Is there a schematic of the NRF24 board?

-

@ServiceXp said:

@ivan.todorovich

Oh it's possible, but I think you will need to build from the pcb up to meet the goal.And that is what I intend to do.

The first application would be controlling our shutters.

I am not sure yet how I am going to do this.

- In wall behind (or replacing) the current timer that operates the shutters;

- Next to the shutter motor (would give more room);

In any case they will be operated with 220v. There are enough ways to do that...

@marceltrapman

Would love to see the results. What type of chips are planing to use DIP, QFP, QFN.?If you are successful, it's going to open up another world of possibilities for MySensors users, Providing it doesn't involve SMD work that is... ;-)

-

@marceltrapman

Would love to see the results. What type of chips are planing to use DIP, QFP, QFN.?If you are successful, it's going to open up another world of possibilities for MySensors users, Providing it doesn't involve SMD work that is... ;-)

@ServiceXp all SMD including

ATMEGA328P-AU, TQFP-32

Winbond W25X40, SOP-8 -

Hello @marceltrapman, how will you power the board from the mains?

I'm a noob in this things yet.. and I'm trying to make a relay sensor to control lights, also put behind the electrical outlet (220vac).. I'm having trouble figuring out if I should add some kind of transformer for every sensor or maybe distribute a 5vdc line from the controller itself..

@ivan.todorovich I'm thinking about re-using the power supply and possibly touch board of this project: http://www.elektor-magazine.com/en/magazine-contents/previous-issues.html?tx_elektorarticle_listissues[article]=26510&tx_elektorarticle_listissues[action]=show&cHash=830afaabd7423433a83dca9198de8e12

Magazine:http://lasersoft.com.au/books/Archived/rocvm.Elektor.Electronics.USA..June.2014.pdf

-

@ServiceXp all SMD including

ATMEGA328P-AU, TQFP-32

Winbond W25X40, SOP-8@marceltrapman

Bummer. Don't think I would be able to handle the SMD requirement. -

@marceltrapman

Bummer. Don't think I would be able to handle the SMD requirement.@ServiceXp said:

@marceltrapman

Bummer. Don't think I would be able to handle the SMD requirement.It is really not that hard.

People seem to solder it I use a rework blower.

A real cheap one (to see what it brings me) but with good result.

With the # of components and the # of boards we need it is really doable... -

@marceltrapman I'd love to see your work when its done.

I'm currently considering wiring 12v around the house to feed sensors, and maybe replace the wireless board by implementing a wired signal protocol (modbus for instance).

I have a feeling it would be more efficient regarding power consumption, and the house wouldn't be so saturated with 2.4ghz radio signals.. which might not be so healthy

I must reiterate though, I'm a noob.. so if anything I just said doesn't make sense please object me :D I would appreciate

-

@ServiceXp said:

@marceltrapman

Bummer. Don't think I would be able to handle the SMD requirement.It is really not that hard.

People seem to solder it I use a rework blower.

A real cheap one (to see what it brings me) but with good result.

