Is there anyone that either still uses a Vera controller or knowssomething about how they work with Alexa? My issue is that my thermostat bridge had the Arduino Pro Mini die and I had to flash a new one. When I did this I had to re-discover it with MySensors in Vera. I then had to delete the node from Alexa to add the new one, but when I go to the list of discoverable devices it doesn't show up. I can control it fin on the Vera but can't add it to Alexa.

dbemowsk

Posts

-

MySensors node not working with Alexa on my Vera -

Old hardware migration@OldSurferDude My old 2.0 setup is with nRF24L01 radios. This is a link to the thread on some light switches that I designed and built.

https://forum.mysensors.org/topic/7376/us-decora-wall-switch-continued/2

I am aware that you cannot have two MQTT gatways. When I designed my old setup I was not that familiar with MQTT so I never ended up implementing it. On the home assistant server that I have set up though, I have installed the MQTT broker on there so I should be able to comunicate with any MySensors stuff over MQTT in the future devices I make/set up. As I mentioned, I do have a Home Assistant box that I have started about 4 months ago and eventually want to migrate my Vera equipment to the HA box.As for the YAML and Python, I'll muddle my way through. used to program in PHP and have done enough on Arduino that I'm sure it won't hurt my brain too much.

-

💬 In-wall scene controller OLED keypad@Michael-Link I have been out of touch with MySensors for some time now and looking to slowly get back into it. I created this and a few other boards back in 2018 All of the GERBER files for this are in the "Design Files" tab. Those you should be able to send to JLC PCB or one of the other fab houses and have some made. This was designed to be used with 2 other boards that I designed. There was the processor board and the power supply board. The processor board was designed in a way that I could use a couple different switch boards. This one and a universal multi-switch board that had multiple configurations. If you look here you will see my other boards.

-

Old hardware migrationSo I have been out of touch with MySensors for a few years now. I still have a bunch of hardware running that uses MySensors 2.0 I believe. It is all connected to my old Vera controller. I am working on setting up a machine to run Home Assistant and plan to slowly migrate hardware to the new system. My question is, if I configure a new 2.3.2 gateway and connect it to the Home Assistant box, will my 2.0 hardware be backwards compatible and connect to the new gateway? Also, is it possible for me to run 2 NRF24 gateways at the same time without the hardware freaking out? I do have the HomeAssistant box configured as an MQTT gateway and may put new hardware on the MQTT side going forward. What are peoples thoughts on the best approach. The migration will most likely be S L O W.

Any input is appreciated.

-

Moisture penetrates my outdoor enclosures...This may sound crazy, and may not be an option after saturation, but what about putting a silica gel pack in there?

-

Website forum search feature [is broken]@mfalkvidd No problem, Now that I know that I'll just do some manual browsing if I need to find answers.

-

Website forum search feature [is broken]So I have been out of the loop with MySensors for a few years, but still run some MySensors 2.0 hardware that I built years ago, and it is still working. I am currently running a Vera Plus home controller and it is working for the most part, but I am thinking of switching either back to Domotcz or to Home Assistant on a Raspberry Pi. This brings me to my question. Being that I have been out of the loop for a while, I am trying to find some information, so I am trying to use the search feature of the forum before I post new topics that have been answered already. The problem is that pretty much every search I do comes up saying "No matches found". Is there a problem with the search feature of the forum?

-

Questions about an old setup@Nigel31 and @ejlane, My Vera controller has a built in app/plugin for alexa. My wife uses it alot and would be sad to see that functionality go. So Controlicz is a skill that I would have to add to Alexa? Currently the plugin for Vera uses the built-in smart home feature of Alexa. As I recall, I didn't have to set up a special skill for it to work on the Vera. I did however have to install the app on the Vera that would talk to it. I think that does use the vera portal to work though as I have to log in to my Vera account to be able to update my Vera connected devices.

