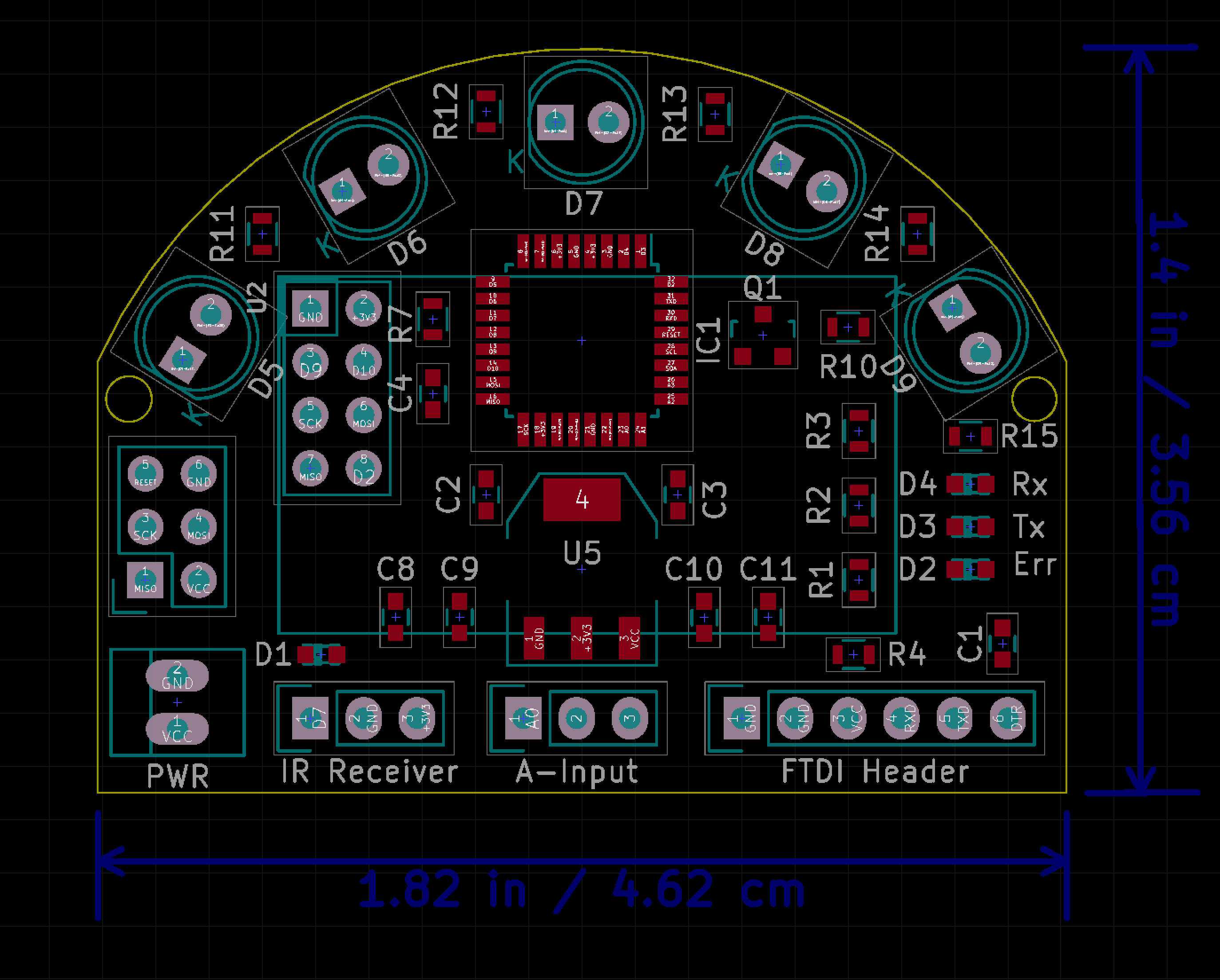

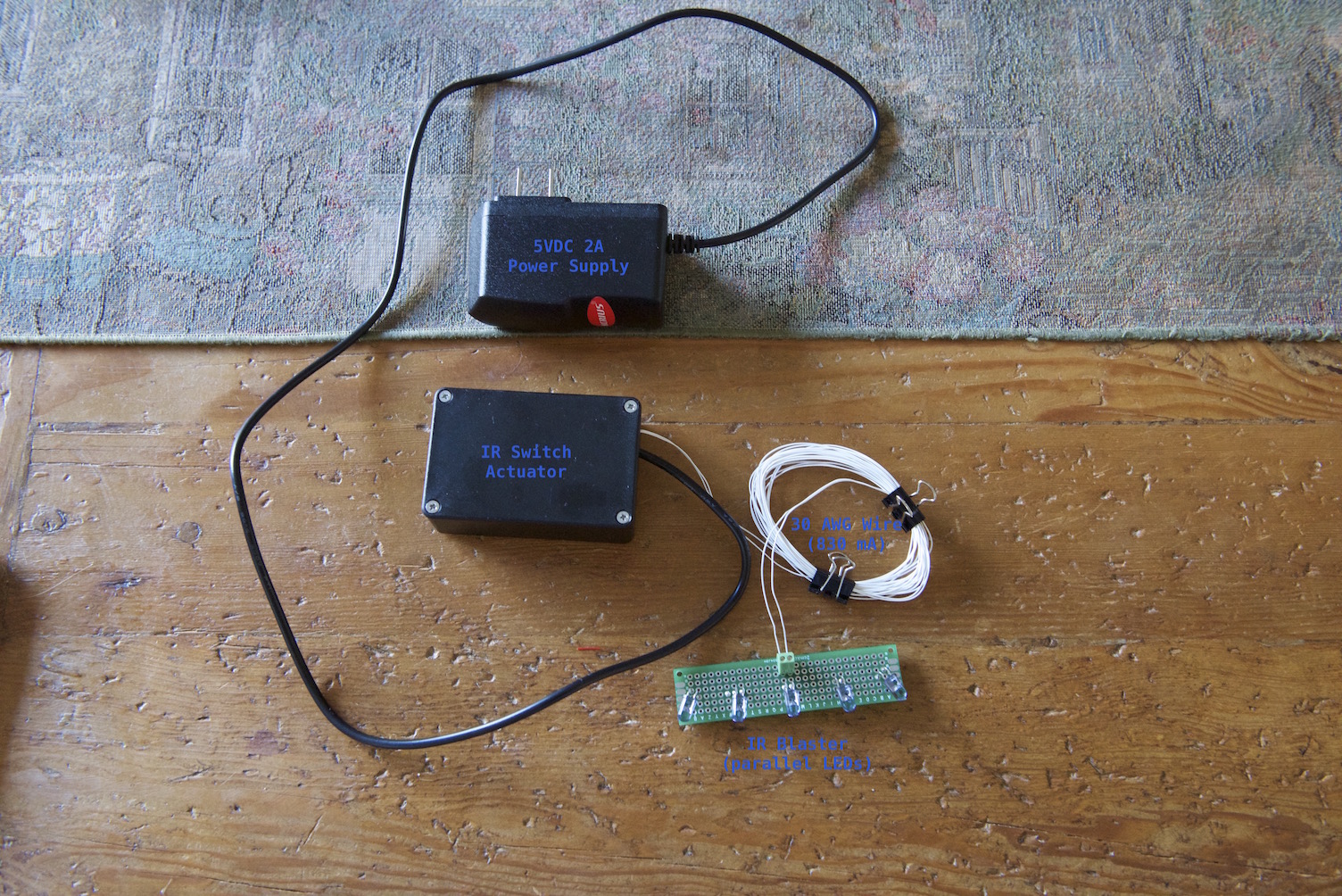

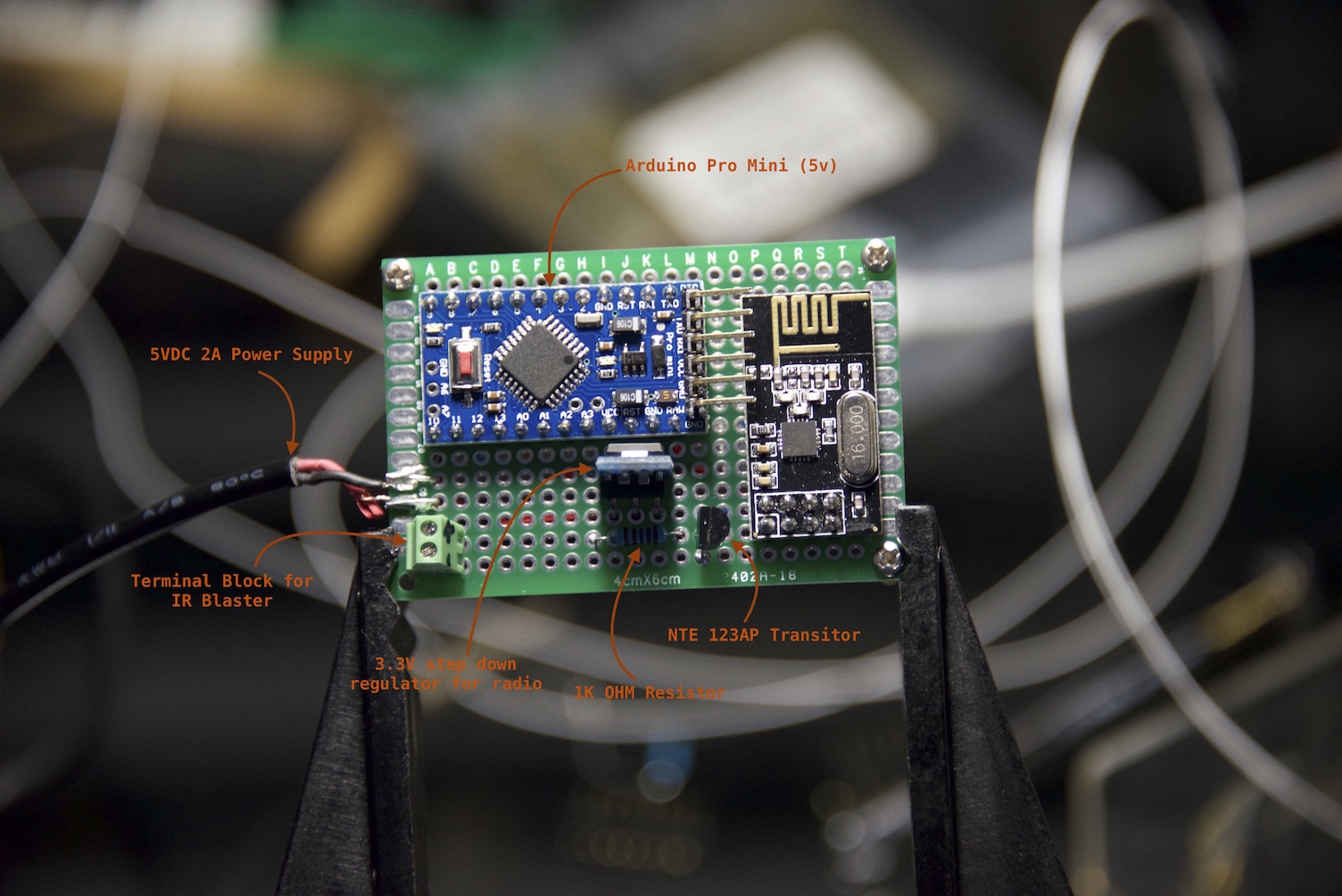

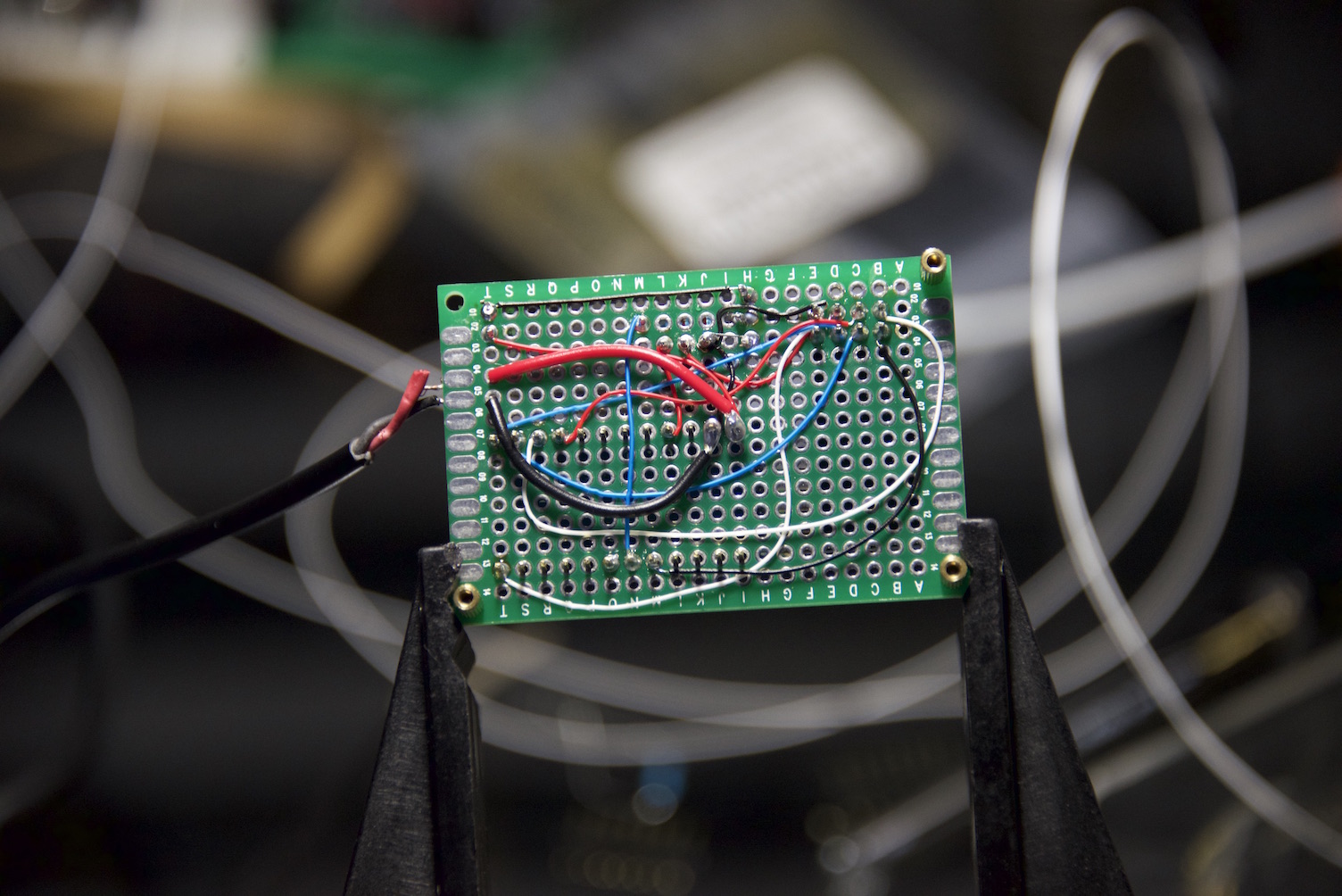

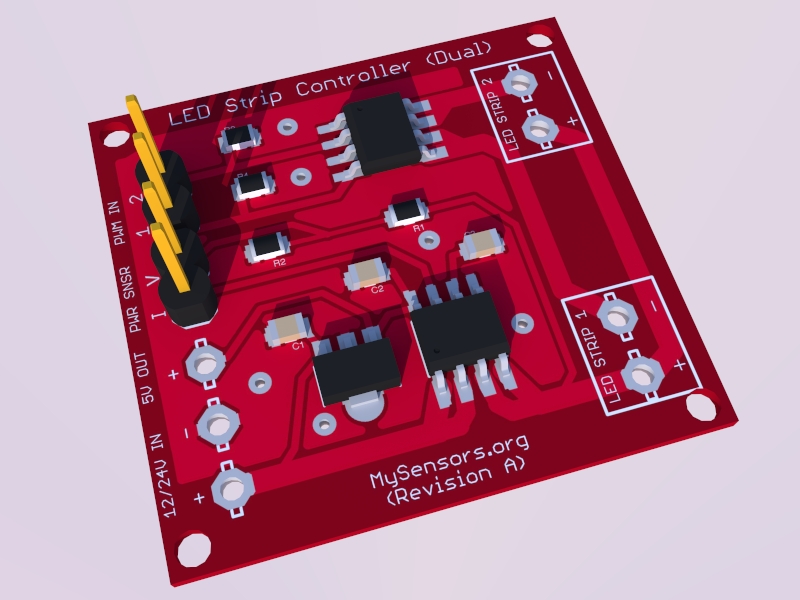

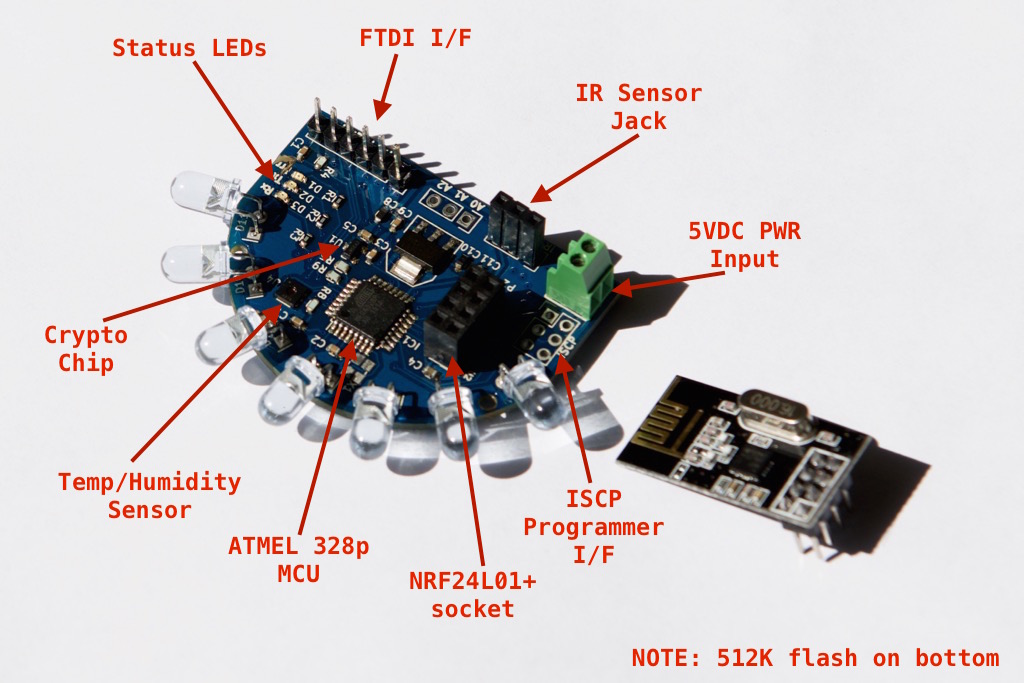

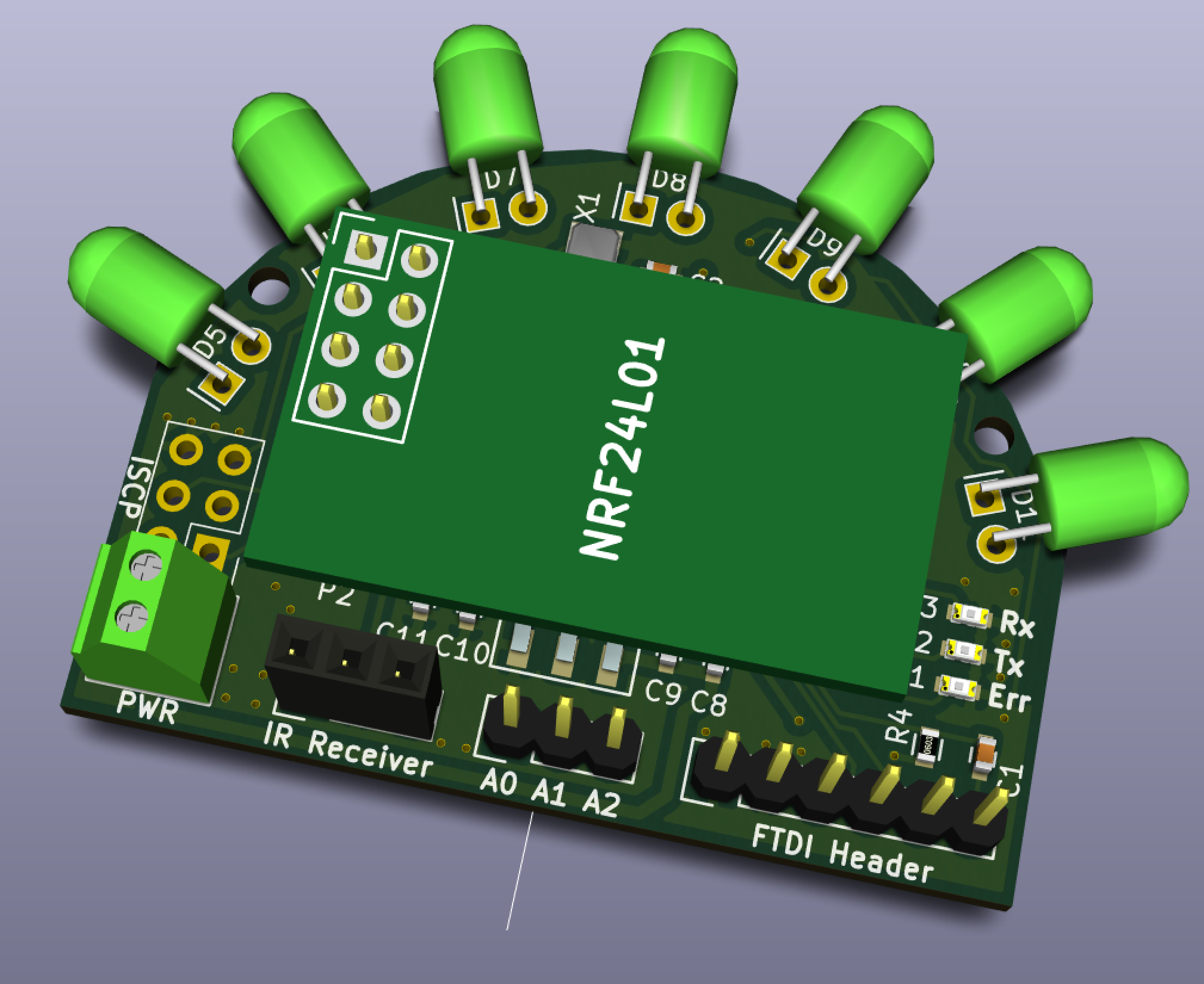

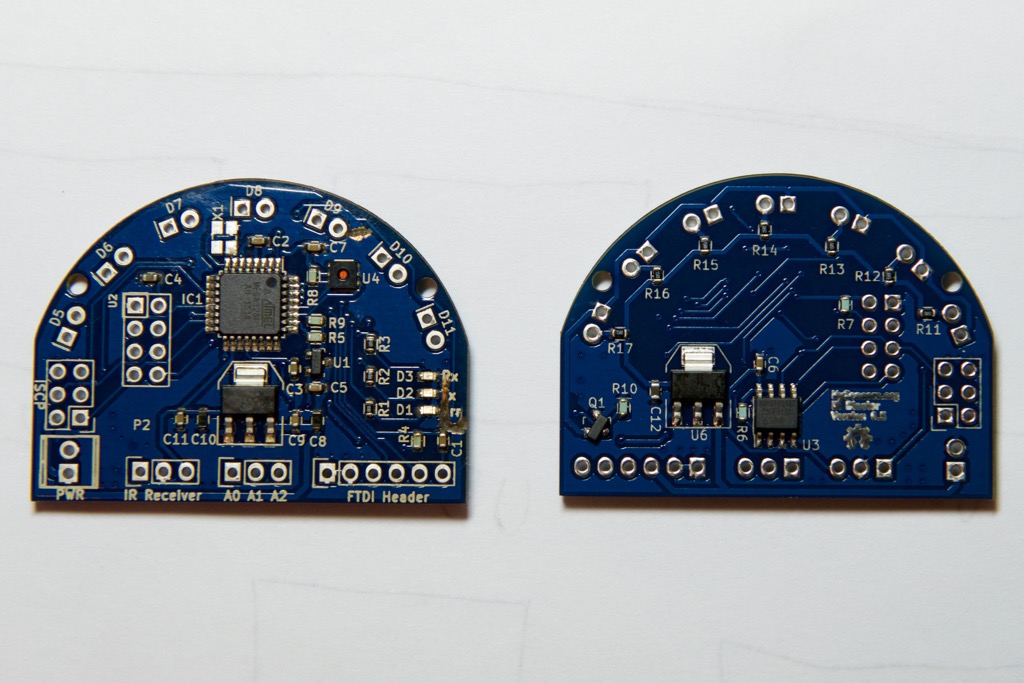

