Board releases

(other colors might be selected when ordering)

- Version 2.0 (black) [order] Now designed in KiCad. "Final release". I'm not developing it further atm, but I know others have some projects going.

- Version 1.4 (red) My latest version in Eagle. Known issues are wrong references due to panelization and broken circuit diagram links.

- Version 1.2 (blue) Some less convienient placed components and the panelized verision has a faulty via.

- Version 1.0 (green) The one described below in this first post. Working but not panelized and lacks a few features.

Share stats and info

The panelized versions 2.0, 1.4 and 1.2 have until today (2019-02-24) been shared 230 (!) times at boardhouse. Together with a few shares of the non-panelized version and my own orders, and the usual 3x10-11 boards/order, it means a lot of boards! Guess very few build nodes with every board, but at least the design should be well proven by now. This also means a few $ to MySensors.org, since 1 $/order will be donated. Great thanks to everyone who has orderd this board! I'll keep this share-info updated for transparency purposes. IMPORTANT: Please understand that DirtyPCBs.com is a non-profit community service, with a lot of manual support required. So please be patient and nice to their support in general. A new site is under development. Read more at their support site. EDIT 2017-06-22: Despite the new site it is still a hassle every time to get a reply from them and then the share credits. If anyone have some more info on this, please let me know.

Introduction

This project describes a successor Node concept to my first 2AA battery sensor. I have combined a few simple design options to a result that I find rather useful myself and I think should be shared. The application specific sensor/-s of your own choice has to be added to this Node design, nor here any example sketches provided here except from a few links further below. I use this design for all my door and window reed switches, temperature (calibrated internal or thermistor), LDR and similar simple sensor types. But, nothing prevents the use of more sophisticated sensors like Si7021 here as well. A few links to sensor examples based on this node will be presented further down in this post.

Features

- Simple, in the sense that it consists of a minimum number of components and common available material.

- Cheap regarding choice of components, assembly work effort, energy storage and power consumption (battery type and life time).

- Flexible universal design base equipped with various sensors. PCB pads used as port connections or prototyping area for extensions.

- Small and discrete to fit in confined spaces and to reach WAF level

And more concrete:

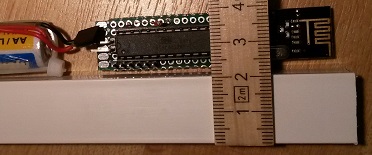

The uC

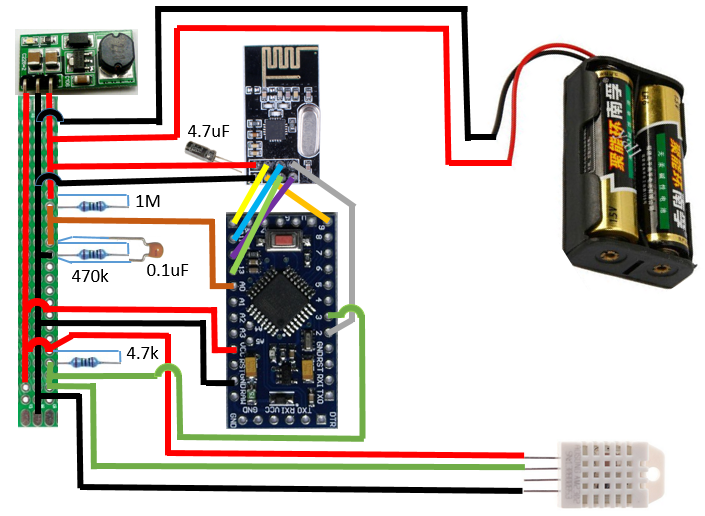

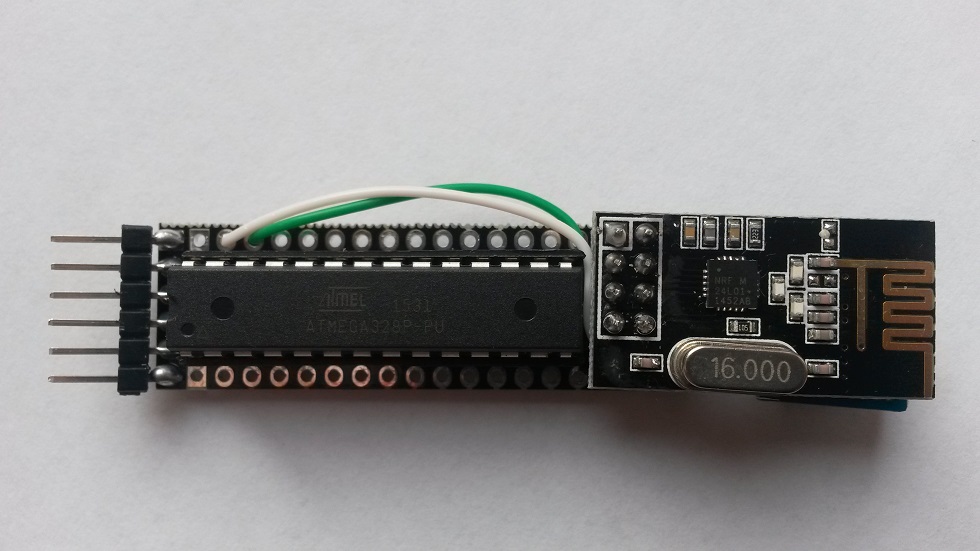

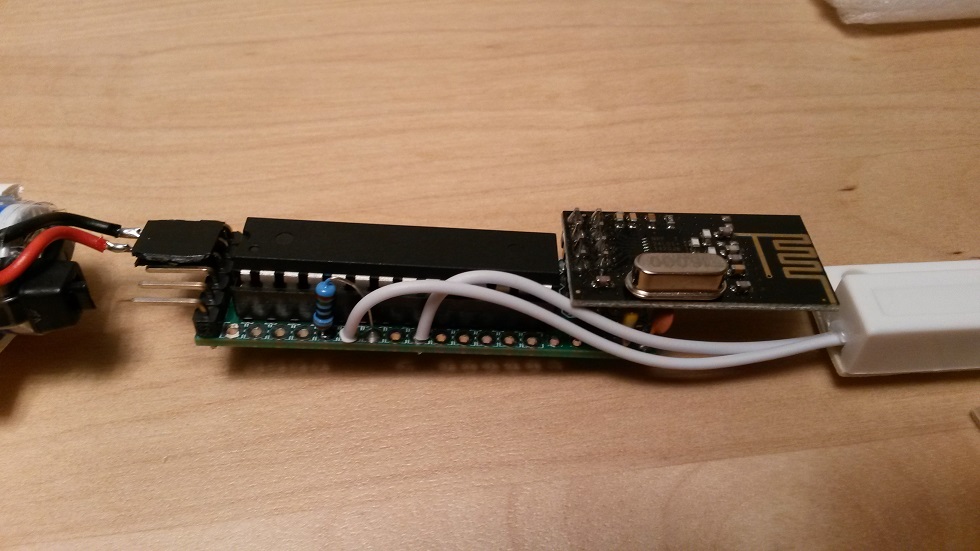

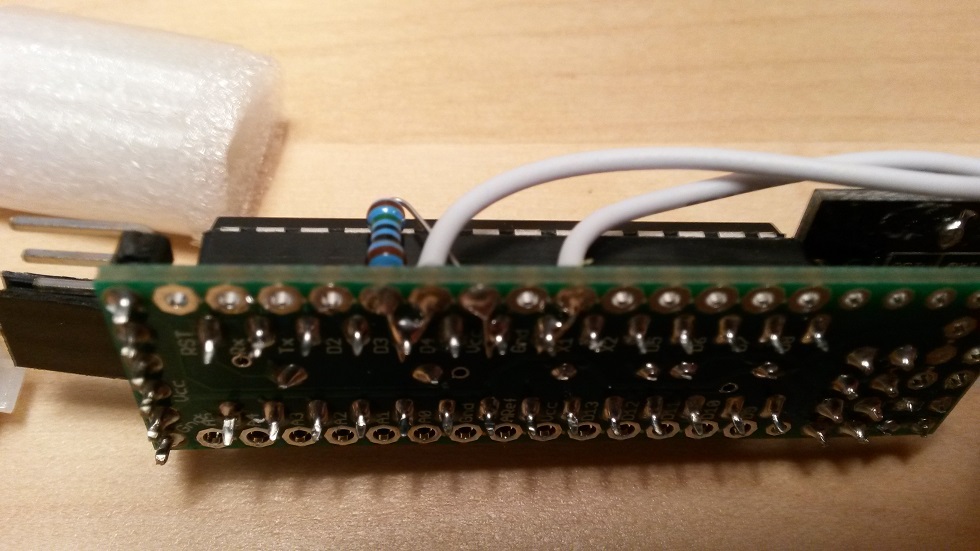

Hardware

A "bare bones" ATMega328p 28pin PDIP (with or without socket). Bought from here and here. My reasons to not use Arduino Pro Mini here are

- The APM width is too big.

- APM has no prototyping/near connection area. There's no spare pads for separate connections unless you accept to use pads connected to softwise inactive ports.

