I’d look into Node-Red. It’s perfect for a simple system like that but it will be able to handle pretty much anything else he decides to throw at it down the line.

Thucar

Posts

-

project for some farming -

MySensors Hydroponics Greenhouse projectA quick video update: https://youtu.be/vnUFV_amSPQ

The tomatos and peas are trying to go through the roof. Cucumbers are close to follow. They are all aiming for the ventilation hatches - I think they are planning a grand escape...The NFT system pump stopped working coupe weeks after setting it up. Have not gotten around to ordering a new pump. That will be a project for next year.

-

Feasibility / Brainstorm for idea of Mobile outdoor Mysensors NetworkAs you will be wanting to receive the information and perform actions in the vicinity of the GW, I would go with a RPi + NodeRed + NRF24. Then switch the Raspi into Access Point mode and you'll be able to hook your phone up to it to receive notifications and control settings.

For a GSM connection, either add a USB modem or a GSM module to the IO pins, then connect to a MQTT broker on a VPSThat way you will only need to supply power to the Raspi and you're done.

-

MySensors Hydroponics Greenhouse projectConfirmed. Removing the jumper and using a power supply separate from the arduino’s has cured it from reboot issues.

-

node-red-contrib-mysensors release threadAwesome work! I was trying to create a bridge between a MQTT gateway and a Serial gateway (over TCP) so I could use firmware upload function of the MySController. However for some reason it seems to only work one way. I can send commands from the MySController to MQTTGateway but nothing is being received on the MySController side when data is sent from MQTT

This is my flow, would be awesome if someone would spot the issue...

[{"id":"e6a66581.c16ec8","type":"mysdecode","z":"229ed636.c3ff2a","name":"","mqtt":false,"x":450,"y":460,"wires":[["58ac0291.04974c","a3ba801.a63be8"]]},{"id":"eb5b52a1.29566","type":"tcp in","z":"229ed636.c3ff2a","name":"","server":"server","host":"","port":"5003","datamode":"stream","datatype":"utf8","newline":"\\n","topic":"","base64":false,"x":270,"y":460,"wires":[["e6a66581.c16ec8","ab0f8982.8a9588","78954899.688c28"]]},{"id":"58ac0291.04974c","type":"debug","z":"229ed636.c3ff2a","name":"","active":true,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":510,"y":560,"wires":[]},{"id":"a3ba801.a63be8","type":"mysencode","z":"229ed636.c3ff2a","name":"","mqtt":true,"mqtttopic":"myGreenhouse-in","x":1040,"y":200,"wires":[["8d64662e.fbada8","595543a3.f537cc"]]},{"id":"ab0f8982.8a9588","type":"globalGetSet","z":"229ed636.c3ff2a","name":"Save Session","topic":"","context":"msg","variable":"_session","outContext":"global","outVar":"_session","x":440,"y":420,"wires":[object