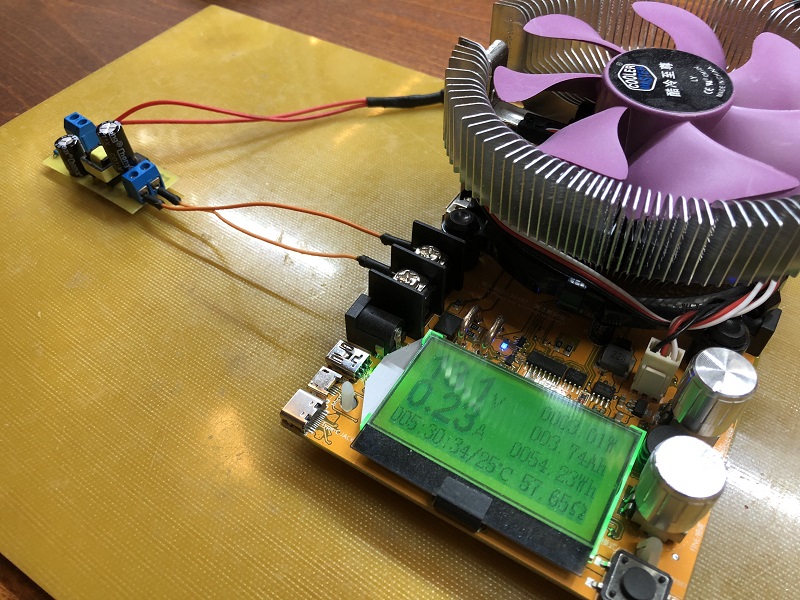

More than a year ago I created this panel based on the RG 32x16 matrix from sureelectronics.

I've posted a local article about it, google translation is here https://translate.google.com/translate?sl=ru&tl=en&js=y&prev=_t&hl=ru&ie=UTF-8&u=http%3A%2F%2Fradiokot.ru%2Fcircuit%2Fdigital%2Fhome%2F194%2F&edit-text=

Just got time last night to migrate it from Plain C + MySensors 1.2 to Arduino + MySensors 1.4.1