- Radio module connection has to be manually made to the APM.

- Low power hacks like removing power led and voltage regulator are needed.

- Necessary support components (resistors and capacitors) are few and can easily be added to a custom pcb.

Software

Since I prefer Arduino IDE for programming (flash) and debugging, I need a bootloader. Bootloader instructions are found all over the internet, but here's anyway how I do it. I use this precompiled bootloader from here. It's an Optiboot with 1MHz internal clock and 9600 baud serial communication. Fuse changed to BOD disable. According to this you should use minimal startup time to reduce power in every 8s sleep cycle, but for the moment I don't care and stick to the default 65ms. I use Avrisp mkII avr programmer for fuse and bootloading similar to this procedure. Arduino as ISP, Avr/USBtiny or whatever any other should of course be just as good. Avr Studio 4.19 is a good choice for Avrisp mkII (perhaps for others too) and 4.19 is the last version before the gigantic (and for me useless) IDEs were released.

I add this new board to my "boards.txt". Fuse settings, don't forget to set the lock bits. If programming a large batch, the ELF production file is handy.

Here's a great tutorial for those who use Arduino Uno as ISP.

UPDATE 1: Today (2017) a lot has happen since I wrote about this. Some things has made it easier for us. A very good selection of precompiled bootloaders is now found here at MySensors. And you don't need to (and shouldn't) mess with the boards.txt any more. Instead I recommend the installation of MiniCore to the Arduino IDE.

UPDATE 2: There have been reported issues with MySensors 2.x freezing on SlimNodes running at 1MHz, which I've confirmed. Recommended solution when using MyS 2.x, is to use 8MHz (internal) instead.

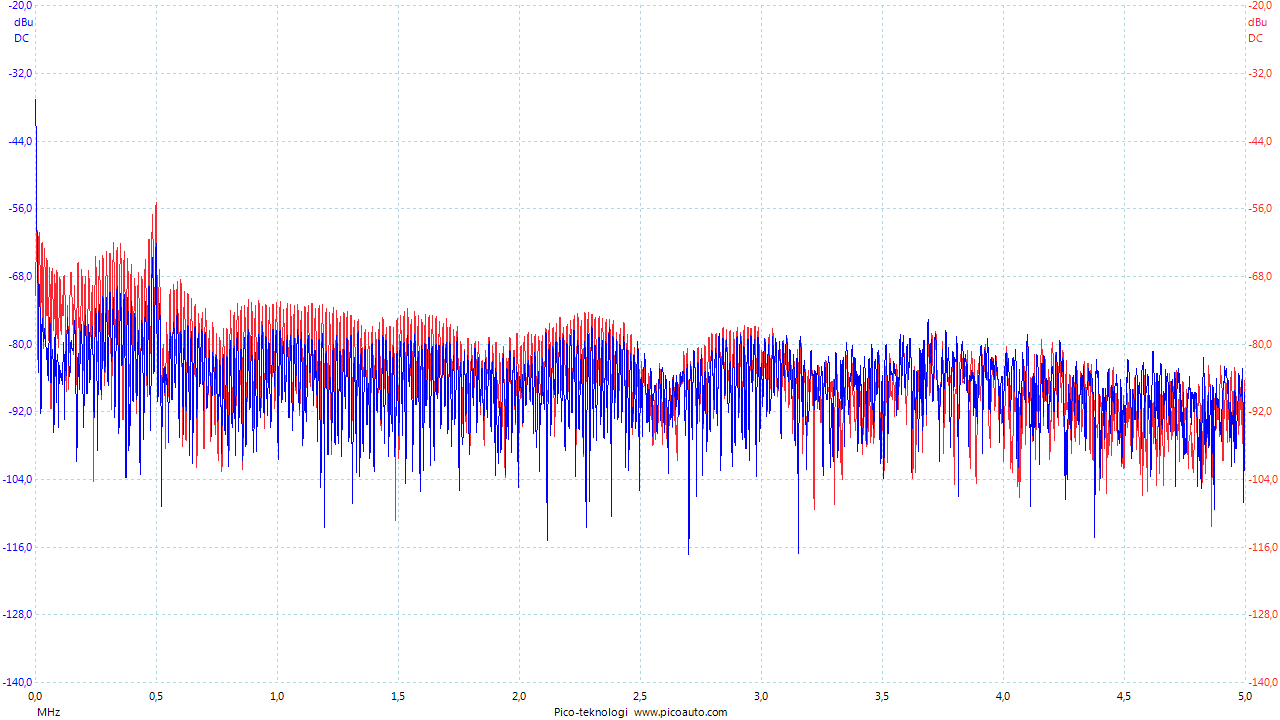

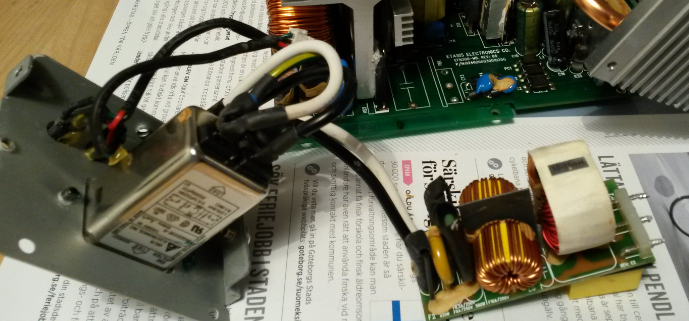

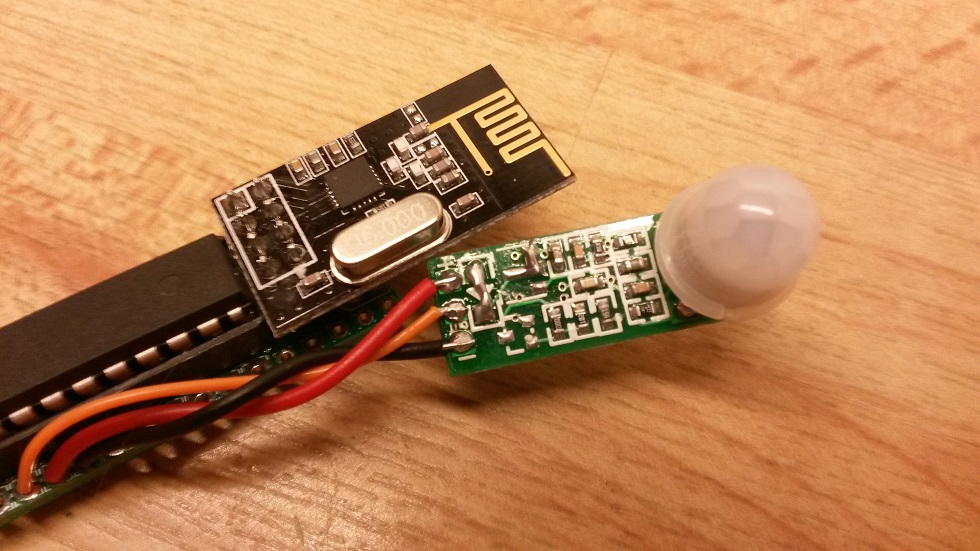

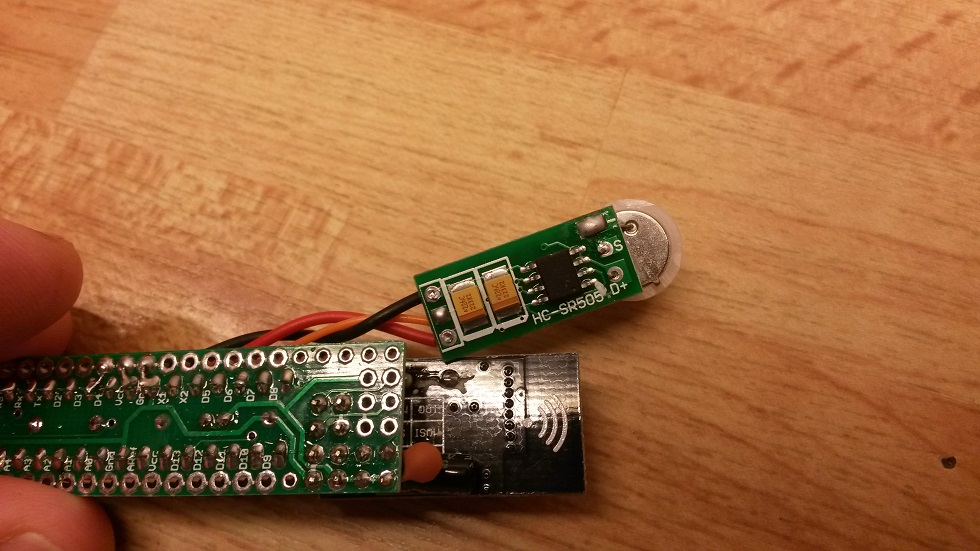

The Radio

A standard NRF24L01+ radio module is used. The width align with the AAs and no mods is needed (like with my other one). As always I try to keep the antenna part of the module free from shading metal.