Object]},{"id":"78954899.688c28","type":"debug","z":"229ed636.c3ff2a","name":"","active":true,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":500,"y":720,"wires":[]},{"id":"cdf94190.9fb8e","type":"myscontroler","z":"229ed636.c3ff2a","database":"5fdbb924.88fb48","name":"","handleid":true,"x":770,"y":200,"wires":[["a3ba801.a63be8"]]},{"id":"8d64662e.fbada8","type":"mqtt out","z":"229ed636.c3ff2a","name":"","topic":"","qos":"","retain":"","broker":"1920bc44.5c3304","x":1270,"y":200,"wires":[]},{"id":"595543a3.f537cc","type":"debug","z":"229ed636.c3ff2a","name":"","active":true,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":1270,"y":260,"wires":[]},{"id":"c800320f.2a2b","type":"mysdecode","z":"229ed636.c3ff2a","name":"","mqtt":true,"x":560,"y":200,"wires":[["cdf94190.9fb8e","aa22f275.cc8ec"]]},{"id":"2222f84e.56c4e8","type":"mqtt in","z":"229ed636.c3ff2a","name":"","topic":"myGreenhouse-out/#","qos":"2","broker":"1920bc44.5c3304","x":320,"y":200,"wires":[["41588b7e.b61114","c800320f.2a2b"]]},{"id":"aa22f275.cc8ec","type":"switch","z":"229ed636.c3ff2a","name":"","property":"nodeId","propertyType":"msg","rules":[{"t":"eq","v":"203","vt":"num"},{"t":"else"}],"checkall":"true","repair":false,"outputs":2,"x":570,"y":360,"wires":[[],["ea8a0d53.8140b"]]},{"id":"41588b7e.b61114","type":"debug","z":"229ed636.c3ff2a","name":"","active":false,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":530,"y":260,"wires":[]},{"id":"ea8a0d53.8140b","type":"mysencode","z":"229ed636.c3ff2a","name":"","mqtt":false,"mqtttopic":"","x":870,"y":420,"wires":[["2036eda1.dd8bf2","ad5ca8e4.1c4f68"]]},{"id":"2036eda1.dd8bf2","type":"debug","z":"229ed636.c3ff2a","name":"","active":false,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":1030,"y":460,"wires":[]},{"id":"ad5ca8e4.1c4f68","type":"globalGetSet","z":"229ed636.c3ff2a","name":"Load Session","topic":"","context":"global","variable":"_session","outContext":"msg","outVar":"_session","x":1060,"y":420,"wires":[["cb6d084b.432238","f99fd97d.5f73c8"]]},{"id":"cb6d084b.432238","type":"tcp out","z":"229ed636.c3ff2a","host":"localhost","port":"5003","beserver":"reply","base64":true,"end":false,"name":"","x":1250,"y":420,"wires":[]},{"id":"f99fd97d.5f73c8","type":"debug","z":"229ed636.c3ff2a","name":"","active":true,"tosidebar":true,"console":false,"tostatus":false,"complete":"true","x":1240,"y":480,"wires":[]},{"id":"5fdbb924.88fb48","type":"mysensorsdb","z":"","name":"Device DB","file":"sqlite"},{"id":"1920bc44.5c3304","type":"mqtt-broker","z":"","name":"LocalNew","broker":"localhost","port":"8883","tls":"","clientid":"Node-RedHome","usetls":false,"compatmode":true,"keepalive":"60","cleansession":true,"willTopic":"","willQos":"0","willRetain":"false","willPayload":"","birthTopic":"","birthQos":"0","birthRetain":"false","birthPayload":""}]``` -

