Hello.

My first contribution to MySensors is going to be a Light Switch node that meets a few lines of criteria. To my knowledge, this hasn't been developed yet and feel that there would be a fair few people that would benefit from a very simple switch node that actually fits in a location where an existing switch does, that way there is no signs of home automation on the switch front. Yes we have scene controllers that can be mounted onto the wall, but this starts to become bulky and obvious that there is some sort of technology there controlling something, what about if you simply just want to switch a light on with natural instincts without having to look at what you're doing? This is where I personally think this Product would prove itself worthwhile. There are currently two other projects like this going on here at the MySensors forum:

@sundberg84's In Wall PCB - This is a node using two PCB's stacked together that will sit inside of Swedish style wall appliance box and have its own power fed to it.

@martinhjelmare's: Box for In Wall PCB - This is a box that simply sits inside of the socket to contain all the open high voltages of electricity if being reduced down from 240v on the PCB itself.

If there is any electricians roaming around here, please, advise me of any serious, specific implications, rules and regulations that this would need to meet that i haven't stated so. I will be getting some mock schematic and PCB designs sorted out for you guys to look at for a starting point. I will make it very obvious now that I'm not a profession electronics guy, nor am i someone that has experience in designing PCB's, electronic designs or anything. This is a huge learning curve for me, but as a community i do believe we can put together some awesome products, alongside of @sundberg84 and @martinhjelmare's proposed outcomes.

Product Criteria:

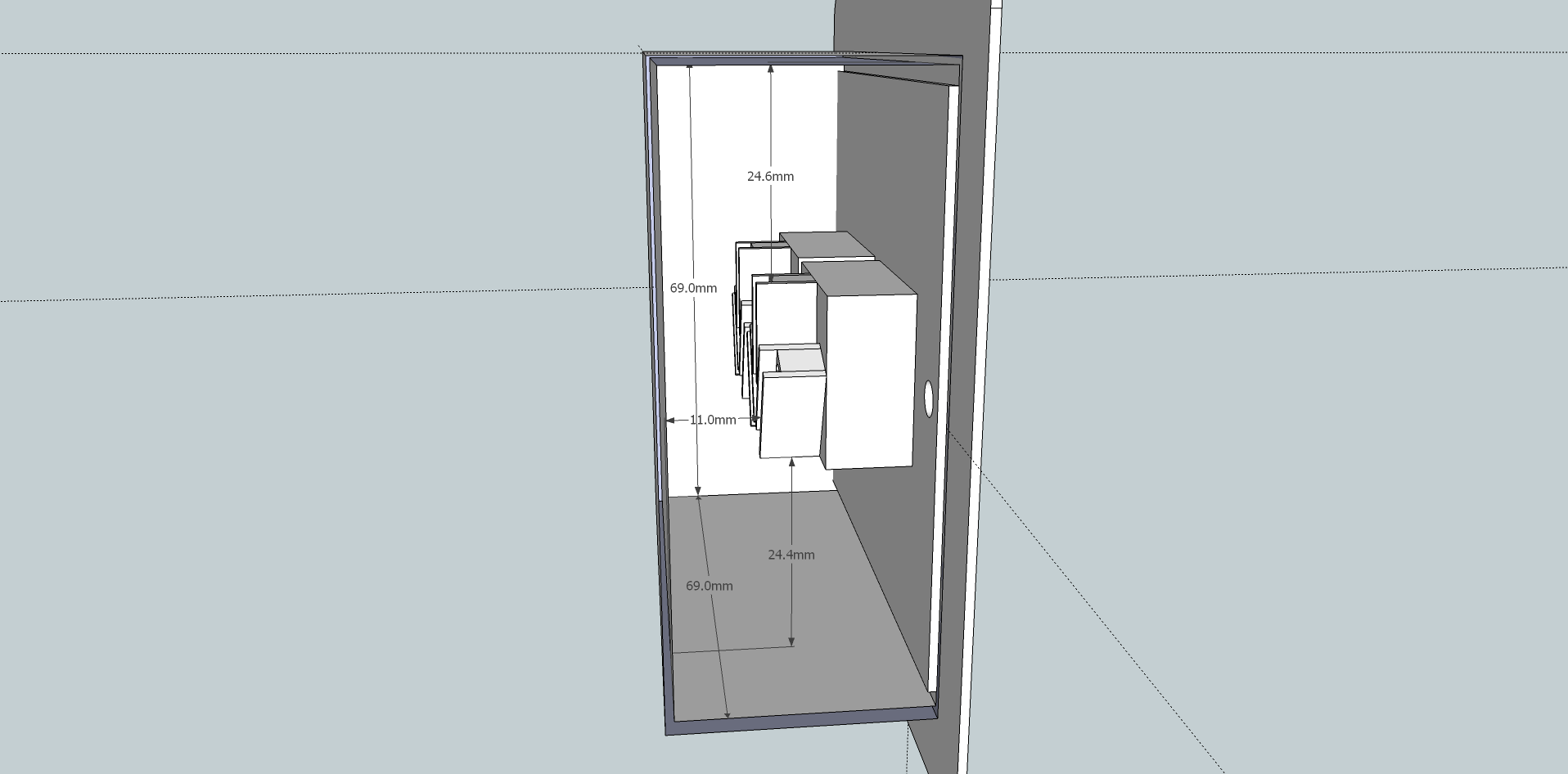

- Fits inside of a slimline (25mm depth) UK Wall metal AND plastic back box/dry lining box.