2020-12-14: On using RFM69 - here's a hint from @joaoabs at this page: I've been troubleshooting this slimnode with RFM69 radios and realized that a shunt between RFM69's DIO0 and Mega328's INT0 is required, otherwise the node will not "hear" the gateway. Even if the nrf2rmf69 board is used this shunt is required. It seems this is a re-current issue

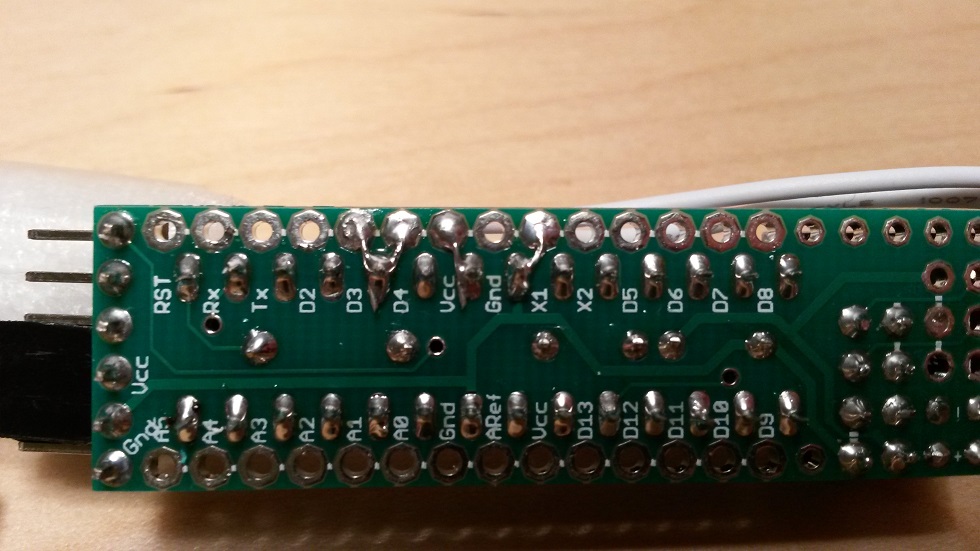

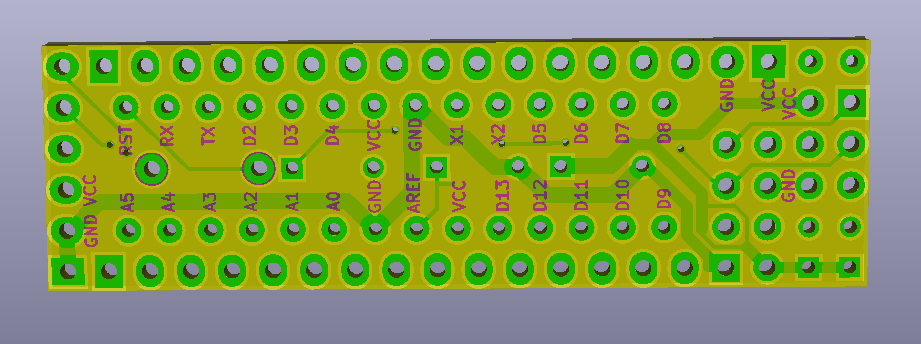

The Board

At first I planned the build on a proto board, just to stick to the cheap-and-standard concept. But with today's low prices on custom made PCBs, it wasn't any longer an option. Space, quality and work effort are so much more attractive.

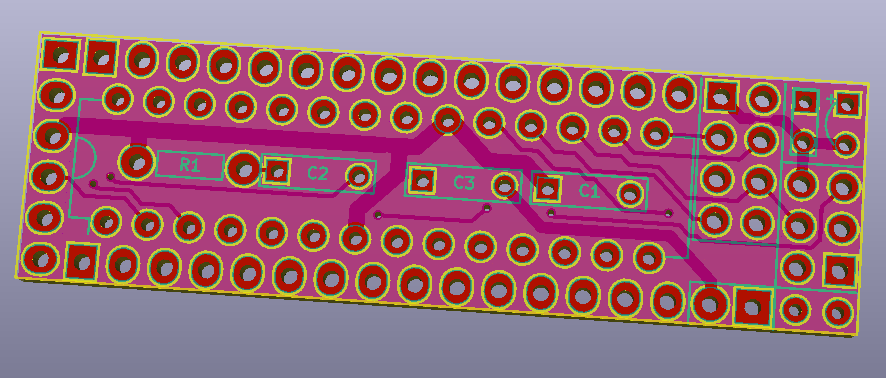

Latest design files are open and available at the openhardware.io site. Please click on the image-link below to access openhardware.io where all design files such as latest BOM, kicad-files and circuit diagram (pdf) are found.

https://www.openhardware.io/view/10/My-Slim-2AA-Battery-Node

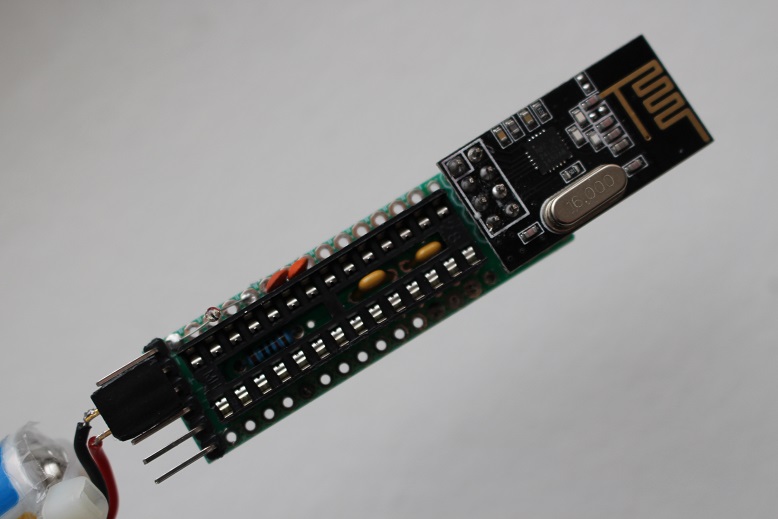

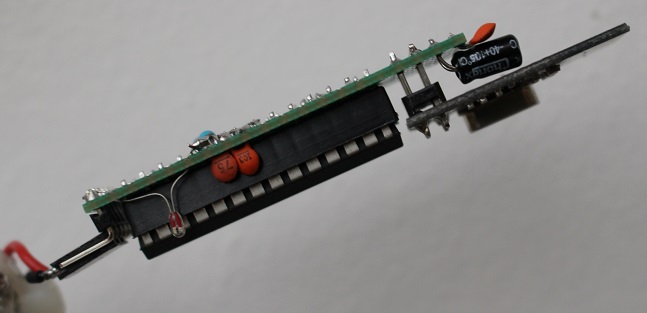

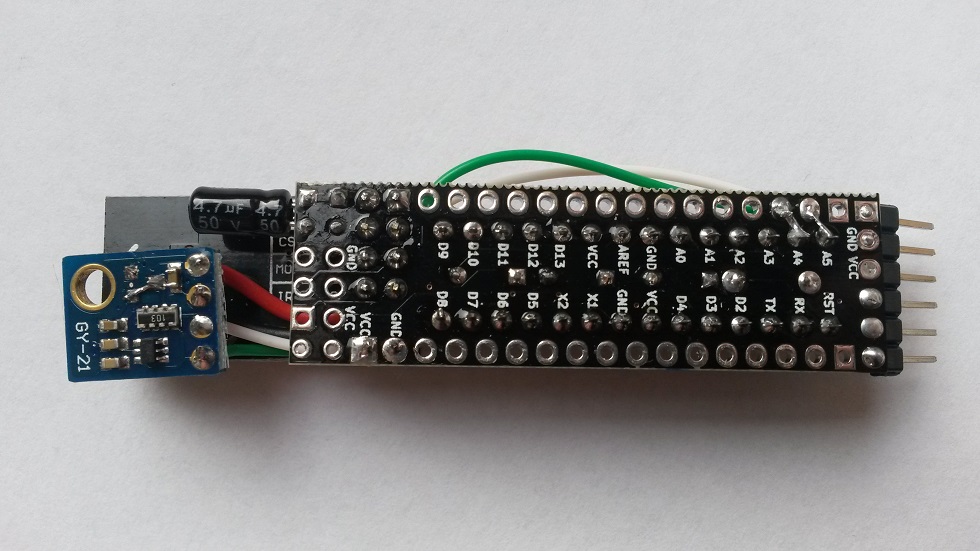

Board (v2.0) Top Side:

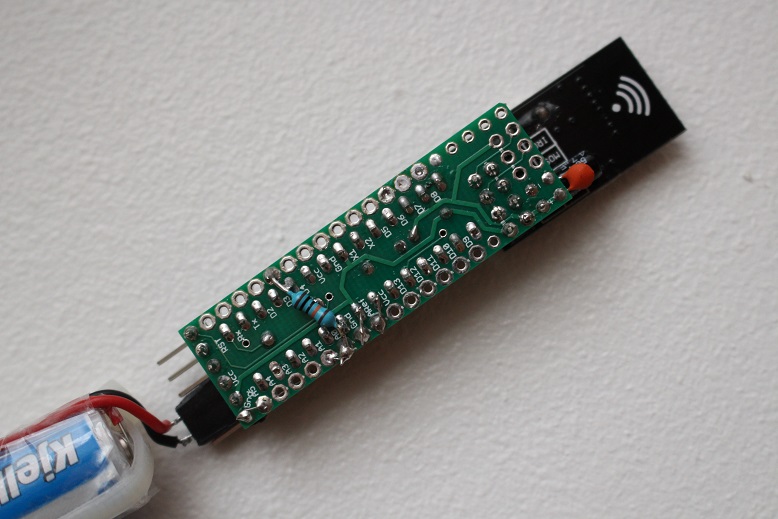

Board (v2.0) Bottom Side:

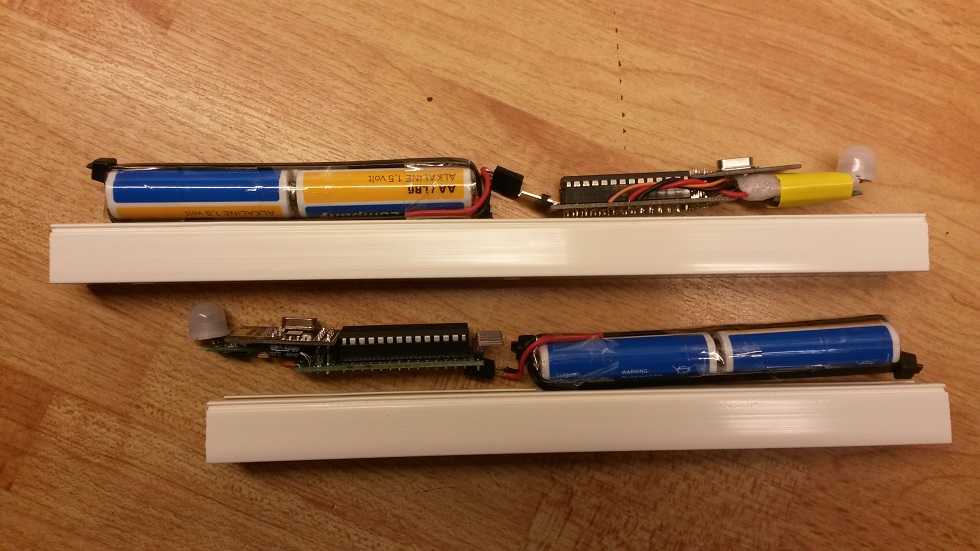

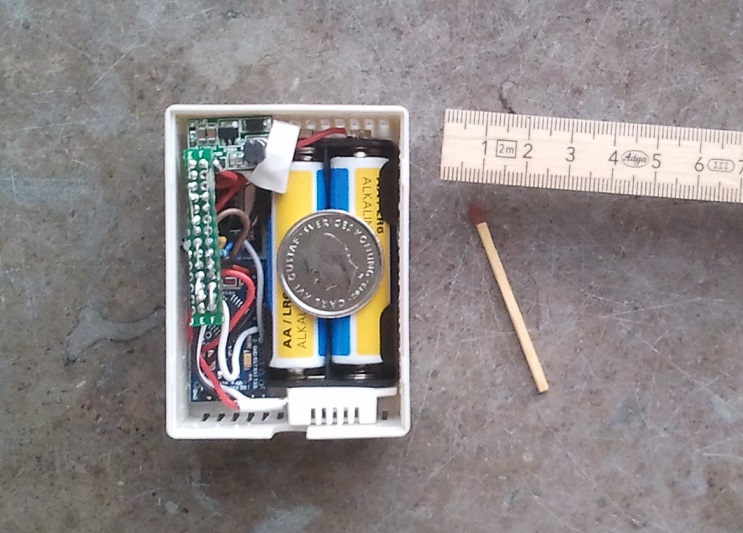

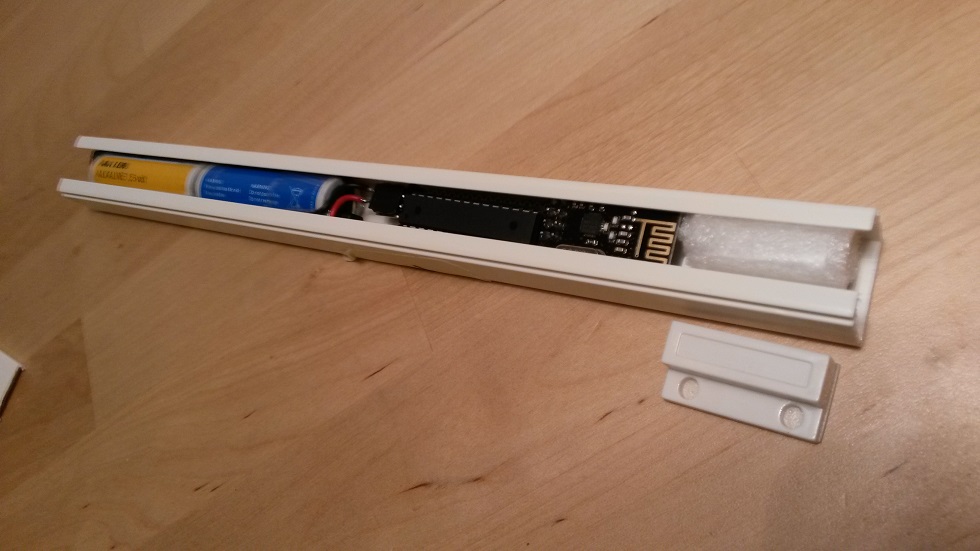

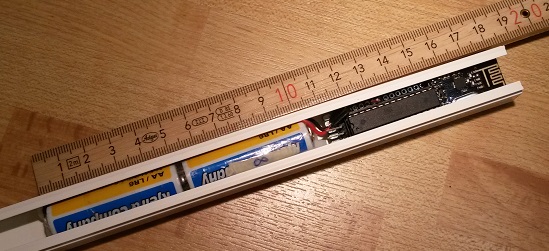

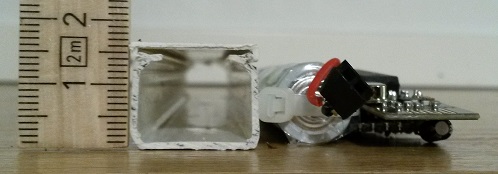

The Enclosure

UPDATE: If you dont't like my primitive casing descibed below, in this post the user @buxtronix made a nice 3D-printed case which you can find here.

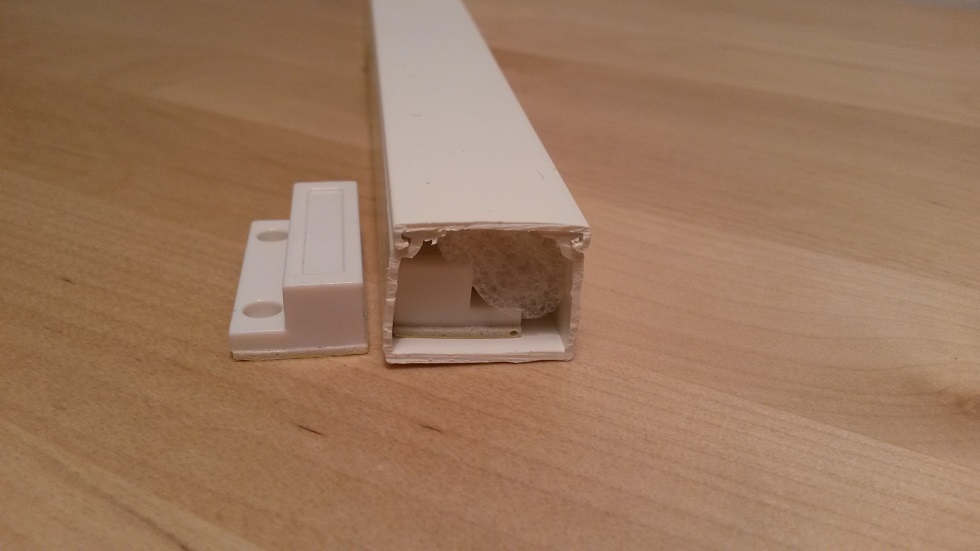

An important overall part of this design idea was to align minimum dimensions of the components and get rid of "expensive" parts like battery holder. It turn out (see below) that the enclosure's functionality as battery holder wasn't needed even though it was the initial idea. The cable duct case has been discussed earlier, but rejected by some due to lack of ways to seal the endings. I still haven't the perfect solution, but I've since many years simply used (cheap) white tape. With some care it looks ok, and still does 5-10 years later. There are often proper terminators/endings to buy, but for some reason to unrealistic high prices.

I used this cable duct with the dimension 17x20mm. Unfortunately it turned out that this particular type I used (Thorsman TMK T20) is now "professional grade" and dimension 17x20 is no longer very commercially available for consumers (here in Sweden at least). Eg. to get it, you have to pay >5$/m from places like this or buy it in bulk (50m) from a professional store (preferably as a professional with discount). The 50m bulk batch will give you 263 sensor nodes of standard length (19cm).

