@mfalkvidd I have hit a dead end. The issue described in the thread is stii not resolved. Any advice on what can help figure out the issue would be helpful.

Thanks

@mfalkvidd I have hit a dead end. The issue described in the thread is stii not resolved. Any advice on what can help figure out the issue would be helpful.

Thanks

Any Moderator or Admin here who can help me, please.

@rejoe2 I am using 2.2.0 on both gateway and node. Using NRF24L01+ with Caps . Strangely one of my node running on 2.1.0 is able to communicate with the gateway. Let's hope Mods have some answers. Appreciate your efforts and time.

Thanks

@rejoe2 I have already tried 2 different RF modules, the known good ones. So RF can be ruled out. I am running it with Domoticz, usually I don't have to change any setting, on presentation the node is shown in Domoticz and I just add it to my UI. Also tried the option Allow discovery for 5 mins in Domoticz that did not work either. So kind of lost here as to what's happening.

@rejoe2 I tried as suggested. Cleared EEPROM using the sketch from MySensors example folder, tried auto ID assignment and also predefined ID. None seems to work.

This is the log when no ID is assigned.

16 MCO:BGN:INIT NODE,CP=RNNNA---,VER=2.2.0

25 TSM:INIT

26 TSF:WUR:MS=0

33 TSM:INIT:TSP OK

35 TSM:FPAR

37 TSF:MSG:SEND,255-255-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

2046 !TSM:FPAR:NO REPLY

2049 TSM:FPAR

2051 TSF:MSG:SEND,255-255-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

4059 !TSM:FPAR:NO REPLY

4061 TSM:FPAR

4063 TSF:MSG:SEND,255-255-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

Log when Node is assigned ID:

16 MCO:BGN:INIT NODE,CP=RNNNA---,VER=2.2.0

25 TSM:INIT

26 TSF:WUR:MS=0

33 TSM:INIT:TSP OK

35 TSM:INIT:STATID=254

37 TSF:SID:OK,ID=254

39 TSM:FPAR

75 TSF:MSG:SEND,254-254-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

2083 !TSM:FPAR:NO REPLY

2085 TSM:FPAR

2121 TSF:MSG:SEND,254-254-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

4129 !TSM:FPAR:NO REPLY

4131 TSM:FPAR

4167 TSF:MSG:SEND,254-254-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

6175 !TSM:FPAR:NO REPLY

6177 TSM:FPAR

6213 TSF:MSG:SEND,254-254-255-255,s=255,c=3,t=7,pt=0,l=0,sg=0,ft=0,st=OK:

8221 !TSM:FPAR:FAIL

8222 TSM:FAIL:CNT=1

8224 TSM:FAIL:DIS

8226 TSF:TDI:TSL

Please advice if there anything that could help me understand the issue and fix it.

Thanks alot.

@rejoe2 Will try that. I did tried assigning ID manually, but that did not work.

@rejoe2 oh, I am sorry. I use the sketch from EEPROM Lib in Arduino. Not from MySensors. I am doing it right?

@rejoe2 I have used the Mockmysensor example sketch from Mysensors.

I updated the gateway to 2.2.0. I have one sensor on 2.1.1 which able to communicate fine with my gateway. I tried testing a node on 2.2.0. I flash the MockMySensor sketch, but its not able to get a node ID from gateway. I also cleared EEPROM and replashed , tied to assign ID to node but did not help. The ID:4 we see in the gateway log is my node running on 2.1.1. Need help in understanding what could be the issue/fix. Thanks

Logs from Node:

6 MCO:BGN:INIT NODE,CP=RNNNA---,VER=2.2.0

25 TSM:INIT

26 TSF:WUR:MS=0

33 TSM:INIT:TSP OK

35 !TSF:SID:FAIL,ID=0

37 TSM:FAIL:CNT=1

38 TSM:FAIL:DIS

40 TSF:TDI:TSL

10042 TSM:FAIL:RE-INIT

10044 TSM:INIT

10051 TSM:INIT:TSP OK

10053 !TSF:SID:FAIL,ID=0

10055 TSM:FAIL:CNT=2

10057 TSM:FAIL:DIS

10059 TSF:TDI:TSL

Logs from Gateway:

Mar 6 15:51:47 myhome mysgw: GWT:RFC:C=0,MSG=0;0;3;0;18;PING

Mar 6 15:51:57 myhome mysgw: GWT:RFC:C=0,MSG=0;0;3;0;18;PING

Mar 6 15:52:06 myhome mysgw: TSF:MSG:READ,4-4-255,s=255,c=3,t=7,pt=0,l=0,sg=0:

Mar 6 15:52:06 myhome mysgw: TSF:MSG:BC

Mar 6 15:52:06 myhome mysgw: TSF:MSG:FPAR REQ,ID=4

Mar 6 15:52:06 myhome mysgw: TSF:PNG:SEND,TO=0

Mar 6 15:52:06 myhome mysgw: TSF:CKU:OK

Mar 6 15:52:06 myhome mysgw: TSF:MSG:GWL OK

Mar 6 15:52:06 myhome mysgw: TSF:MSG:SEND,0-0-4-4,s=255,c=3,t=8,pt=1,l=1,sg=0,ft=0,st=OK:0

Mar 6 15:52:07 myhome mysgw: GWT:RFC:C=0,MSG=0;0;3;0;18;PING

Mar 6 15:52:10 myhome mysgw: TSF:MSG:READ,4-4-0,s=255,c=3,t=24,pt=1,l=1,sg=0:1

Mar 6 15:52:10 myhome mysgw: TSF:MSG:PINGED,ID=4,HP=1

Mar 6 15:52:10 myhome mysgw: !TSF:MSG:SEND,0-0-4-4,s=255,c=3,t=25,pt=1,l=1,sg=0,ft=0,st=NACK:1

Thanks @mfalkvidd and @gohan . That helped.

