💬 Easy/Newbie PCB for MySensors

-

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"Also a bit worried the 4,7uF cap os to far away from radio.

I agree especially with other traces to cross before reaching the radio.

@nca78 said in 💬 Easy/Newbie PCB for MySensors:

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"I actually had a long discussion with @Anticimex which is the designer of MysX and he said it is not wrong. Can you please explain why it's wrong ?

I was thinking pin 1 should go towards both vertical and horizontal edge of the pcb (that's why I asked him because I though It should go where the radio is) but he said the only rule is pin 1 should go towards the edge. I looked at the rules and that is what it said so I don't think I'm breaking any rules.

The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this. It should be oriented so that pin1 is always closest to the board edge parallel to the connector. This allows a daughter board designed using the same constraints to be facing back "inwards" over the motherboardEither way it has changed like less than 1mm

If we can somehow get Anticimex to recommend and we can agree on a better placement I'm happy to re-think my design.

If you thinks it's hard to create MysX boards for EasyPcb I have created a finished Kicad project with board outlines, connector and drill holes you can use as a template. Check it out on the project page.

-

@nca78 said in 💬 Easy/Newbie PCB for MySensors:

@sundberg84 said in 💬 Easy/Newbie PCB for MySensors:

- MysX location changed to accept more MysX boards and align like RFM version.

Please don't do like that and follow the guideline for the MYSX connector (location was already wrong in previous versions and it's a bit annoying to make MYSX boards for Easy PCB):

*"The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this"I actually had a long discussion with @Anticimex which is the designer of MysX and he said it is not wrong. Can you please explain why it's wrong ?

I was thinking pin 1 should go towards both vertical and horizontal edge of the pcb (that's why I asked him because I though It should go where the radio is) but he said the only rule is pin 1 should go towards the edge. I looked at the rules and that is what it said so I don't think I'm breaking any rules.

The MYSX connector should be placed close to the board edge with a 100 mil spacing from all edges. The footprint has a courtyard outline to emphasize this. It should be oriented so that pin1 is always closest to the board edge parallel to the connector. This allows a daughter board designed using the same constraints to be facing back "inwards" over the motherboardEither way it has changed like less than 1mm

If we can somehow get Anticimex to recommend and we can agree on a better placement I'm happy to re-think my design.

If you thinks it's hard to create MysX boards for EasyPcb I have created a finished Kicad project with board outlines, connector and drill holes you can use as a template. Check it out on the project page.

@sundberg84 I cannot see anything wrong with the MYSX placement on that board.

If one could pick freely, ideal placement of the connector would be in the middle of the board side to allow daughter boards to extend both "upward" and "downward".

But the important rule is the one already cited, that pin1 is oriented to ensure daughterboard orientation relative to the motherboard and that there is spacing around the connector so that the daughterboard female connector does not come in contact with main board cirquitry.

Also that the daughterboard does not protrude outside of the mainboard at least along the edge the connector is aligned to.

Daughterboards in general should not be designed to be wider than the MYSX connector used for this reason (avoiding daughterboard protruding outside mainboard area) to allow a mainboard specific case to be reused with daughterboards mounted.Edit: if possible, try to move the components right next to the connector. (remember the 100mil spacing). The resistor below can probably be mounted on the reverse side.

-

@sundberg84 I will just go ahead and update the spec. Yes, it may cause some existing designs to violate the spec, but that will always be the case. We look forwards, not backwards :)

Spec is here.Back to the drawing desk! :)

Edit: MysX alignment changed so PCB needs to be redesigned.

-

I have moved the discussion about the alignment here :

