CNC PCB milling

-

I'll probably get this to power my new spindle after it arrives:

https://www.amazon.com/gp/product/B0716XVR7P/ref=ox_sc_act_title_1?smid=AFHAE9RJVUMB&psc=1#customerReviewsInstead of PWM, I'll just adjust the voltage directly. Wish they could have given it a normal power plug for its AC input voltage....

-

In any case, I suspect that greater control over the speed of the spindle will lead to greater control over vibration as well. i.e. select a speed where there is less resonance/vibration of the pcb/spindle. Using an accelerometer to measure vibration, perhaps that could even be made somewhat automatic.

Alternatively, a trick I've seen used is to continuously vary the RPM over some range, so that the amount of time spent dwelling at the resonance frequency is reduced. That would also be easier to implement.

I imagine that either method might also lead to a generally quieter machine, which, IMHO, is generally desirable.

-

BTW, using a dremel or a proxon for cnc may be a bad idea. Tom Sanlanderer tried it (twice) with a Proxon, but the bearings rapidly burned out both times:

CNC mill built from a 3D Printer! – 07:56

— Made with Layers (Thomas Sanladerer)On the other hand, etching PCB's shouldn't be as taxing as full-on CNC work, so I'm not yet convinced it wouldn't work for etching PCB's. I think it's worth a try. If 35,000RPM turned out to be a great speed to etch at, then I'd be motivated to upgrade further and try 60,000RPM.

Would there be more runout at those higher speeds? On the one hand, the spindle is possibly more precise to begin with. On the other hand, at those rotational speeds, the bit might want to bend just from the centrifugal forces on it, unless it was perfectly balanced. Most etching bits don't even look perfectly balanced though....

-

@neverdie so to get the max rated RPM out of a dc motor you need to operate at its max rated voltage ? with no PWM ?

Running a DC motor rated at say 12-60V with PWM at only 12V would never get to top speed ?

Am I understanding correctly ? Thanks for the link

-

@rfm69 AFAIK, yes.

-

-

Dc aka brushed spindles run on constant (dc) current&voltage. They have some limits. Power it under minimum voltage and they will stall (stop rotating) and only one coil will be energised, heat up and blow. Over maximum voltage they overheat and burn (logically).

You can use a constant voltage source or pwm a maximum voltage since the electro-mechanical inertia will act as an integrator and smooth out the pwm pulses asuming pwm frequency is high enough. The driving circuit can be as simple as a high power FET or a complex constant dc voltage source. You control that circuit via a low power pwm or voltage signal. Pwm can be easily converted to dc by a low-pass RC filter. -

Brushless motors NEED a driver, same as steppers, since phases must be shifted in syncronisation to shaft speed and position. The control of the driving circuit is the same pwm or dc voltage talk as above.

-

-

@executivul Thanks makes sense and I just started to read simular explaination in other places, but yours helped.

How about rpm ? Is it generally considered that higher RPM is better, or at least not being limited by a low speed ? I've seen 1 300w spindle rated at 60,000rpm would this be better than a higher power slower spindle ?

-

@NeverDie I use my 60k rpm spindle at 30-40k rpm most of the time. I manualy crank the vfd pot to max rpm, then slowly start lowering taking notes where the lowest harmonic resonance points are, then chose the highest acceptable one. Eg 100% rpm high noise, 94% rpm low noise, 93-84% rpm noise again, 83%rpm even lower noise, 82-xxx% noise again. I chose 83%. Most Vcarve milling bits are rated to 40k rpm anyways. This speed / resonance tuning must be done after every tool change, even a slight tightening of the tool a bit more can change balancing.

IMHO 24k rpm are enough for up to 1000mm/min pcb milling.

-

@executivul Which 60K rpm spindle is it that you are using? Are you generally happy with it, even if you tend to run in the 30-40K rpm range most of the time? i.e. would you buy it again, or would you maybe get something different?

-

@rfm69 the honest answear: "It depends!"

I've had much better luck at higher rpm. I've even posted a gcode to determine the best feed/rpm in this thread.

To mathematically know for sure you would need a few hundred thousand dollars worth of equipment, engraving pcbs is not milling, so chipload calculators won't work. Lower rpm rips the copper leaving rough edges, too high of a rpm increases runout. As I've said IMHO 24-30k rpm is enough for our machines, you need a far better, stiffer frame, servos instead of steppers and a very good controller board to be able to go over 1000mm/s (400in/s).

-

@neverdie i would go for a 24k 800W water cooled spindle, far better "all around" tool, can mill wood or aluminium easier

The 60k is great for pcbs and that's about it.A larger wattage, lower max rpm spindle has a larger and heavier rotor, higher inertia, can withstand higher chiploads.

Remember, as in stepper's case, running a spindle at 50% of max rpm yelds far less than 50% of power, maybe as low as 10%. Going under 50% you get as low as 3-5% of max rated power. For pcbs that's no biggie, but for anything else... And you can't mill wood or metals at 60k rpm because of the feedrate needed to keep the chipload and the cooling needed not to burn the tool and stock.

-

Quoting DavidSohlstrom from a thread on a different forum (https://discuss.inventables.com/t/runout-of-24v-dc-spindle/9984/11) in reference to vibration:

I've said it before and I'll say it again. This is a low cost DC motor that has a ER collet adapter attached to it. It is not a CNC spindle that incorporates the tool holder right into spindle with a minimum of stick out from the housing.

There is no bearing preload and the bearings are low cost bearings that have a lot of slop in them.

A bent motor shaft of just a couple of thou will cause a large run out at the tool.I notice that a lot of the available spindles are exactly that: a motor with an ER11 collet attached. So, the stickout is going to be greater. I haven't yet tried to find a proper CNC spindle like what he describes, where there's minimal stickout. In a perfect world, it sounds like that may be the way to go though.

-

@neverdie any half decent watercooled spindle should have the ER collet holder integrated. My 60k one has an ER8 and the default DC that came with the machine an ER11. Bought some ER high precision collets from ali, and some precision nuts and things got even better.

-

This one would appear to fit @executivul 's criteria and also have a short stickout:

https://www.aliexpress.com/item/800W-electric-water-cooled-spindle-220V-ER11-with-65MM-diameter-158MM-length-for-cnc-router/32641099025.html?spm=2114.search0104.3.8.23ac8afeEe3r4S&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711211_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620_5722415_5711313,searchweb201603_2,ppcSwitch_5&algo_expid=da6db481-06cd-4131-b9a1-e7278ac9d3f2-1&algo_pvid=da6db481-06cd-4131-b9a1-e7278ac9d3f2&transAbTest=ae803_5&priceBeautifyAB=0It would seem to need some kind of controller to go with it though, plus a water pump, water tubing, and fittings and all of that. Definitely a major upgrade.

-

@neverdie that's ok. Beware you need a VFD for it (driving circuit) and it's bettery to buy as a kit so they match, my 2c

-

@executivul said in CNC PCB milling:

Bought some ER high precision collets from ali, and some precision nuts and things got even better.

How can tell you tell if the collet and nuts are "high precision" or not?

-

You can tell by the listing title or after doing some tests either with a dial gauge or by running it and listening.

Beware 2: diameter, my 3040 came with 53mm spindle holder, single piece with z carriage, so the 48mm only needed a 3d printed sleeve, but to add a 63mm or 80mm diameter spindle some heavy mods were needed so that's one of the reasons I didn't go with them

Beware 3: weight, the frame must support it without complaining, z drop, backlash or whatever

-

My 10^5*2c: get a 6040cnc with supported rails and a 0.8-2kw water cooled spindle, will serve you good for anything from pcb to alu or bronze milling, even some light steel work on the 2kw one and will save you a lot of hassle in the long run.

LE. 3020 and 3040 don't have supported rails and many don't even have ballscrews

And if you're really anal about it get the ballscrew frame only from rattm on ebay, a set of hybrid servos, a spindle+vfd+pump, a controller of your choice and you can say you have the best tool in the entry class of router cncs.

-

@executivul Maybe I've missed it, but none of the Chinese 6040's I've seen have had supported rails. They all seem to require that as some kind of DIY "upgrade".

For that reason, I've been considering a c-beam type design. There exists a relatively cheap Chinese clone of that:

https://www.aliexpress.com/store/product/C-Beam-machine-large-Mechanical-Kit-DIY-C-Beam-machine-Large-bundle-C-Beam-Frame-kit/1752067_32846185306.html?spm=2114.12010608.0.0.55bc1dafCeSt8dor maybe the WorkBee, which seems to be an upgrade to the OX CNC (though I'd prefer something where the screw holes are already tapped):

https://www.aliexpress.com/store/product/OX-CNC-Upgrade-Version-WorkBee-CNC-Router-Machine-CNC-Mechanical-Kit-with-Nema-23-Stepper-Motors/1752067_32850266842.html?spm=2114.12010608.0.0.36611dafYZdcH4

-

@neverdie please search for the 6040 frame only from "rattm motor", it's not stated I believe but you can clearly see in the photos with the bed beams removed that y rails are supported. X are not, but they are high diameter and pretty stiff for 40cm wide span.

Imho wheels on rails will never ever ever be as stiff and have less flex than the lousiest linear bearing. Wheels on rails are for printers and lasers.

-

@executivul You're right:

-

@executivul said in CNC PCB milling:

Imho wheels on rails will never ever ever be as stiff and have less flex than the lousiest linear bearing. Wheels on rails are for printers and lasers.