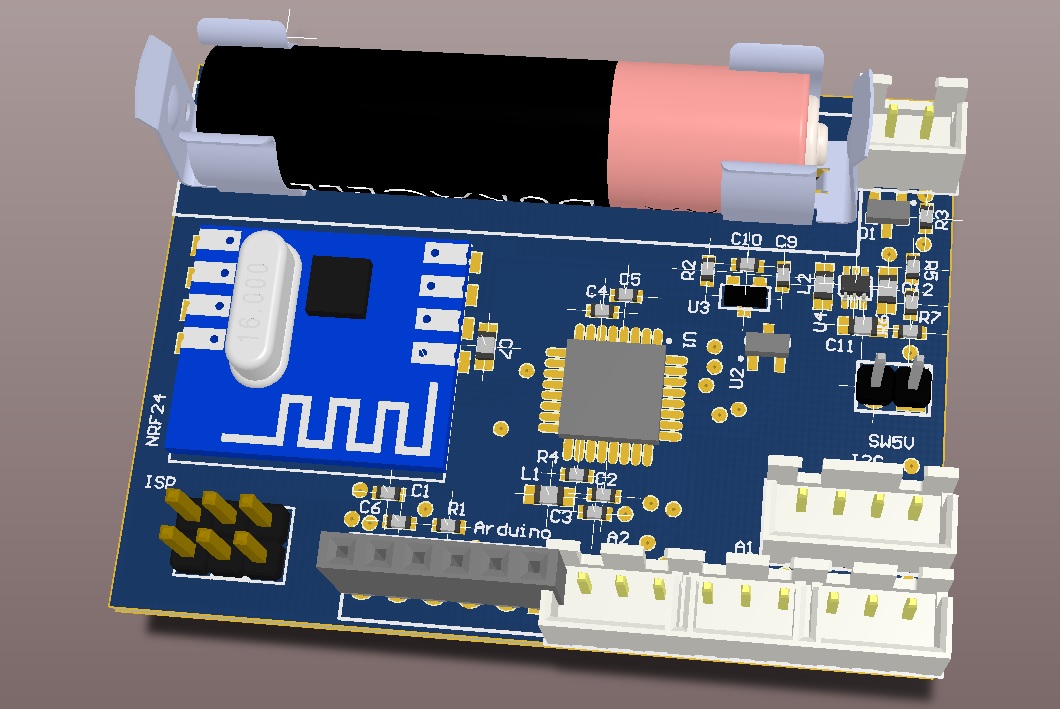

It was a bit trickier. I had to create a configuration of arduino based on atmega128. I used a way described here http://download.chip45.com/chip45-arduino-extension.zip (http://www.chip45.com/products/crumbuino-128_arduino_compatible_atmega128_module_board_usb.php)

The C code was adjusted to C++. I keep usign C based libraries for RTC, BMP85 and for the matrix.

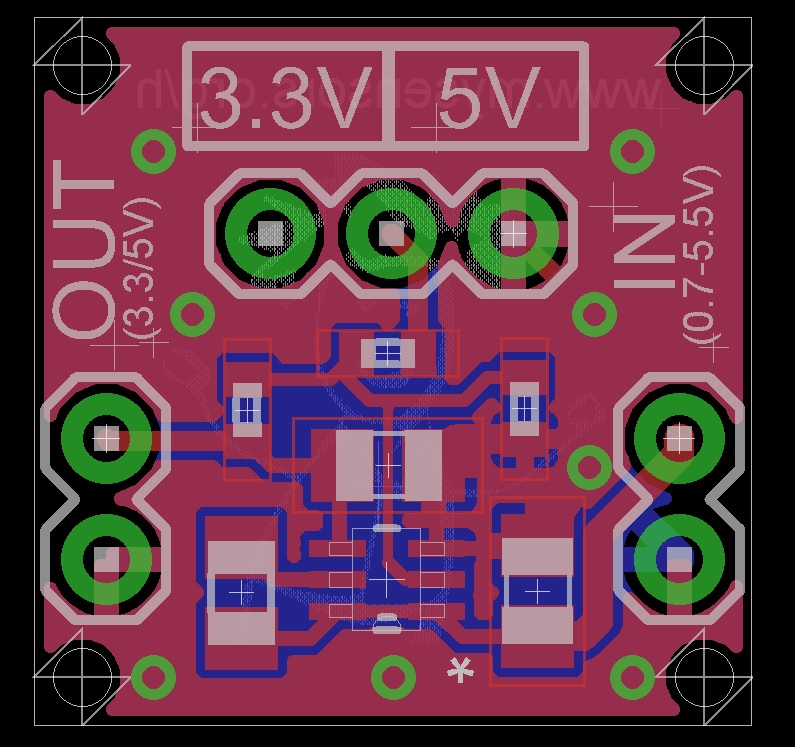

Schematic is here http://radiokot.ru/circuit/digital/home/194/01.jpg and here http://radiokot.ru/circuit/digital/home/194/02.jpg

