Looking for tips on mounting thermal fuses.

-

I have had some trouble with thermal fuses like these when building some of my in wall light switch/scene controllers. I need to be SUPER CAREFUL when soldering these as the heat from the soldering iron can cause them to blow.

The ones I have are 73°C fuses that I am using for added protection with my HLK-PM01 power modules. Just working on one controller yesterday, I blew 3 of them just trying to get them soldered to the board. GOOD THING I had extras and was able to get the board going, but now I am out. Does anyone have any good suggestions for mounting/using these?

-

@dbemowsk this also happened to me. Those fuses are very hard to solder without damaging them. I tried to use alligator clips to act as heat brakes but with no success.

I finally managed to solder them using a third hand and dipping the body in cold water like in this

this videoSo in the end it is the fist component I solder on my board. Not very convenient

-

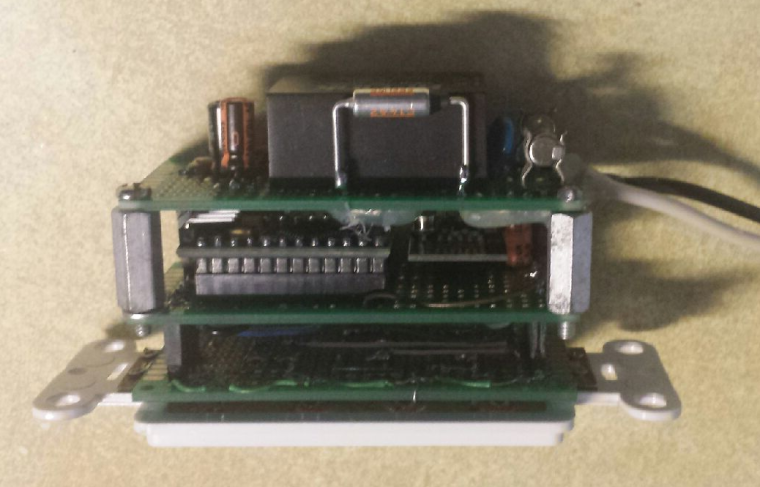

I just ordered 20 more for my parts bin. You can kind of see in this picture, I soldered the one in and blew it, so I just cut the leads leaving them stubbed off so I could solder the new one to those leads rather than try to remove and re-mount it to the board.

-

@dbemowsk Bit lame, but you could mount them in a screw terminal block.

-

Gripping it with nose pliers between the fuse itself and where you are soldering should absorb a lot of the heat, especially id you make sure the pliers are cold when you start soldering. Nose pliers can absorb much more heat than alligator clips.

But I like Yveaux's idea to not solder at all. How about soldering female header pins and just stick the thermal fuse in?

-

I just wrap it with wet toilet paper, works every time.

-

@mfalkvidd I am just guessing here because I have not actually tried it, but I am guessing that the holes would be too small on the female header. In order to get it to fit in the proto-board that I use, I have to drill the hole slightly larger which is why I think that, but it never hurts to try. Making the holes larger on the PCB is one of the main reasons why when these have blown on me I have cut the leads and left them in the board. I was afraid that the pads on the board would lift if I did because making the holes larger I am sure took away the thru-hole plating.

-

@dpressle I was thinking more last night and thought about putting an ice cube in a bag and holding it on there while I solder it.

-

@dpressle said in Looking for tips on mounting thermal fuses.:

I just wrap it with wet toilet paper, works every time.

Haha that's a funny way to do it, but the concept is good thank you for the idea

I didn't have problem before but as a precaution I'll use with a small sponge for soldering iron, it will hold more water, be less messy and resist to heat.

-

@Nca78 said in Looking for tips on mounting thermal fuses.:

I'll use with a small sponge for soldering iron, it will hold more water, be less messy and resist to heat.

Another good idea. Thanks.

-

Am i the only one that struggles my as off with 4 pairs of pliers on these little annoying things?

-

My only precaution is to raise(!) the soldering iron temperature. It allows a fast action with less propagating heat. It sounds foolish, but I actually like it and rarely fail.

-

@m26872 I will definitely have to try this. Something I hadn't thought of, but makes sense.

-

@m26872 - I do this too, hotter the iron is the better for me. Hotter and quicker wins the race.