-

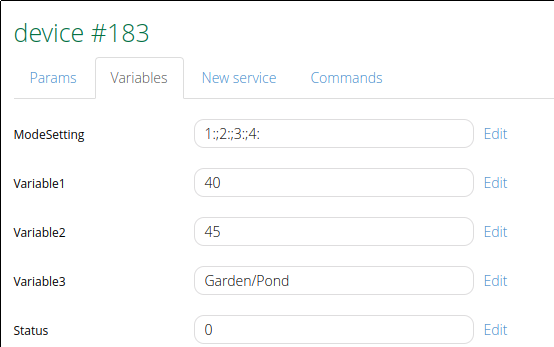

Questions about an old setupSo I have been out of the MySensors loop for a number of years now, but still have a number of version 2.0 devices that are still running in my house with my Vera Plus controller. Prior to the Vera Plus I was running Domoticz on an old Orange Pi and I am thinking of possibly switching back to that as there were some features of it that I liked. I have a few Raspberry Pi 2B+ boards that I could run it from. My question is, will my old 2.0 NRF24L01 gateway still work with the latest version of Domoticz and recognize my devices? Another question has to do with my sprinkler controller. The sprinkler controller was part of the reason I switched to the Vera in the first place. The reason being that Domoticz, at the time, didn't support the variables 1,2 and 3 for setting the 2 zone time options and the zone name like this:

I am wondering if Domoticz has gained better support for these things or if I will still have these hangups with the sprinkler controller?

The last thing is my alexa devices. I currently have this working with my Vera controller and am able to control all of my MySensors devices. I see that there is a skill called Controlicz.Has anyone used this and if so, ho well does it work for the MySensors hardware?

I remember this being a GREAT community of people. I am open for any insight into this issue. I know my Vera controller is getting old and will one day die on me leaving me stranded. I want to catch things before that day comes.

Thanks all.

-

US decora style wall switch@alex_the_techy I have had an A8 for just over 2 1/2 years now and it has been a relatively good entry level printer. Most of these entry level printers have some quirks about them, but they give you a good start into 3D printing. It does have an acrylic frame which is not quite as sturdy or durable as the aluminum extrusion frame that something like the Ender 3's or the Creality printers have. You can pick up an Ender 3 now for less than $200 US at aliexpress which is right around the same price as an A8. I would go with that over an A8 if I were to buy one these days. Many people that buy the A8 printers end up doing an AM8 frame conversion on them which basically gives you a frame similar to the Ender 3. I am not sure what the cost of the AM8 extrusion parts cost, but whatever the price is, it's too much when you can start out with the Ender 3 for around the same price as buying an A8 and you don't have to go through the hassle of the conversion, which by the way requires some 3D printed parts.

-

Mini lightshow project ideasAnother thing that might be cool would be to figure out a way to do something with EL wire. If you are unfamiliar with EL wire, the EL is for ElectroLuminescent. You can get many different colors of EL wire and a controller from SparkFun. https://www.sparkfun.com/products/12781

And here is an example of something someone did with EL wire.

https://www.youtube.com/watch?v=1lGfMqEstKA -

Mini lightshow project ideasOn the lines that @TheoL was talking, here is some information on doing DMX with Arduino. https://playground.arduino.cc/Learning/DMX/

-

Best sensor for falling alert@nca78 said in Best sensor for falling alert:

a LIS3DH will use 50-100 times less current for free fall detection (between 6 and 11µA), ADXL345 over 10 times less (40µA)

That is an excellent point. If using it for personal monitoring, quiescent current draw would definitely be a factor. The longer you can have the device last on a battery charge the better.

I had just used the MPU-6050 for building a recovery parachute system for my drone in which I needed free fall detection, and it worked well which is why I commented on that one.

-

Best sensor for falling alert@nca78 said in Best sensor for falling alert:

There are accelerometers with built-in free fall detection, you should use one of those.

The MPU-6050 has built in free fall detection using an interrupt.

-

Best sensor for falling alert@bjacobse I have done a little bit of work with the MPU-6050 IMU sensor (made a servo based 3 axis camera gimbal and a free-fall sensor for deploying a recovery parachute for my drone). I would think that with the MPU-6050 you should be able to distinguish between the two scenarios you mentioned. I can't say for sure, but if you looked at the data from the sensor in the two different scenarios I would think that you would be able to find some discernible difference and be able to code for that type of scenario. I think it would be worth doing some tests to see. The sensors are cheap.

-

Questions for a thermostat project.@nagelc Just ordered one of those buck converters from Digikey. Thanks for the suggestion. That might fix my whole issue.

-

Questions for a thermostat project.@mfalkvidd and others. I am aware of what buck converters are and have used them before, what I was trying to avoid was changing the design of the case to make more room for something like that, but I guess if it comes down to it I may have to. I was hoping that someone might have a solution that might fit my space constraints. I like the one that @nagelc suggested as it looks like it might fit in the space I have. Another option I thought of if I had to change the size of the case was to use a couple batteries. I have some extra 18650's in my parts bin, I would need to check the current draw to determine how long they would last powering the UNO and the TFT shield.