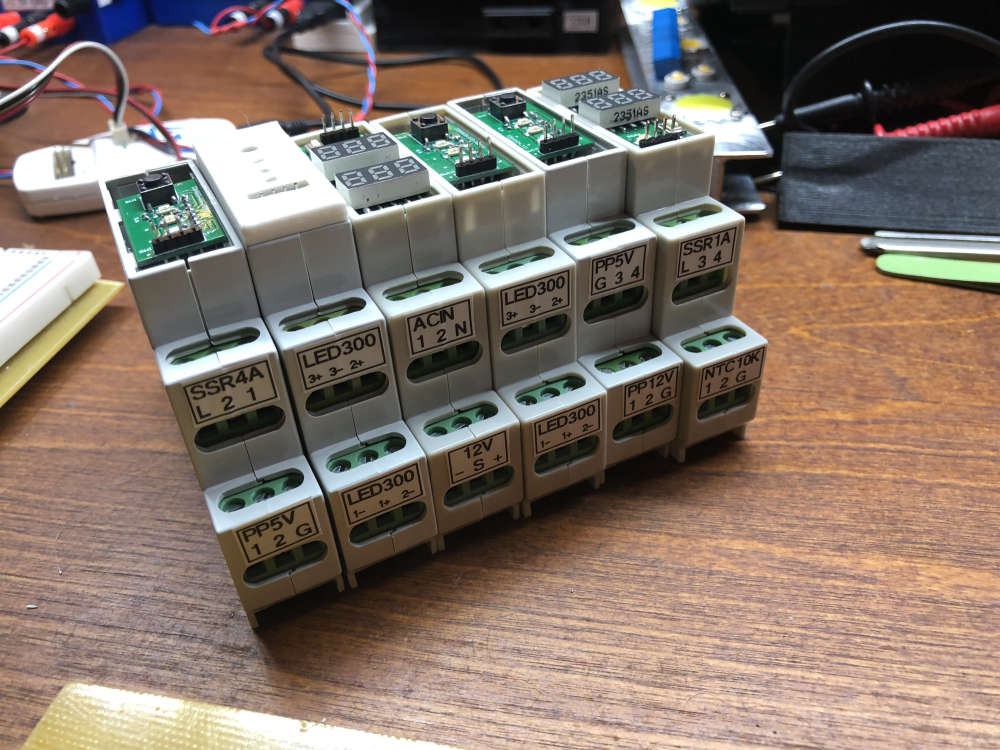

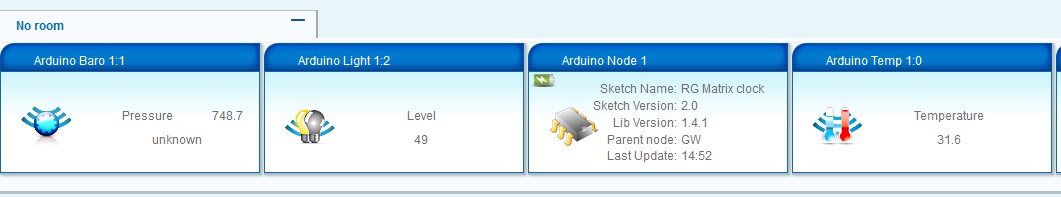

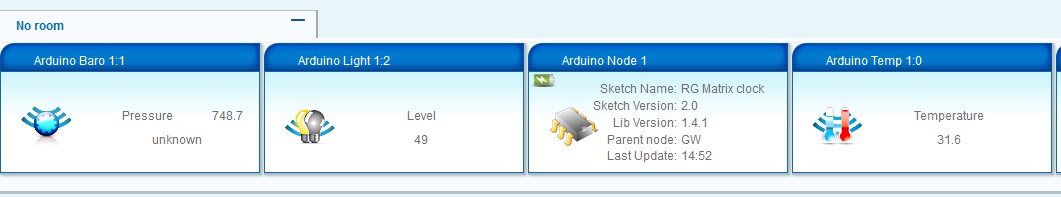

Clock creates 3 child devices on controller side:

Controller is updated with preassure, temperature, light level and RTC battery status

This Lua is used to push Street temperature from vera to the Clock:

local temp = luup.variable_get("urn:upnp-org:serviceId:TemperatureSensor1","CurrentTemperature", 61)

temp = temp*10.0

luup.call_action("urn:upnp-arduino-cc:serviceId:arduino1", "SendCommand", {radioId="1;255", variableId="VAR_5", value=temp}, 430)

61 is vera ID of wheather plugin current temperature device

430 is Clock node vera device ID

Similar Lua is used to populate Clock with average home temperature:

local temp = luup.variable_get("urn:upnp-org:serviceId:TemperatureSensor1","CurrentTemperature", 384)

temp = temp*10.0

luup.call_action("urn:upnp-arduino-cc:serviceId:arduino1", "SendCommand", {radioId="1;255", variableId="VAR_4", value=temp}, 430)

384 is vera ID of temperature average device

you can also use VAR_1 to show a short text message on the panel

VAR_2 is reserved to populate a numeric ID to third party connected to Serial1. I plan to setup a voice talking device. ID will call ID.wav or ID.mp3 file to play

A short video is here

http://www.youtube.com/watch?v=YOuO6zLDz6U

My hardware kept without changes but it was a challenge to download arduino sketch because I use JTAG. The solution was found with Visualmicro and Atmelstudio. I setup an arduino sketch inside VisulMicro and a separate project for debug of the object file inside atmelStudio,. This allows me not only to upload using the JTAG but also to run a hardware debugging