Hi everyone,

I'd like to show you a recently completed project. A reed switch-based sensor that can be implemented either normally open to normally closed. (I like normally open (with sense magnet) for low/no current draw, but normally closed (with sense magnet) can also be realized).

If one does a bit of research on reed switches, it can be found that the switches can utilize two magnets for making a normally open switch (without sense magnet) a "normally closed" switch (without sense magnet).

The idea is to drill a 7/16" hole in the jamb of a door and imbed the reed switch, then imbed a magnet into the door to complete the install. One wouldn't even know it is there; I would have a node close by to connect directly to the switch in the wall, (for me, new construction will allow this). Have a look, let me know your thoughts.

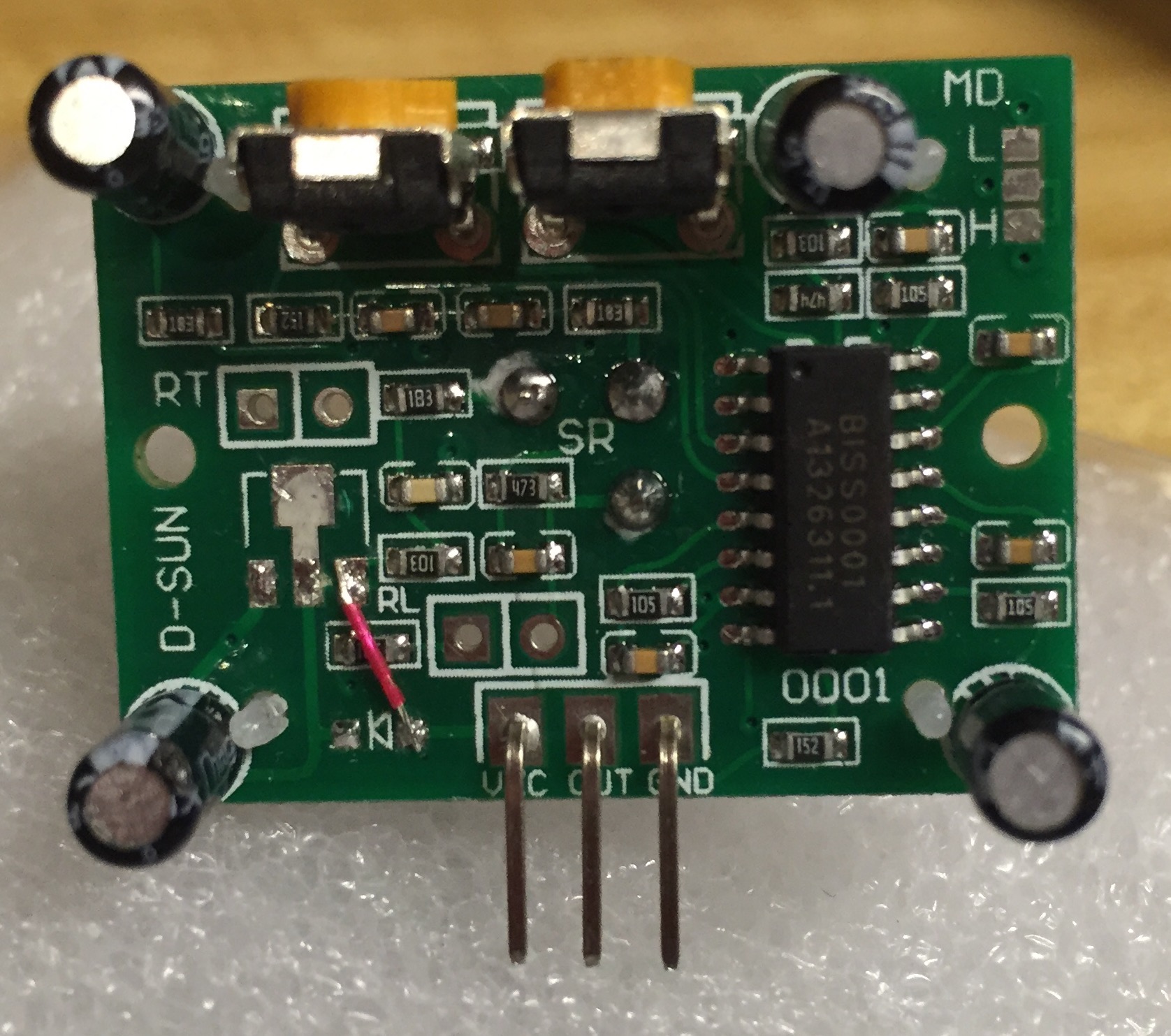

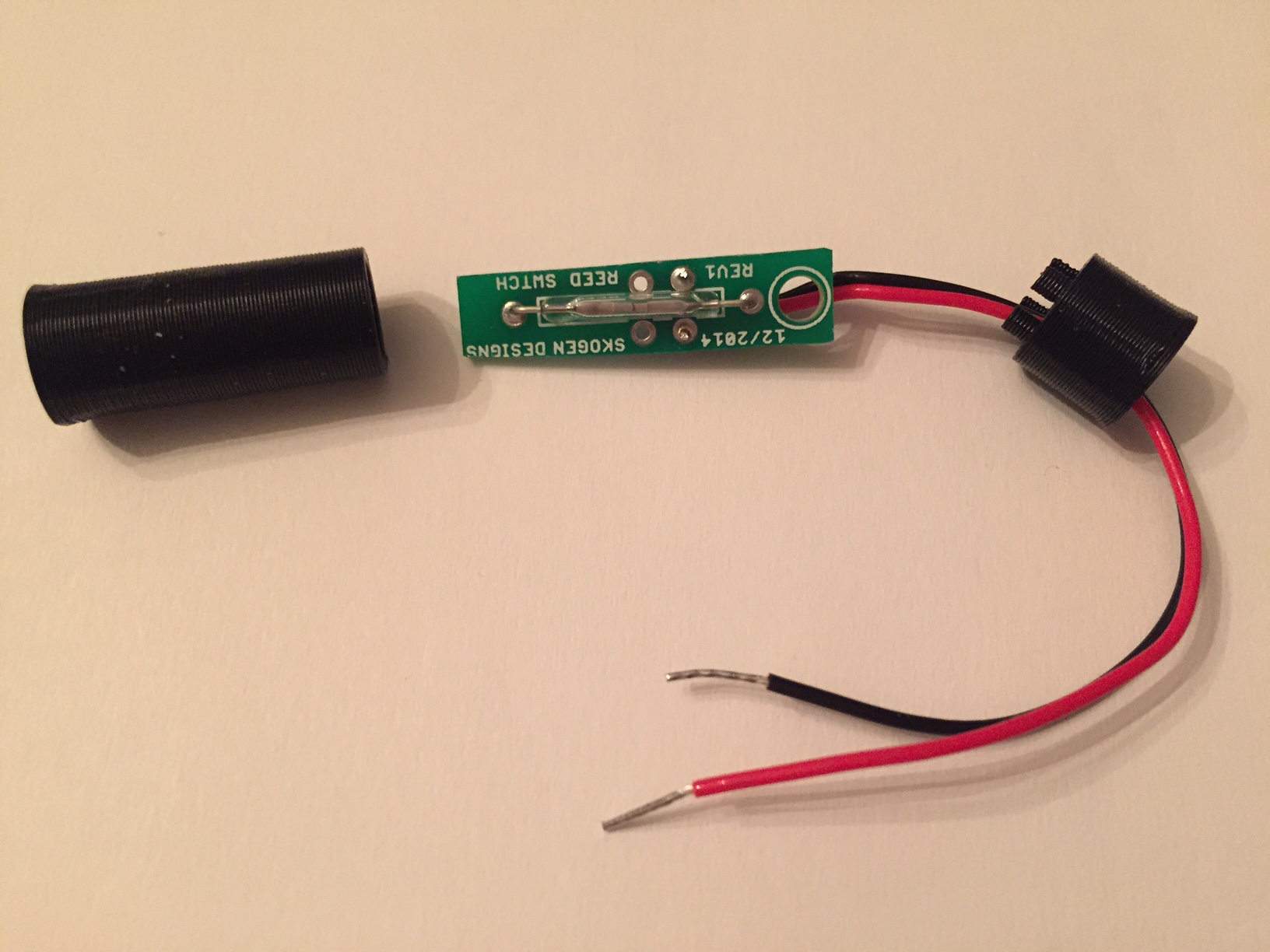

I have designed a PCB and case (3D printed) for the switch. The PCB is straight forward, I'll leave that to anyone who'll want to replicate it, but the case took a few revs. Here is the prototype.

