@Yveaux I'm embarrassed to admit I did buy a RTL-SDR last year on account of the problems I had with 433MHz sensors on the RFLink gateway and wanting to decode wireless m-bus. But I never really learned how to interpret the data from SDR#. I booted it back up just now and am flailing around in the interface :-)

bjornhallberg

Posts

-

RFM69 Range issues -

RFM69 Range issues@evb Thanks I'll try that.

I was thinking about setting up a second gateway also (I have another sensebender gateway I'm not using) and running a different frequency for the network. The new driver allows you to set basically any frequency that the module supports right down to the Hz?

And the 868MHz modules are able to go as high as 915MHz (even if it isn't optimal) and vice versa? I do recall something from Lowpowerlabs from years ago that said the 915MHz ones could at least be run at 868MHz? Felix and other users on their forum even confirm it. So that would rule out the possibility that I have radio modules of the wrong frequency,

I am starting to question some of these radio modules I bought off of AliExpress 3-4 years ago. I know for a fact that I have RFM69W modules that are 915, don't remember why I even have those. The signal scanner used a good and known *W 868 module. All the *CW modules are marked as 868. But I am nevertheless starting to wonder if there could be some foul play here. Either knockoffs, or real duds. It would explain a lot of the problems I've had with HopeRF modules over the years, with them often being outperformed by knockoff nrf24s.

-

RFM69 Range issuesNo neither the temp sensors nor the mailbox sensor are working on 2.3.0 with the new rfm69 driver at any serious range at least. The hardware is this (https://github.com/EasySensors/ButtonSizeNode) and this (https://github.com/EasySensors/SwitchNode). Have tried different types of antenna.

The hardware difference would be that the scanner is running on AA batteries with no regulator and the sensors above use 3V button cells and some sort of regulator I think. Plus they use RFM69CW while the scanner uses RFM69W.

Like I say above, I've really only disabled debug to save some memory because I read in some other thread that it in fact helped. I have not tried setting TX power manually on either the gateway nor the sensors.

Still 5bdm on the gateway doesn't sound too bad though. What was the gateway TX dbm on 2.2.0 and old regular driver?

-

RFM69 Range issuesSo I've been a little bit inactive for the last couple of years. I recently updated my nodes and gateway to 2.3.2 to see if it would fix some of the range issues I've been having and because it seemed convenient to be able to see RSSI and TX power. I also built the signal scanner (https://forum.mysensors.org/topic/7822/portable-rfm69-signal-scanner/6) so I'd be able to walk around and see if communications were working in certain spots.

Gateway (rfm69hw) initialization:

#define MY_IS_RFM69HW #define MY_RFM69_FREQUENCY RFM69_868MHZ #define MY_RFM69_NEW_DRIVERExample node (rfm69cw) initialization:

#define MY_NODE_ID 0xAC #define MY_PARENT_NODE_IS_STATIC #define MY_PARENT_NODE_ID 0 #define MY_RADIO_RFM69 #define MY_RFM69_FREQUENCY RFM69_868MHZ #define MY_RFM69_NEW_DRIVERI have a couple of nodes in my garage that are just damn near impossible to get to work. It's odd because I have deployed nrf24 modules there in the past and while transmission has been spotty, 868MHz should be superior in this regard, at least not perform worse. The nodes are all the same, but are using three different antennas. I originally had #define MY_TRANSPORT_UPLINK_CHECK_DISABLED and #define MY_DEBUG with those nodes but commented it out this afternoon on two of them. Still only one is coming through and that is the one with the commercial thick coil antenna that you can find on ebay. I recall reading somewhere on the forum that people had good results with those (https://forum.mysensors.org/topic/7845/rfm69-antennas-comparison).

Another node that I have out in the mailbox and that had been performing flawlessly on 2.2.0 I think it was and the old driver is now completely out of reach. I did the same commenting out as above but it still wont work.

I guess my first question is regarding ATC and how it works on 2.3.2. In particular in this case where nodes are either initialized within range of the gateway and brought outside or initialized out of range and installed. I understood the system as starting at the lowest dbm and working itself up until it reached an acceptable RSSI? How does it proceed if it cant reach the gateway?