As for the relays, I am switching them from the original 5 volt coil ones to 12 volt coils. I have decided to power them from the 12 volt supply as I should have plenty of current from that to hold a relay or two since that comes from the house batteries of the motorhome. There would never be more than two relays energized at one time since one relay is for heating and one for cooling, So it would either be a heating or cooling relay and possibly the fan relay being powered at any given time. I like the suggestion @skywatch made about using latching relays to save power, the only problem in using those is that I am limited to 3 data lines (D0 - D2) because of the TFT shield. My understanding of latching relays is that there are two types. Single coil which uses reversing the polarity for set and reset, or the dual coil type which use one coil for set and the other for reset. I think in either case I would have to use more than one data line for each relay which won't work.

-

Questions for a thermostat project.My main question with this was what is a small cheap and cool (literally) way of getting the 5V I need for the UNO from my 12 volt supply. Preferrably something other than a linear regulator.

-

Questions for a thermostat project.So this project at this point in time is not a MySensors based project, but I may make it into one in the future and use one for my home. That said,

MY PROJECT

My project is a digital thermostat using an arduino uno and a 3.2 inch touch screen TFT shield. This thermostat is going to replace the thermostat in my RV.

One difference from an RV thermostat to a normal house thermostat is that the house system typically runs on 24 volts AC whereas the RV runs on 12 volts DC. My original plan was to use the incoming 12 volts to power the uno. The specs for the UNO say that you can put up to 12 volts in the barrel jack. The only problem I have with this is that the linear regulator that the UNO has gets quite hot when running it from 12 volts. This heat will no doubt affect the temp sensor that reads the open air temp. I need to find a reasonably small way to regulate 12 volts to 5 volts without a lot of heat.MY DESIGN:

And now a bit about my design. I have most of this built and my firmware is nearly ready. I am designing it as an auto changover setup with a relay for fan speed (low or high). Here is the board setup that I have.

The area of the board marked in yellow will be where the screw terminals will go for connecting it to the system. The 3 relays are heat, cool and fan. I was originally going to use 5 volt relays supplied from the 5 volt pin on the arduino. I found out that when two relays would trigger, the UNO would reset. I tried adding a capacitor to the power line near the relays, but that didn't help. I am changing the relays to 12 volt relays so I can just use the incoming 12 volts to power them. I am triggering them with NPN transistors connected to 3 digital pins.Here are a few more pics of the setup. I have designed and 3D printed a case for this also.

This is with the TFT shield in place.

And this is with the cover in place. The cover needs a little bit of cleanup work, but otherwise not too bad.