https://forum.mysensors.org/topic/9060/mysx-connector-alignment -

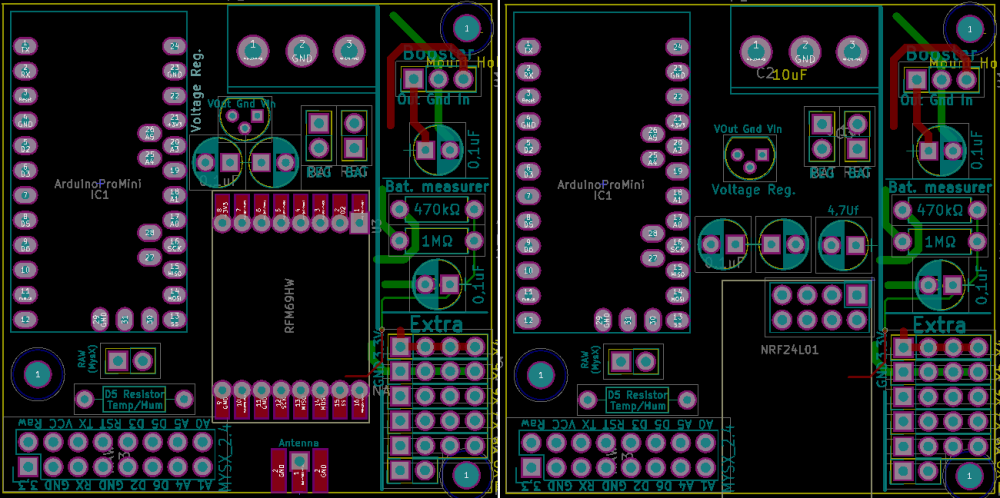

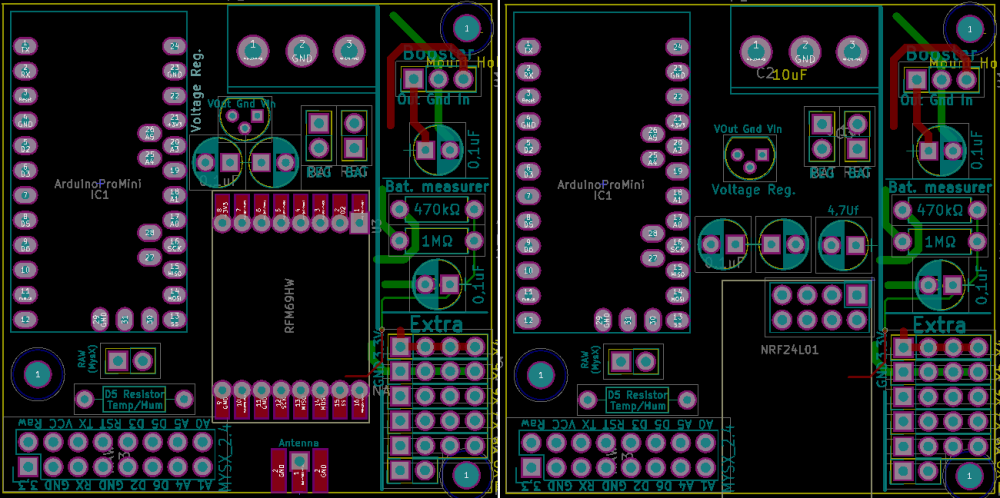

Thoughs? (Noth Nrf + RFM)

@Nca78 - MysX alignment? -

Thoughs? (Noth Nrf + RFM)

