My Slim 2AA Battery Node

-

@m26872 I am fairly sure that all methods work in normal cases but nothing worked for me fore some reason :) .

The only way I could get it to work was when I finaly put the chip in an Arduino Uno clone with 328p Dip(?) socket and connected an USBtiny ISP to the ISCP of that Uno. It took just a couple of seconds and then it was done :).

I flashed like 6-7 ships right away with bootloader and blink-sketch just for fun. Biggest problem now is to get the damn chip in/out of the sockets without bending any legs. But I ordered a chip extractor to remedy that problem (in 4-6 weeks :()

-

@m26872 I am fairly sure that all methods work in normal cases but nothing worked for me fore some reason :) .

The only way I could get it to work was when I finaly put the chip in an Arduino Uno clone with 328p Dip(?) socket and connected an USBtiny ISP to the ISCP of that Uno. It took just a couple of seconds and then it was done :).

I flashed like 6-7 ships right away with bootloader and blink-sketch just for fun. Biggest problem now is to get the damn chip in/out of the sockets without bending any legs. But I ordered a chip extractor to remedy that problem (in 4-6 weeks :()

@Cliff-Karlsson

:thumbsup:To get the ICs out from the DIP socket, I just use a small screw driver (2-3mm) and gently push it all the way under from one side only. And of course, don't push in the IC to hard to begin with.

-

@m26872 I am fairly sure that all methods work in normal cases but nothing worked for me fore some reason :) .

The only way I could get it to work was when I finaly put the chip in an Arduino Uno clone with 328p Dip(?) socket and connected an USBtiny ISP to the ISCP of that Uno. It took just a couple of seconds and then it was done :).

I flashed like 6-7 ships right away with bootloader and blink-sketch just for fun. Biggest problem now is to get the damn chip in/out of the sockets without bending any legs. But I ordered a chip extractor to remedy that problem (in 4-6 weeks :()

@Cliff-Karlsson

You shall buy Textool ZIF socket. not sure which fits your Arduino, If you at some point get's lazy (Solder less, and accept to use a little more space) and use Arduino Pro Mini then textool 224-3344 ZIF will be your friend -

Hi all, I'm seeing replies, but I'm not sure if any are aimed at my question? I think not?

-

Hi all, I'm seeing replies, but I'm not sure if any are aimed at my question? I think not?

@rsachoc

I've started a new thread aimed at your question. I'll soon delete much of the content in the post you based your question on and refer to the new thread instead. -

@meddie I don't use any of it myself yet, but I know it's only a matter of time until they'll be needed. I think a add-on board to all already existing nodes would be my personal priority then, but new users would prefer it on-board of course and only populate if needed. I'll put on my not yet posted future requests list. (I remember top-side labels are also wanted.) A thing to remember though, is that my Slim Node design is a concept was a lean and simplicity concept, without preparations for maximum flexibility etc.

As I've said earlier - if anyone like to do their own Slim Node design, you're very welcome. And if you share it, it's even better.

-

@m26872: slowly getting there: http://forum.mysensors.org/topic/3043/new-nrf24l01-smd/14

-

What i like on this node is the great idea with the casing. To use a cable duct is a great idea. We have wooden windows and i found in a diy market cable ducts in wooden look

like this:

The Problem is that the size is 15x15 mm outside. inside the pcb can be max. 13 mm.

-

What i like on this node is the great idea with the casing. To use a cable duct is a great idea. We have wooden windows and i found in a diy market cable ducts in wooden look

like this:

The Problem is that the size is 15x15 mm outside. inside the pcb can be max. 13 mm.

-

@m26872: slowly getting there: http://forum.mysensors.org/topic/3043/new-nrf24l01-smd/14

@GertSanders Good job! If you go the SMD way I think a lot could be done. Perhaps matching AAA width? Leave some (only few) SMD pads open for sensor connection, no proto area, etc.

-

Currently this is my favorite board. Minimal size, traditional components and just enough breadboard space. A few variations:

Soldered an 8 mHz resonator (a 'crystal' which does not need the capacitors) for a more stable clock.

Soldered a 3.3v LDO (662k) under the radio to have it powered with a rechargeable Lipo (4.1V max) battery. And added a voltage divider to measure the actual battery voltage.

With a SMD version of the radio. Needs some creative soldering...Compared to an other favourite ( @GertSanders )

It would even be better if the smd radio could be soldered on the board. Kicad is giving me a headache so if anybody wants to volunteer with a panelized design.... (I will reward you with a free batch of 'dirty' boards, just drop me a pm)

-

AA batteries are 14mm in diameter. AAA batteries are 10mm in diameter.