Even in the case of the Rattm Motors 6040, where the z-axis is hanging off an X-axis that is dangling by unsupported smooth rod? Is it still better even then?

-

@neverdie it might be better than a rigid x axis aluminium profile dangling on some wheels all together. Then comes the profile joining piece dance.

On the cnczone forums people go like: linear rails are the best, round bars are good, wheels on rails are for toys. That is for normal milling on a small machine. These things are routers by the way, real mills are taig style and are small size and meant for steel and heavy metal milling (no pun intended). For wood, plastic, soft stuff it might be acceptable though.

For pcbs you need high precision, flatness, high rpm etc.

For wood you need large size, think of table or door pieces. Tolerances are not so tight. You won't go like: look! Your door engraving is 0.1mm off in that corner!

For metal you need precision, high rigidity and power at lower spindle speed.The classic ebay cnc is a good all around tool but excels at nothing

-

@executivul

How thick is the aluminum that such a 6040 machine could mill?

-

@neverdie you must use a chipload calculator according to your spindle power at requested rpm, tool diameter and tool profile. Stock can be as thick as you want, the machine has about 100mm of z travel, you mill in multiple passes anyway so milling depth per pass is based on the results from calculator, experience or many broken tools.

-

What end mill bits should I get for doing PCB work? Do you just use a V bit and a drill?

-

-

Interesting way to make an inexpensive closed-loop stepper motor:

Making a Arduino Based Closed Loop Stepper Part 1 – 05:10

— MBcreatesI think a better way to do it would be to directly couple the encoder to a dual-shaft stepper motor, but that would, of course, mean purchasing a new stepper motor. Nonetheless, these small stepper's are pretty cheap.

The other way to do it with the existing single shaft stepper but without a belt might be to use a magnetic encoder, but I can't say that I've tried that, so I'm not sure how hard the retrofit would be.

Also, I guess the main point in doing this would be to hotrod your CNC, to make it move faster without skipping steps. i.e. you probably don't absolutely need to hotrod your CNC.

-

@neverdie said in CNC PCB milling:

I think a better way to do it would be to directly couple the encoder to a dual-shaft stepper motor, but that would, of course, mean purchasing a new stepper motor. Nonetheless, these small stepper's are pretty cheap.

I never looked, but do they make a dual notched pulley? Then you would only need to buy a pulley vs an entire stepper.

-

-

@executivul

This guy bought a 6040 CNC with supported y-axis rails (just like the RATTM one), but starting at time index 4:52 he discusses the "well known problem" of flexing on the 6040's unsupported x-axis when milling aluminum:

My first experience with milling Aluminium on a CNC 6040 Router – 12:52

— MBcreatesHe concludes that upgrades to the 6040 (e.g. possibly a supported x-axis rail) will be necessary.

It's just a pitty that an inexpensive, already "upgraded," 6040 isn't for sale. Instead, it becomes a DIY quest.

In fact, this guy did do the x-axis supported rail upgrade, but it solved only 50% of the problem:

cnc 6040 x axis supported linear rail upgrade – 01:39

— Blake Slater

-

@executivul

Do you suppose that linear rails, rather than supported rods, would fix this twisting problem that people seem to be having?i.e. Notionally, something like:

https://www.ebay.com/itm/Portable-Steel-MGN12H-Linear-Sliding-Rail-Block-Tool-250-550mm-CNC-3D-Printer/382360155951?var=651145928342&hash=item590670f72f mah05n6MWl2QkZTLIZW2vJQ

mah05n6MWl2QkZTLIZW2vJQ

that's made out of steel.

-

@rfm69 Almost always just PCBs. Maybe sometimes some acrylic, but nothing very solid, if that's what you're asking. Those little 1610 CNCs have so many plastic parts, that I'm not sure it'd perform very well cutting anything much harder than plastic.

-

@neverdie Yes; brushless motors are for sure more technically complex than brushed, and usually require an external driver. Most of the time those drivers have inputs allowing you to control the speed via PWM or an analog voltage.

Adapting the 1610's woodpecker board to supply that PWM speed control signal to an external driver is super easy -- I can show you a photo of what I did to mine if it'd help.

-

@neverdie said in CNC PCB milling:

@executivul

Do you suppose that linear rails, rather than supported rods, would fix this twisting problem that people seem to be having?i.e. Notionally, something like:

https://www.ebay.com/itm/Portable-Steel-MGN12H-Linear-Sliding-Rail-Block-Tool-250-550mm-CNC-3D-Printer/382360155951?var=651145928342&hash=item590670f72f mah05n6MWl2QkZTLIZW2vJQ

mah05n6MWl2QkZTLIZW2vJQ

that's made out of steel.Yes, but MGN15 or larger and of better quality, but that is expensive...

-

@executivul

I guess the difficulty of finding a satisfying solution to this problem explains why milling machines are built around a stationary, highly rigid z-axis.

-

@neverdie And finding a good tool at an affordable price is a challenge. Specialised machines do a s specific job better than general purpose ones, but only do that job. Professional machines do a better job at a higher price tag. We are just poor hobbyists

I'm so happy with my $50 UT61E, what a great multimeter, of course I would rather have a HP 8.5 digit one any day but I'd rather spend that money on a holiday or something since I don't need that 0.0001uV precision anyway, at 1V a 3V bat is as empty as a 0.9999999987V one if you get my point. Too many times I've spent a fortune for professional tools which I don't use/need so I tend to get what I need + a small margin, for eg I got a huge DSLR and lenses, used a few times, great photos, but lately, guess what, I tend to use my phone for taking photos 99.9% of the time, the camera backpack is just too heavy to carry arround .

Get a 3d printer, get a 3040/6040 cnc, get a 40/50W laser, get a lathe if you have space for it, maybe get a vertical mill for metal parts and you'll have a maker space of your own, as long as you won't start manufacturing space ships ebay tool tolerances will be ok.

-

Reminds me of a quote from the MPCNC website (https://www.v1engineering.com/frequently-asked-questions/ ) :

Diminishing returns kicks in really fast in the CNC world.

-

I suppose, in theory, that somehow replacing the x and z-axis with these might mitigate against the twist problem:

Presumably the rails are precisely spaced and held perfectly flat by the base plate, so you'd avoid binding problems that might otherwise arise from a purely DIY manual retrofit of just the rails.

I don't know what the MGN number is for that rail though, so I don't know whether its MGN15, MGN20, or something else.

-

@neverdie said in CNC PCB milling:

@dbemowsk said in CNC PCB milling:

a dual notched pulley

I don't know what that is.

I wasn't sure of the exact name for it, but I was referring to something like this:

https://www.amazon.com/ReliaBot-Aluminum-Timing-Pulley-Printer/dp/B079JGYYKV/ref=sr_1_5?s=industrial&ie=UTF8&qid=1520378263&sr=1-5&keywords=dual+timing+pulley

-

@dbemowsk

I take back what I said earlier. I like the way this guy did it better, because with the gearing you can get even more resolution out of your encoder:

Converting a Stepper Motor to a Closed-loop Stepper Motor - Part 1 – 04:08

— Kris Temmerman

-

@neverdie I agree, that that may be better. To change the precision, you would just have to change the gear ratio of the two meshing gears.

-

I did some more reading about CNC'ing aluminum, and it's being claimed that virtually any CNC machine can cut aluminum, provided it uses the right depth of cut and speeds and feeds. i.e. it may simply take a lot longer than you would prefer if your machine isn't already super rigid. If that's true, I can probably live with that.

Meanwhile, it has been suggested that using PID might improve things. There's SuperPID for AC powered spindles and I'm not sure what for DC powered spindles. Regardless, I'll need to sense the RPM of the spindle, or it won't work, so that's now on the critical path. I think I'll try a spinning magnet and a hall sensor to sense the RPM.

-

@coddingtonbear said in CNC PCB milling:

@NeverDie -- the motors used in 1610 CNC mills are generally what are called a "775 Motor". You might be able to find other specs, but the ones I've found suggest that at 24V and no load , they claim 7kRPM -- http://linksprite.com/wiki/index.php5?title=File:Motor_performance_parameter.png; I'm not sure how much slower we could expect it to be while milling. As far as actually measuring this, there are devices you could buy, but you could pretty easily fabricobble your way to an answer if you wanted to make a project out of it: http://www.instructables.com/id/Measure-RPM-DIY-Portable-Digital-Tachometer/.

I have the same mill as you, and swapped for one of these https://www.amazon.com/gp/product/B074FVKRZM/ and have had much better results so far.

Does the controller that comes with your motor allow you to set the RPM of the motor, or does it just set the voltage? If it knows RPM and can act like a PID (i.e. adapts to maintain the target RPM even under varying loads), then it would be very attractive.

-

I went ahead and orderd the Hall Effect version, which appears to come with some kind of DSP PID controller to control the speed of its DC spindle.

https://www.aliexpress.com/item/Freeshipping-Brushless-spindle-motor-driver-Motor-base-kit-BL-Engraver-Spindle-Motor-24VDC-60VDC-12000RPM-ER8/32849306845.html?spm=2114.search0204.3.72.2cc61acfYE6xkB&ws_ab_test=searchweb0_0,searchweb201602_5_10152_5711320_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10084_10083_10618_10307_5711220_5722420_10313_10059_10534_100031_10103_10627_10626_10624_10623_10622_10621_10620,searchweb201603_25,ppcSwitch_5_ppcChannel&algo_expid=7790ac4f-6dbd-47b4-9574-1d713348386c-11&algo_pvid=7790ac4f-6dbd-47b4-9574-1d713348386c&transAbTest=ae803_3&priceBeautifyAB=0

-

I used a piece of white tape, a photo resistor, and an oscilliscope to measure the RPM on the existing spindle that came with the 2418 kit. Unloaded, it's 8333RPM.