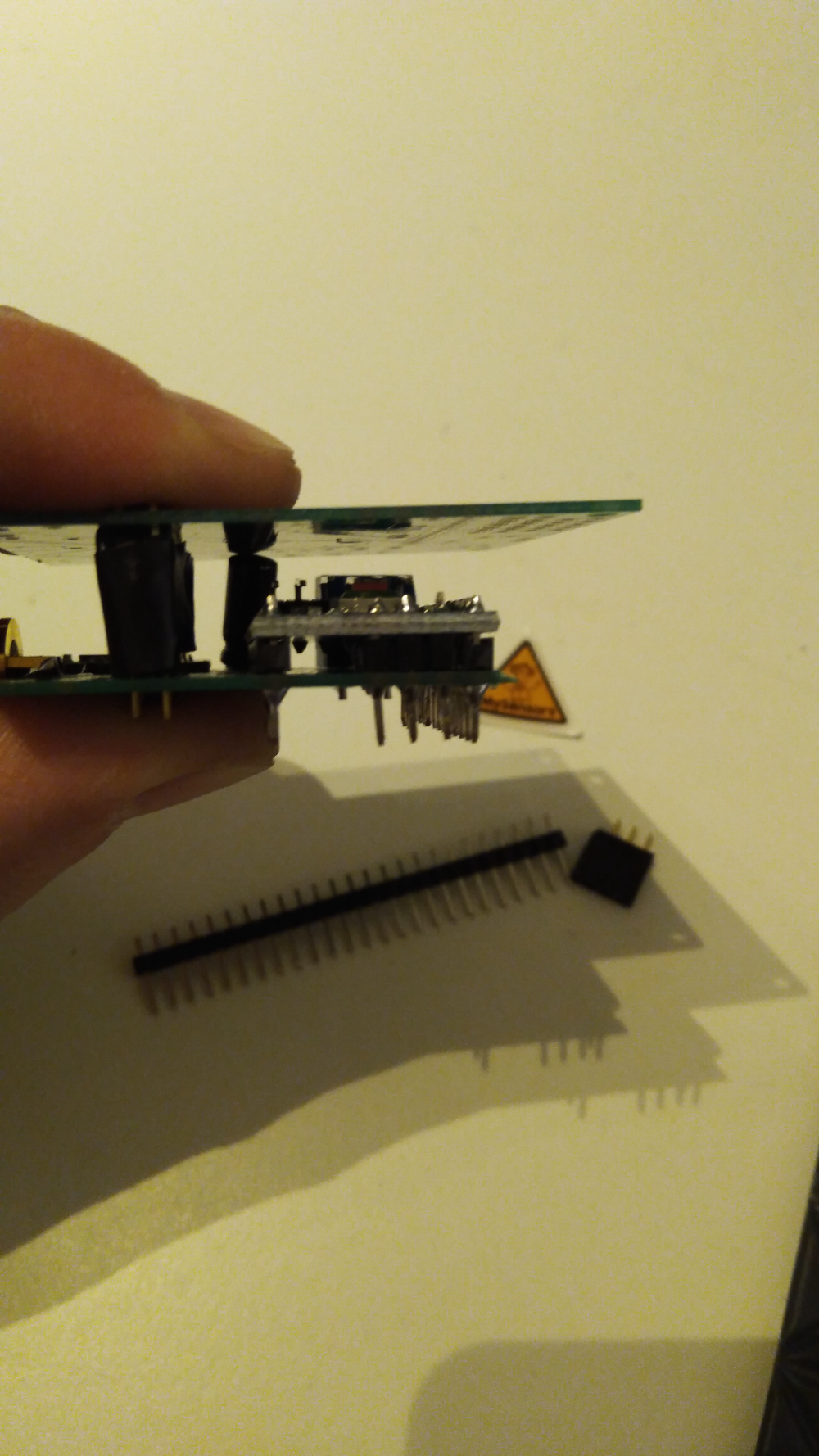

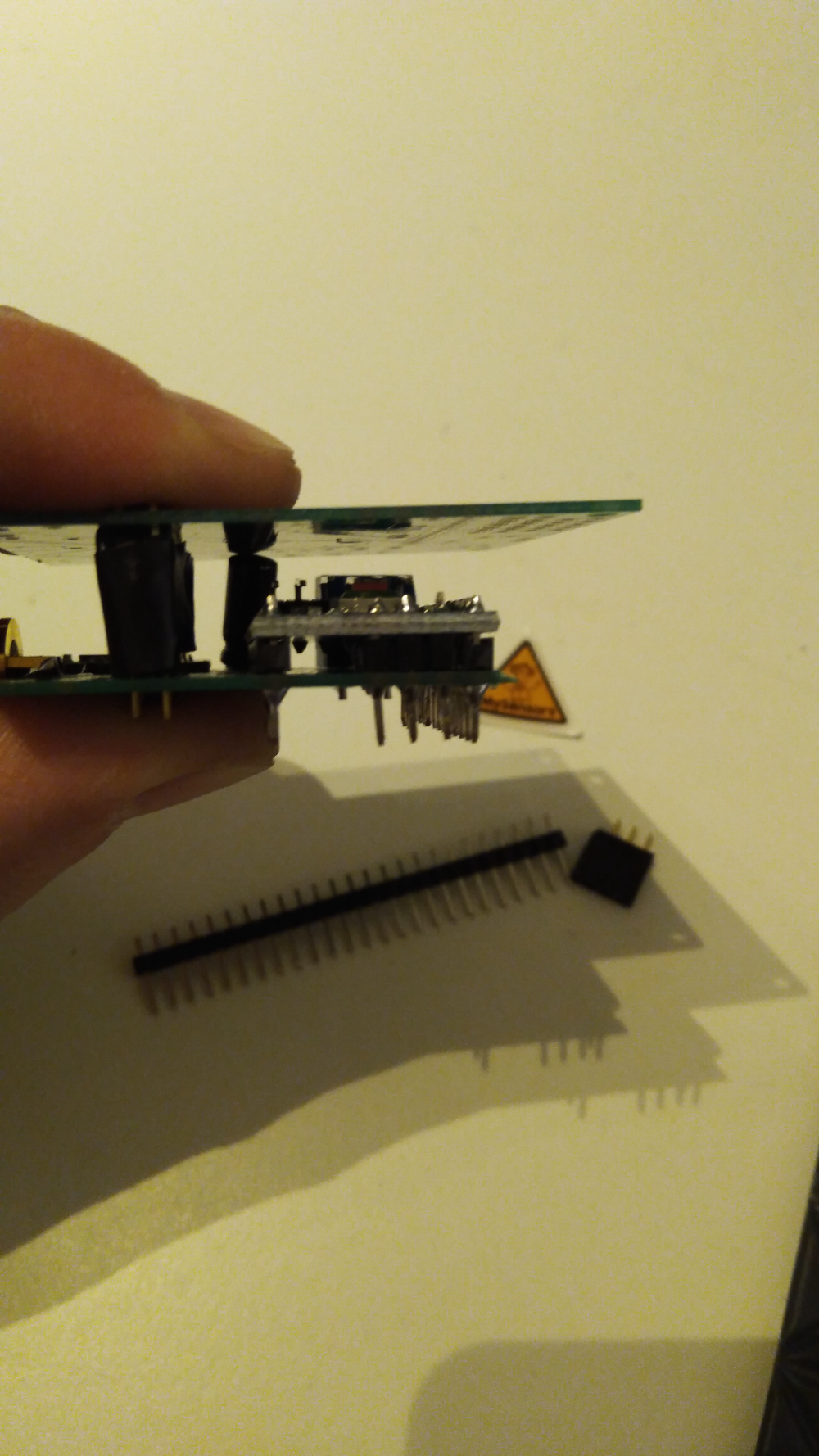

@Nca78 - MysX alignment?@sundberg84 be careful about daughterboards colliding with the pro mini.

-

@sundberg84 be careful about daughterboards colliding with the pro mini.

@anticimex - thanks for input. Same with radio I guess... ? Don't know how to solve it by fitting all these things into one board.

-

@anticimex - thanks for input. Same with radio I guess... ? Don't know how to solve it by fitting all these things into one board.

@sundberg84 The rfm69 radio can be surface mounted. If one goes for headers, the pitch it uses allow for low profile headers so the radio should go clear under a daughterboard assuming it does not have reverse side mounted components with a high profile.

-

@sundberg84 The rfm69 radio can be surface mounted. If one goes for headers, the pitch it uses allow for low profile headers so the radio should go clear under a daughterboard assuming it does not have reverse side mounted components with a high profile.

@anticimex you could use male headers on mother and female headers on daughter...

Or just mount the mother on top.

here it seems the capacitor is the biggest concern.

-

@anticimex you could use male headers on mother and female headers on daughter...

Or just mount the mother on top.

here it seems the capacitor is the biggest concern.

@sundberg84 if I remember correctly, the motherboard has to use male MYSX. So there is no option for that. I thought you planned to use sockets for the arduino. But if it is soldered directly on the pcb, it should go clear I think. But best to use angled ftdi interface then.

-