MySensors Hydroponics Greenhouse projectDisconnecting the load eliminates the issue flat out.

I think your previous question just triggered a lightbulb. While the module does have optocouplers in place, I have the VCC bridging jumper in place. So essentially Arduino is still sharing the power with relay coils. I'll install a step-down to get a 5V line from the pump power supply and use that to drive the relays. I believe that should eliminate my reboot issues.

-

MySensors Hydroponics Greenhouse projectYes, the relay module has optocouplers separating data lines from the relays.

-

MySensors Hydroponics Greenhouse projectA long overdue update.

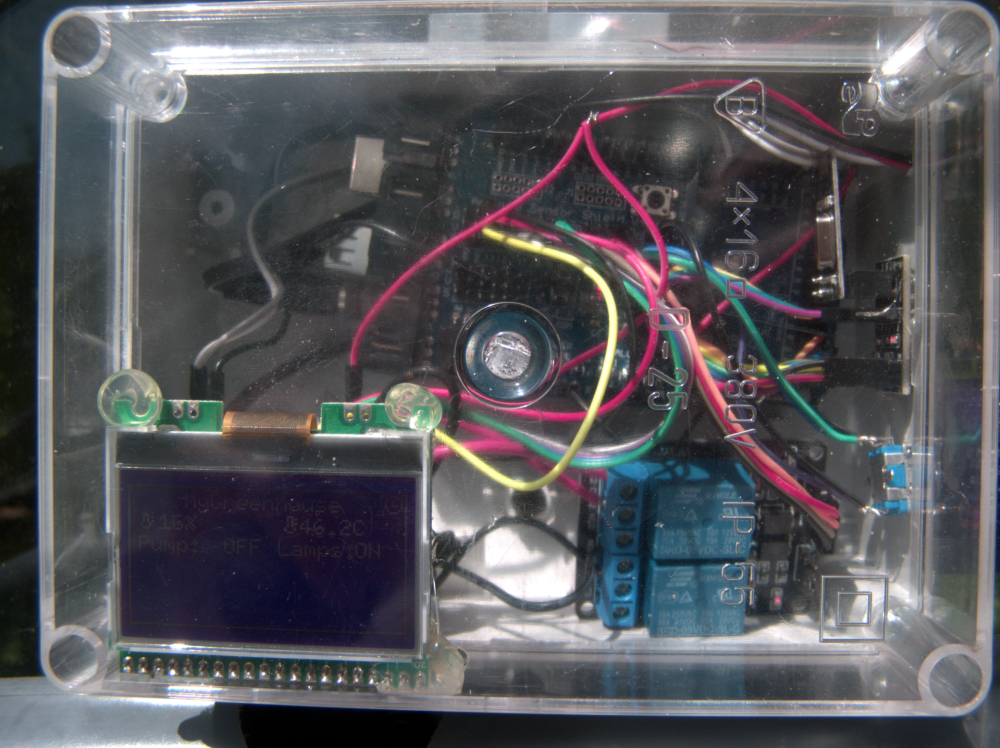

In the end I basically ended up using a GSM gateway with a LCD and couple sensors (air temperature and air humidity) and two relays. The relays control my Dutch bucket system pump and ventilation fans.

As a separate sensor I'm using a Z-Wave multisensor to keep track of nursery temperatures and lux levels.

The pH meter module did arrive but I do not feel comfortable keeping it submerged in the nutrient solution at all times so I've been just taking a sample of the nutrient solution from the tank after mixing a new batch, and testing it indoors, at the computer.

As for the EC meter, I failed to get any of the "arduino only" examples to produce reliable readings. So I've ordered 5 PCB's for this thing: https://www.sparkyswidgets.com/portfolio-item/miniec-i2c-ec-interface/

Once they arrive, I'll see if I can get more reliable results with a separate module.So far the whole thing has been running almost perfectly. The only drawback is an occasional reboot of the gateway when switching off the Dutch bucket system pump. I'm using two separate power sources for Arduino and the pump, Added a 1000uF cap to the Arduino power rail and a flyback diode across the pumps power lines. Still getting that reboot about 50% of the time.