-

I did further tests on my CNC this morning, with interesting results.

First, I confirmed that the motor is, indeed, being powered at 24VDC using pulse width modulation from the WoodPecker. As an experiment, I tried powering it directly from my lab bench power supply at different voltages, and it definitely runs smoother that way rather than relying on PWM.

Second, when I ran it at very low speeds, I could tell visually that the spindle runout was attrocious. I think this is a big contributing factor to vibration, audible noise, and probably tearing in the copper of the PCB. It may be that the large stick-out of the ER11 is a contributing factor.

-

I have a question regarding setup of the CNC. Which directions are the positive directions for all of the axes? For example, if I send "Z10" should the spindle move up or down?

X - left or right?

Y - forward or backward?

Z - Up or down?

-

@dbemowsk

X: right

Y: forward

Z: up

-

@neverdie Yes, it does. There are a variety of ways of controlling the one I bought, and you can easily configure which method is in use. I think this one has three different options -- controlling RPM via an analog voltage, controlling RPM via PWM, and controlling RPM via a knob on the controller. I use PWM, but you'll probably always want to be at full speed when milling PCBs, so I'd bet just using the knob would be fine.

-

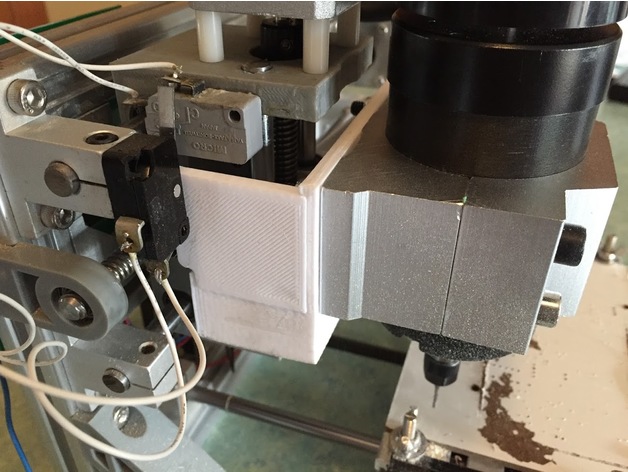

@neverdie Congratulations on your purchase! I think you'll find having a real spindle will help a ton.

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

-

@coddingtonbear said in CNC PCB milling:

@neverdie Yes, it does. There are a variety of ways of controlling the one I bought, and you can easily configure which method is in use. I think this one has three different options -- controlling RPM via an analog voltage, controlling RPM via PWM, and controlling RPM via a knob on the controller. I use PWM, but you'll probably always want to be at full speed when milling PCBs, so I'd bet just using the knob would be fine.

So, during deeper cuts, the controller responds by giving the spindle more oomph to maintain the specific RPM you set? That's the key question.

-

@coddingtonbear said in CNC PCB milling:

@neverdie Congratulations on your purchase! I think you'll find having a real spindle will help a ton.

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

Thanks! That does increase the cantilever effect, but it's a good start. I guess it's even good enough based on your experience so far, which would be awesome. Thanks for sharing.

-

@neverdie Hrm; honestly I haven't monitored it very closely, and almost always run the spindle at full speed; so I can't really say for sure if it would attempt to adjust to make up for higher friction. Also, I have the NVBDL rather than the NVBDH version, so I'm not even sure if it is able to tell if the motor is spinning slower than intended.

If either of us have a chance of that being a possibility, it's probably you with the slightly better spindle driver.

-

@coddingtonbear Makes sense. I should be able to trap the signal from the hall effect encoder to confirm the RPM using an Arduino, and then I can compare actual against prescribed RPM to see how well they match. But, as you say, it may not matter if the best speed for etching PCB's is simply "as fast as possible." i.e. if 'it's already running at maximum voltage, then there's no headroom left to speed up an overloaded bit.

-

I ordered a 3.175mm ER8 collet for the new spindle so that I can continue using my same bits:

-

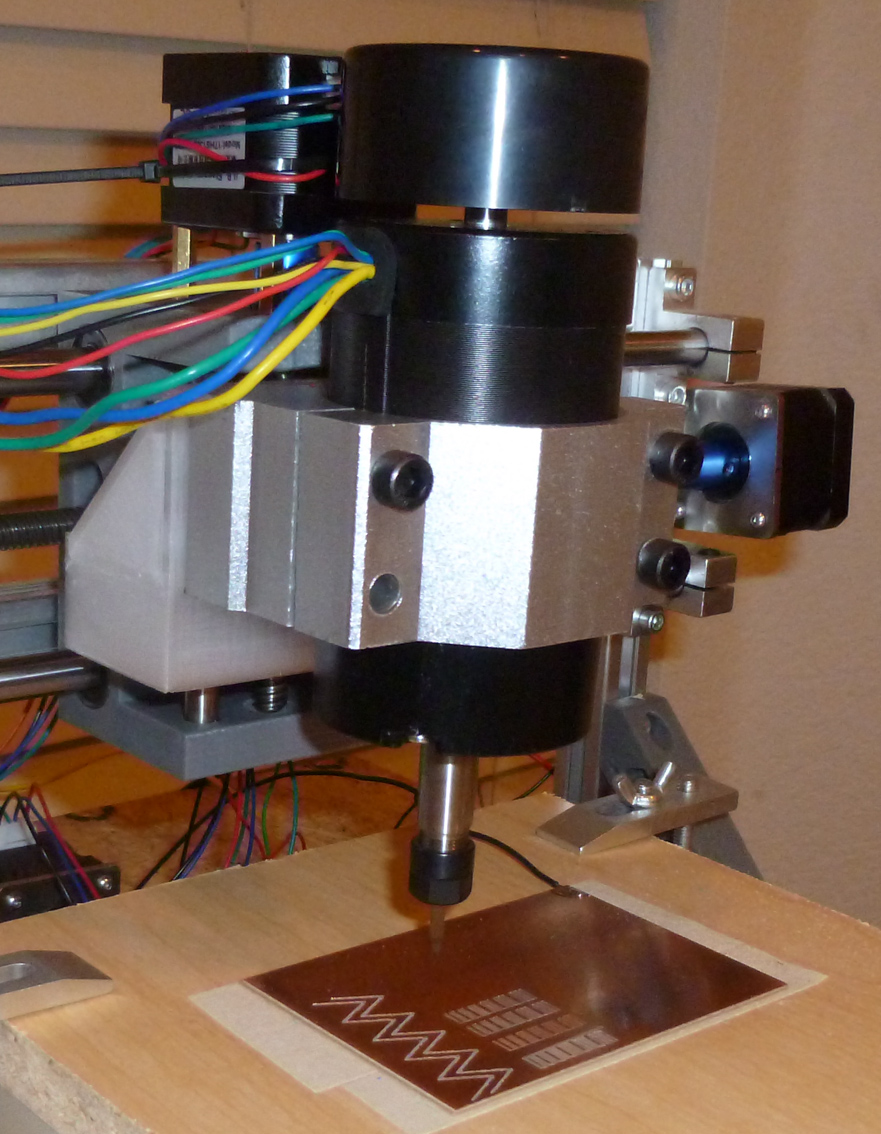

The NVBDH+ brushless spindle and controller arrived today, and so I hooked them up to a power supply and gave them a quick test spin. It runs comparatively quiet. The motor itself is pretty much sealed. On the positive side of that, little if any dust will ever get inside it. On (maybe) the negative side, the fan basically directs air at the back of the motor, and not really anywhere else. I’m only guessing, but keeping other parts of it cool may prove challenging if doing a lot of deep cuts on wood, for example.. For milling PCB’s, I don’t think it will be a problem though. It has little, if any, visible run-out, so in that dimension it appears to be far better than the spindle that came with the 2418 kit.

I won't be able to test it on the CNC itself until after my 3D printer arrives because it's too large to fit the kit spindle's holding bracket.

-

@coddingtonbear How hot does your motor get when you're using it? I'm concerned that only one end of it seems to be getting blown by the fan, and since it will be held by plastic....