Yes I guess the only viable solution with MYSX and a pro mini is to solder the promini without headers so it can be under the daughter board and big (electrolytic capacitor) or sensible (radio antenna) stuff can be as far away as possible.

@sundberg84, I'm not sure it's great to have antenna in that position for my "vertical" concept but I guess it's not a great idea any more to do that. Now that pin 1 is in a corner I have all the space in the world to put reed/hall switch next to the other side (on top of pro mini) and it will be much more in line with expected use of MYSX connector.

Antenna is on the side that's not supposed to be below daughter board so I don't think you can do better for that., I think it's much better than before, I'll be able to make a board that's more versatile than the current one with footprints for most common sensors. -

@sundberg84

not sure but on your preview, I see that you don't use any gnd planes?? Imho, just sayin for your users :), it would be better to have it, ideally unbroken+ vias, for impedance, emi, rf counterpoise, impedance matching rf feedline to sma depending on its length and how it's routed etc.., maybe a little google it ;)looks nice :+1:

-

@sundberg84

not sure but on your preview, I see that you don't use any gnd planes?? Imho, just sayin for your users :), it would be better to have it, ideally unbroken+ vias, for impedance, emi, rf counterpoise, impedance matching rf feedline to sma depending on its length and how it's routed etc.., maybe a little google it ;)looks nice :+1:

@scalz - yes it is true about ground plane! I did that one rev 4 or something but something broke the thing... so I have been hesitating since but I know all about the benefits - been reading and googling.