Also I was wondering about disabling ATC and setting another modem config? Would it be a better troubleshooting strategy?

#define MY_RFM69_ATC_MODE_DISABLED #define MY_RFM69_MAX_POWER_LEVEL_DBM (13) // 13dbm/20mw max on rfm69cw? #define MY_RFM69_MODEM_CONFIGURATION RFM69_FSK_BR9_6_FD19_2Anything else I can tweak in the settings?

I should add that the "signal scanner" (with a rfm69w) works really well with the code in the link. Transmit % is about ~0% next to the gateway. About 50-60% in the garage. And 70-80% at the mailbox. Perhaps a little bit lower once it has settled in those spots. Nothing special about the hardware either. Built it exactly like described.

-

💬 Sensebender GatewayAs previously noted, Sensebender Gateway sketch from 2.3.2 with MySensors SAMD Boards 1.0.6 does not compile with Arduino SAMD Boards 1.8.9. Rolling back to Arduino SAMD Boards 1.8.8 or earlier version works.

-

Wirsbo/Uponor thermostat replacement@Denke Any updates to this project? Did you deploy the sensors? Any issues or has it been smooth sailing for the last couple of years?

-

💬 Power Meter Pulse SensorIs there a suggested replacement for the TSL250? While it can still be found, it seems to be discontinued for the most part.

I've had no luck with the LM393 solution for my new power meter. Just can't tune it to pick up the led impulses. What sort of diode solution is everyone else using? I'm aware of the possibility of IR communication (https://wiki.hal9k.dk/projects/kamstrup) but it seems a little over the top.

-

💬 Water Meter Pulse SensorWhile looking into the water meter I realized that we are getting a "smart" meter replacement soon. I'll see if I can speed up the replacement schedule. Anyhow, the replacement is a Kamstrup Multical 21 (https://www.kamstrup.com/en-en/water-solutions/water-meters/multical-21) which has several options for reading:

- Requesting the data via optical interface?

- Enabling the pulse function via optical interface, and then reading the IR pulse at 1imp/10lit.

- Reading the wireless mbus signal? (e.g. https://github.com/weetmuts/wmbusmeters)

-

💬 Water Meter Pulse Sensor@flopp Did you ever manage to stabilize the readings? Am I understanding you correctly that the readings were fine but the transmission got the reading scrambled?

Did you try to find a magnetic field with the meter instead? I have a similar meter and I'm wondering how best to approach the problem. I've seen people hook up Raspberries and cameras to do OCR basically but that seems like way too complex for an easy problem.