Standard consumer dimension cable duct is e.g. 15x15mm from what I've seen. It'd be nice to design a 2AAA node in that one. If only there is a thin radio module? (Future project.)

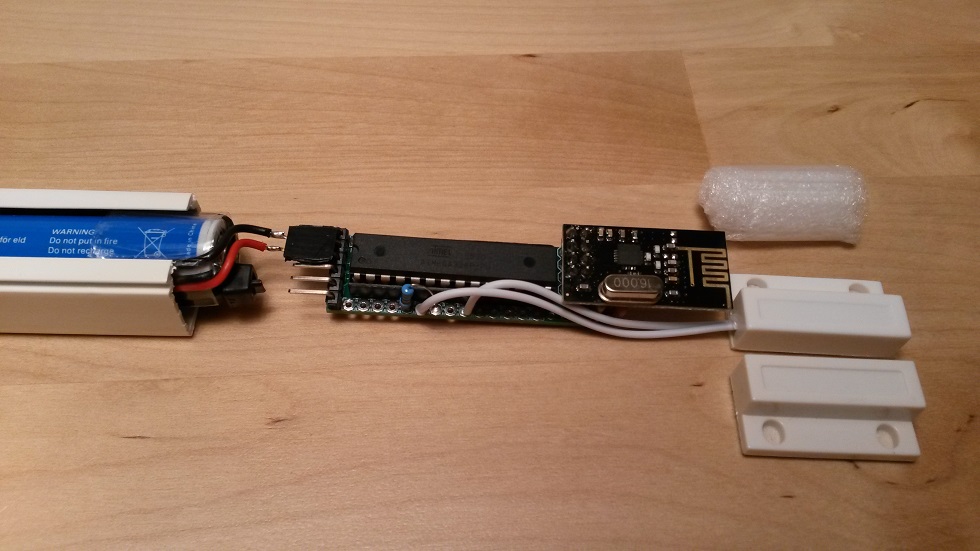

The Battery pack

Easy home made 2AA battery pack. Maybe it looks more demanding and time consuming than it is. (Usually its the other way around in my experience.)

- Start by taping the two (connecting) batteries together.

- Prepare the wires and make a small bun at the battery connecting ends.

- Attach the wires with tape.

- Tighten the cable ties and carefully note

- that the wires are pressed to make good contact with the battery poles

- how the cable tie ends must be placed to not steal lateral space

- that the wire from the bottom must be routed near the cable tie to not steal space.

- Make the pack more rigid by taping one or two times around at the top, bottom and middle.

- Trim wires and solder the female connector. If desired, leave at least a small part of one wire naked for current measurements.

A battery change is done fast when cables a already made (use solid wires that preserves its shape). So why pay for a battery holder when you can remake a pack with fresh batteries in 1-2 min and your low power sensor will live 5-10 years before anything needs to be done?

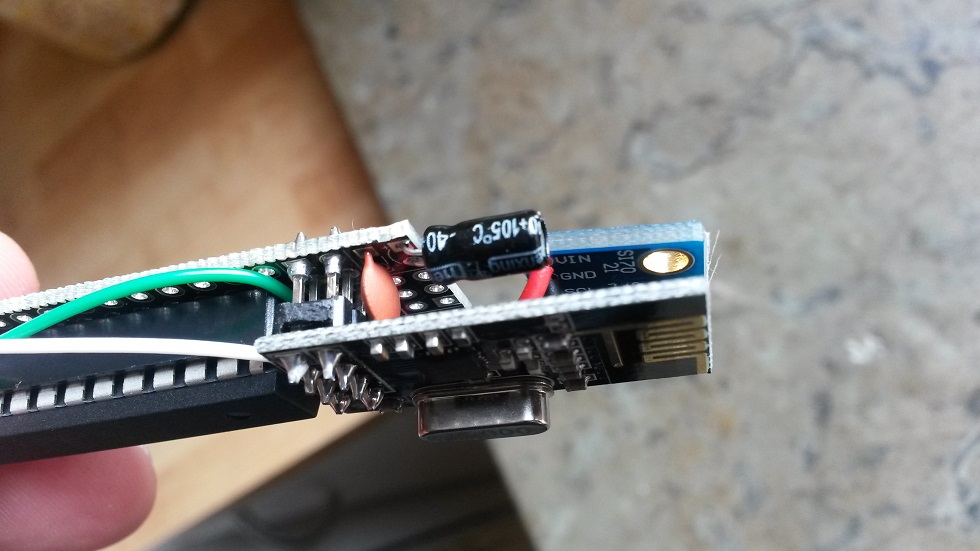

The Interface/Connections

Convenient there's the 6 pin standard serial interface exactly like on the Arduino Pro Mini. Perhaps it's mirrored here, but I think everybody double checks Gnd and Vcc before connecting. The Vcc and Gnd pins also serves as a connector for the battery pack. (CTS is connected to GND on the PCB.)

"Under" the radiomodule are pads for the ICSP pins. The idea was to have a socket for the radiomodule instead of the "expensive" 328p socket and still have easy future access to the SPI/ICSP interface. Perhaps not very useful. But nice to have Gnd and Vcc in this end of the board for general purpose.

