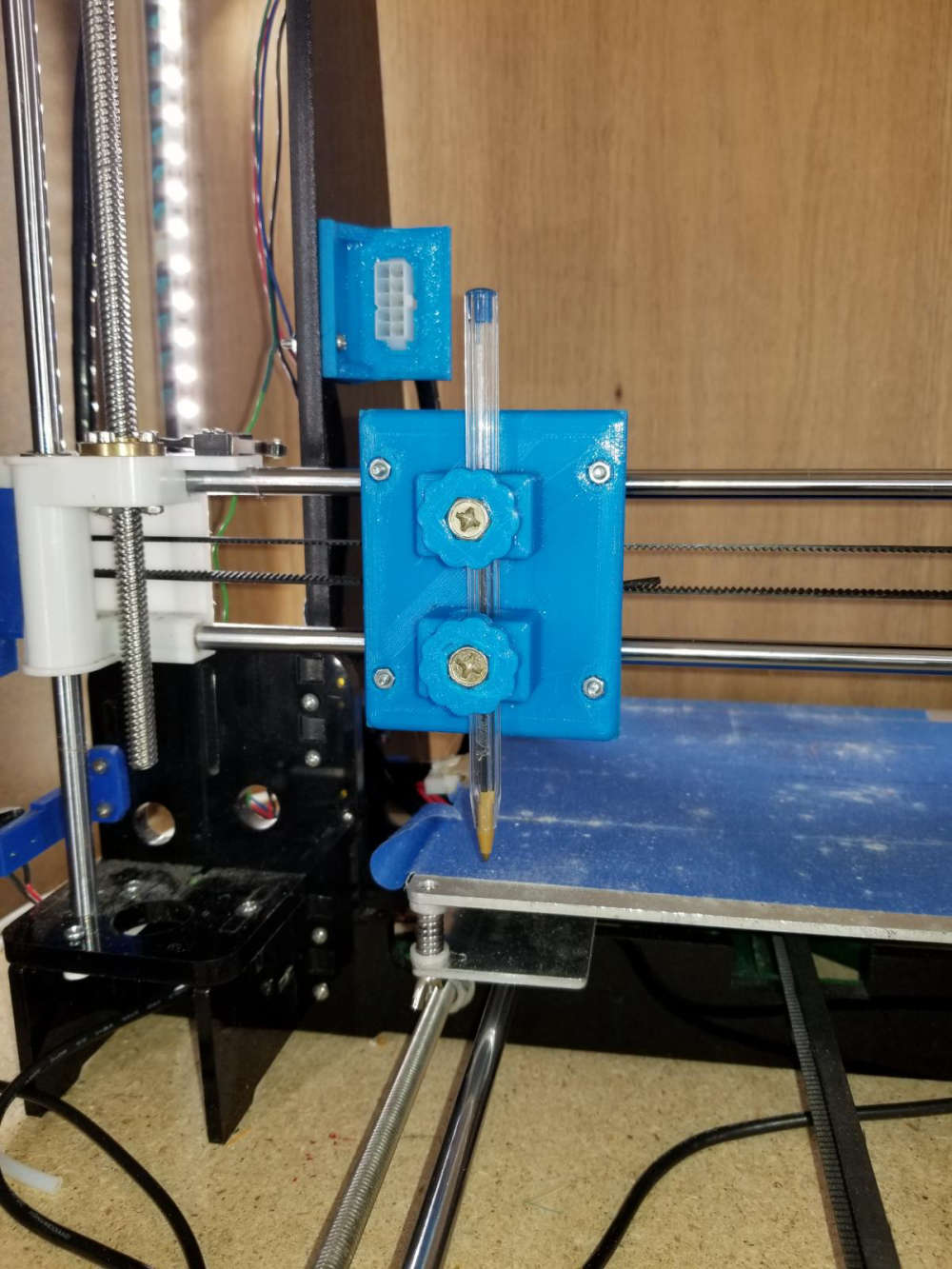

Here are a few more teaser images.

I actually have 17 pics of this, so instead of posting them all here, I put them in an image gallery on my website.

https://dan.bemowski.info/image-gallery/nggallery/robotics/Mowbot

This is probably going to be a long drawn out project, and I don't know at what intervals I'll post progress, but I will post progress at some points.