-

Perhaps it would be possible to buy a water cooling jacket for the spindle? That would cover the bases against even heavy duty use. Notionally, something like: https://www.aliexpress.com/item/1Pcs-Hobbywing-SEAKING-Water-Cooling-Jacket-Water-Cooled-Tube-Cover-for-Motor-2040-2848-3660-Tube/32824602383.html?spm=2114.10010108.1000015.2.1e5d6295V0eV3w

Alternately, I notice an inexpensive brushless motor with a water cooling jacket already installed, for not much money:

https://www.aliexpress.com/item/B2040-4000KV-3000KV-Inrunner-Water-Cooled-Brushless-Motor-For-Rc-Boat/32713150282.html?spm=2114.10010108.1000015.6.1e5d6295V0eV3w

It could also go up to around 48,000RPM at 12v. The main downside to that is that it would require installing an ER11 collet, and so runout might be an issue.Or, just get this, which goes to 24,000RPM and has water cooling already a part of it:

https://www.aliexpress.com/item/CNC-65MM-ER11-1-5KW-WATER-COOLED-MOTOR-SPINDLE-AND-DRIVE-INVERTER-VFD/32721276915.html?spm=2114.search0104.3.1.6558afa34wxhfY&ws_ab_test=searchweb0_0,searchweb201602_5_10152_10151_10065_10344_10068_10130_10324_10342_10547_10325_10343_10546_10340_10548_10341_10545_10696_10084_10083_10618_10307_5711212_10313_10059_10534_100031_10103_10624_10623_10622_10621_10620_10810_10811_5722415_5711312,searchweb201603_25,ppcSwitch_5&algo_expid=9b150460-dd19-4ed5-bba5-dea1262c58d2-0&algo_pvid=9b150460-dd19-4ed5-bba5-dea1262c58d2&transAbTest=ae803_5&priceBeautifyAB=0

-

I found a very similar motor being used on a thingiverse printed CNC machine: https://www.thingiverse.com/thing:1001437 and also: https://www.thingiverse.com/thing:1750276 . That's giving me more confidence that the heat will be manageable.

-

Epilog: I ran the brushless spindle unloaded continuously at its maximum speed and monitored its temperature using a DS18b20 temperature sensor beneath the holding bracket (so, getting the least amount of circulated air onto it). It reached an equilibrium temperature of around 31C. Also, it turns out that it actually does have pretty good air flow. So, I’m no longer worried about this spindle getting too hot.

-

UPDATE: I received and installed a pair of chromed hardened steel rods onto the x-axis. Wow! I could feel an immediate improvement in rigidity. I wasn't really expecting that, so it made me curious. I tested the new rails with a magnet: yes, they attract a magnet. Then I tested the old rails with a magnet. No attraction! Therefore, I think maybe the old rails are probably aluminum. Aaaargh! That would explain a lot. So, FYI for anyone else who buys one of these Chinese kits.

-

Yup, I just now did a spark test on the old rods, and the result is conclusive: definitely aluminum. I should probably replace the z-axis rails as well.

-

Epilog: Definitely much less vibration in the CNC now that the x-axis rods have been replaced with steel rods. I've ordered y-axis and z-axis steel rods, so I plan to replace those as well. Hopefully doing so will damp the vibration even further.

-

I just now ran across z-axis tape, which may prove to be a God send for using any of the 6mil isolation routed PCB's that I might make on this PCB etcher. The problem I was having with such isolation routed boards was: no solder mask! So, soldering parts to the boards just wasn't working for me, and I had fallen back to producing boards with much larger isolation widths. However, it appears that with 3M's z-axis tape, I can just tape the SMD parts down onto the board, with no soldering required!

Amazing! From my perspective, it's downright revolutionary:

https://www.adafruit.com/product/1656

-

@neverdie Interesting stuff! I didn't know it existed.

I saw a sparkfun youtube video in which they use it to tape down an ATMega TQFP instead of soldering it, but they keep it pressed down during the demo.

So, do you think it can also be used to mount chips?

-

@yveaux said in CNC PCB milling:

So, do you think it can also be used to mount chips?

Yes! One of my favorite youtubers shows it being done at time index 1:00 on:

Part 2: Hi-Res Pressure Sensor Matrix Mat finished – 09:37

— Marco Reps

-

Anyone know whether it is possible to etch some or all of the silkscreen onto the PCB? I've tried some googling, and I haven't found any leads on how to do it using flatcam.

-

-

@neverdie What about using toner transfer paper and ironing it on. Just print it reversed on a sheet, cut it out and iron it on. If you use a color laser you could do something other than black. Obviously you won't get white like a lot of fabs use, but I would think it would be good enough.

-

@executivul said in CNC PCB milling:

@neverdie http://caram.cl/software/flatcam/tracing-the-silkscreen-with-flatcam/

Have you tried it? i.e. Do you know if it works, or is it a blind reference?

-

Here's a very impressive looking demo of PCB etching:

https://www.youtube.com/watch?v=cwE3FqRb8ZgI checked the machine specs, and it's a maximum of 11,000RPM on a brushless spindle . That's very encouraging.

-

@neverdie I never used it to do silkscreening, but years ago I made a few PCBs to try a sheet out. It worked okay. I had some gaps in some traces on some the boards. That may have been from me not cleaning the board well enough before doing the transfer.

-

@dbemowsk Since the etching has to work (else there will be no PCB), I'd rather keep it within that domain if possible. Wegstr's lettering (above) looks very nice.

-

@neverdie said in CNC PCB milling:

@executivul said in CNC PCB milling:

@neverdie http://caram.cl/software/flatcam/tracing-the-silkscreen-with-flatcam/

Have you tried it? i.e. Do you know if it works, or is it a blind reference?

I've done it a few times, be careful though you don't cut your traces with the silkscreen

I use the tracing option all the time for custom cutouts when panelising boards, generate cutout paths in Altium and trace in Flatcam.

-

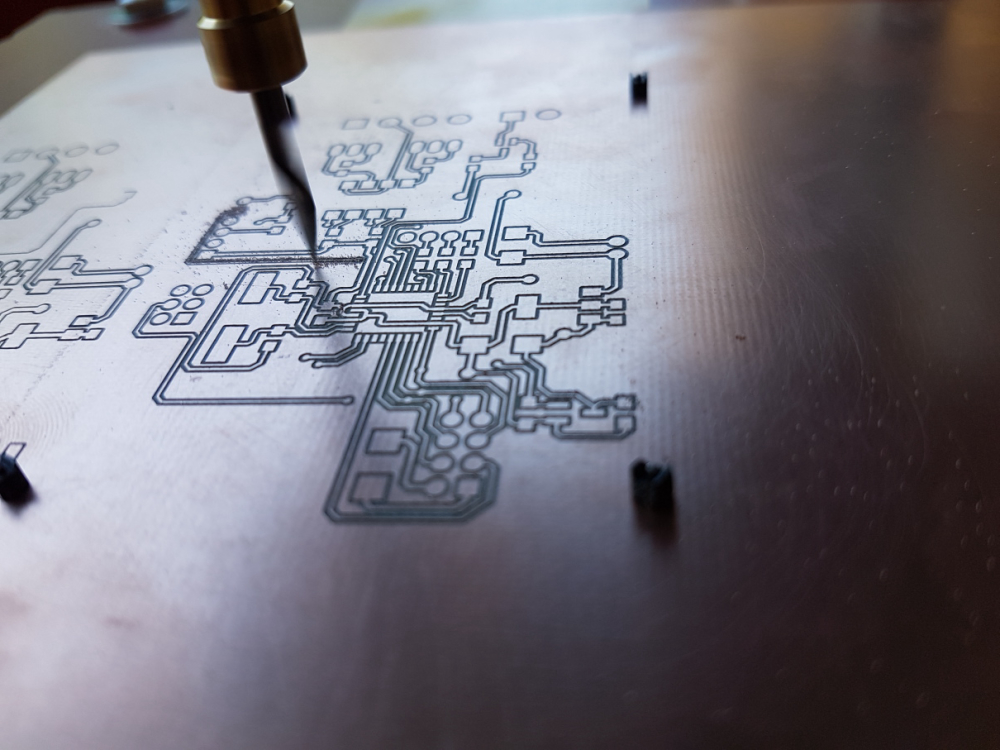

My Prusa i3 Mk3 still hasn't shipped due to production delays, and so I haven't been able to mount the new spindle yet on my PCB etching mill. Meanwhile, it looks as though the existing setup may just barely be good enough for etching pads for the atmega328p SMD. By using lots of rosin flux, it looks like I can solder to it without unresolvable solder bridges.