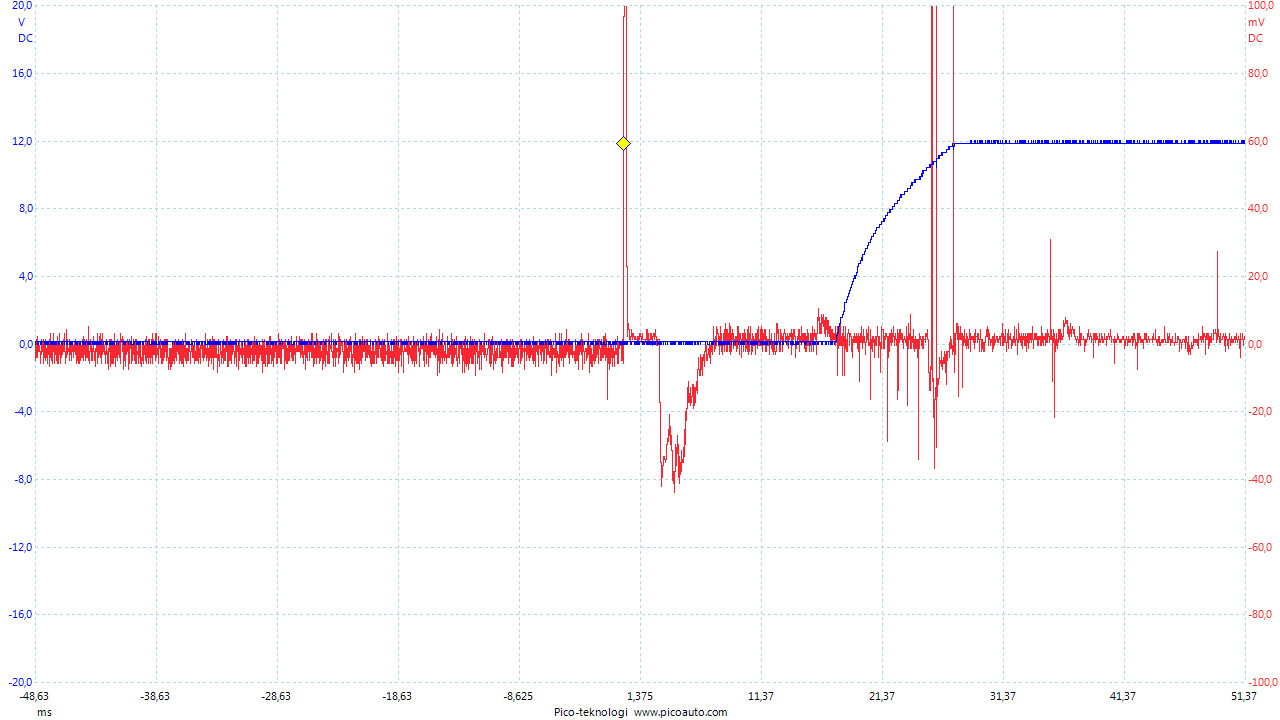

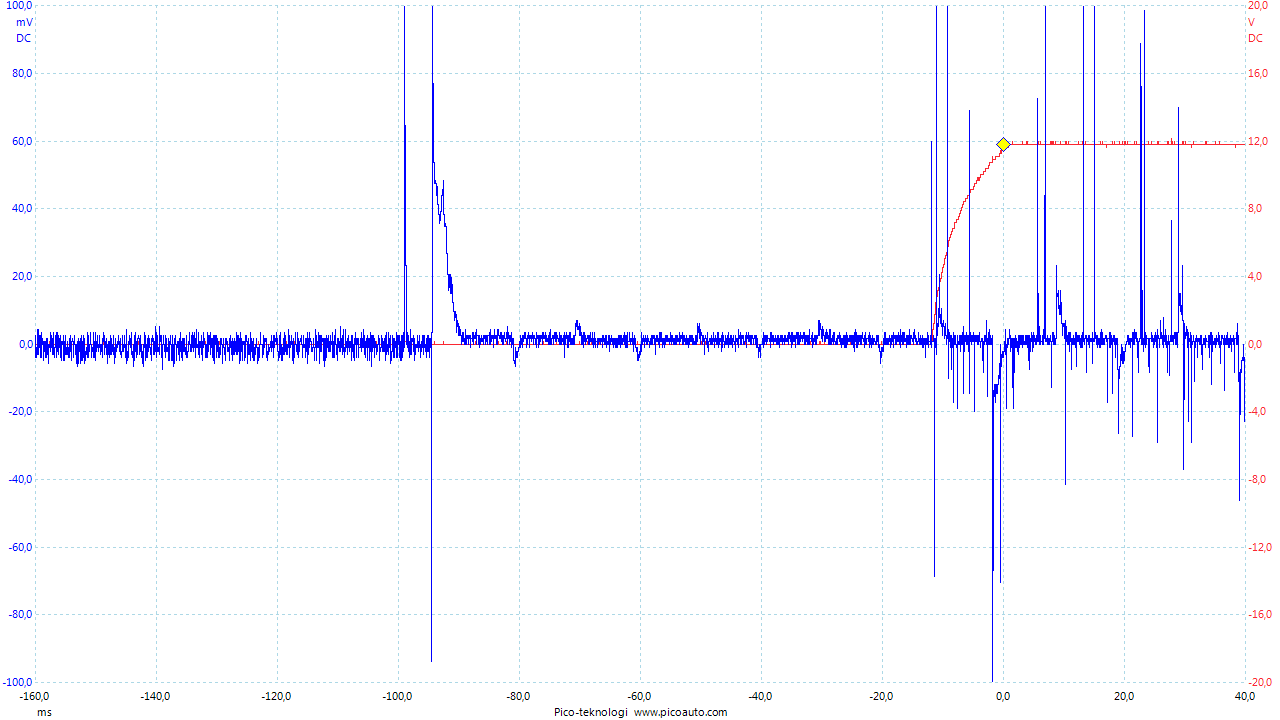

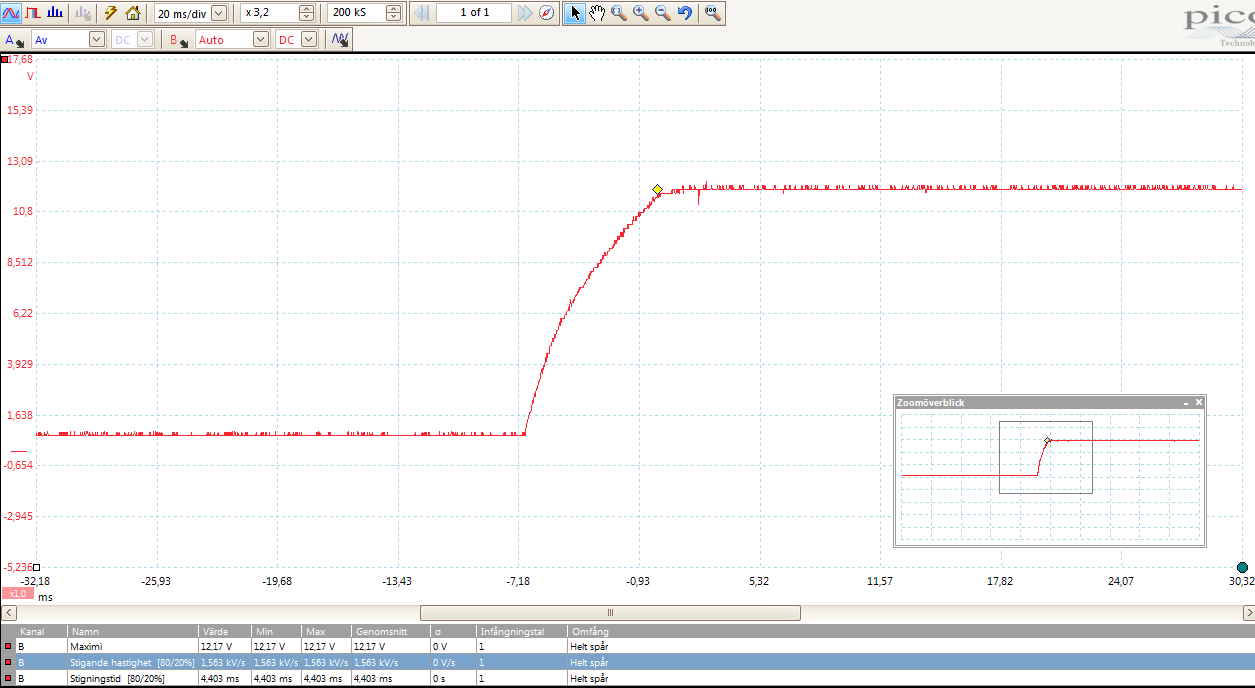

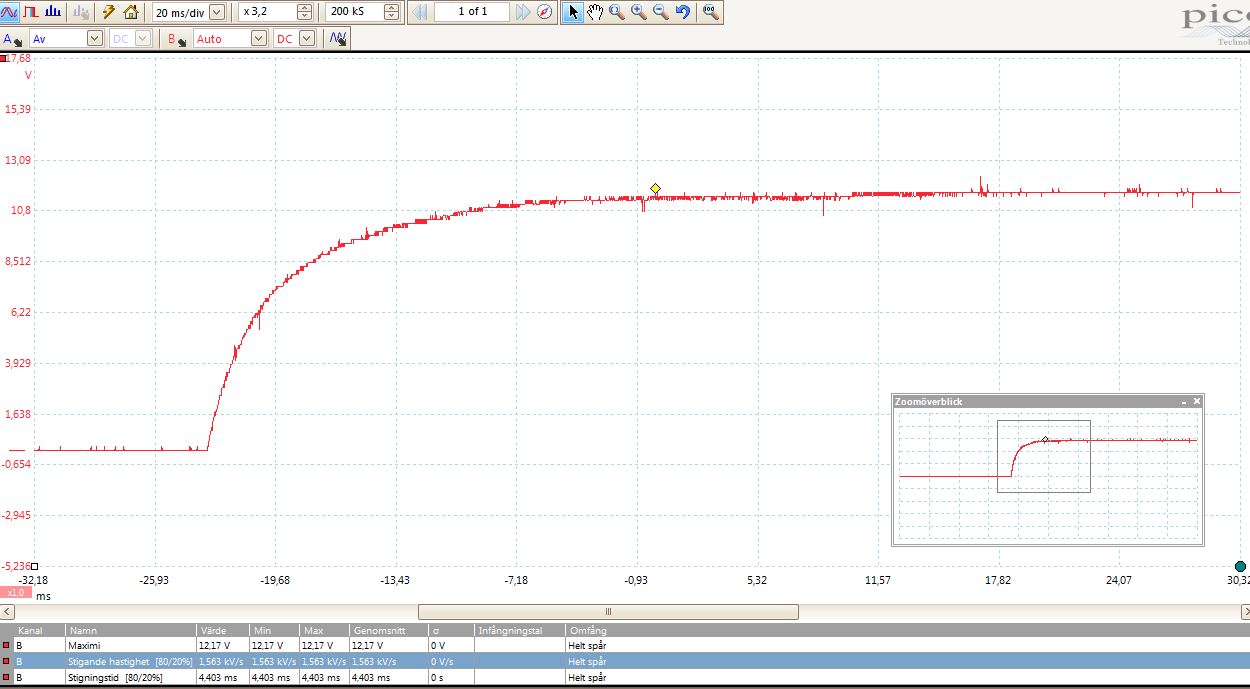

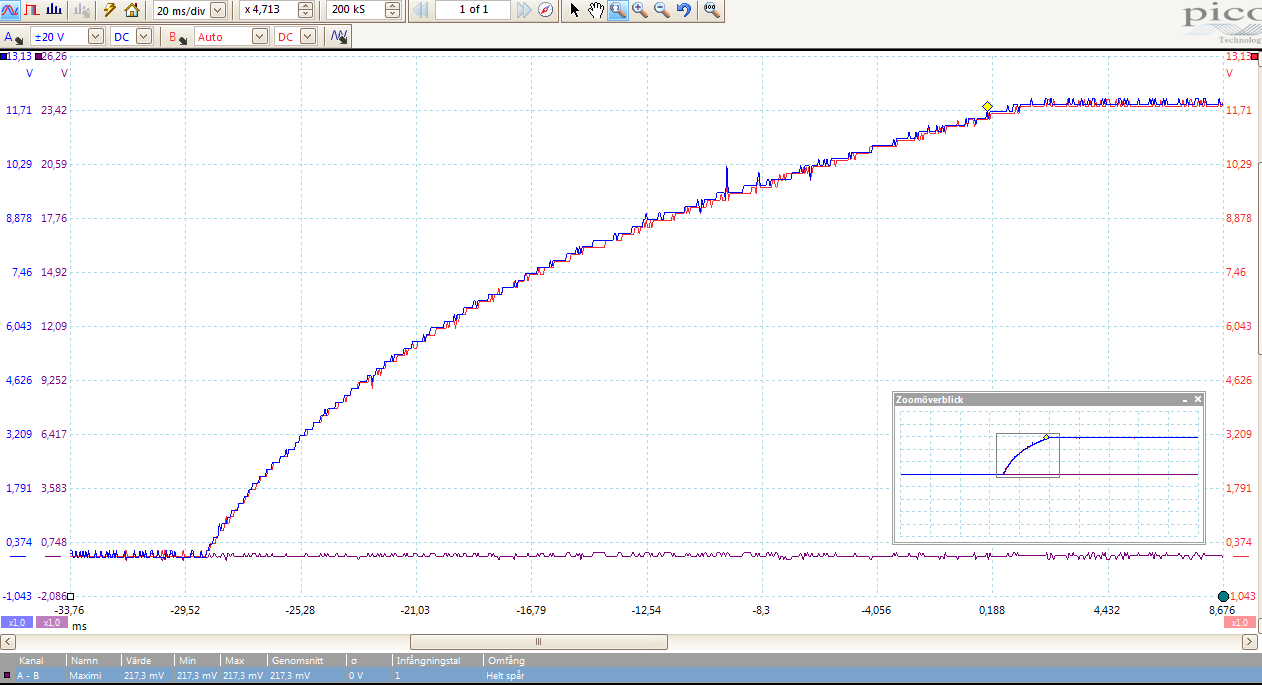

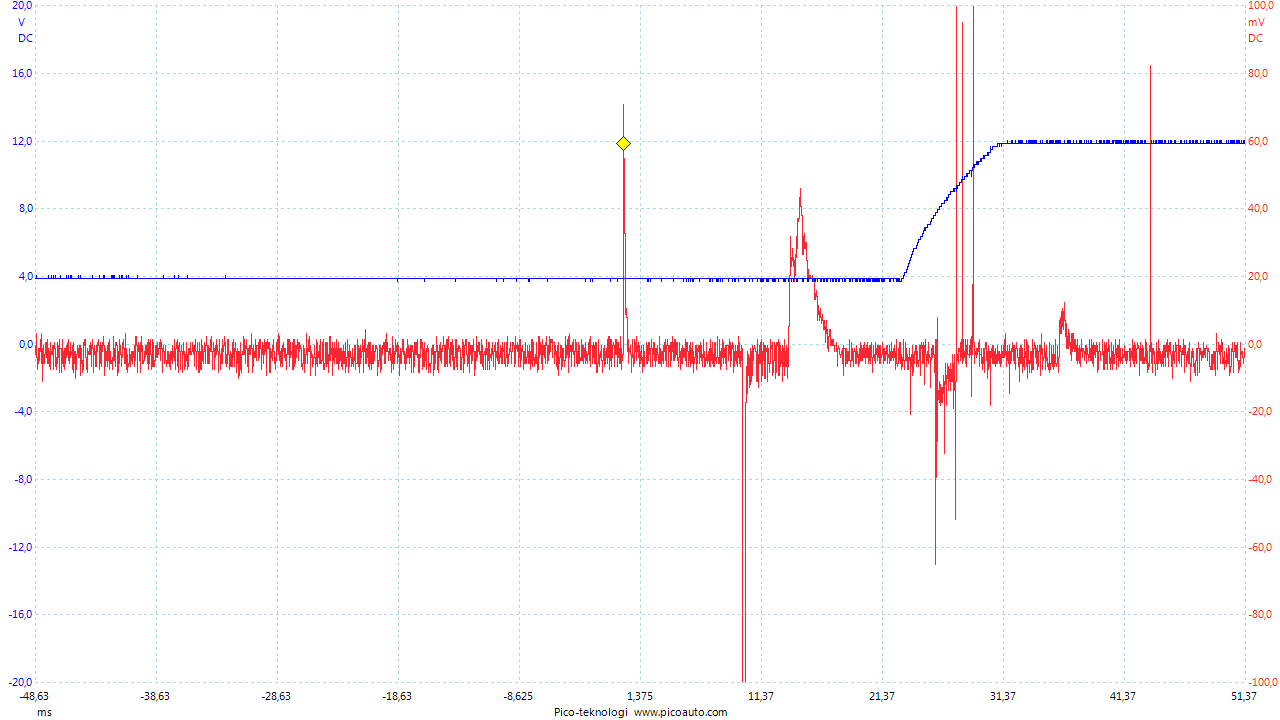

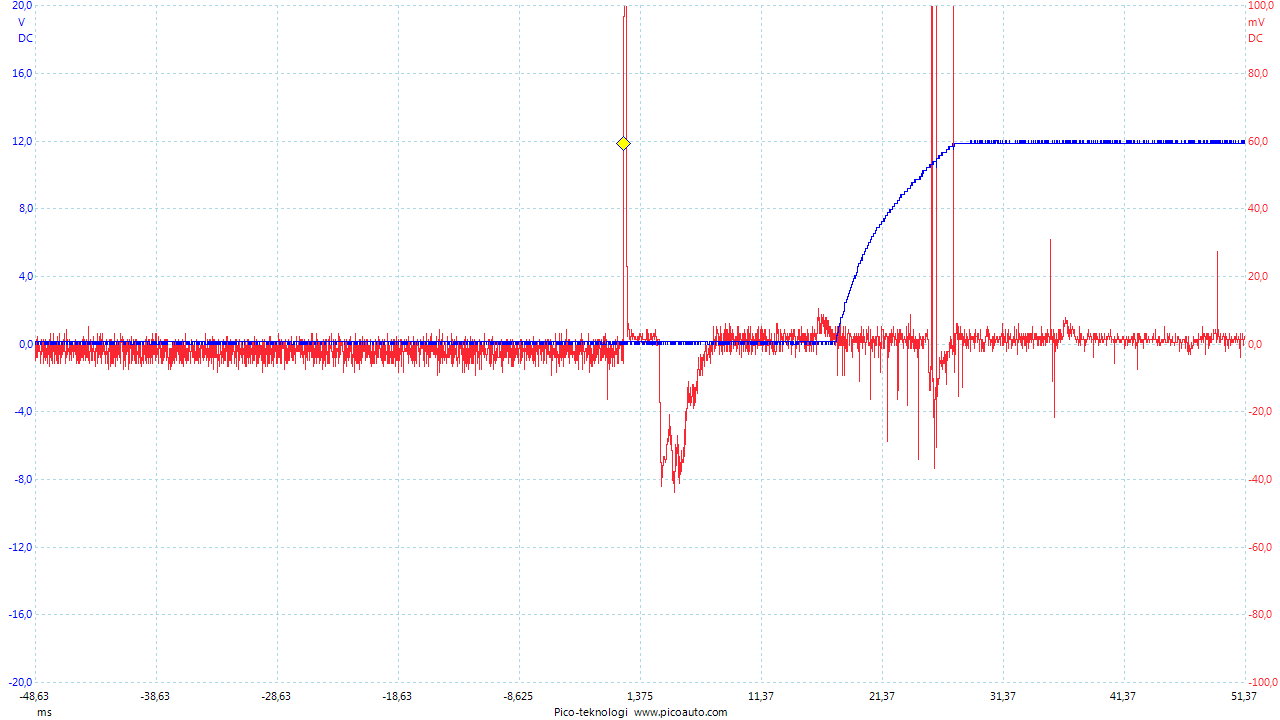

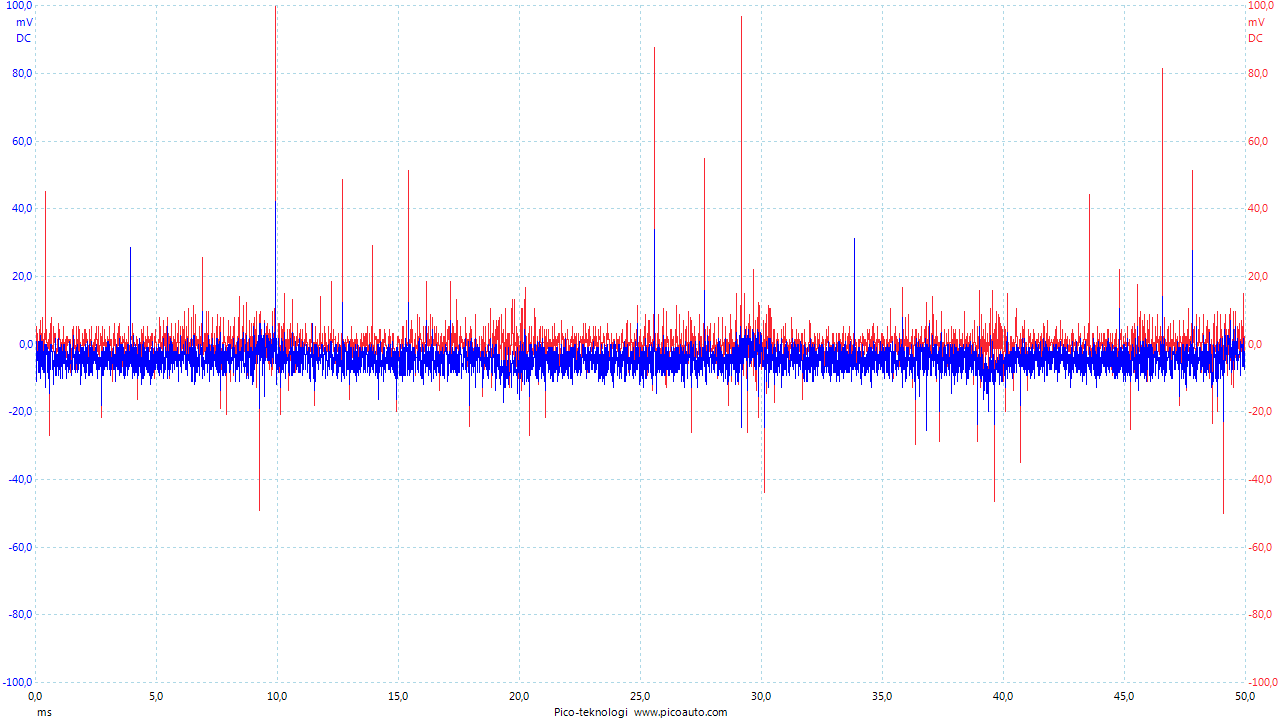

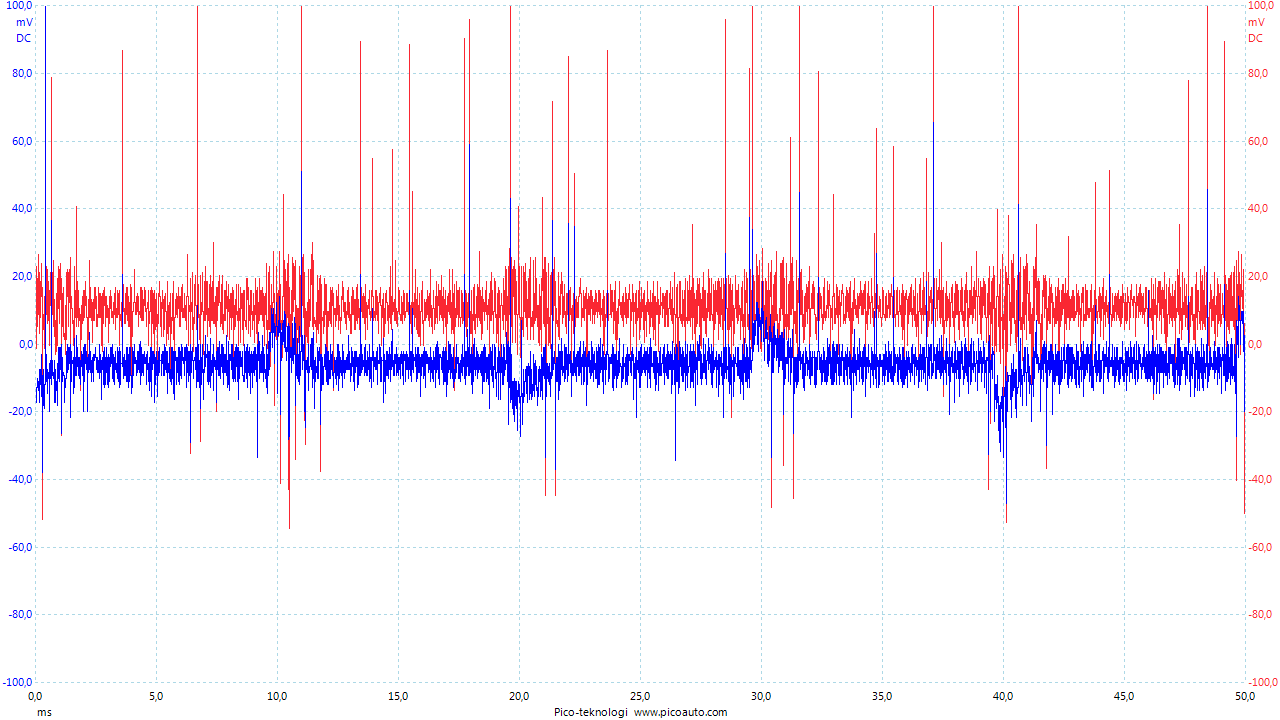

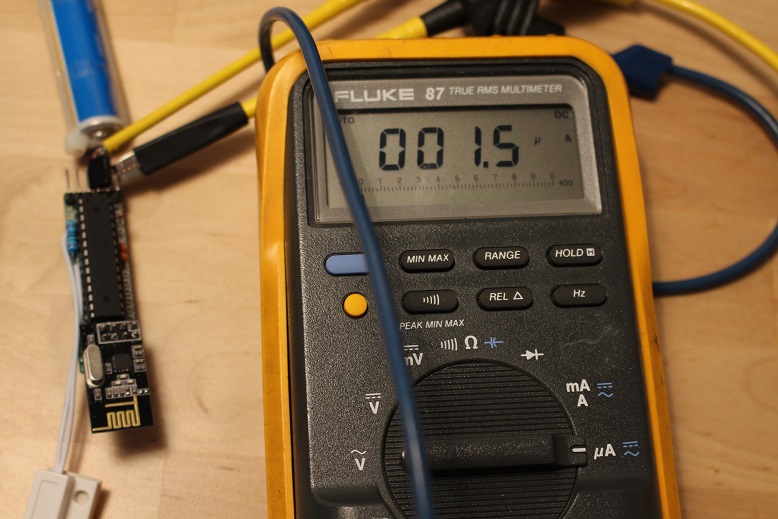

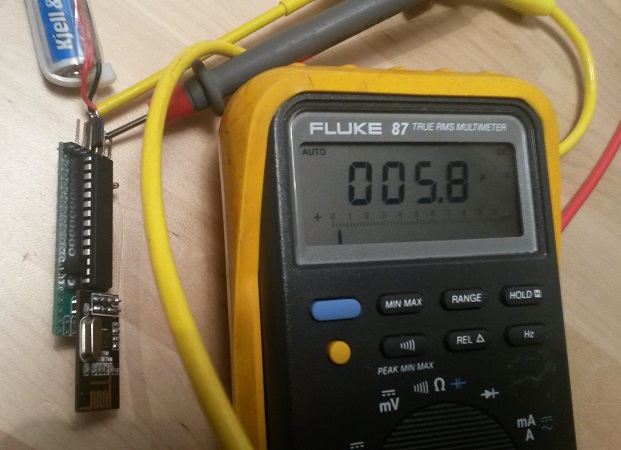

The Sleep Mode Power Consumption

I measured the sleep mode current draw to be 1.5uA when it's set to interrupt wake up and 5.8uA when it's set to timer wake up.

Sensor Examples and more