MY FIRMWARE

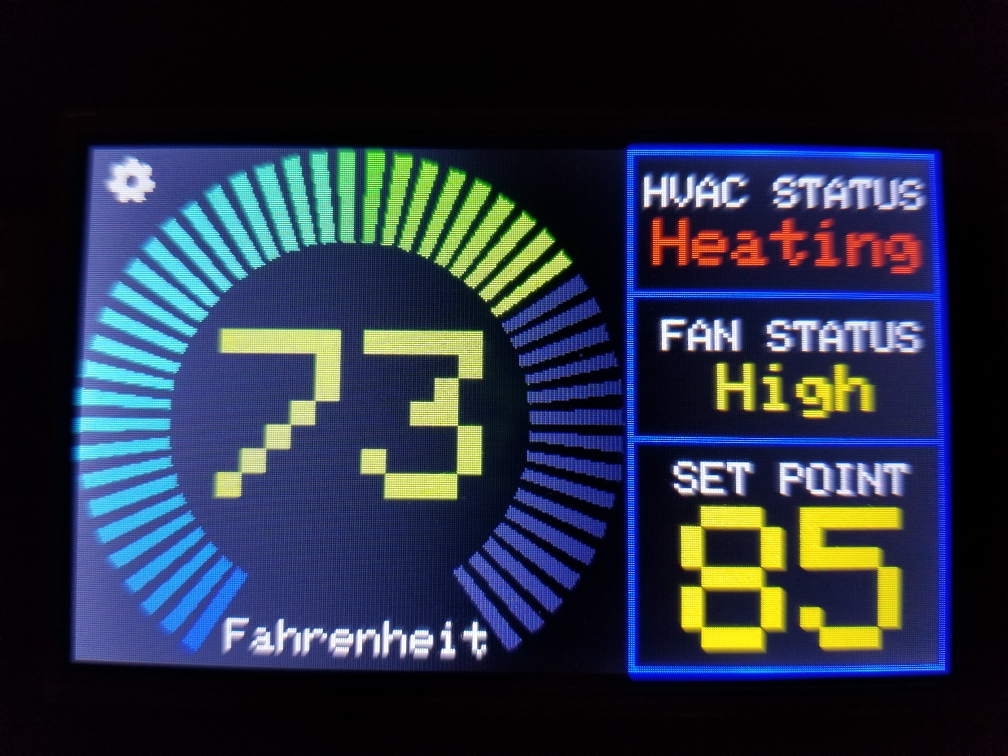

And now a look at the firmware. The first image is the main screen. The main screen shows the current temp with the HVAC, fan status and set point on the right side of the screen.

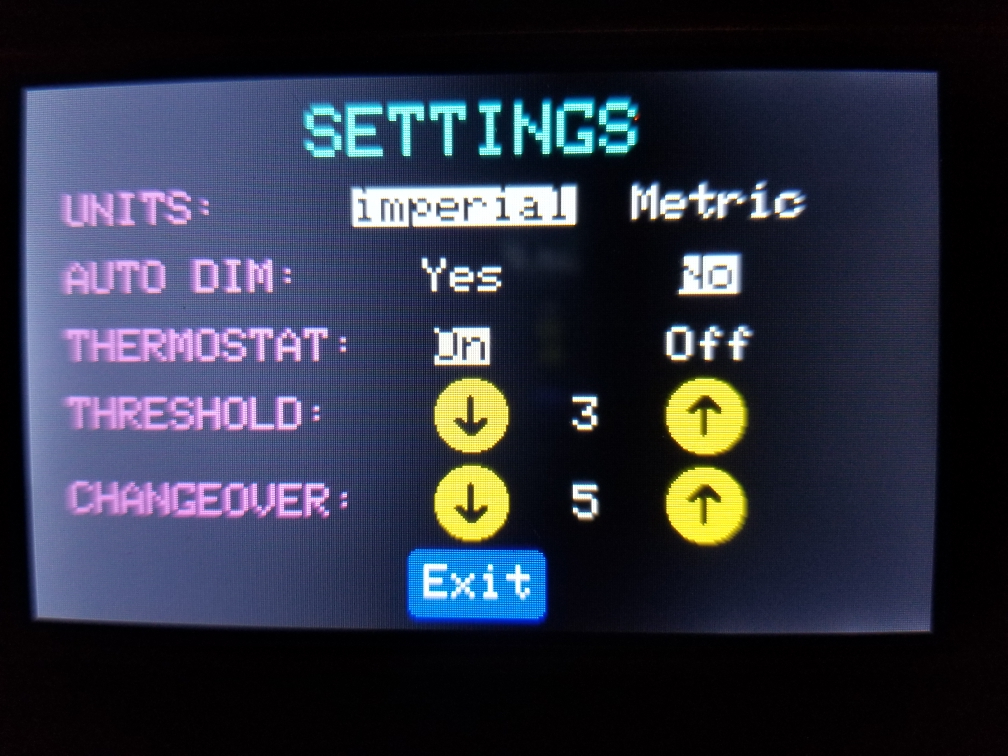

The main screen has two touch areas, the gear in the upper left corner and the set point box. Touching the gear icon gets you to the settings page, seen here.

When you touch to change any setting, it is stored in the EEPROM on the UNO allowing it to recover on the same settings if it were to loose power. Most of the settings are pretty self explanatory except for the threshold and changeover settings.The threshold value is either added or subtracted from the set point to offset when the heater or AC is switched on to know if it should have the fan on high or low. if the temp is with the threshold value of the setpoint, the fan is set to low, otherwise set it to high. On the RV, this just sets the fan to low or high. On a house multi-stage HVAC system it could switch stages.

The changeover value tells the system how many degrees the temperature must go up or down from the setpoint before the system changes over from heating to cooling or vice versa.

Clicking Exit at the bottom will take you back to the main screen.

On the main screen, clicking anywhere in the box that shows the set point temp will take you to the setpoint screen.

This screen is self explanatory in its function. The up and down arrows let you set a new setpoint, and Exit at the bottom will take you back to the main screen. The setpoint value is also saved to EEPROM on any change in value.