- Able to be powered via Battery and/or mains electricity, either 240v straight from the power circuit or have it transformed down to the 5v in a central location/outside of the socket box then fed into the box for application.

- Allowing you to keep existing wires in the box, but terminated. This would allow us backward capabilities of reverting our alterations in case of selling the property.

- Form factor/Footprint must be a small as possible to remove any possible issues on the space allocated.

The Product itself:

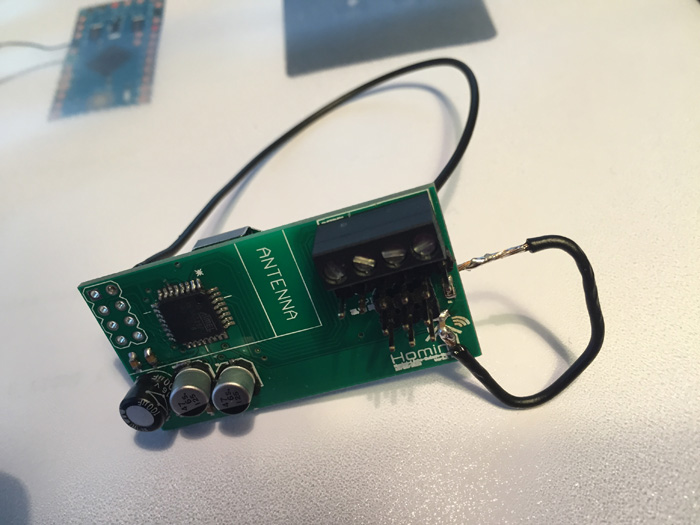

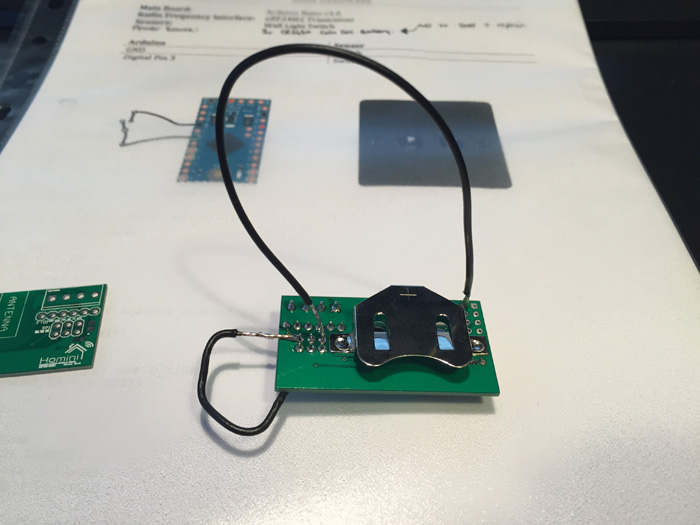

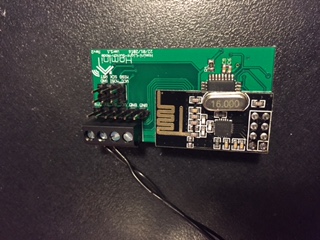

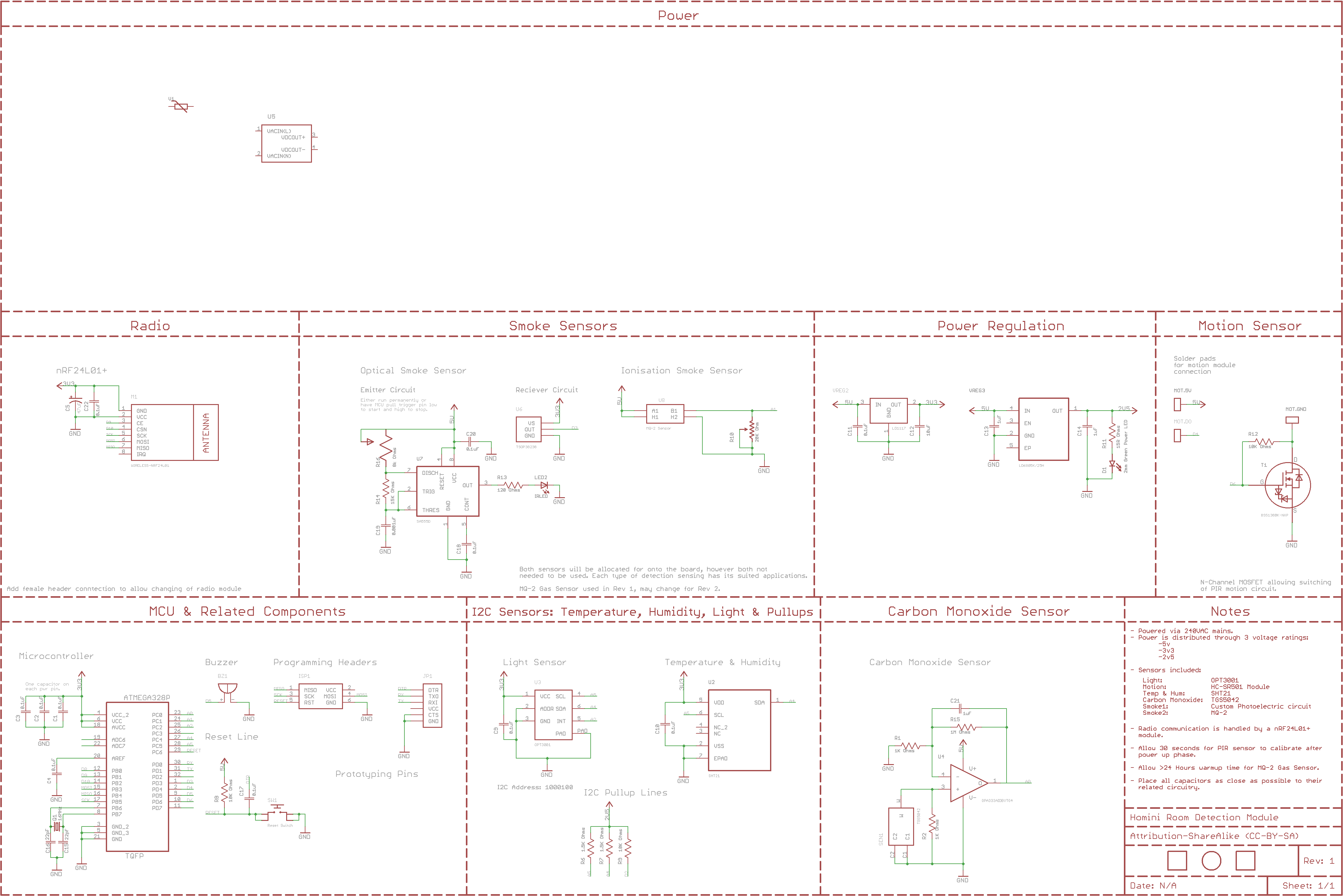

The product itself will be based around an Arduino Mini Pro powered via either a cell coin battery, AA batteries or a mains electric feed reduced down to the required voltage, I'm thinking 5v step down outside of the box (in a central location, maybe even in the electric room (where your main breaker is located) then stepped down from 5v to 3.3v on the board itself. The whole system will be created and located onto a custom PCB that i propose to be all SMD, to allow for a smaller form factor for the already challenging installation size. This product will start out to be a simple ON/OFF switch, a dimming version will be the first upgrade offered to the product. The product will include a nRF24L01 radio transceiver to deal with its networking, so that is going to need some revision for the metal back box version to allow the transceiver to work with the metal, if it has issues that is.