I have single AAA batteryholders which are 13mm wide at the base, and including a battery they are 13mm high at the highest point.

LEGRAND sells 16x16mm cable ducts (http://www.ecataleg.be/fr/category/2751/16-x-16), which is what I plan to use, but the 15x15 ducts should work as well.

-

@GertSanders Good job! If you go the SMD way I think a lot could be done. Perhaps matching AAA width? Leave some (only few) SMD pads open for sensor connection, no proto area, etc.

@m26872 I'm trying to make a full SMD board with the smd variant of the nrf24.

So far, my first design is a 21mm square.

I have been thinking about a long 13mm x 100mm variant. That would allow plenty of space, at least 1 AAA, but more importantly would allow panelisation when combining with a 13x100 board for two AAA battery holders.

This would give 3 sensor nodes + 3 battery holder boards in one 100x100 panel, or 6 sensor boards if we use your technique of "ty-wrapping" batteries.

-

A couple of more questions. In one of the pictures at the top the electrulyte 4,.7 uf capacitator is placed closer to the atmel chip and the 0.1 uf (c5) is placed closest to the edge does it matter witch capacitator goes where?

The 10k resistor should be 1/4 or 1/8 W according to the bom. I had some small 1/6 W 10k resistors can I use them? I also have some bigger blue 10k resistor that I do not know the W rating on.

Where did you purchase the female pin-header that are used for the chips? I have some atmega chip-sockets that are quite narrow and it is hard to fit the components underneath. I also have some other female pin-headers but they are atleast twice as high than the ones in the pictures.

-

Currently this is my favorite board. Minimal size, traditional components and just enough breadboard space. A few variations:

Soldered an 8 mHz resonator (a 'crystal' which does not need the capacitors) for a more stable clock.

Soldered a 3.3v LDO (662k) under the radio to have it powered with a rechargeable Lipo (4.1V max) battery. And added a voltage divider to measure the actual battery voltage.

With a SMD version of the radio. Needs some creative soldering...Compared to an other favourite ( @GertSanders )

It would even be better if the smd radio could be soldered on the board. Kicad is giving me a headache so if anybody wants to volunteer with a panelized design.... (I will reward you with a free batch of 'dirty' boards, just drop me a pm)

@AWI said:

panelized design

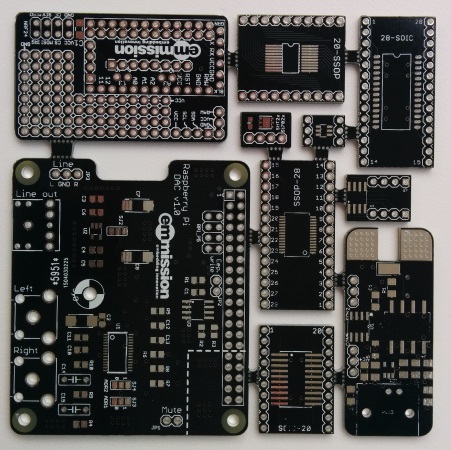

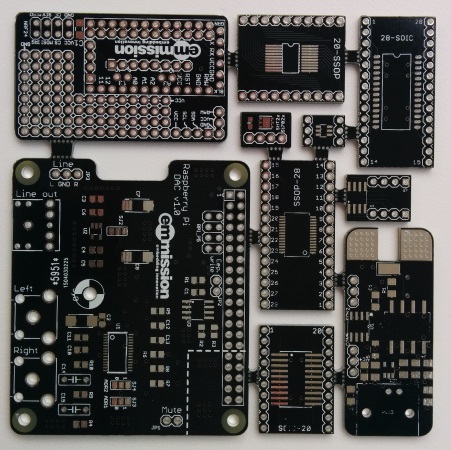

If you're struggling with panelizing boards I can recommend the excellent gerber tools from Stijn Kuipers.

It allows you to create designs like this (10x10cm, DirtyPCBs):

Drop him a message and he'll send you a download link.

-

@AWI said:

panelized design

If you're struggling with panelizing boards I can recommend the excellent gerber tools from Stijn Kuipers.

It allows you to create designs like this (10x10cm, DirtyPCBs):

Drop him a message and he'll send you a download link.

-

@Yveaux Tnhx, but I guess I am not ready for the first step (creating/ adapting a board in Kicad) yet ....

-

@Yveaux I tried to find an email address on the website, but apart from a LinkIn link I could not find anything. Also, in LinkedIn you need a paying version to be able to send InMail, and I do not have a paid account. Would you care to tell me how you were able to send Stijn a message ?