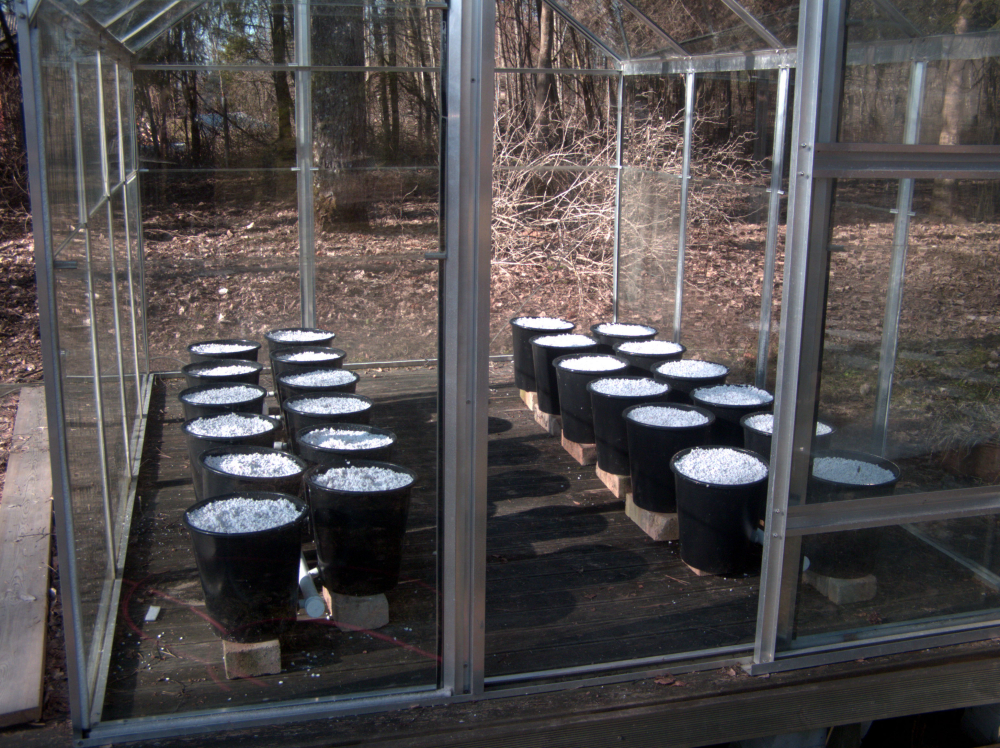

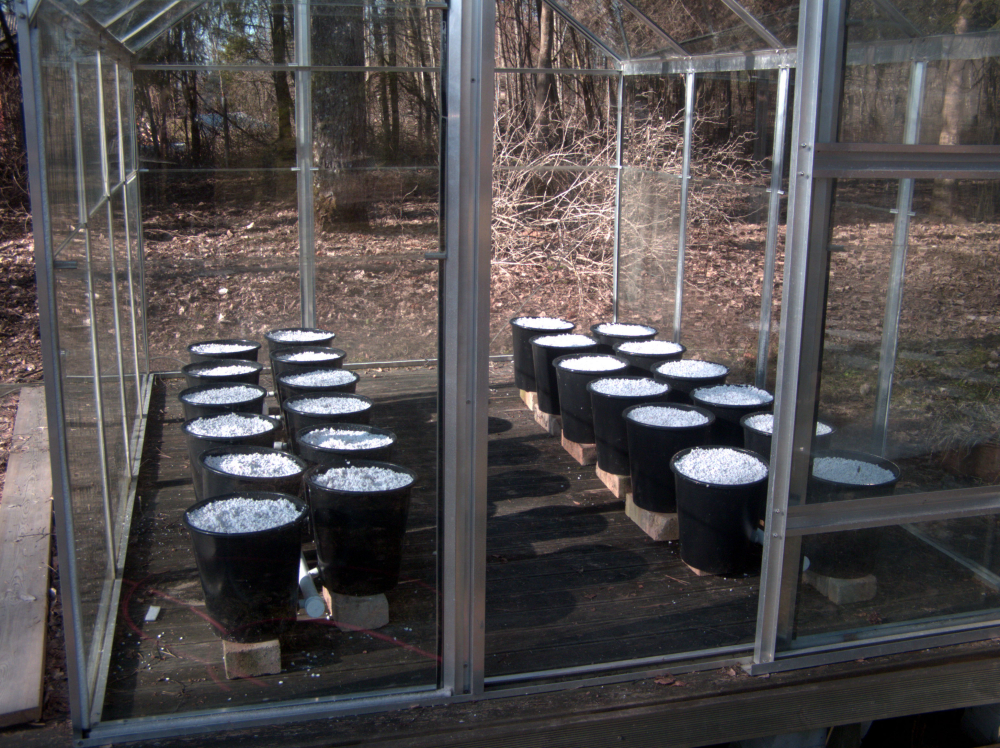

Some pics to wrap up my rant.

PS. Yes, that's a webcam in my greenhouse. It's taking hourly snapshots for a timelapse :)

My NFT rails for herbs. A good eye can spot some dill, basil and cilantro plants in there.

That's my "Nursery" - an old fish tank I can cover with a piece of glass when night temps dip below 10C

That's my Fibaro Motion sensor. An easy way to get some essential readings. Like the length of day, hours of sunlight, temperature.

This is my ratsnest. I should have moved the relays to a separate enclosure further away. Right now I think the arc when breaking contact is what's causing an EMP pulse and rebooting my Mega.