I build a Gateway on Rpi. Post build it was working fine. I reboot and it stops working. Unable to interpret what this means. Please help. I did go through the forum but not able to solve it. I am using the latest 2.2.0 release. I ruled out hardware and radio issues as one of my node was able to communicate and send messages.

Any help would be appreciated.

Thanks

pi@myhome:~/MySensors $ sudo ./bin/mysgw -d

mysgw: Starting gateway...

mysgw: Protocol version - 2.2.0

mysgw: MCO:BGN:INIT GW,CP=RNNGL---,VER=2.2.0

mysgw: TSF:LRT:OK

mysgw: TSM:INIT

mysgw: TSF:WUR:MS=0

mysgw: TSM:INIT:TSP OK

mysgw: TSM:INIT:GW MODE

mysgw: TSM:READY:ID=0,PAR=0,DIS=0

mysgw: MCO:REG:NOT NEEDED

mysgw: bind: Address already in use

mysgw: Failed to bind!

mysgw: MCO:BGN:STP

mysgw: MCO:BGN:INIT OK,TSP=1

mysgw: accept: Bad file descriptor

mysgw: accept: Bad file descriptor

mysgw: accept: Bad file descriptor

mysgw: accept: Bad file descriptor

mysgw: accept: Bad file descriptor@jacikaas Ok.

//Remove this line from loop function

stepper1.run();

//Change this line

stepper1.moveTo(CURTAIN_CLOSED);

//to

stepper1.runToPosition(CURTAIN_CLOSED);

I hope this works. Also make similar changes in block which closes curtains.

Refernce article: https://www.pjrc.com/teensy/td_libs_AccelStepper.html

@jacikaas said in Curtain Control Node.:

void receive(const MyMessage &message)

{

// if message = V_UP start moving until closed

if (message.type==V_UP) {

digitalWrite(powerPin, HIGH);

if (stepper1.distanceToGo() == 0){

if (stepper1.currentPosition() == CURTAIN_OPEN){

stepper1.moveTo(CURTAIN_CLOSED);

// Store state in eeprom

saveState(message.sensor, message.getBool());

request(CHILD_ID, V_UP, 0); // request new values from controller

}

}

}

if (message.type==V_DOWN) {

digitalWrite(powerPin, HIGH);

stepper1.moveTo(CURTAIN_OPEN);

// Store state in eeprom

saveState(message.sensor, message.getBool());

request(CHILD_ID, V_DOWN, 0); // request new values from controller

}

if (message.type==V_STOP) {

digitalWrite(powerPin, HIGH);

stepper1.setCurrentPosition(0);

// Store state in eeprom

saveState(message.sensor, message.getBool());

request(CHILD_ID, V_STOP, 0); // request new values from controller

}

// delay(CURTAIN_CLOSED);

// digitalWrite(powerPin, LOW);

}

You can enable and disable outputs and try. In the following function:

void receive(const MyMessage &message)

//add the following at the begining of the function

stepper1.enableOutputs ()

//and add the following at the end in the same function.

stepper1.disableOutputs ()

I hope this helps haven't tried it myself.

@TON-RIJNAARD You need to select the board based on the bootloader you have flashed. Complile the code in Arduino and try burning the hex file using a programmer (USBasp, AVRISP, etc..) if are facing issues with Arduino.

@Tmaster Thanks for bringing this up. I was able to find LNK family ICs where I'll be able to source at cheaper price. I have ordered some LNK306 to test them. Cost me 80Rs/$1 and some cents. Will test once I receive them and post the results.

@rvendrame My current design uses Hi Link 5V PSU, however I am looking at lowering the cost and this was one of the options.

I also reverse engineered some cheap 5v phone chargers, its an SMPS based design using single transistor. Are safe as there is isolation.

This might be my next option to look into. The problem is with the transformer. How do I get the transformer to my specification. Do I wind them myself? will have to look into it.

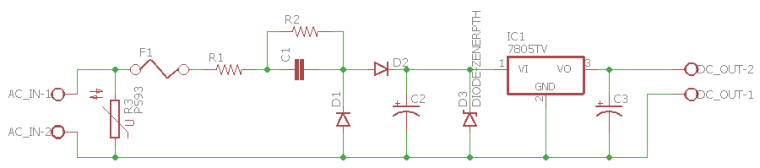

@Suresh-Mali I modified the above schematic, just to add some protection and regulation.

@Toyman That helps. Thanks.

@sundberg84 Thanks for your valuable information.

@gohan Overvoltage and short I guess can be solved if I use an MOV and Fuse.