-

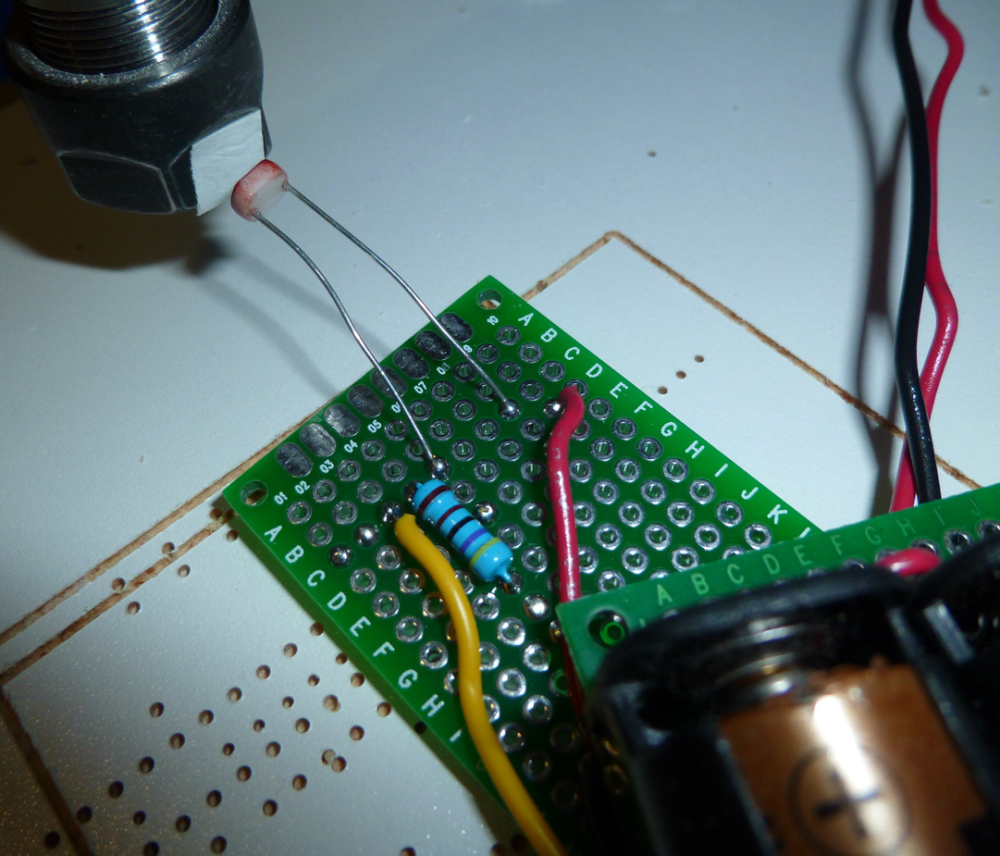

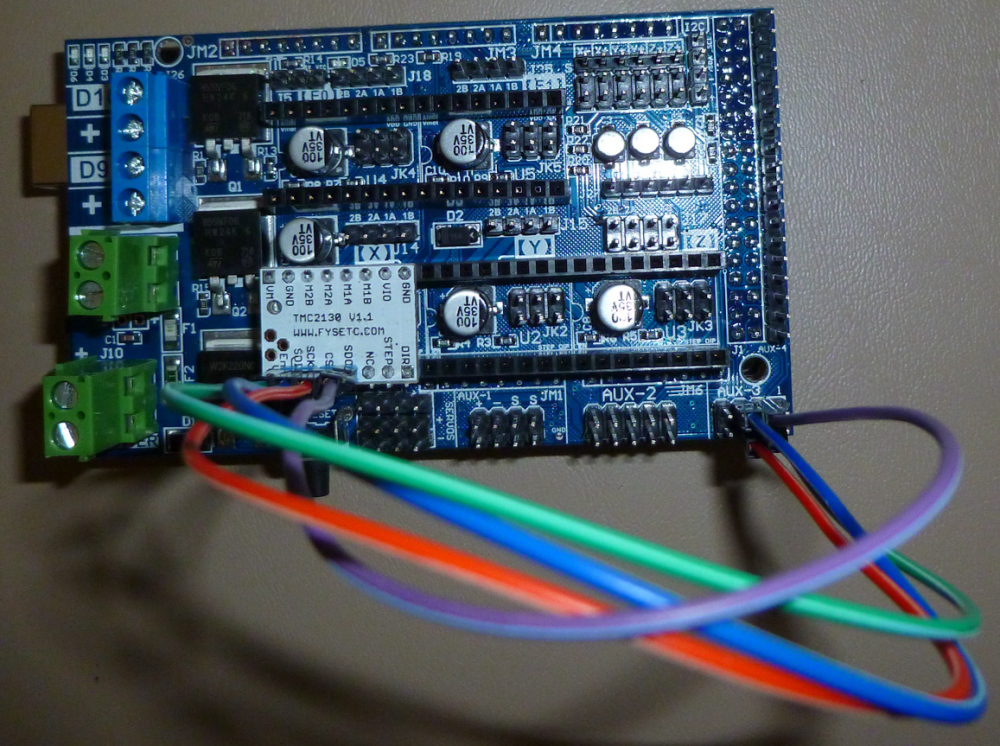

Also, I received a TMC2130 stepper driver, so I'll be auditioning that fairly soon:

Supposedly it is a bit more precise, and so that may help also. If it pans out, then I'll order TMC2130's for the Y and Z axis also.

-

@neverdie Here is an interesting approach that might work, but it requires etching.

Making PCB with 3D printer and permanent marker – 07:57

— Lamja Electronics

-

@dbemowsk Using a laser is another way:

Casually Laser-Exposing 0.2 mm PCB features on a 3D printer – 09:10

— Marco Reps

-

Good news! This guy has identified what may be the ultimate stepper motor driver for CNC:

Precision motion control: ODrive Servo? Trinamic Stepper? Chinese Hybrid? – 11:38

— Marco RepsAnd he says that by pairing it with your own mosfets, you can send up to 20amps to your stepper motor. Taken altogether, this sounds like a really good setup to me.

I assume that with this gear you can just tell the motor to go at maximum speed all the time and let it decide (through monitoring) what that speed should be. No more underperformance or endless tuning of parameters.

-

@coddingtonbear said in CNC PCB milling:

If you haven't designed your own mount, you might want to check out the part I posted on Thingiverse the other day: https://www.thingiverse.com/thing:2817974 .

I'm finally able to print this. Is 20% infill OK, or does it need to be completely solid?

-

@neverdie IMHO I wouldn't think you would need it completely solid. make sure your side walls are thick enough though. I would use 1mm or more for strength. That's just my opinion though.

-

I blithely printed the parts using PLA. Now I need to find a strong glue to weld the braces into place. Anyone know of a strong glue that works well with PLA?

-

@neverdie Answering my own question, it appears (according to this Hackaday article: https://hackaday.com/2018/02/07/locally-sourced-pla-adhesive/) that weldon #16 will do the business in terms of solvent welding PLA.

-

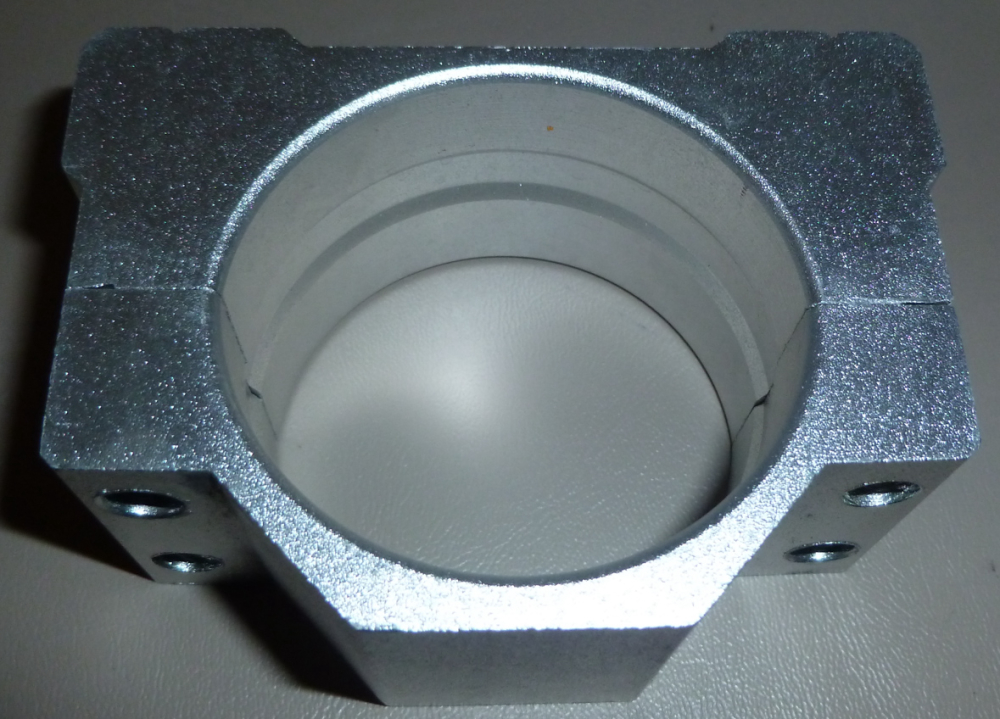

Comparing my spindle mount:

to Coddingtonbear's 55mm spindle mount:

it seems that mine is intended for a 52mm spindle. Unfortunately, I'll just have to make do, as nobody that I can find seems to be selling standalone true 55mm spindle mounts, like Coddingtonbear has.Fortunately, though, the holes on mine do align with the holes on Coddingtonbear's 3D printed adapter.