I have not made any traces or planes on the images - just component placement. I will give it another shot... maybe I have learned some since rev 4 ;)

Thanks for your feedback.

-

@scalz - yes it is true about ground plane! I did that one rev 4 or something but something broke the thing... so I have been hesitating since but I know all about the benefits - been reading and googling.

I have not made any traces or planes on the images - just component placement. I will give it another shot... maybe I have learned some since rev 4 ;)

Thanks for your feedback.

@sundberg84 I forgot to mention that your nRF24 module goes very close to the MYSX. There is a risk a female receptacle might collide with the rf module if you are unlucky. And daughterboards will most likely be at least as wide as the courtyard of the MYSX.

-

@sundberg84

yes not talking about your latest but saw that on your rev9 and 10 pics.

it will make it better, and it's good point for rf quality (range and msg fail) ;)

placing planes is one of the first thing I usually do after component placements.. then it's easier to route as it solves many connection.keep the good work!

-

@sundberg84 I have a "newby" question about how to use the Extra's part of the board. If I want to connect a DS18B20 sensor per example can I just solder it on the extra area and connect is with some wires to the pinout I need?

Asking this because I did this with the i2c sensor on the board discussed here. having a wire form the extras towards the arduino i2c pins directly. Later I discovered that the i2c pins are also on the board.

So how to deal with this? -

you can add a wire to the I2C pins, in your case you just need a short wire to a digital pin that are just next to the Extra area

@gohan said in 💬 Easy/Newbie PCB for MySensors:

you can add a wire to the I2C pins, in your case you just need a short wire to a digital pin that are just next to the Extra area

Ok. And if attaching a DS18B20 I have a pull up resistor soldered on the board. Than it is also just the digital pin I need from the board? D3 I think?

-

@gohan said in 💬 Easy/Newbie PCB for MySensors:

you can add a wire to the I2C pins, in your case you just need a short wire to a digital pin that are just next to the Extra area

Ok. And if attaching a DS18B20 I have a pull up resistor soldered on the board. Than it is also just the digital pin I need from the board? D3 I think?

@mr_sensor with a DS18B20 temp sensor I just solder it to the MysX pins (D3, Gnd and VCC) directly and populate the resistor for D3.

-

@mr_sensor with a DS18B20 temp sensor I just solder it to the MysX pins (D3, Gnd and VCC) directly and populate the resistor for D3.

@sundberg84 Yes thanks I did so. But do not get any temp read out? Have al in space also the 4,7 k resistor.

this is my sketch:

[code] /** * The MySensors Arduino library handles the wireless radio link and protocol * between your home built sensors/actuators and HA controller of choice. * The sensors forms a self healing radio network with optional repeaters. Each * repeater and gateway builds a routing tables in EEPROM which keeps track of the * network topology allowing messages to be routed to nodes. * * Created by Henrik Ekblad <henrik.ekblad@mysensors.org> * Copyright (C) 2013-2015 Sensnology AB * Full contributor list: https://github.com/mysensors/Arduino/graphs/contributors * * Documentation: http://www.mysensors.org * Support Forum: http://forum.mysensors.org * * This program is free software; you can redistribute it and/or * modify it under the terms of the GNU General Public License * version 2 as published by the Free Software Foundation. * ******************************* * * REVISION HISTORY * Version 1.0: Henrik EKblad * Version 1.1 - 2016-07-20: Converted to MySensors v2.0 and added various improvements - Torben Woltjen (mozzbozz) * * DESCRIPTION * This sketch provides an example of how to implement a humidity/temperature * * Dallas temperature sensor DS18B20 * * For more information, please visit: * http://www.mysensors.org/build/humidity * HTU21D Humidity Sensor Hardware Connections (Breakoutboard to Arduino): -VCC = 3.3V -GND = GND -data = D3 met pcb 470 uf resistor */ #define MY_NODE_ID 4 #define MY_PARENT_NODE_ID 0 #define MY_PARENT_NODE_IS_STATIC // Enable debug prints #define MY_DEBUG // Enable and select radio type attached #define MY_RADIO_NRF24 //#define MY_RADIO_RFM69 //#define MY_RS485 #include <MySensors.h> #include <OneWire.h> //#include <Wire.h> #include <SPI.h> #include <DallasTemperature.h> // Force sending an update of the temperature after n sensor reads, so a controller showing the // timestamp of the last update doesn't show something like 3 hours in the unlikely case, that // the value didn't change since; // i.e. the sensor would force sending an update every UPDATE_INTERVAL*FORCE_UPDATE_N_READS [ms] //static const uint8_t FORCE_UPDATE_N_READS = 10; #define COMPARE_TEMP 1 // Send temperature only if changed? 1 = Yes 0 = No #define ONE_WIRE_BUS 3 // Pin where dallase sensor is connected #define MAX_ATTACHED_DS18B20 16 //unsigned long SLEEP_TIME = 30000; // Sleep time between reads (in milliseconds) OneWire oneWire(ONE_WIRE_BUS); // Setup a oneWire instance to communicate with any OneWire devices (not just Maxim/Dallas temperature ICs) DallasTemperature sensors(&oneWire); // Pass the oneWire reference to Dallas Temperature. float lastTemperature[MAX_ATTACHED_DS18B20]; int numSensors=0; bool receivedConfig = false; bool metric = true; #define CHILD_ID_TEMP 0 #define CHILD_ID_BATTERY 1 #define CHILD_ID_VOLT 2 //#define CHILD_ID_PRCNT 3 //float lastTemp; //float lastHum; //uint8_t nNoUpdatesTemp; //uint8_t nNoUpdatesHum; //boolean metric = true; void presentation() { // Send the Sketch Version Information to the Gateway sendSketchInfo("Temperature Sensor", "1.1"); // Register all sensors to gw (they will be created as child devices) // present(CHILD_ID_HUM, S_HUM); present(CHILD_ID_TEMP, S_TEMP); present(CHILD_ID_BATTERY, S_MULTIMETER); //metric = getControllerConfig().isMetric; // Fetch the number of attached temperature sensors numSensors = sensors.getDeviceCount(); // Present all sensors to controller for (int i=0; i<numSensors && i<MAX_ATTACHED_DS18B20; i++) { present(i, S_TEMP); } } int BATTERY_SENSE_PIN = A0; // select the input pin for the battery sense point unsigned long SLEEP_TIME = 60000; // Sleep time between reads (in milliseconds) 60000 static int oldBatteryPcnt = 0; //Create an instance of the object MyMessage msg(0,V_TEMP); //MyMessage msgHum(CHILD_ID_HUM, V_HUM); MyMessage msgTemp(CHILD_ID_TEMP, V_TEMP); MyMessage msgBattery(CHILD_ID_BATTERY, V_VOLTAGE); //MyMessage msgBattery(CHILD_ID_BATTERY, V_PRC); void setup() { // Startup up the OneWire library sensors.begin(); // use the 1.1 V internal reference #if defined(__AVR_ATmega2560__) analogReference(INTERNAL1V1); #else analogReference(INTERNAL); #endif // requestTemperatures() will not block current thread sensors.setWaitForConversion(false); } void loop() { // Fetch temperatures from Dallas sensors sensors.requestTemperatures(); // query conversion time and sleep until conversion completed int16_t conversionTime = sensors.millisToWaitForConversion(sensors.getResolution()); // sleep() call can be replaced by wait() call if node need to process incoming messages (or if node is repeater) sleep(conversionTime); // Read temperatures and send them to controller for (int i=0; i<numSensors && i<MAX_ATTACHED_DS18B20; i++) { // Fetch and round temperature to one decimal float temperature = static_cast<float>(static_cast<int>((getControllerConfig().isMetric?sensors.getTempCByIndex(i):sensors.getTempFByIndex(i)) * 10.)) / 10.; // Only send data if temperature has changed and no error #if COMPARE_TEMP == 1 if (lastTemperature[i] != temperature && temperature != -127.00 && temperature != 85.00) { #else if (temperature != -127.00 && temperature != 85.00) { #endif // Send in the new temperature send(msg.setSensor(i).set(temperature,1)); // Save new temperatures for next compare lastTemperature[i]=temperature; } } // some delay here delay(500); // get the battery Voltage int sensorValue = analogRead(BATTERY_SENSE_PIN); delay(500); #ifdef MY_DEBUG Serial.println(sensorValue); #endif // 1M, 470K divider across battery and using internal ADC ref of 1.1V // Sense point is bypassed with 0.1 uF cap to reduce noise at that point // ((1e6+470e3)/470e3)*1.1 = Vmax = 3.44 Volts // 3.44/1023 = Volts per bit = 0.003363075 int batteryPcnt = sensorValue / 10; #ifdef MY_DEBUG float batteryV = sensorValue * 0.003363075; Serial.print("Child ID "); Serial.print(CHILD_ID_BATTERY); Serial.print("Battery Voltage: "); Serial.print(batteryV); Serial.println(" V"); Serial.print("Battery Percent: "); Serial.print(batteryPcnt); Serial.println(" %"); #endif if (oldBatteryPcnt != batteryPcnt) { // Power up radio after sleep sendBatteryLevel(batteryPcnt); oldBatteryPcnt = batteryPcnt; } sleep(SLEEP_TIME); //sleep a bit } [/code]```