-

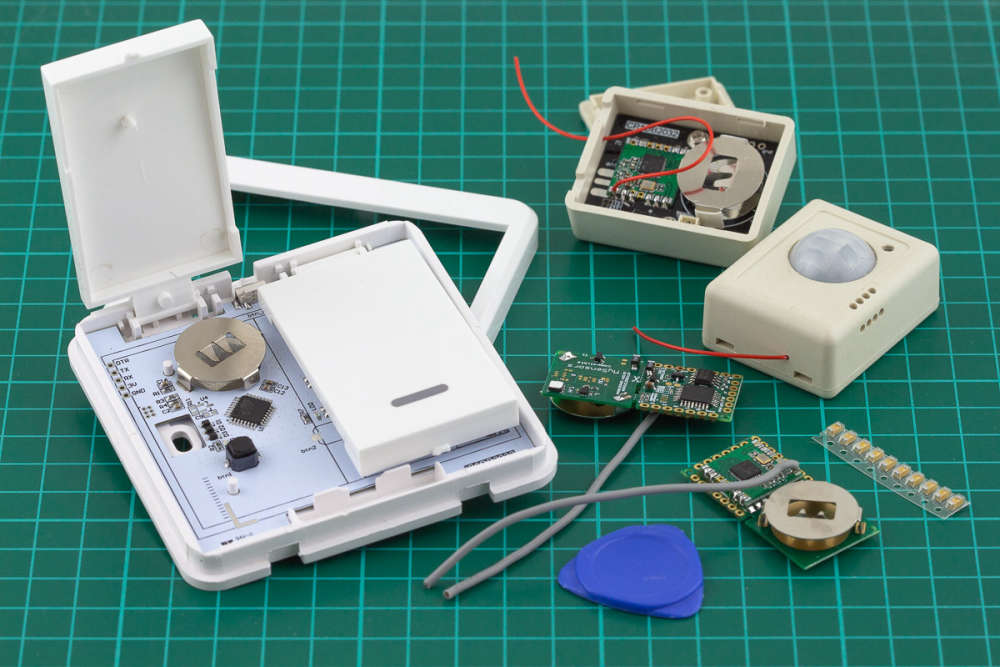

💬 Button size radionode with sensors swarm extension@koresh Package went under the "Postnord" radar! Woohoo, perfect! I will start replacing the old capacitors and finally be able to deploy the sensors. Very nice of you to include some product samples as well. Really excited about these sensors!

-

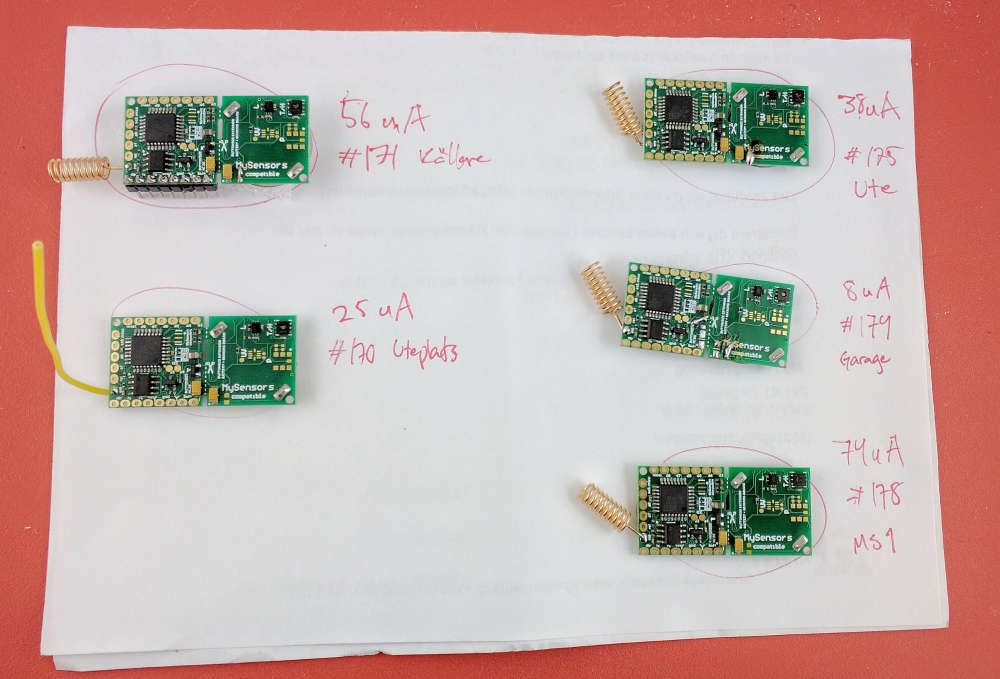

💬 Button size radionode with sensors swarm extension@alexsh1 I may have made a bit of a mistake with some glitchy chinese test probes. De-glitched cables and connected to a proper lab power supply gave very different readings (with the default git-sketch) ...

Still a bit confused over the differing readings. I get that the board I stripped from regulator and capacitors would perform better though. So do I have to do the same for all the other boards as well? Of course, I could save the worst performing boards for later and run them on 2xAA or something in places where space isn't an issue.

-

💬 Button size radionode with sensors swarm extension@alexsh1 Thanks for the suggestions! Reassuring to know that you succeeded.

- I haven't added any sensors so it's just the default ones.

- https://github.com/EasySensors/ButtonSizeNode ... may need some cleaning up @Koresh or do we use v2 code for v1 sensor as well?