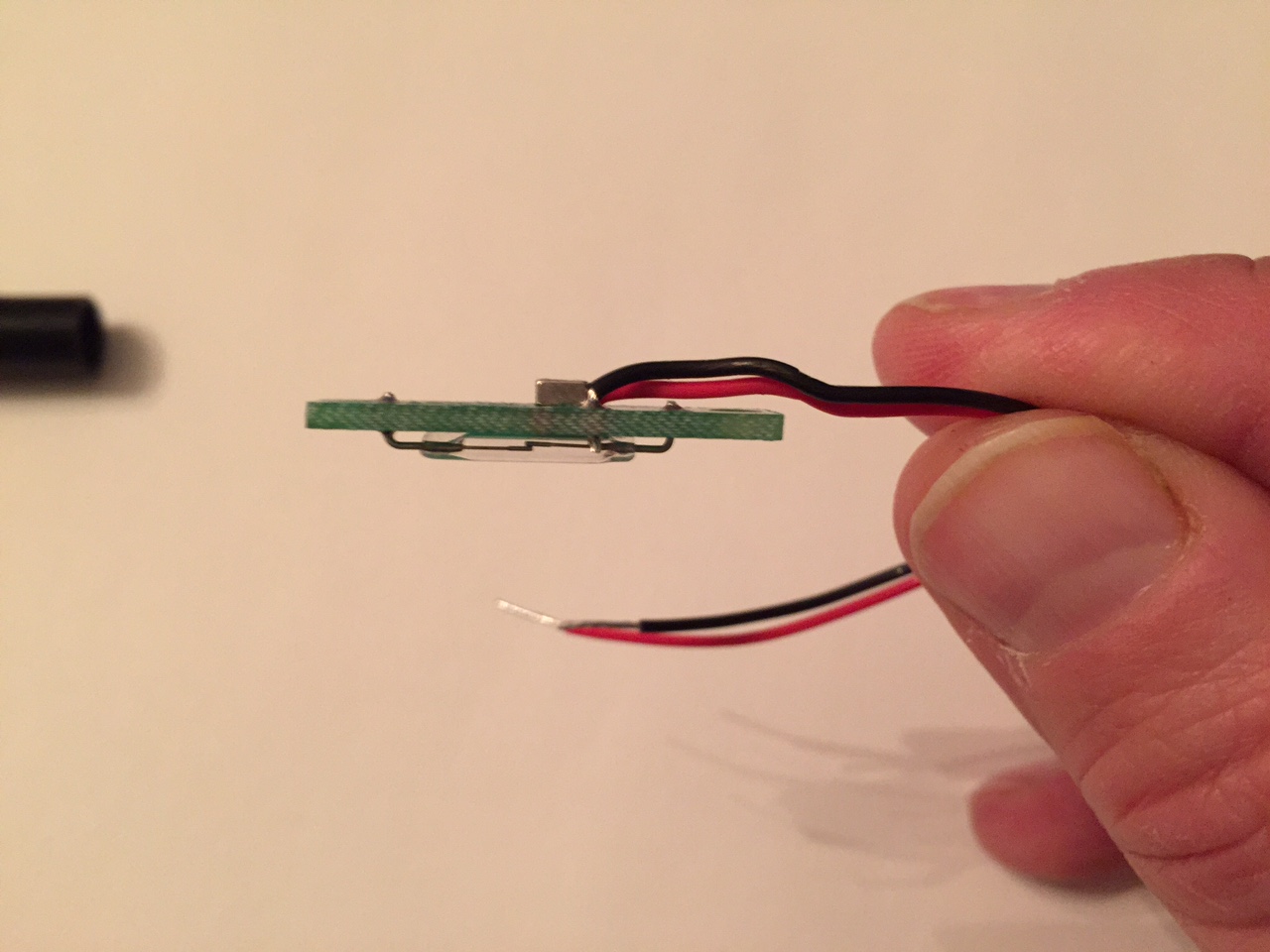

Figure 1. Side view of the switch PCB. The switch is the glass tube; on the other side, I super-glued a magnet to the PCB to change the switch from normally open to "closed" (conducting). In this configuration the switch is closed (conducting), and when another magnet (sense magnet) is brought near (must be opposite polarity) the switch changes to open.

Figure 2. Reed switch PCB and case.