-

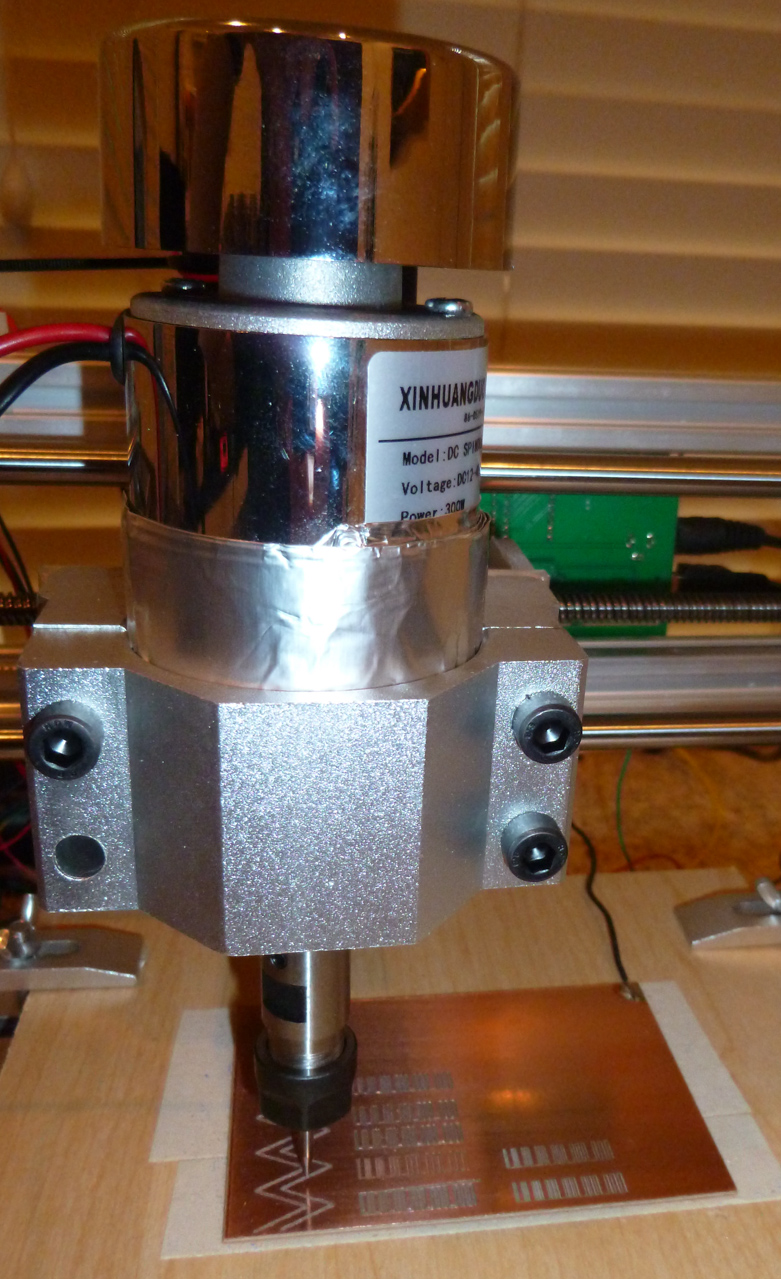

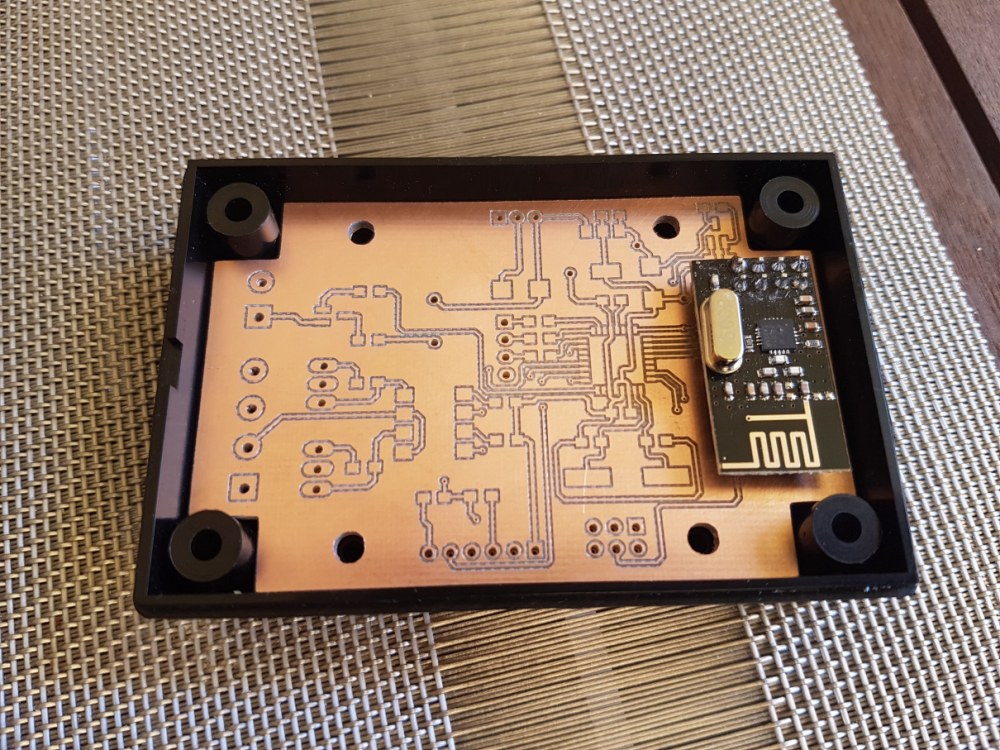

I upgraded to the brushless motor after 3D printing cottingbear's adapter. Then I ran @executivul 's test scripts to check its performance. It looks as though the new spindel can support faster feedrates, but the trace isolation is 0.7mm, which is much larger than the original cheapo spindle.

It has an ER8 on it, not an ER11. Not sure if that's to blame (?). I wouldn't think so, though, because I'm using a 1.75mm collet on it.

It has an ER8 on it, not an ER11. Not sure if that's to blame (?). I wouldn't think so, though, because I'm using a 1.75mm collet on it.The z-axis still has a lot of flex in it. I think that's probably a factor. I'm not sure what can be done to mod my way out of that. Perhaps I'd be better off getting a proper CNC mill rather than this wobbly type of design.

I can now see the advantage of having two z-axis motors, one on each side of the spindle. That would probably give it at least a bit more rigidity. Either that, or a single very rigid,, unmoving central column as used by mills.

-

Any suggestions on how to improve it?

-

@neverdie said in CNC PCB milling:

I can now see the advantage of having two z-axis motors, one on each side of the spindle.

Maybe just a stronger stepper motor.