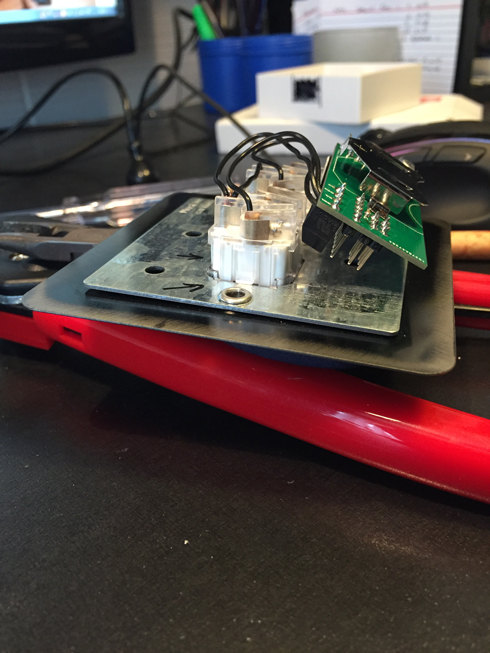

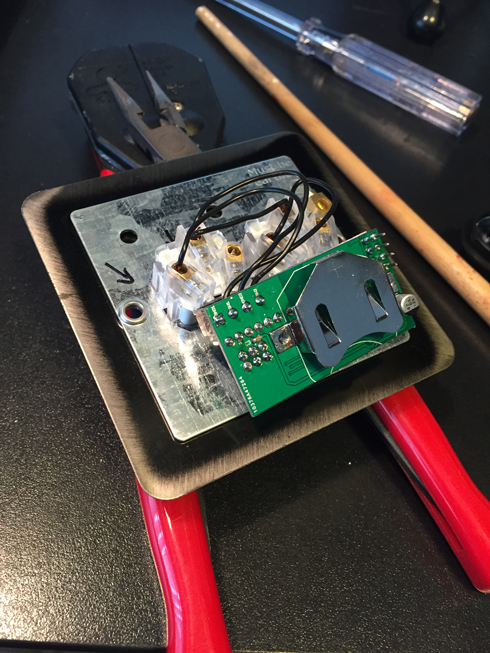

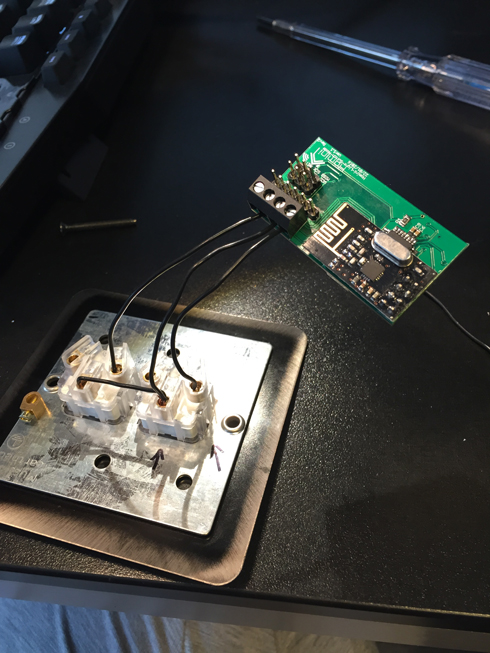

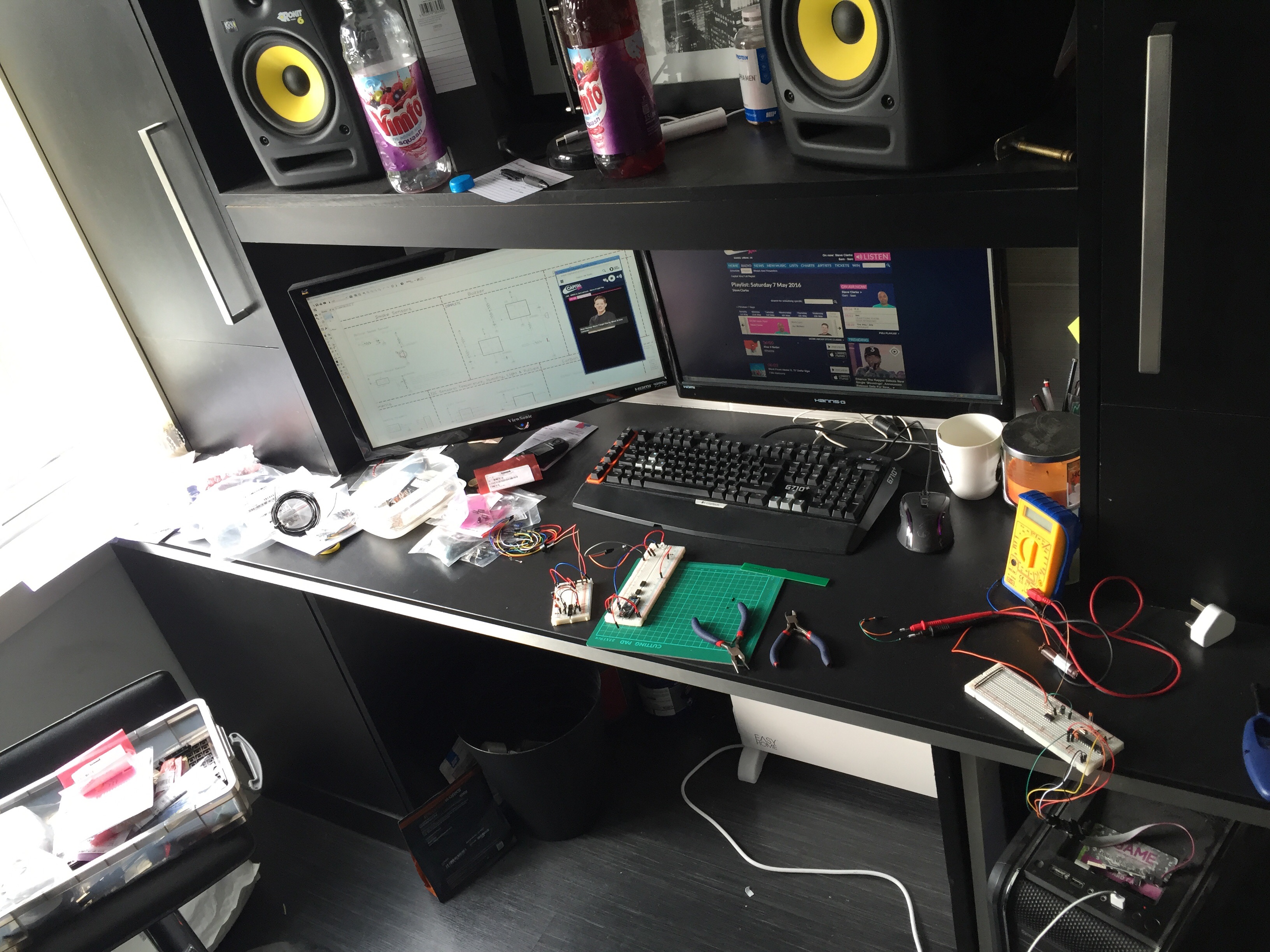

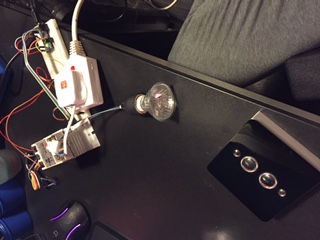

Currently, I have a breadboard setup with an Arduino Nano, a light switch faceplate doing the switching and an nRF24L01 doing the transmitting back to my MQTT gateway. So currently outside of the Arduino, all that is needed is terminals for the switch itself and a resistor for the switch. Then we will need the power solution, so a coin cell holder, resistors, caps whatever is needed to feed a stable 3.3v to the micro controller. The mains connection, this is going to need screw terminals, and again caps, resistors and whatever else is needed to reduce down the power (I'm still thinking to bring the mains in at 5v, so step them down outside of the application). If anyone feels like pointing me in the right direction in terms of whats needed to bring mains power down, feel free. I will continue to research the correct ways to do such a thing in the meantime.

Environment Design work:

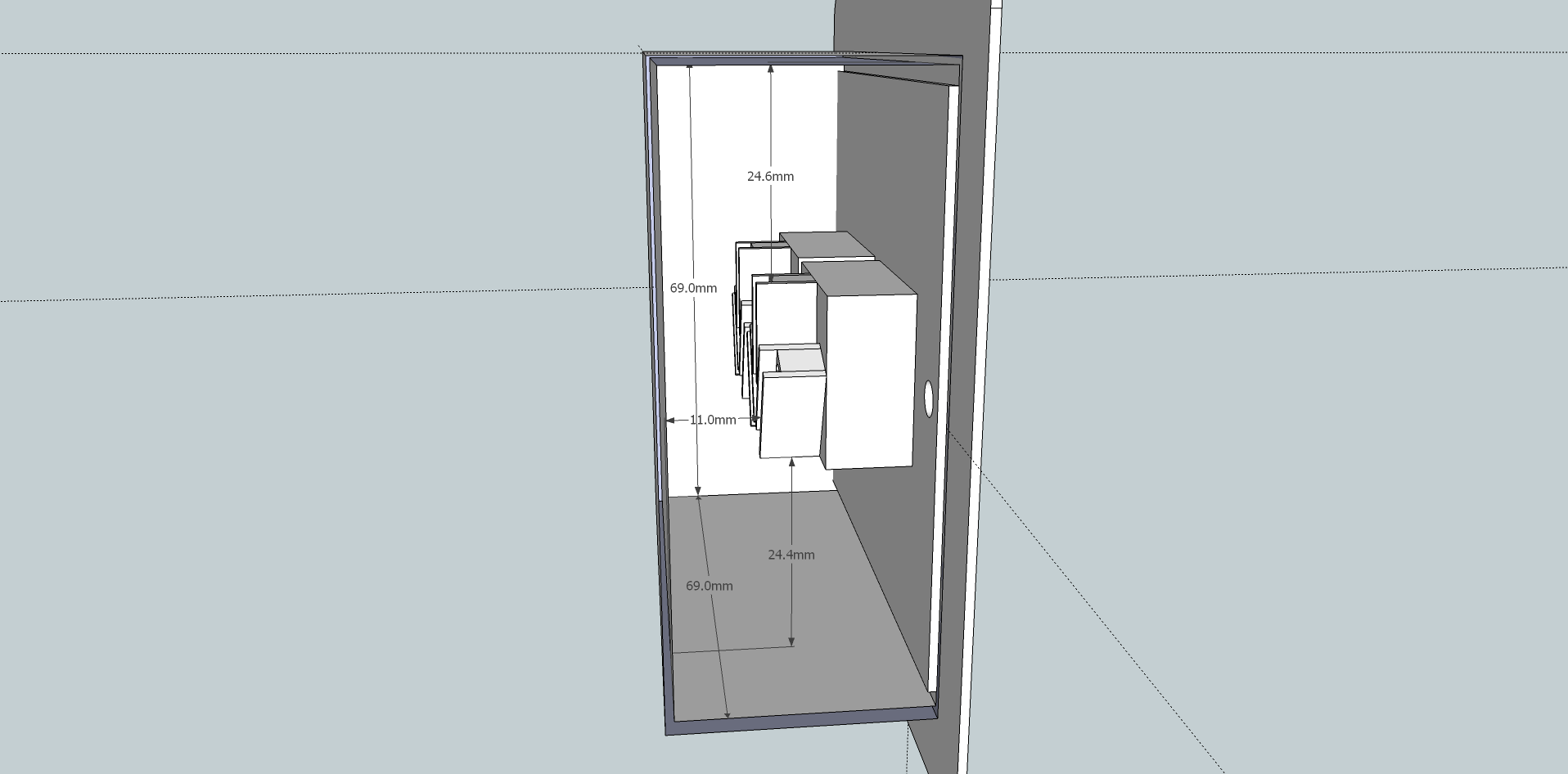

I have made a pretty accurate design in google sketchup as a starting environment for the first installation of this product detailing sizes that we have to work with to enable us to fit this inside of the existing wall back box.

The Environment for the Product:

For example, the below images show a light switch placement that i currently have, hopefully this will give some indication the room that we have to work with here to allow the existing cables to be terminated and left where they are for future needs. A normal back box or dry lining box installed now would be 35mm to sometimes even 50mm boxes, however we must allow for such situations that arise where the plasterers (Like myself) have had no choice but to install a 25mm box.

DISCLAIMER: I did not install the current switch, which as you can see is a pretty poor installation to say the least. I will be using an electrician to do any mains electrical work, and therefor I'm not going to allow anything below the national standard to be installed into my property.

DISCLAIMER: I do not advise you in any way to make/install this product into a property and therefore I take no responsibility for any issues, problems you have or even health implications that you endure while completing the installation or even using the product after installing.