- I thought as much ... damn. I'm using the CW version radio with the adapter plate. I also thought about the radio but unlike the NRF radio this one should work with no counterfeit units?

No my other DMM was out of batteries.Found my old crappy DMM and it says the same, ~2mA.- I did remove both caps and it's still at ~2mA.

You're probably right about something not sleeping. Or else I've done a horrible soldering job on the four radios I've attached so far. All four sensors behave pretty much the same.

Also, at least on Domoticz they changed things around now so you have to use V_LEVEL instead of V_LIGHT_LEVEL or what? https://www.domoticz.com/forum/viewtopic.php?t=18577 With V_LIGHT_LEVEL I get some incomprehensible percent value reported.

-

💬 Button size radionode with sensors swarm extension@yury No I ran them on just a 2032 battery at the time, just had it in an external battery holder. I also removed the LDO on one of the boards and bridged the two top pads, with no apparent effect.

Unless there is something wrong with my DMM.

-

💬 Button size radionode with sensors swarm extension@Koresh I still have a bunch of v1 boards that I never got to work because of power consumption (I presume). I thought I'd make one more attempt.

I tried bridging the jumper and I'm using a 2032 battery. Consumption varies between 2 and 4mA on different boards. On some boards it fluctuates a lot. The instructions above are not immediately clear. Do I have to remove the LDO AND capacitors as well?

-

Which 3D modelling software do you prefer for 3D printing *and* CNC?I'm sold on Fusion360 as it is basically professional 3DCAD that can be used for free. Full on parametric with a powerful history tree. As you've no doubt seen it has built-in CAM functionality as well, equally professional and it can output G-CODE for most CNC-controllers. So very much all in one. And you'll be glad you learned real 3DCAD instead of meddling with 123D, Sketchup or anything else.

Personally I prefer the Vectric programs (Aspire) for making G-CODE for the CNC as they are geared towards woodworking with features like v carving. Fusion360 CAM feels more like it was made for mills and lathes but can do most things as well.

-

Best CNC for milling/routing wood?@rfm69 I think the mechanical stuff is ~$1400 and then ~$600 for steppers and spindle and a few other things.

Of course the machine we're building at the makerspace is the biggest suggested model. Working area ~100x150cm with steel reinforced Y and X and with laser cut steel plates instead of aluminum. So I don't think he ever sold that as a kit internationally because of weight and size. A smaller machine would be much cheaper obviously.

@neverdie Yeah the guy behind the RawCNC has been a bit difficult. This is sort of his side project and he keeps changing his mind on how to proceed. He actually rolled back some of the features to make the machines lighter and easier to ship. But then he didn't sell internationally anyway. At least not for long.

-

Best CNC for milling/routing wood?Yes but can he do this? ;-)

https://youtu.be/Nz8k2MSAasI?t=47s -

Best CNC for milling/routing wood?The MPCNC is a smart project but I would assume it would struggle with a bigger motor.

The 2.2kW we are going to use weighs A LOT. Around 5kg at least I'd guess. The 1.5kW is not much better. With a smaller spindle, or router like a Kress things would be different. Still I'm glad to have the extra power, and standard ER20 collets up to 13mm. Plus these chinese spindles are really quiet compared to a regular router. And the speed can be set and spindle can be started from the control panel or from the computer. The downside is the low quality VFD I guess, but if it works it works. And you can always use shielded cables everywhere.

-

Best CNC for milling/routing wood?@neverdie Yeah that is a surprisingly good machine as it seems to be built from scratch with no plans or whatnot. It says in the Youtube comments that he spent $4K-4.5K on it though, with 1K of that being for the extra cost of servos as compared to steppers. Nice to have those linear rails and ball screws though.

By comparison the machine we're building is maybe $2K. It will have worse precision (than ball screws) as it is rack and pinion. But a work area of ~100x150cm.

-

Best CNC for milling/routing wood?The RawCNC uses rods that are glued or pressed into a shaft clamp and then a u-groove bearing on top of that.