| / |_ / | ___ _ __ ___ ___ _ __ ___

| |/| | | | _ \ / _ \_ \/ __|/ _ \|_/ __|

| | | | || || | / | | _ \ _ | | \�

|| ||_, |/ ___|| ||/_/|| |/

|__/ 2.2.016 MCO:BGN:INIT NODE,CP=RNNNA---,VER=2.2.0

26 TSM:INIT

28 TSF:WUR:MS=0

34 TSM:INIT:TSP OK

36 TSM:INIT:STATID=4

38 TSF:SID:OK,ID=4

40 TSM:FPAR

43 TSM:FPAR:STATP=0

45 TSM:ID

47 TSM:ID:OK

47 TSM:UPL

53 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=24,pt=1,l=1,sg=0,ft=0,st=OK:1

67 TSF:MSG:READ,0-0-4,s=255,c=3,t=25,pt=1,l=1,sg=0:1

71 TSF:MSG:PONG RECV,HP=1

75 TSM:UPL:OK

77 TSM:READY:ID=4,PAR=0,DIS=1

116 !TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=15,pt=6,l=2,sg=0,ft=0,st=NACK:0100

2125 TSF:MSG:SEND,4-4-0-0,s=255,c=0,t=17,pt=0,l=5,sg=0,ft=1,st=OK:2.2.0

2138 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=6,pt=1,l=1,sg=0,ft=0,st=OK:0

4177 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=11,pt=0,l=18,sg=0,ft=0,st=OK:Temperature Sensor

4196 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=12,pt=0,l=3,sg=0,ft=0,st=OK:1.1

4214 TSF:MSG:SEND,4-4-0-0,s=0,c=0,t=6,pt=0,l=0,sg=0,ft=0,st=OK:

4227 TSF:MSG:SEND,4-4-0-0,s=1,c=0,t=30,pt=0,l=0,sg=0,ft=0,st=OK:

4235 MCO:REG:REQ

4237 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2

6246 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2

8255 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2

10264 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=26,pt=1,l=1,sg=0,ft=0,st=OK:2

12273 MCO:BGN:STP

12275 MCO:BGN:INIT OK,TSP=1

12279 MCO:SLP:MS=94,SMS=0,I1=255,M1=255,I2=255,M2=255

12285 TSF:TDI:TSL

12288 MCO:SLP:WUP=-1

12290 TSF:TRI:TSB

915

Child ID 1Battery Voltage: 3.08 V

Battery Percent: 91 %

13297 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:91

13305 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255

13312 TSF:TDI:TSL

13314 MCO:SLP:WUP=-1

13316 TSF:TRI:TSB

13320 MCO:SLP:MS=94,SMS=0,I1=255,M1=255,I2=255,M2=255

13326 TSF:TDI:TSL

13328 MCO:SLP:WUP=-1

13330 TSF:TRI:TSB

826

Child ID 1Battery Voltage: 2.78 V

Battery Percent: 82 %

14340 TSF:MSG:SEND,4-4-0-0,s=255,c=3,t=0,pt=1,l=1,sg=0,ft=0,st=OK:82

14346 MCO:SLP:MS=60000,SMS=0,I1=255,M1=255,I2=255,M2=255

14352 TSF:TDI:TSL