Reed Switch Sensor: post 116

Humidity Sensor: Slim Node Si7021 sensor example

Motion Sensor 1: Slim Node as a Mini 2AA Battery PIR Motion Sensor

Motion Sensor 2: Slim CR123A (2AA) battery node..

Scene Controller: Slim Node scene controller/ keypad

(work in progress to collect more examples here)

Not Sensor exemples, but some nice to see "node variations" from @AWI:

Here (post 88) and here (post 233). And now there's also @AWI 's My Slim 2AA Battery Node Tools.

Still not "slim" enough? Check out Very Narrow and Minimal Switch Node ! by @GertSanders

And also, there's this 5V-slim-node a 5V-slim-node mod by @Soloam

Feature Requests

Here's a collection of suggestions and development ideas for future versions of the board (or other parts). If anyone else make their own board where some of this is included, I'd be happy to reference it from here.

- Pin labels/references also on board top side.

- Turn the nRF footprint to make the assembly shorter.

- Make the board suitable for the nRF SMD version.

More Pictures

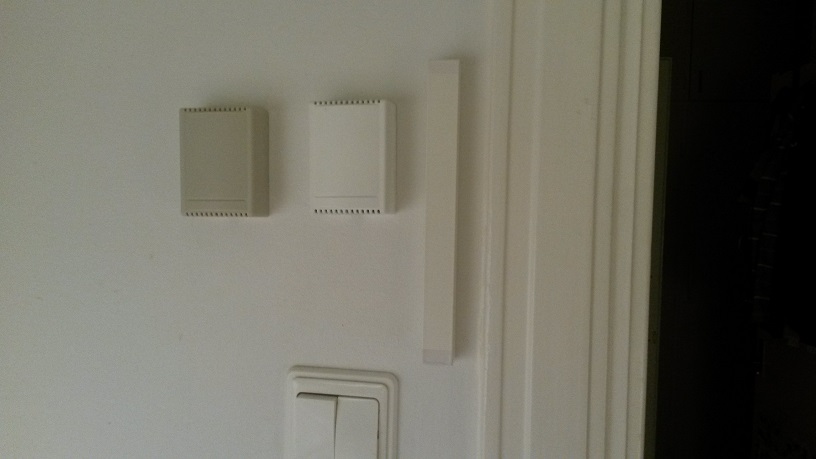

Some photos. First a comparison next to My (old) 2AA battery sensor, one painted and one not. (Note the high WAF of the colour even without the paint.) Then some placement examples. Reed switch nodes for all my doors and windows are my first priority.