-

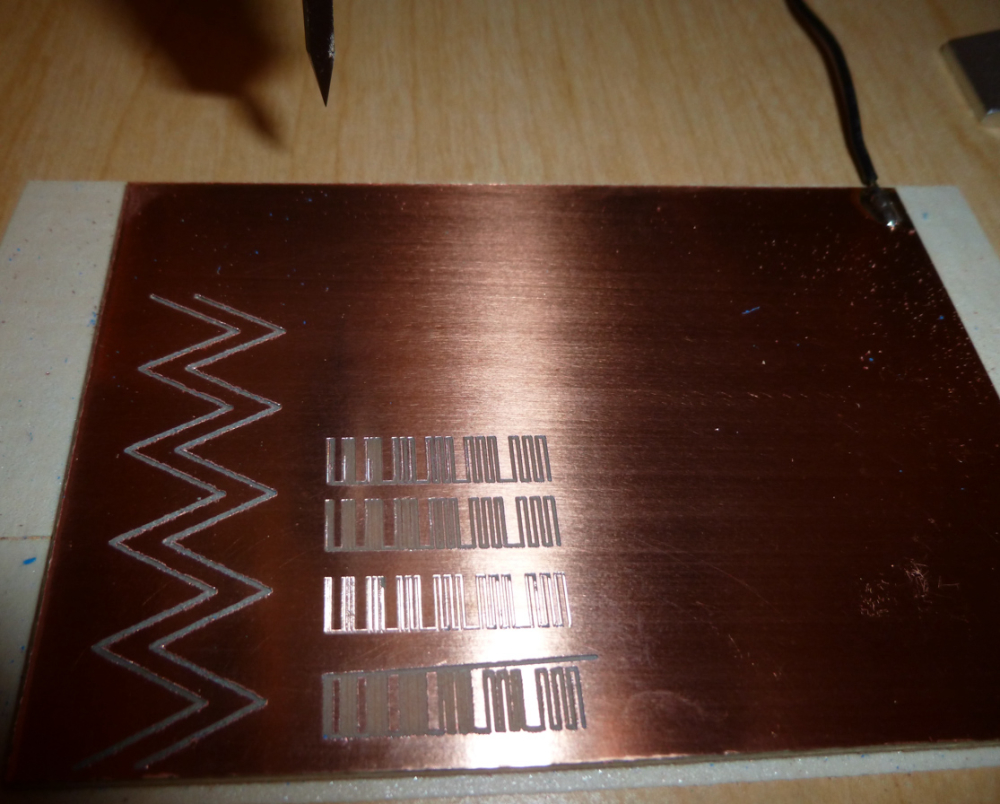

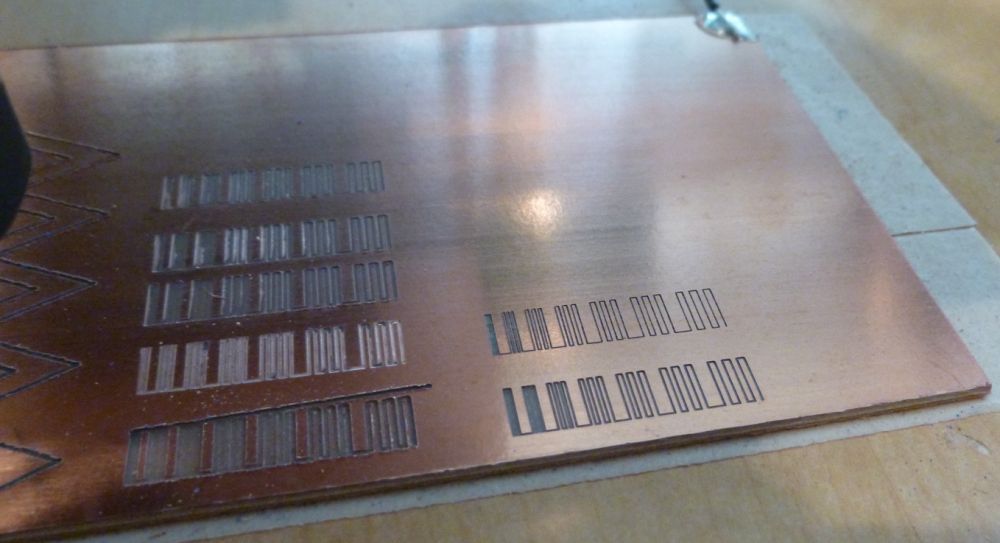

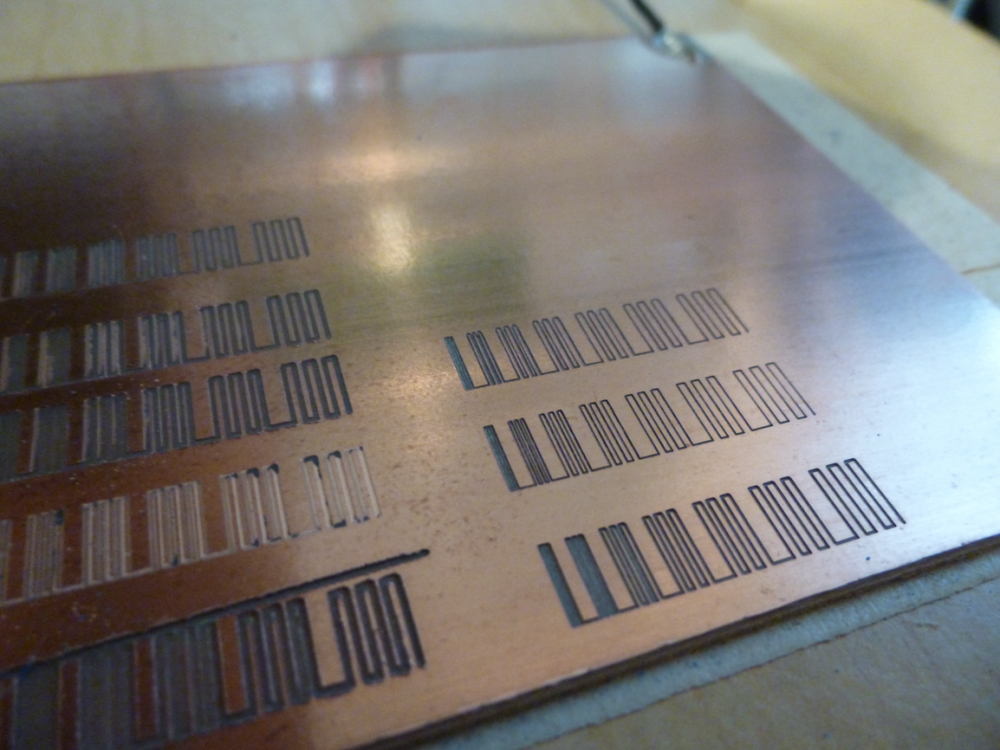

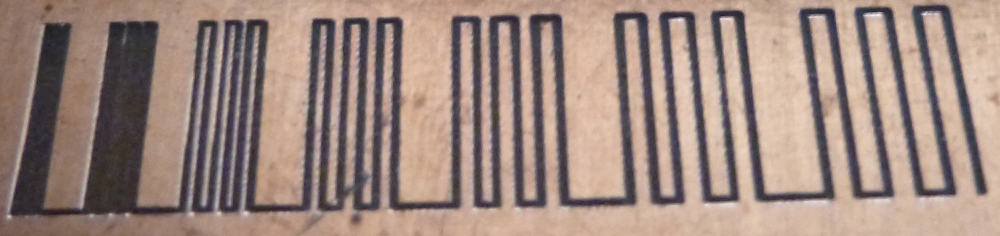

I switched to a 52mm spindle, and now I'm getting better results:

The benchmarks on the right were produced by the 52mm spindle. Those on the left by the 54mm brushless spindle.

Those on the left by the 54mm brushless spindle.

-

@neverdie I guess some backlash being present. Is the brushless heavier than the other one?

The width of the cut is proportional to engraving bit tip size, depth of cut, tip angle, the spindle itself should be irrelevant except runout, of course, but you will hear the runout long before you see it, a 0.1mm of runout will make a hell lot of noise and rattling.

For greater rpms er8 is better than er11, my 60k rpm has er8 the 24k have er11.

Try to find the highers resonance pole rpm, turn the rpm to max, slowly decrease it while listening carefully, take a note when it's quieter, use the highest rpm that runs quietly. This setting unfortunately changes with every tool change, sometimes you won't have a good enough rpm resonant pole so you take out the bit, nut and collet and reassemble. By turning them you change the invisible runout a bit and you get another system state. On my spindle every 1/10-1/15 tool changes results in heavy resonance and I must proceed as above.

-

@executivul Cool! Here's my first attempt at that, and it's already producing a visibly different result:

As to which spindle is heavier, I don't know. The next time I demount the brush spindle, I'll weigh it and let you know.

Thanks!

-

This guy developed his own method for balancing the high speed motors used on his quadcopter. I can't help but think that maybe something similar could be done on a CNC spindle.

In depth video how to balance brushless motors using a vibration meter and tape - Ontaerial – 25:35

— Yuri Retro

-

And these guys have the same idea, but they instead use a laser to visualize the magnitude of the vibration:

Flite Test - Laser Balancing Props - FLITE TIP – 07:11

— FliteTest

-

@neverdie knowing the vfd has a speed input I guess I could wire a simple arduino with a mic. Take note of the sound level and get it calibtared in no time, at the push of a button, but that project is far away, I have other things on my mind for the next few months.

-

hello everyone,

what is the current status with the quality, fine traces and result stability?

after a long absence I finally had some time to finish my new board and prototype it.

I don't have those issues that appearing for some of you, the result is pretty nice, the milling quality is the same across the whole board.

in this design the thinnest traces were 15mils, and the smallest vias were 0.8mm with 0.3mm drilled holes.

just for reference, please see my relevant configuration options detailed below:

tools

- cnc: cnc2418

- carving: 2001 bit (20 degree, 0.1mm end)

- mounting holes and outline milling: 0.8mm endmill

config

- isolation routing: tool dia: 0.1176326981mm; width (# passes): 2; pass overlap: 0.05mm; cut-z: -0.05mm; feed rate: 200

- milling: tool dia: 0.8mm; cut-z: -1.75mm; feed rate: 170; depth / pass: 0.3mm

- drilling: feed rate: 120

software:

- flatcam

- bcnc (also for the autoleveling)

-

Hi Andrew,

Since you ask about status, here's mine: I've now replaced all the aluminum smooth rods that came with my 2418 kit with chromed hardened steel ones which, it turned out, had about 0.04mm larger diameter. The result has been much less apparent vibration. I also upgraded the spindle to a higher rpm motor. I don't as yet have any quantified numbers to know whether the combination of doing all that has made any tangible improvement or not.