Several people have requested the IR Blaster that I demonstrated in this this Luminara Candle Actuator post but the 1st generation IR Blaster is tedious to build by hand so I decided to develop a purpose-built IR Blaster Actuator. The concept is to collapse everything from the 1st generation IR blaster down to a single PCB that also incorporates all the MySensor's capabilities (e.g. OTA sketch updates and hardware message-signing), add a temperature and humidity sensor (why not?), and a high-luminance, long-range IR Blaster all powered by a standard 5VDC AC power adapter. The IR Blaster can be used to control multiple devices in your home that use a standard infrared remote control (e.g. TV, Receiver, DVR, Air Conditioner, Luminara candles, etc.). Below is an overview, the initial schematic and a rough board layout to give you a sense of the design and size. In discussing with @Hek, if there is enough interest, we will offer this board on ITead Studio so if you are interested, please weigh in and more importantly blast away (pun intended) with critiques or flaws in the features, design, etc.

MySensors Core (derivative work of @tobowmo's Sensebender Micro who deserves a ton of credit and huge thanks for this circuit!)

- ATMEL MCU - ATMEGA 328P / Arduino compatible

- Hardware encryption for message signing - ATSHA204A (thanks to @Anticimex for developing the message signing support)

- Flash for OTA sketch updates - AT25F512C (thanks to @tosa and @tekka for the OTA sketch support)