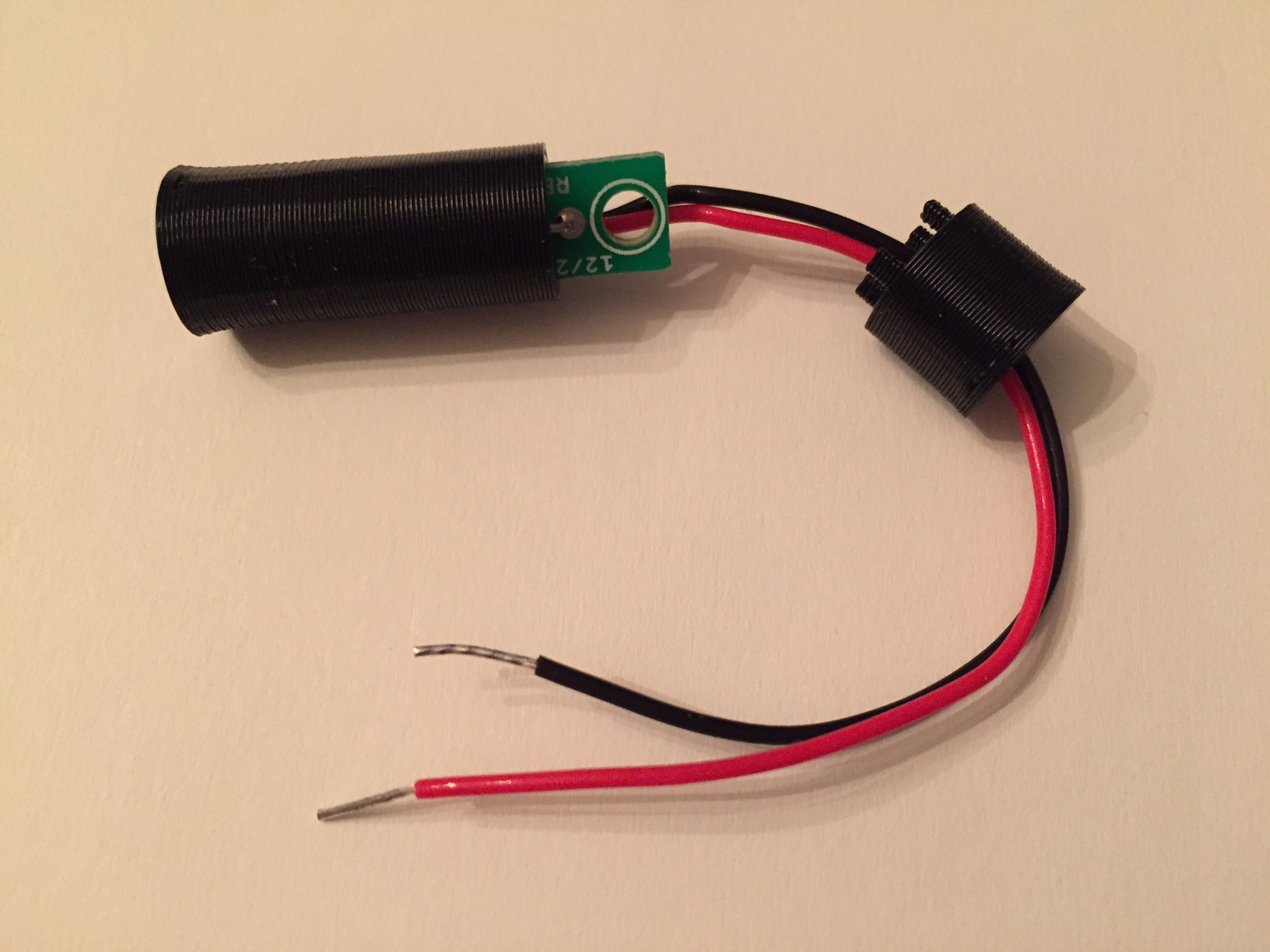

Figure 3. Reed switch fitting into case.

Figure 4. Reed switch inside case. ready to be inserted into drilled hole in door jamb. The wires would travel to a node through a smaller hole at the end of the case. (if that makes sense). The sense magnet will be brought close to the 'top' of the cylinder when the door is closed making the switch 'open'. In this configuration, I believe a burglar would have a very hard time cutting wires that are inside a wall, so, no worries and I value normally low power (no current) operation.

Here is the SketchUp file used to create the 3D print...you should install the "export to .STL" extension and then print away. The PCB is 1.6 mm thick. ReedSwitch_WorkingSet.skp

Oh, and for those in the USA, I get the magnets from K&J Magnetics