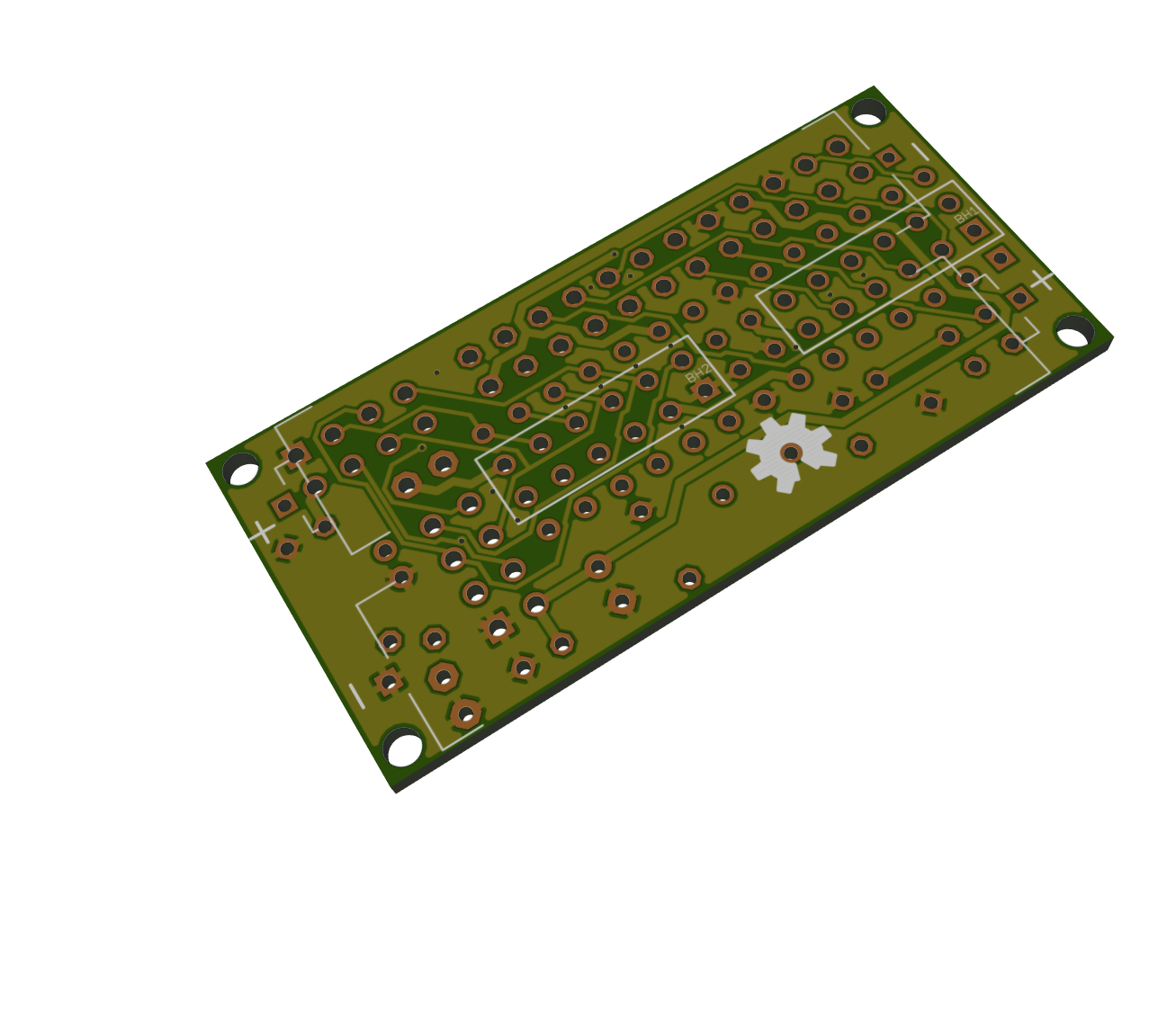

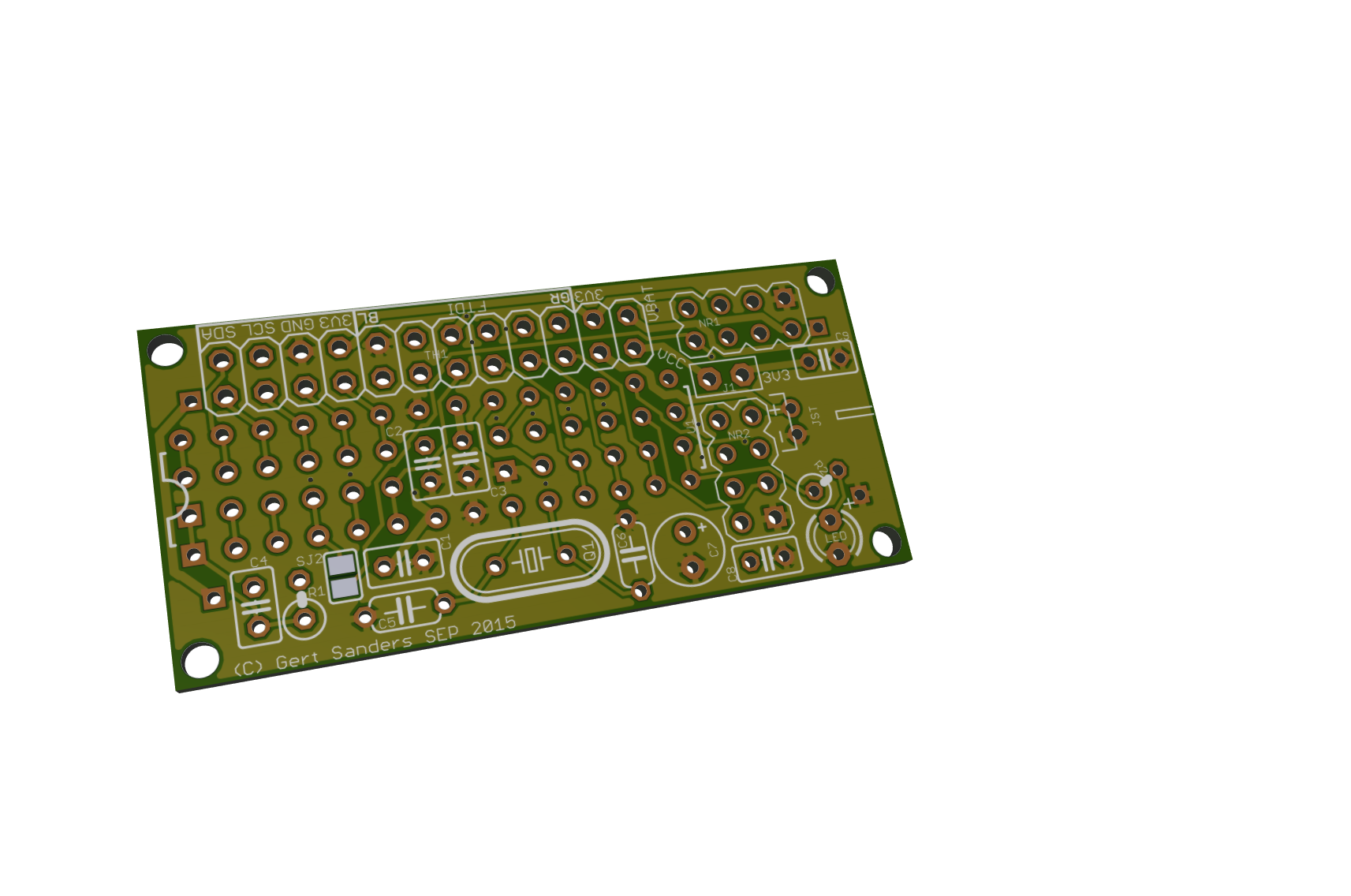

My own board (50mm x 30mm)

-

@ahhk said:

This is my Case-Prototype - very flexible and easy to manufacture:

Why do you say it's "easy" to manufacture?

-

@Andreas: nice woodcase. Do you have access to a CNC machine at home or at work ?

