@iotcrazy It is Jeedom, you can find some information here: http://www.mysensors.org/controller/jeedom

It use an RPI2 if you ant to make it yourself, and a major version will come during the week !

Pierre P

Posts

-

Sensebender Micro + button -

Sensebender Micro + buttonI can't tell you for the moment, I haven't check the real voltage of the CR2032 at the beginning. I'll try to make two mesure between 30 days.

But my sketch is 1800000ms or 30min sleeping (if no-one press the button). Because it's a redundant information, my Jeedom controler have a meteo plugin who's working good. (i'll use it for the mini-night-temperature to have a message if there is glass on my car's windows). -

Office plant monitoringMy node doesn't work anymore. Even with new set of accus. I will check again when I'll solder it.

-

Office plant monitoringA week.

New accus i think. I do it again but this time, i'm making voltage report with my voltmeter and a picture. -

[security] Introducing signing support to MySensorsThanks for the complet answer !

-

Office plant monitoringI'm already at 2.73Volts on my two AAA batteries. Is the last sketch a batteries killer ? With a 10 hours sleeping ??

-

[security] Introducing signing support to MySensorsIsn't blacklisting cool too to use ?

Like, if we know the "name" of the sensor lost, we push it to the black list and voila ? This way, we don't have to put a long list a agreed sensors if we have only two nodes outside the house.

... I think. -

Making a dual radio repeaterToo bad, way out of my ability...

-

Making a dual radio repeaterThanks for the answer.

May we trick and use two arduino talking via serial ?

My controller doesn't support two gateway yet. -

Making a dual radio repeaterHello everyone,

I would like to make a repeater with tow radio, because my gateway is 2.4Ghz, but i wan't to put outdoor sensors in 433Mhz.

BUT: as i'm not english native, i may haven't found the keyword to find this kind of project into the forum, is there anything like this ?

Thanks, and have a good day !

-

Battery button sensorOh YES it is a great project !

-

Safe In-Wall AC to DC Transformers??Do you want some tips to make "safe" crash tests ? Like putting it in a closed electrical box and switch on and off an old vacuum with no electronic ? Or make a shortcut make the relay ko... Because you cannot test that if you don't have a good electrical installation at home...

-

In wall LCD Switch/Scene controller for MySensorsThanks for the fast answer, I was thinking that you haven't used the "big" HLK. But, it seem it's there !

Sorry ! -

In wall LCD Switch/Scene controller for MySensorsSeem nice !

And look like a KNX clim controler.Do you have a topic talking about your 230Vac/5Vdc solution ?

-

[example] GPS Sensor@drock1985 said:

Hey @Pierre-P

Yeah, you would need a new gateway for each radio type.

I found a new mysensors page ! here:

https://www.mysensors.org/download/sensor_api_15#create-repeating-nodesAdvanced initialization

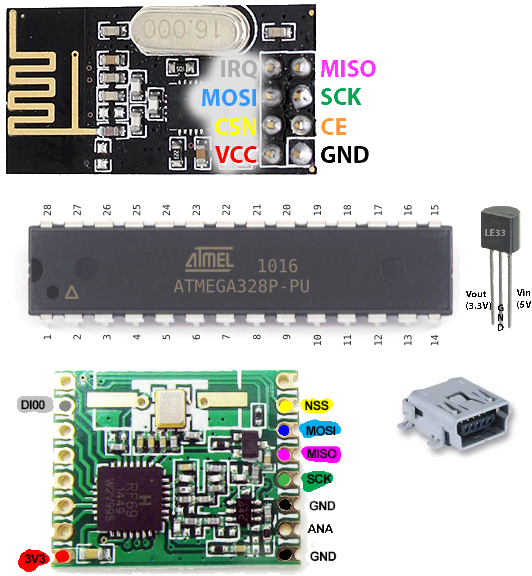

It's also possible to construct an instance with RFM69 radio driver and/or enable signing support. You can choose one of the following radio drivers:

MyTransportNRF24 transport(RF24_CE_PIN, RF24_CS_PIN, RF24_PA_LEVEL_GW);or

MyTransportRFM69 transport(RFM69_FREQUENCY, RFM69_NETWORKID, RF69_SPI_CS, RF69_IRQ_PIN, isRFM69HW, RF69_IRQ_NUM); -

"Internet Of Things" Security is hilariously broken and getting worseFor instance, with "orange" internet provider, i know how to redirect the port :1234 from internet to :80 intranet... but only once.

This is cool for 1 non editable port.

Sadly I don't think we can close the :80 port. It is (was) used by all the chat software.For the rest: never keep the box-user, never keep the box-software, try to never keep the box-ports. The bad guys KNOW this things. For a old but still used automation-device (witch can control big companies) it still the box-parameters. So... easy to enter into the programs.

It was the same for Americans money distributor !!! (now, the have a random password when send to the client) -

"Internet Of Things" Security is hilariously broken and getting worse@sundberg84 said:

I have a log on my controller port and get login attemps from tor routers a couple of times each week but its probably bots since they move on quickly.Could changing the default port ( :80 ) by something else be a good start ?

-

Power from flowing waterThis is not the same. The very first video can power out a big power. Then there is a box transforming it into 230Vac (or 110Vac) 50Hz.

The same box as for photovoltaïque or wind turbine.Then you have you product, who is only for low power device (like ours). But cannot feed an house.

Still, it can be cool for many mysensors device outdoor. -

Infrared Temp Sensor@Pierre-P said:

@scalz water temperature ? For baby bath ? I'll check if it work with my next coffee. Let me find my ir sensor.

For science !

https://www.youtube.com/watch?v=NPzUHAgRijc

ps: yes it's working -

My Slim 2AA Battery NodeI've made it with that link: http://www.gammon.com.au/breadboard with no cristal.