This is a work in progress! , but most everything works.

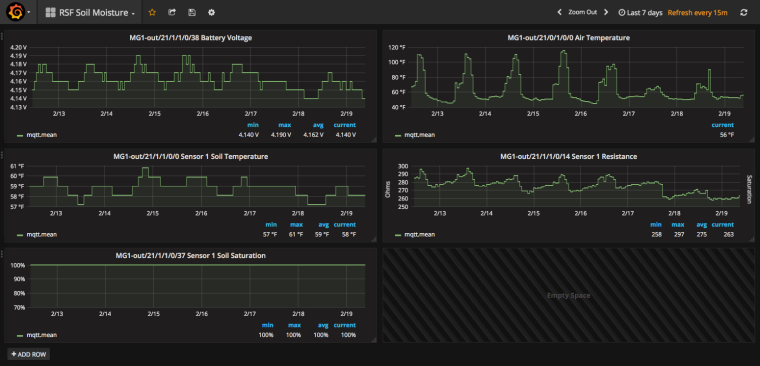

Heavy rain lately, so soil is at 100% saturation...

This was developed with MySensor 2.1.1 https://www.mysensors.org/

IDE 1.81

SAMD 1.6.11

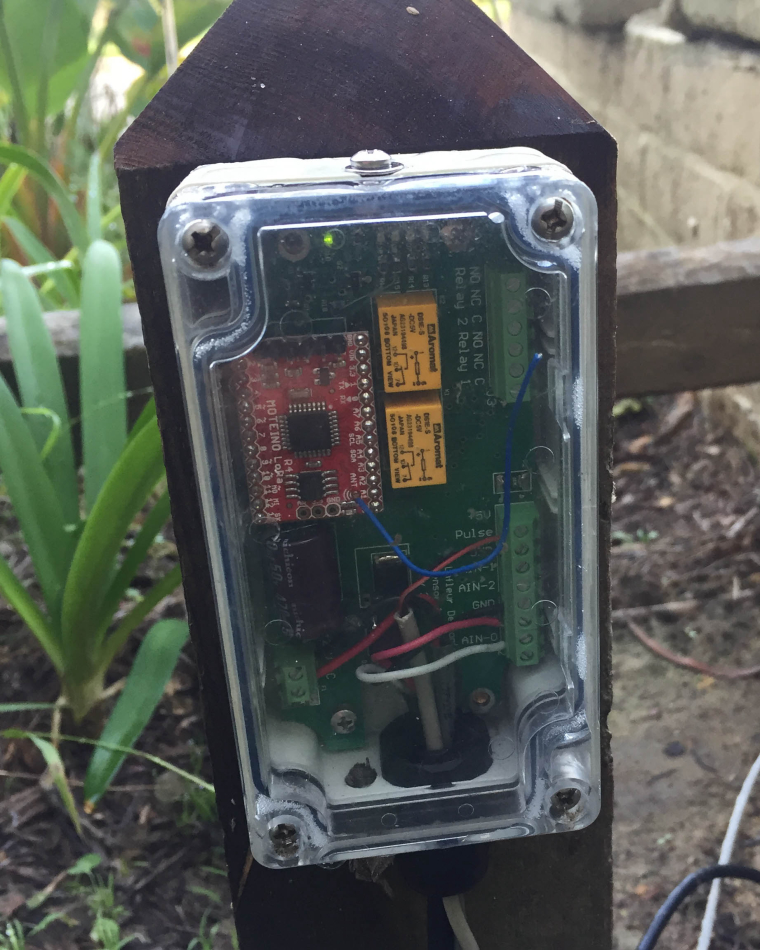

RocketScream M0 with RFM95 radio

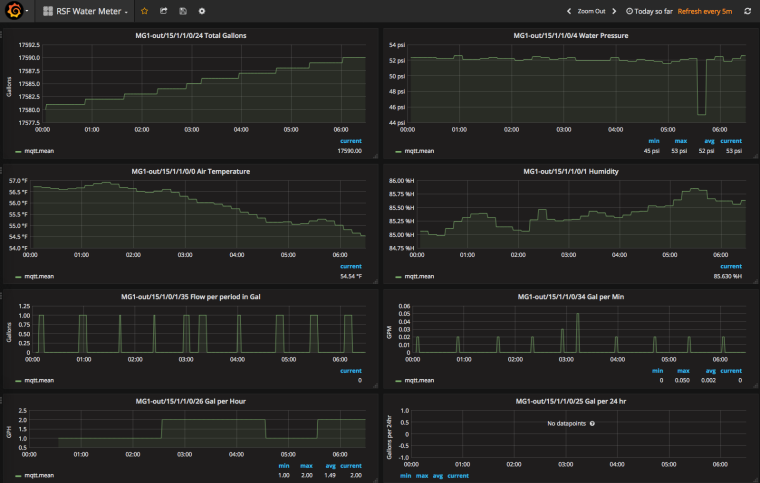

Data from the sensor to MQTT-gateway to MQTT to (Telegraf to InFluxdb to Grafana)

Controller function via NODE.RED connected via MQTT.

It measures soil moisture from 1 to 4 sensors, has options for soil and air temperature.

Support MCP9800 or Si7021 (humidity also) or temp sensor in DS3231 for air temp

DS18B20 for soil temp

Support of a water pressure sensor via an analog port

Has a DS3231 Real Time clock to wake up processor at designated hour

Has support on the board for a flow meter and pressure sensor (but no software in this code base)

Solar, battery Powered or via 8 to 28v AC or DC

Sleep's most of the time and just wakes up to see if its time to send a report.

Support for requesting and receiving time of day for setting RTC

Support for updating sensor tx schedule via V_VAR1

(Board is designed to fit in a Hammond 1554 case)

https://github.com/trlafleur/Soil_Moisture_Sensor_MS_R1.1-RFM95

http://www.rocketscream.com/blog/product/mini-ultra-pro-with-radio/

Sensor are made from plaster of paris (gypsum)

http://vanderleevineyard.com/1/post/2012/07/the-vinduino-project-2-making-and-installing-gypsum-soil-moisture-sensors.html

http://www.irrometer.com/sensors.html#wm

https://www.amazon.com/Delmhorst-GB-1-Gypsum-Sensor-Moisture/dp/B0002IKRUS (pkg of 10 each)

Based on the work of: Reinier van der Lee, www.vanderleevineyard.com