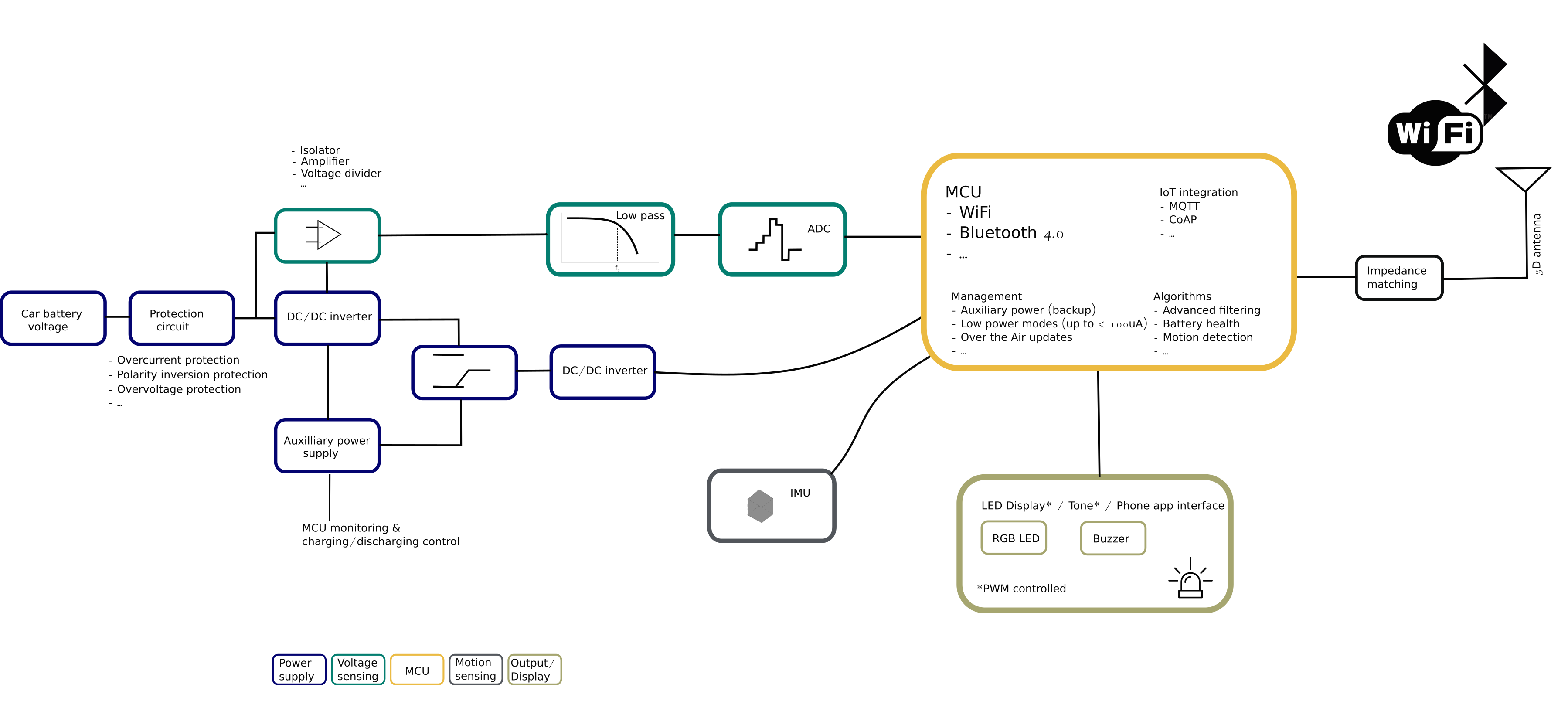

@NeverDie Thx for appreciating the work done. There will also be an open source part in the future. When and how extensive the open source part will be, remains to be seen. The release of certain information (block diagram, ..., in this post) is related to those open source parts.

There are some OBD solutions, however most of them (in my experience) give back low frequency data put by the car manufacturer on the OBD-bus (CAN, ...). Therefore transients evolving directly from the battery could only be recorded if the manufacturer sends those data accordingly on the bus. Due to the small bandwidth(also because of other car data that have to be sent, ...), such battery data are sent more often once per second or less. Fast battery events (i.e. cranking events, ...) are therefore imperceptible. Unless the manufacturer processes the fast events and then sends them (once per second or less), which is very unlikely if the manufacturer does not market this feature itself. Third parties devices for high frequency sensing costs several hundreds dollars.

In my experience, important battery states (especially the fast ones) are recorded by measuring and processing corresponding data directly on the battery.

I agree with you about the limits related to the communication over Bluetooth. But i think Bluetooth 5.0 will improve a lot. However, WiFi will always remain an important option due to the high data throughput. The combination of both (BLE & WiFi), especially with regard to energy consumption, will gain in importance.

6

5 Votes5 Posts325 Views

6

5 Votes5 Posts325 Views 1

2 Votes3 Posts211 Views

1

2 Votes3 Posts211 Views