UPDATES

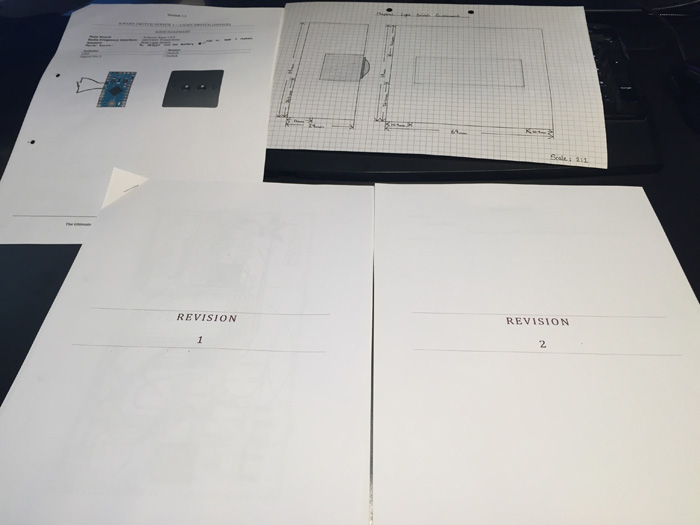

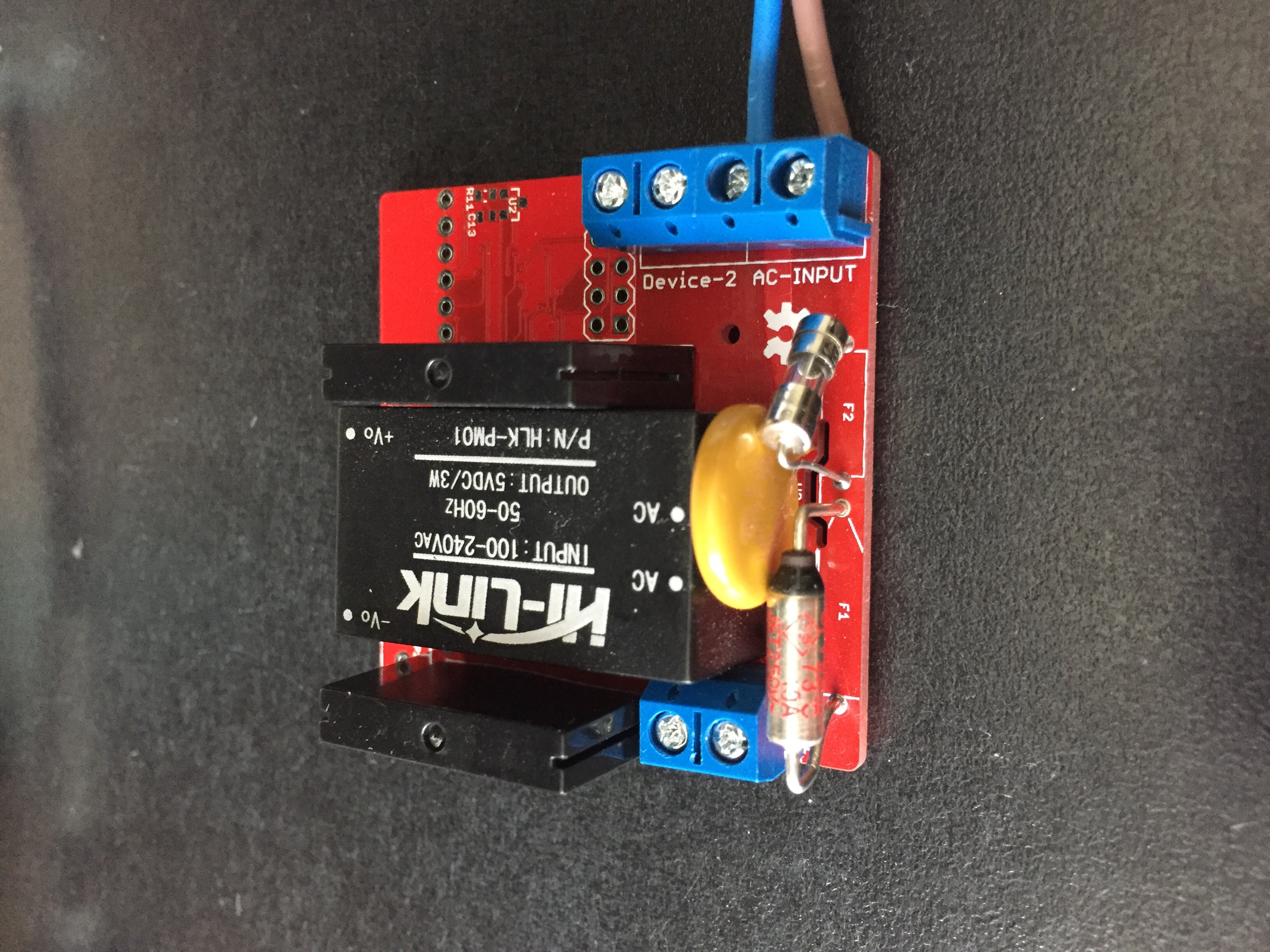

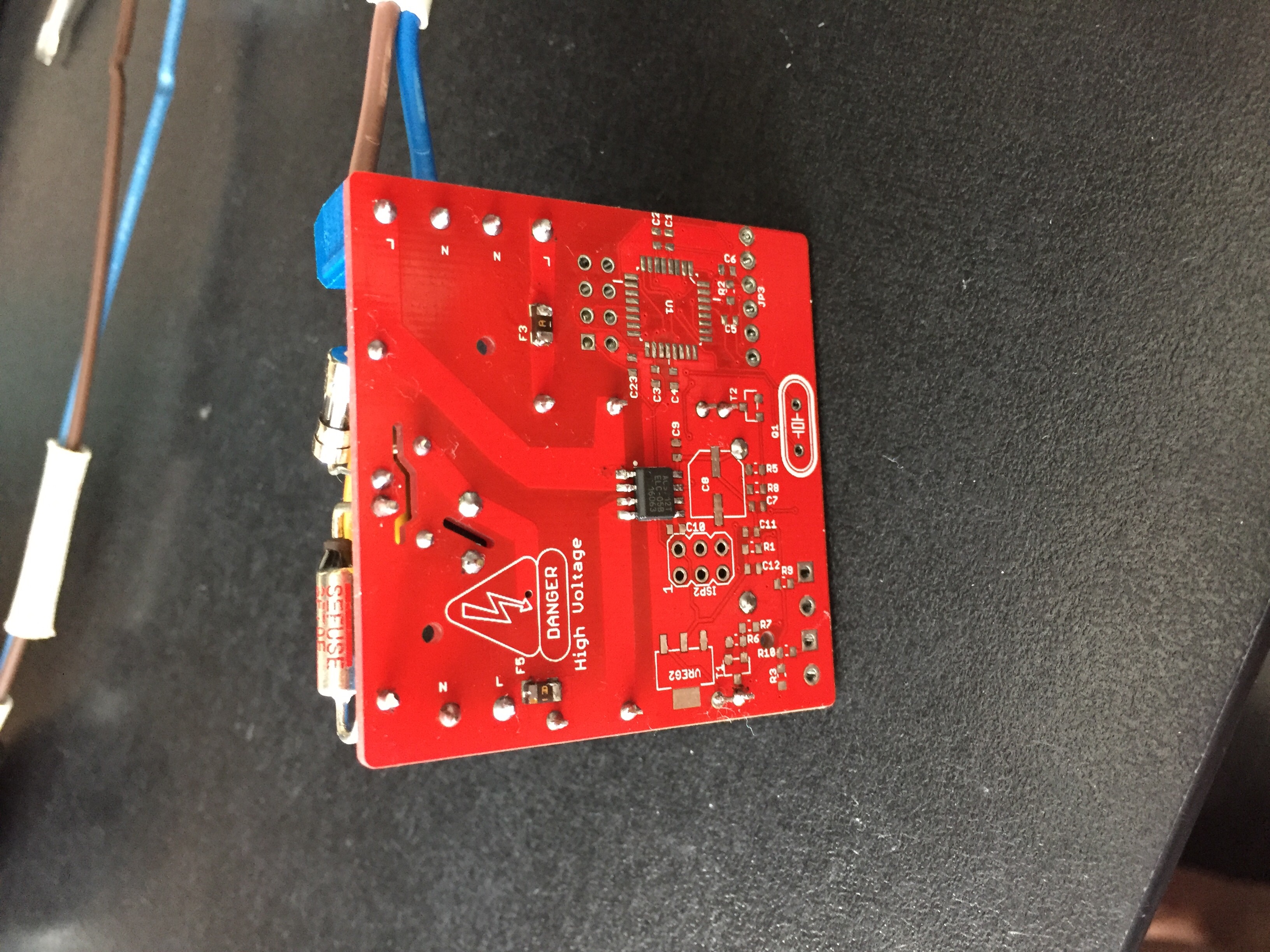

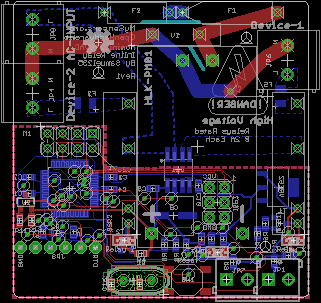

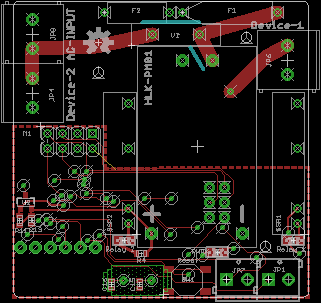

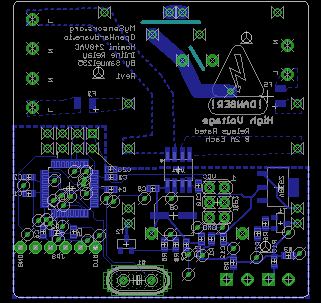

24th December 2015 - Version 1.1 Revision 1 boards have been ordered and currently being produced with ITead.cc.

24th December 2015 - Parts have been ordered for the production of 1 evaluation node.

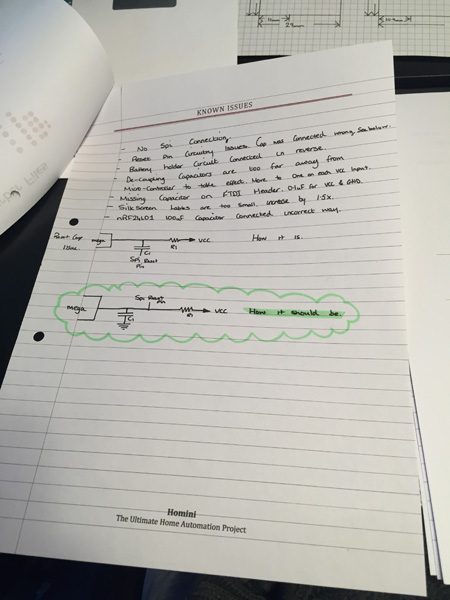

14th January 2016 - Version 1.1 Revision 1 board has arrived, populated with components.

23rd January 2016 - Version 1.1 Revision 2 boards have been ordered and currently being produced with ITead.cc.

13th February 2016 - Version 1.1 Revision 2 boards have been received and populated.

19th February 2016 - Version 1.1 Revision 2 boards are currently going through their first 24-Hour long testing period.

21st February 2016 - Version 1.1 Revision 2 boards are undergoing troubleshooting work.

5th March 2016 - Version 1.1 Revision 2 boards are completed and power usage tests are currently taking place.

19th March 2016 - Version 1.1 Revision 2 has been uploaded to https://www.openhardware.io/view/48/Homini-In-Wall-Battery-Powered-Light-Switch-Module

FILES

Current Eagle Files - Homini_Light_Switch_Node_Version_1.1_Revision_2.zip

Schematic PDF - 1_1457169973710_HominiSwitchNode1.0Rev2_Sch.pdf

Board PDF - 0_1457169973709_HominiSwitchNode1.0Rev2_Brd.pdf

Gerber Files - 0_1457460927449_Rev2 Gerbers.zip

BOM - 0_1457593789223_HominiSwitchNode1.0Rev2BOM.csv