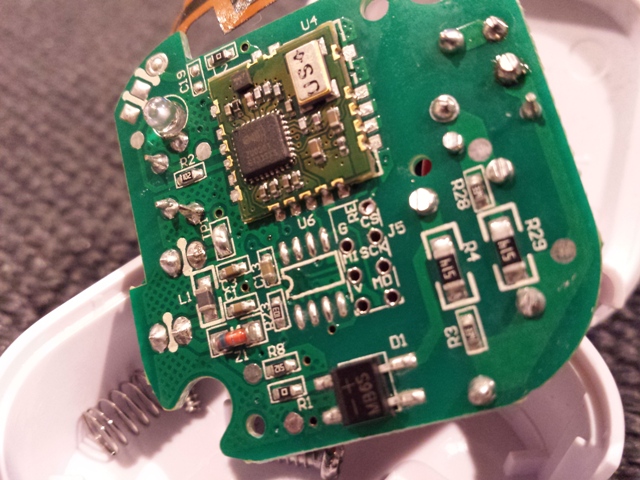

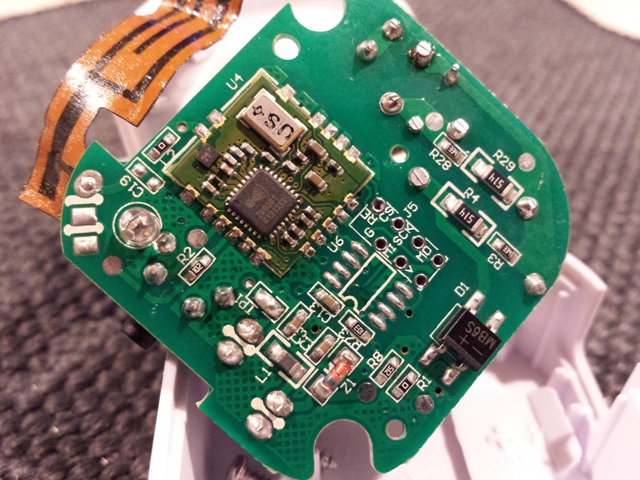

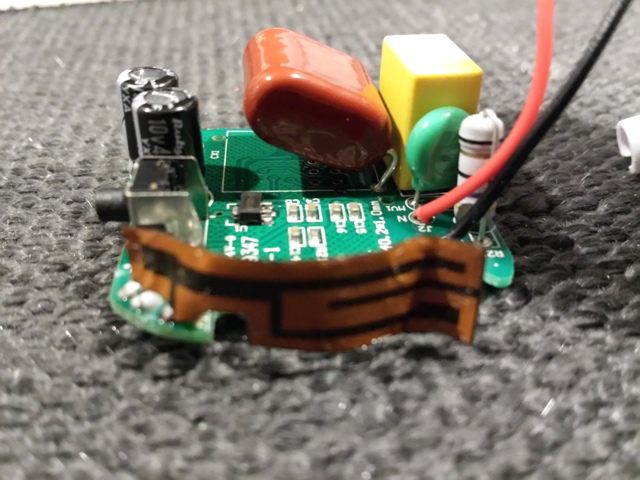

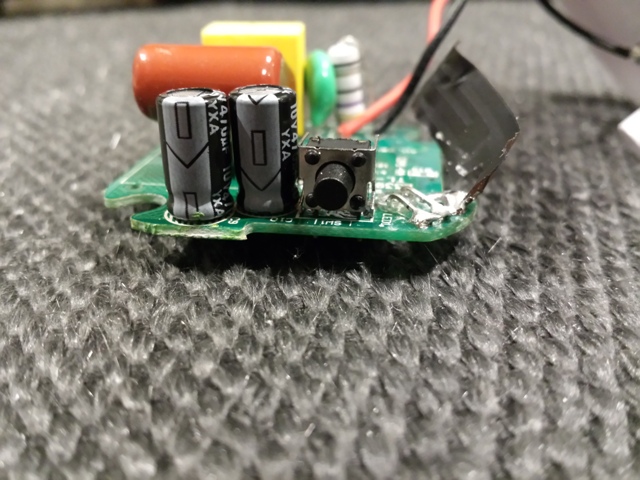

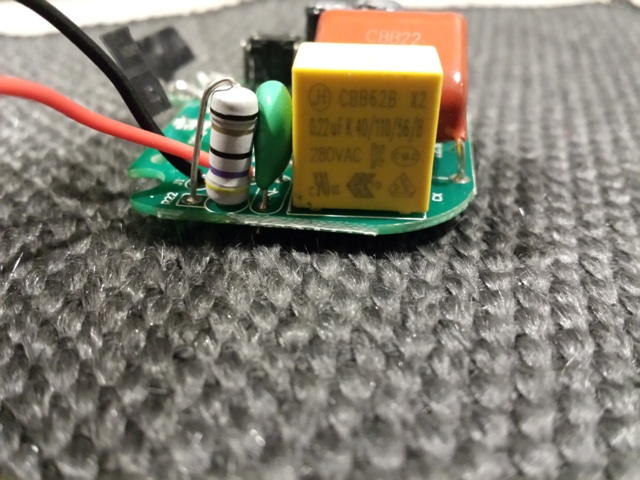

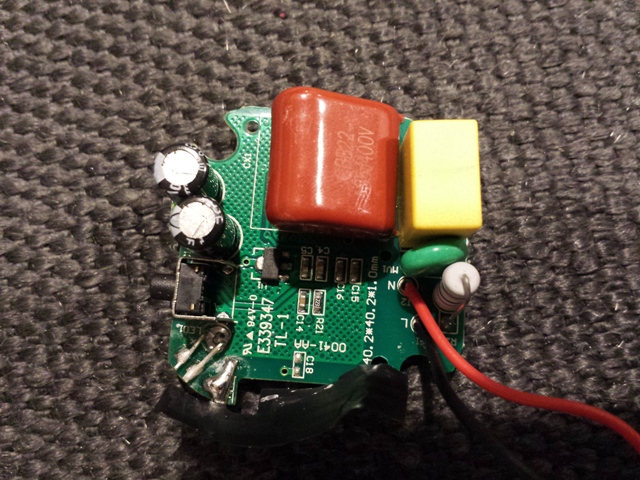

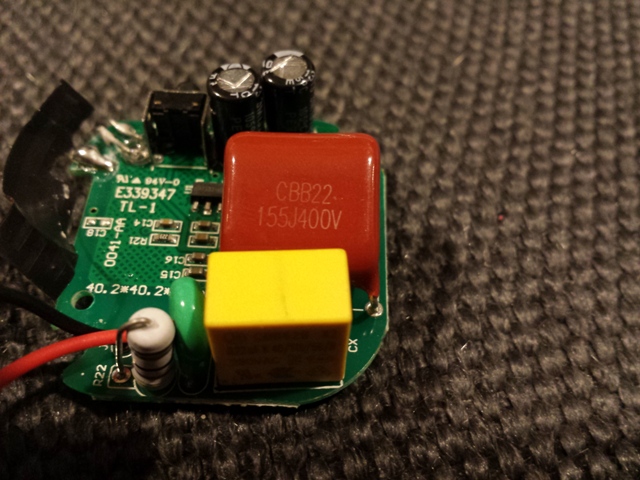

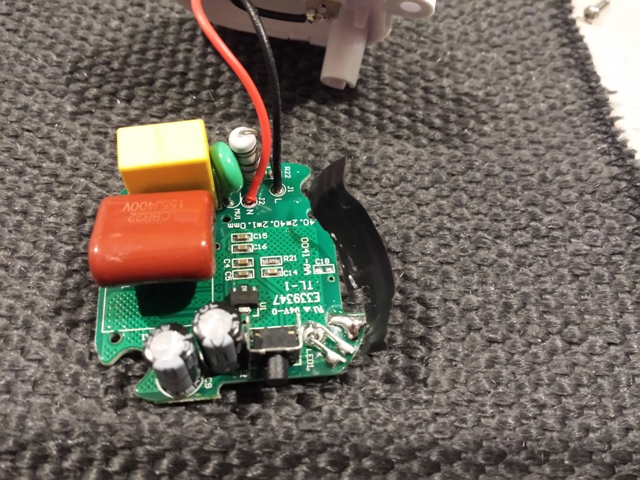

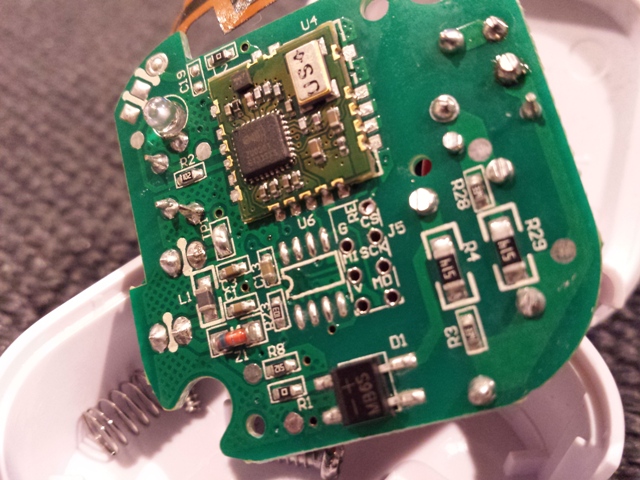

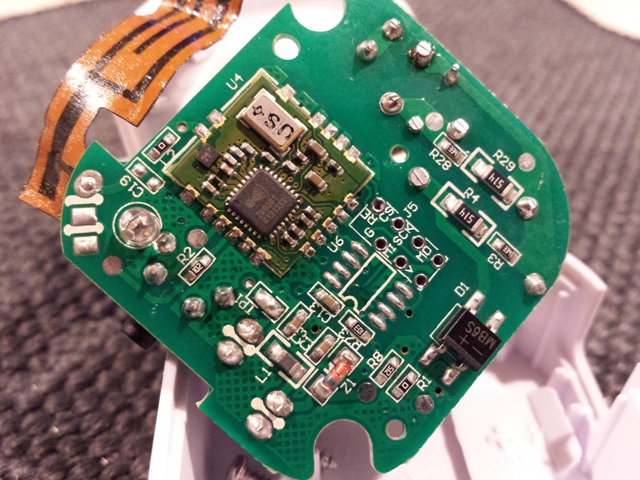