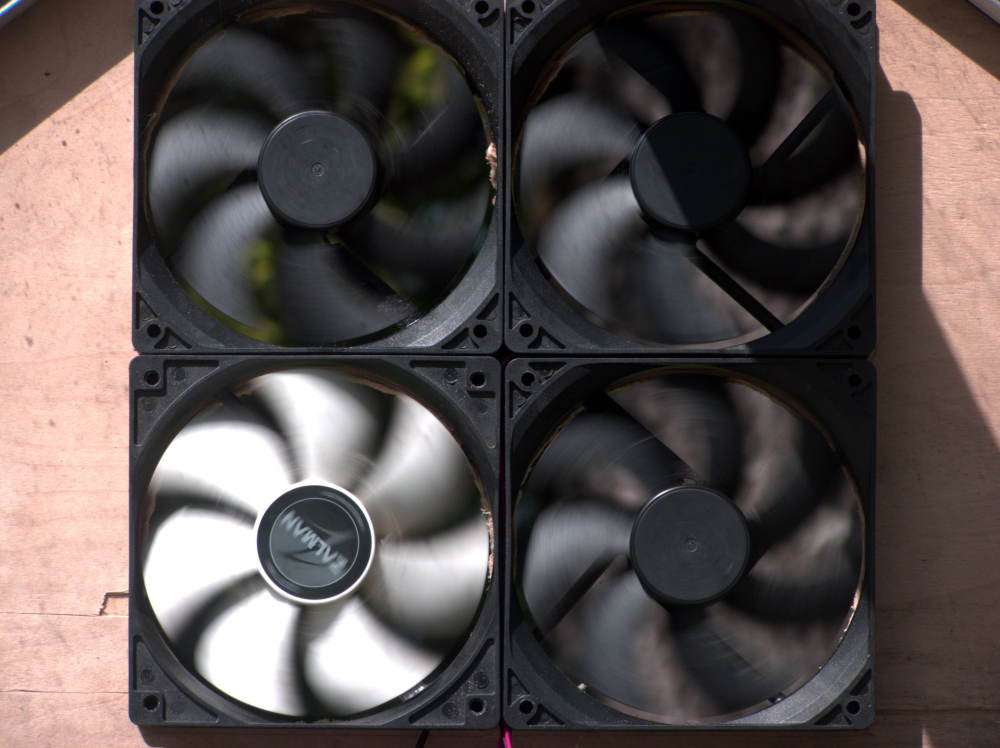

Ventilation fans. The temps soared to high 40's and low 50's with door and both ceiling hatches wide open. The fans kick in when air temp reaches 25C

-

MySensors Hydroponics Greenhouse projectGot some work done on the hardware side of things. Drainage is done, next up is feed part.

-

What did you build today (Pictures) ?Built half of my dutch bucket system. Namely the drain part. Irrigation to follow.

-

MQTT Gateway Network On DemandAccording to thethingsnetwork.org map, the closest lora gateway is about 120km from me :)

-

💬 Soil Moisture Sensor Pro Mini@UL7AAjr do you feel like sharing some information on that sweet looking sensor of yours? I'm doing my research on different styles of capacitive soil moisture sensors right now and would love to hear about your solution and the reasoning behind the choices you made :)

-

Looking for SensorAnd what are the benefits/drawbacks of the sensor in regards of your project? So we could get a better picture of what kind of limits your project puts on the selection.

For instance, does it not do what you need, is it not precise enough, is it too expensive? -

Looking for SensorDo you have any sensor names you have looked at? So we could take a look at them and offer our advice?

-

Looking for SensorHello and welcome to the forum @777upender

Could you tell us what's your research on the topic so far? Which sensors have caught your eye and what strengths drawbacks they have in regard of your project? I'd be happy to offer my 2 cents worth in helping you narrow down the choice or add recommendations of my own to that list.

-

Ventillation unit via phone cable@sola I know for a fact that I have used ModBus with Systemair ventilation units in three different occasions. I just can not remember the exact models. They all used the above linked documentation though, so that leads me to believe they are using either the same full controller on all their residential models, or at least the ModBus firmware is the same.

-

Ventillation unit via phone cable@sola check this out: https://planetaklimata.com.ua/instr/Systemair/Systemair_Modbus_for_Residential_units_User_Manual_Eng.pdf

If my memory serves me, I have done Villavent 400 unit integrations with ModBus. They have a decent ModBus support with a good range of functions available. Keep in mind that it's ModBus RTU, not TCP so you'll need to connect it via RS485. By far the easiest method is to use a usb-to-RS485 dongle.

If your ventilation unit is located far from your home controller and it's not easy to set up direct wiring, look into a serial-to-ethernet converter

I would not use serial-to-wifi models, as they have proven to be way less reliable.

So the bottom line is: if your unit indeed supports ModBus, you do not need an Arduino to do the talking. Just connect the unit to your controller and use a ModBus plugin for OpenHAB

-

MySensors Hydroponics Greenhouse projectNow that the GSM Gateway is done, I can start focusing more on the Greenhouse controller. I’m still waiting for the two most important components though - the pH sensor module and the stainless steel EC sensor probe. I’ve stumbled on another very good post on the EC topic which I’ll have to work through: https://thecavepearlproject.org/2017/08/12/measuring-electrical-conductivity-with-an-arduino-part1-overview/

-

MQTT Gateway Network On DemandIt's not going to be a WiFi gateway. It will be a GSM Gateway. I used the ESP8266 example as that's familiar to everyone whereas the GSM Gateway might raise more questions.

As it is now, I'm thinking a gateway that is semi-responsive. Meaning either when it has data to publish, or if a certain time interval has passed, brings up its network connection, connects to the broker, publishes the data it has and reads the messages it has received while the connection was down. If any messages required an ACK, it would get sent at this point.

-

MySensors Hydroponics Greenhouse project@elcaron said in MySensors Hydroponics Greenhouse project:

HASL

The pitchfork i'm currently using has solid copper traces on the forks. For more long term use I'm planning on switching to capacitive soil moisture sensors. Those can be additionally coated with epoxy resin for example for added longevity.