- Radio - NRF24L01+ socket

- 3.3 VDC on-board LDO voltage regulator to power MySensors MCU & Radio Core

Actuators

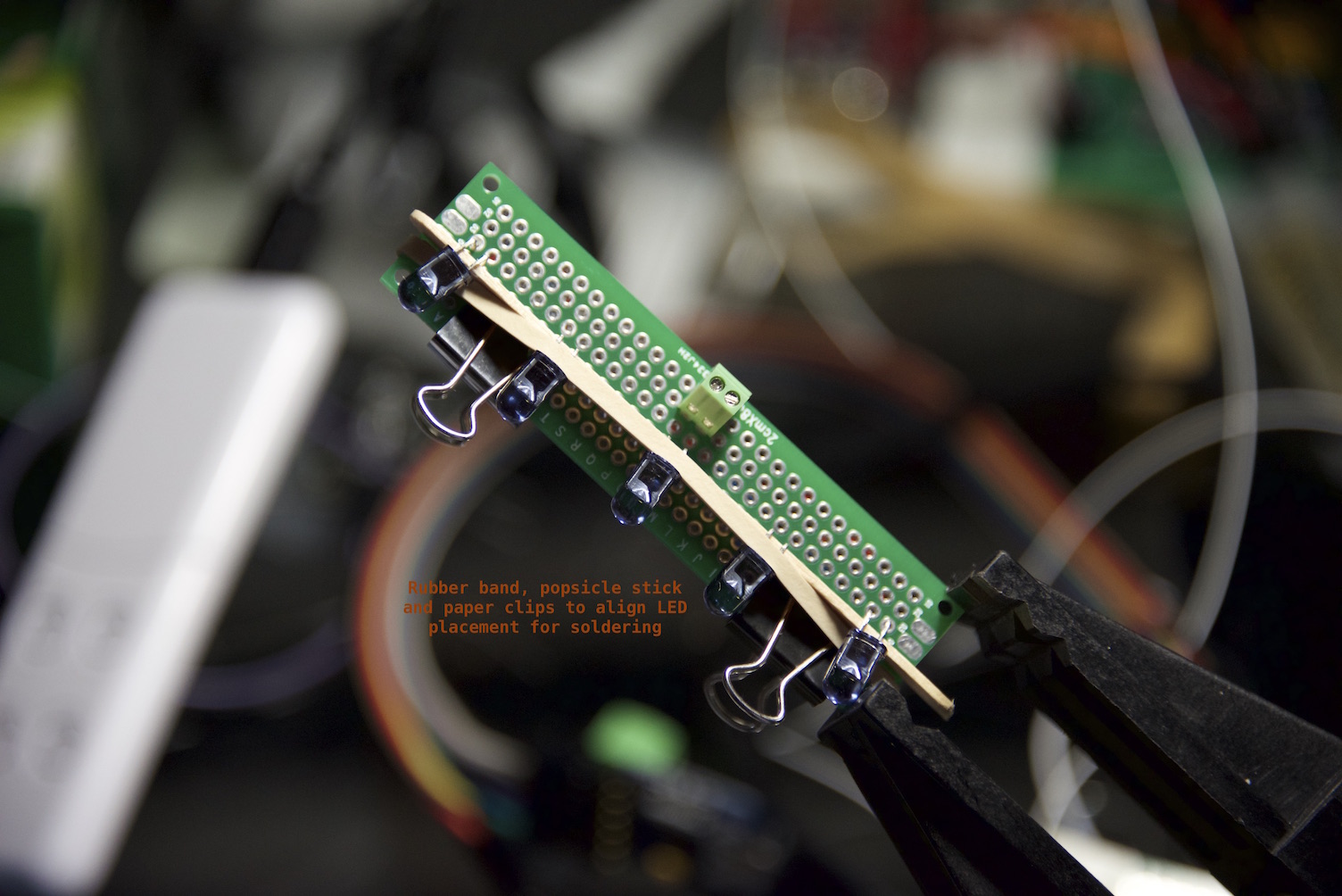

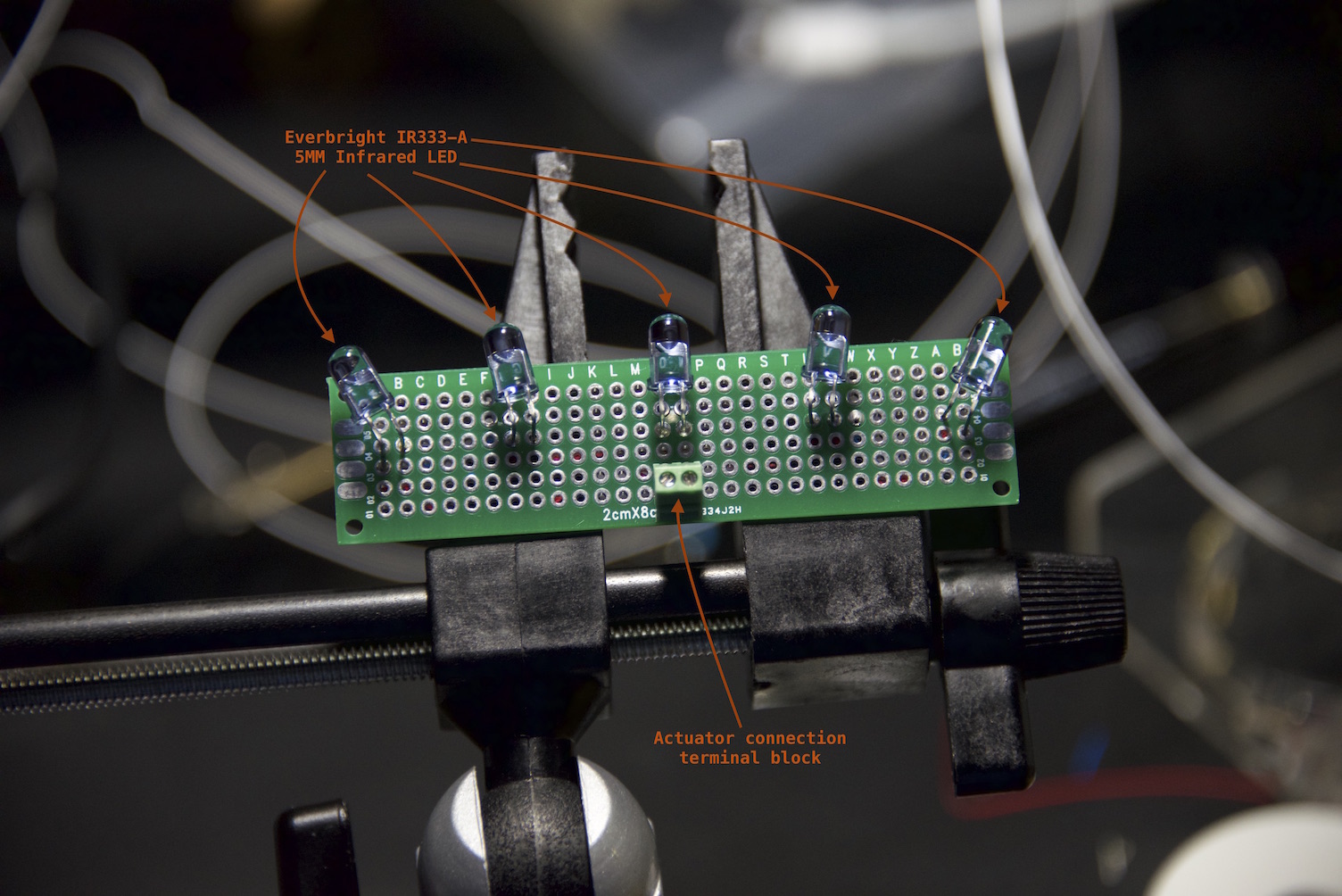

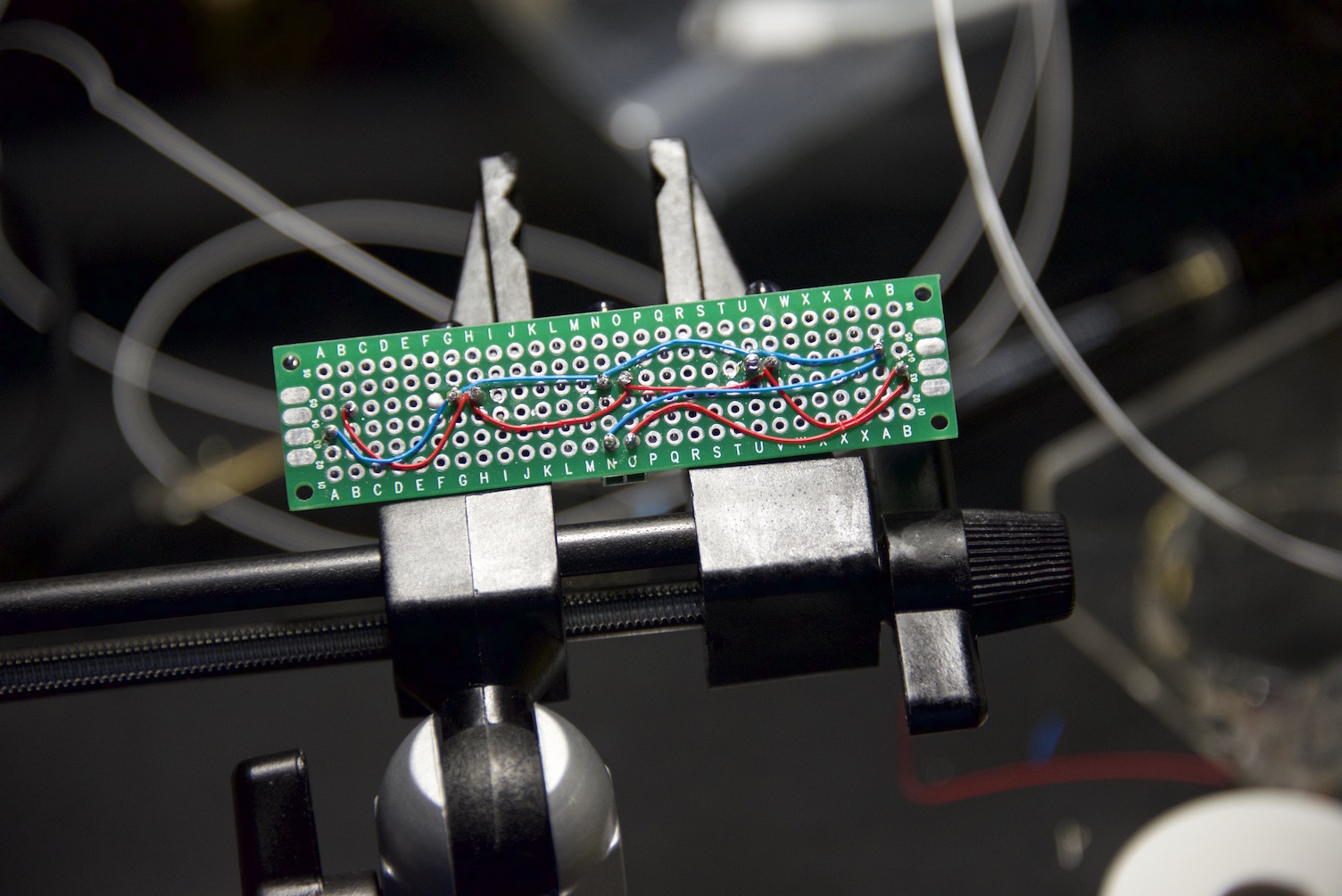

- High-Luminance IR Blaster (5 IR LEDs)

- Driven by logic-level MOSFET for maximum current distribution to IR LEDs

- Separate 5.0 VDC on-board LDO voltage regulator to power IR blaster (Isolate MySensors Core from IR current dips)

- 180 degree illumination

Sensors

- IR receiver socket (can be used for IR decoding for sketch customization)

- Temperature and Humidity (Si7021 - same sensor that Thomas Mørch selected for the Sense-Bender Micro)

3 Analog Inputs

- A0, A1, A2 (auxiliary input for other sensors - e.g. PIR, luminance, etc.)

Other

- Rx, Tx, and Err LEDs (credit to @thozza for adding LED support to sensors/actuators)

Power

- list itemStandard 5VDC adapter (regulated on board to 3.3V)

Open questions

- IR LED choice - range versus luminance spread (IR-333-A vs. IR-333-C or hybrid)

- Include an external oscillator/crystal

- Decoupling capacitor value for NRF24L01+

- Include barrel connector to simultaneously drive external IR LED emitters

- Physical learn-mode trigger

(added) Driving 5 IR LEDs at maximum luminance with a single transistor (will breadboard to confirm)(added) Include a 5V power plane