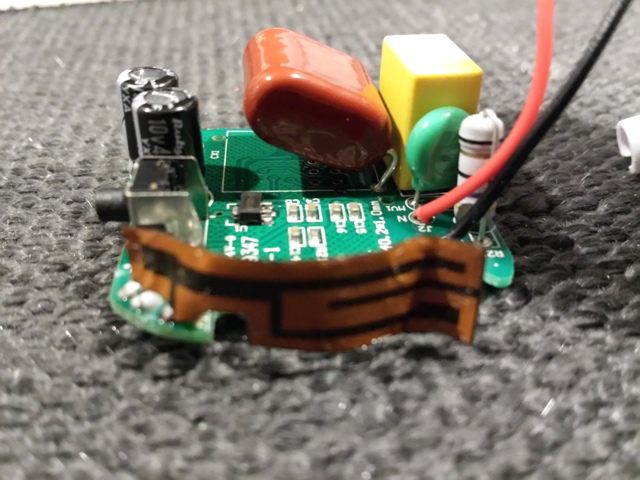

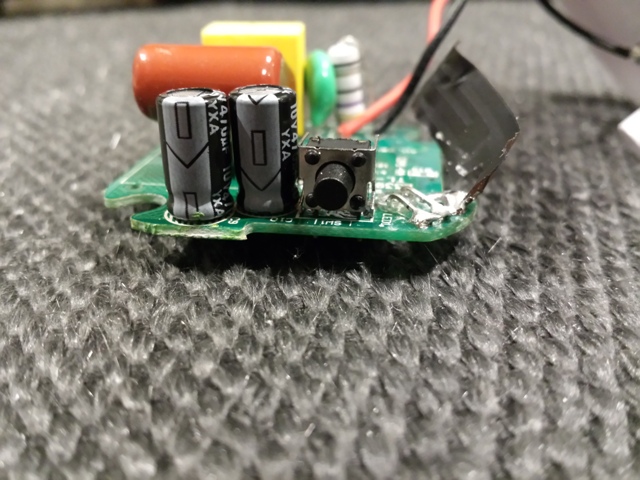

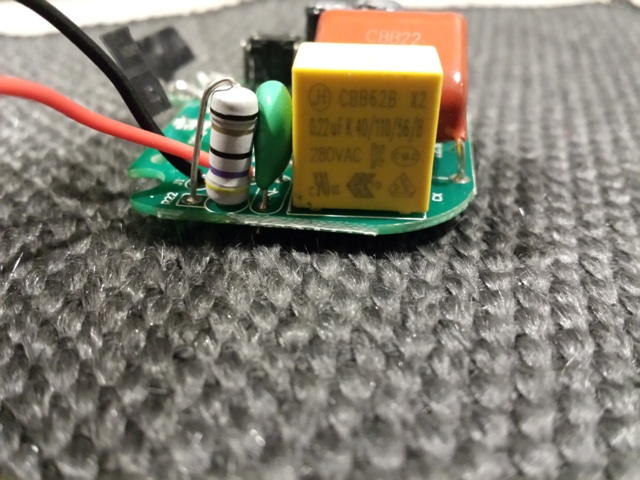

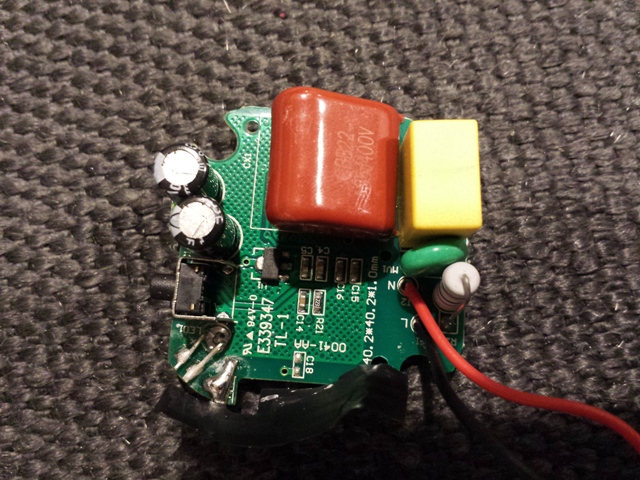

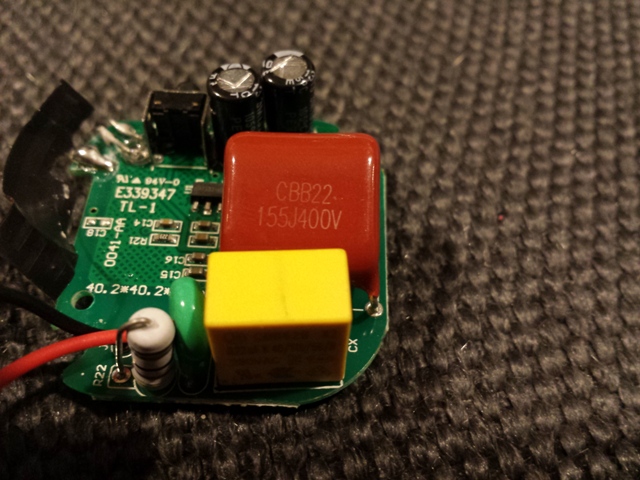

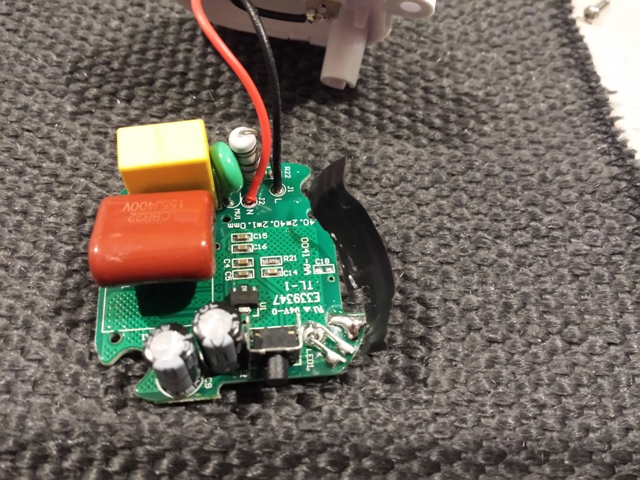

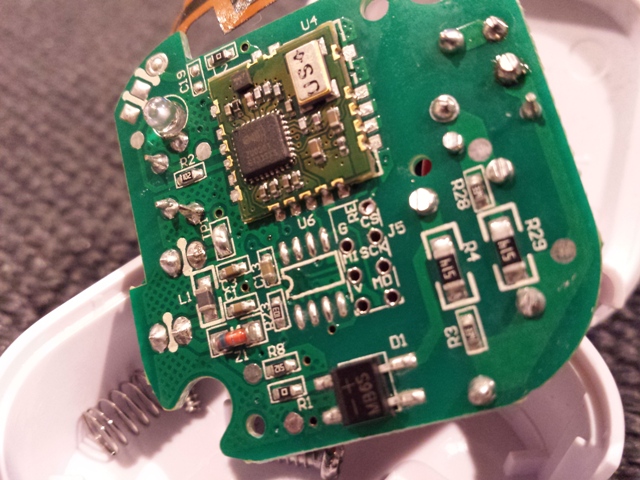

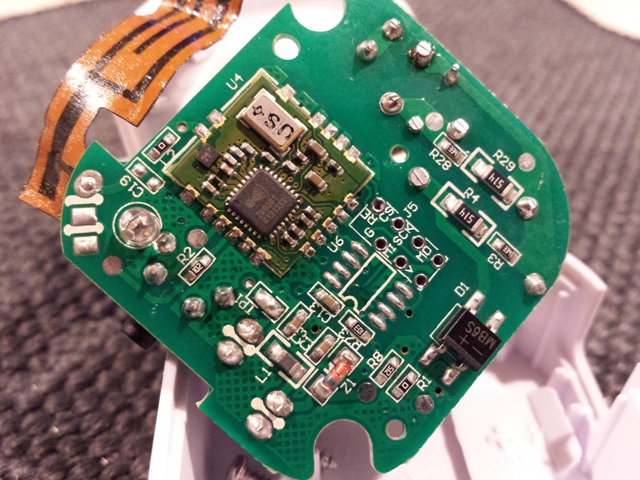

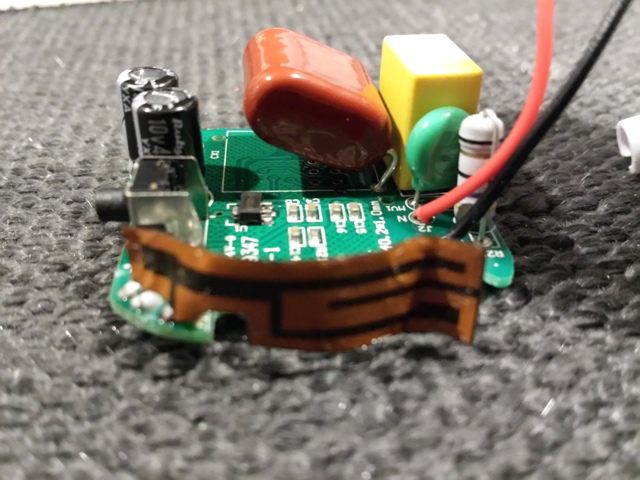