-

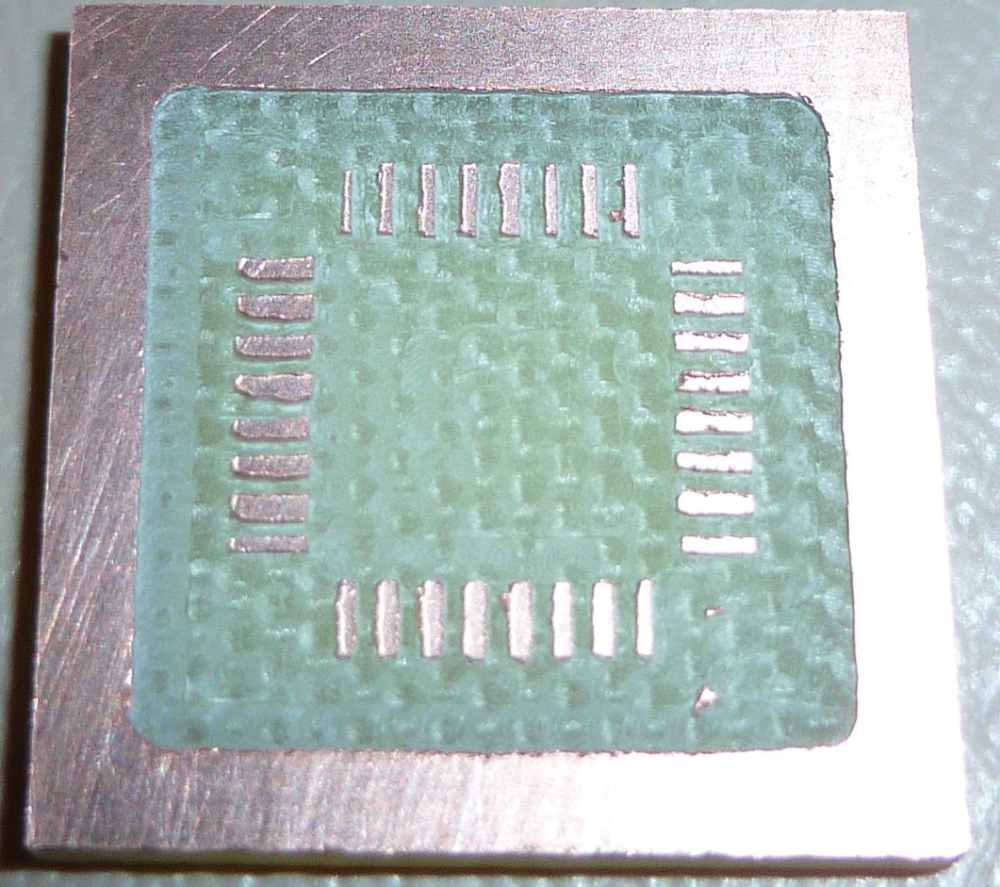

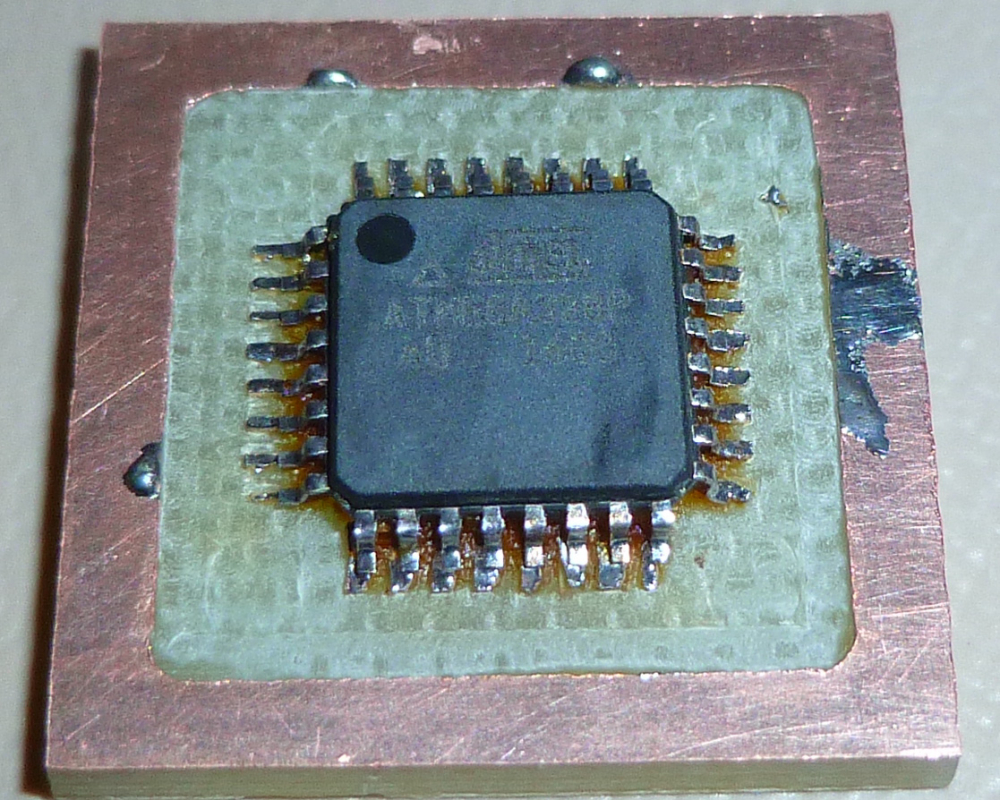

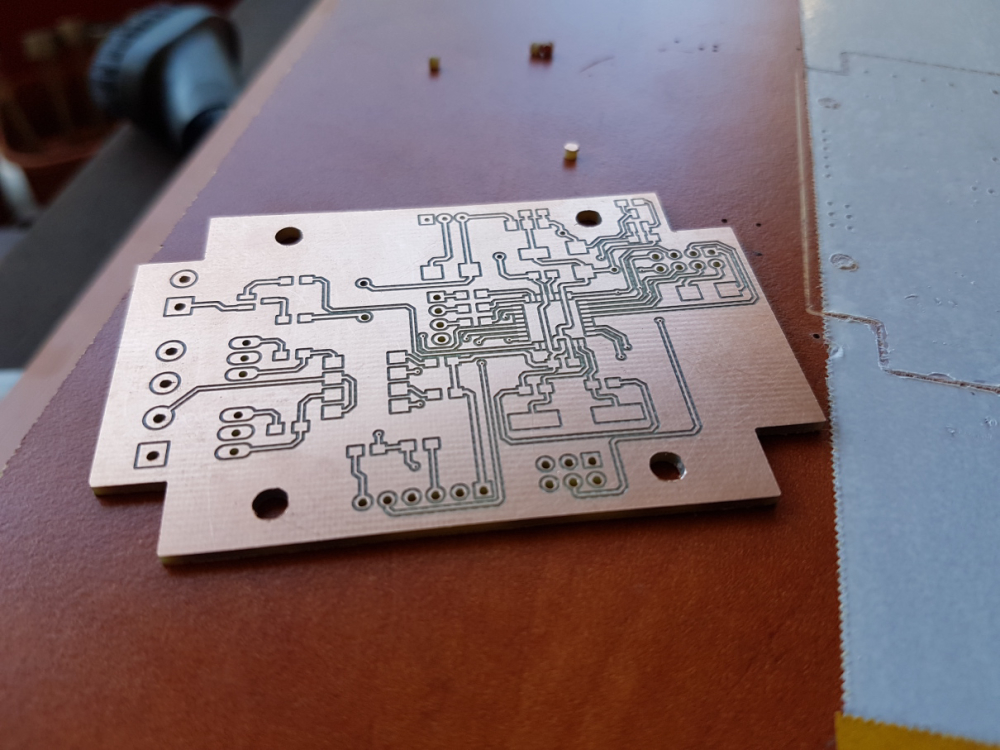

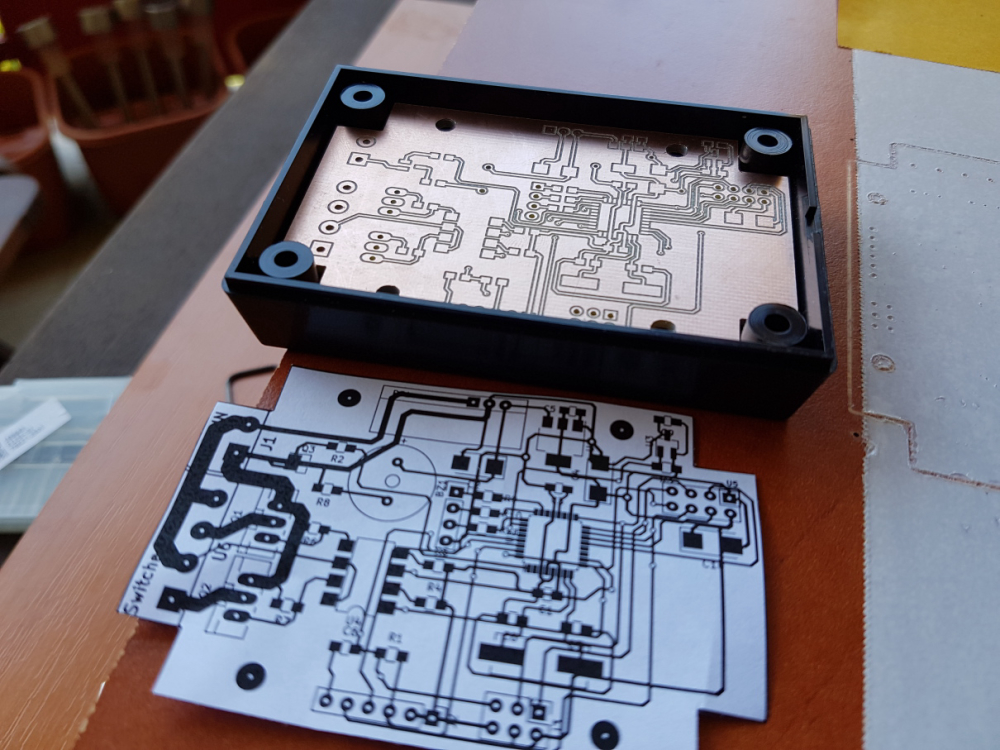

@andrew I ran @executivul 's diagnostic with my new setup:

Starting with 0.1mm, the trace width's increase by 0.1mm in each block.@executivul's g-code specified the feedrate at 1400.

So, yeah, 15mil looks like it would be achievable, even at that faster feedrate. On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

The next upgrade after this will be switching over to trinamic drivers, which may (?) be able to drive things a bit faster. That will likely require dropping woodpecker and switching over to marlin firmware so as to get the most out of the trinamic drivers.

-

@neverdie what was the cost for the overall upgrade?

for me the 10 mil traces also worked with the default sw/hw configuration.

did you change any parameter in the grbl firmware? 1400 feedrate is very nice, much faster than mine, however I did not use higher rates than 200 so far.

your steppers are still the same? is it ok for the high feedrate without any issue?

-

@neverdie said in CNC PCB milling:

On the otherhand, the woodpecker setting limits x and y to 200mm speeds, so I guess (?) the speed never actually gets beyond those limits anyway.

-

@neverdie the controller does not limit it, but the firmware settings. however, based on my default settings the feedrate is limited (by config) to 800. check your $110, $111, and $112 config options.

https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration#110-111-and-112--xyz-max-rate-mmminyou are free to override this configuration with a different value, so you can try 1400 in the grbl firmware settings, which will cause real 1400 feed rate in case of you test G code.

the questions is that how the steppers/spindle could handle this.