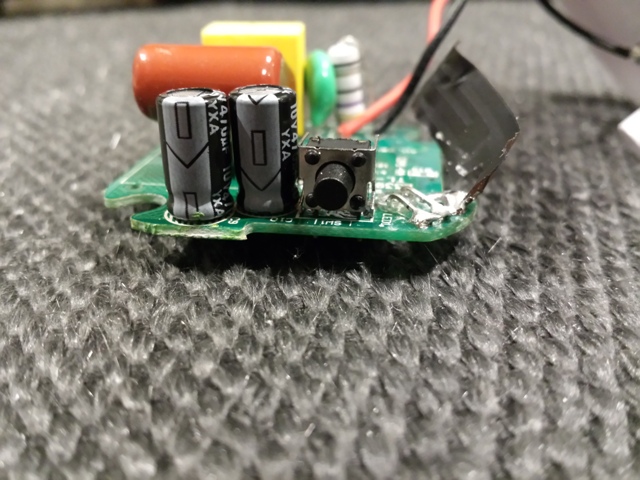

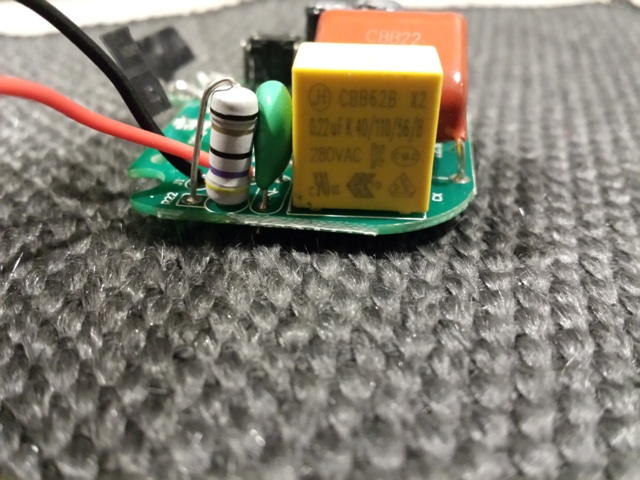

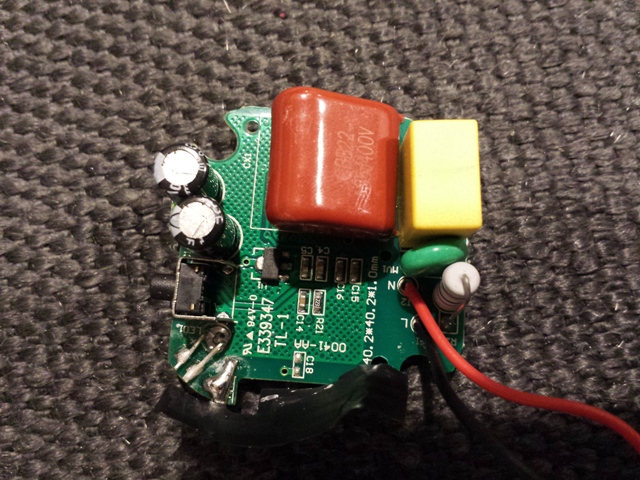

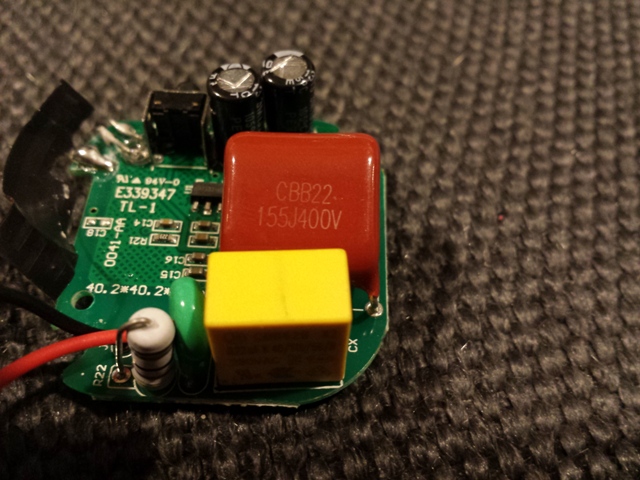

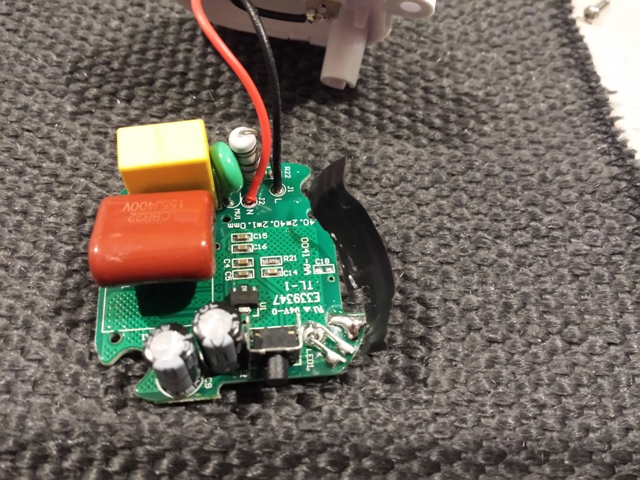

With the # of components and the # of boards we need it is really doable...Don't know if this will help you with some idea's but I pulled apart my Aeotec Zwave extender and took some pics. If you need me to get any other info from any of the components just let me know.

This thing is pretty small. and is powered from Mains

-

Don't know if this will help you with some idea's but I pulled apart my Aeotec Zwave extender and took some pics. If you need me to get any other info from any of the components just let me know.

This thing is pretty small. and is powered from Mains

-

Don't know if this will help you with some idea's but I pulled apart my Aeotec Zwave extender and took some pics. If you need me to get any other info from any of the components just let me know.

This thing is pretty small. and is powered from Mains

@ServiceXp Thanks it looks pretty much the same as my AEOTEC range extenders.

The only difference is 220v :) -

Hello @marceltrapman, how will you power the board from the mains?

I'm a noob in this things yet.. and I'm trying to make a relay sensor to control lights, also put behind the electrical outlet (220vac).. I'm having trouble figuring out if I should add some kind of transformer for every sensor or maybe distribute a 5vdc line from the controller itself..

Hi! See this examples how to power it from 220V without tranformer.

http://www.designercircuits.com/DesignNote1a.pdf