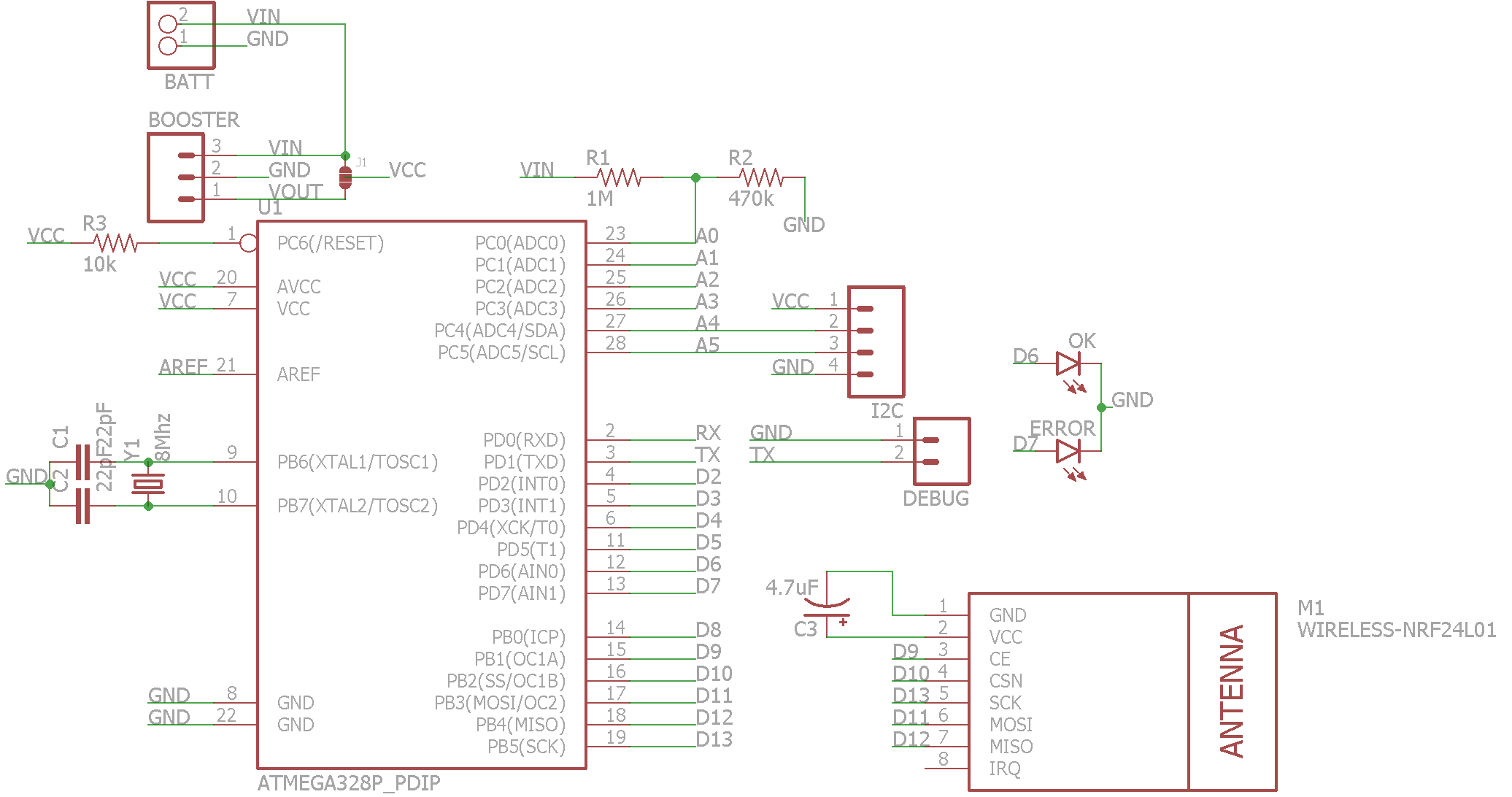

My design is based on the idea that I want to have a maximum of options with the same PCB. Last night I printed some boardoutlines on paper and then placed the actual components on top. I find limitations in space this way. My idea of 1 long connector has a disadvantage: the small radio covers 4 pins, so that a top board would not be able to plug into these. I went back to a seperate header for the small radio and for the top board.

Still thinking about powering options. VRAW (anything external), VCC (regulated to maximum 5V, e.g. from a USB port), 3V3 (regulated via bottom- or top-daughter boards), VBAT (from onboard AAA batteries). The problem is finding an elegant and easy way to choose. Solderpads are compact, but permanent. Jumpers are easy but big. Small toggle- or slide-switches are expensive.The fruit of last night's meditations:

I have still not decided if I should use the pintout of the SI7021 breakout modules (VCC-GND-SCL-SDA) or the HTU21D (VCC-GND-SDA-SCL). Most breakouts seems to use 3V3, so I may need to plan for that.

-

hi.

nice boards guys!

yep, so lot meditation for tiny things I am still asking myself on some points..

I am still asking myself on some points..in my case I choosed solderpads. not difficult to change and it is small. but not as easy to use as jumpers. I think jumpers are useful for proto stage but then in real you won't need it and it will take place.

I was thinking about having pinout for breakout too. but what if sellers change or stop boards. I don't think so, but it could happen...and it increase overall size too.

but I understand your vision of your board (mine is full smd). I like your ideas too!See you soon and good luck for meditation

-

@NeverDie said:

@ahhk said:

This is my Case-Prototype - very flexible and easy to manufacture:

Why do you say it's "easy" to manufacture?

I put a wooden 8mm-plate on my cnc and mill the parts

Very cheap and fast made....

Very cheap and fast made....@GERT: I have a cnc at home. i built it several years ago

Take a look if u want: http://www.rc-network.de/forum/showthread.php/304809-CNC-FRÄSMASCHINE-OPEN-SOURCE-PROJEKT/page11

Take a look if u want: http://www.rc-network.de/forum/showthread.php/304809-CNC-FRÄSMASCHINE-OPEN-SOURCE-PROJEKT/page11Power

I have only 2 possible variants in mind:- Battery with or without step up (plugin boost converter)

- USB-Powered

For the last one i wanted to use these pcbs - glued into the case or plugged instead of the step-up module:

http://www.ebay.de/itm/301652467812?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AITOr i install a small connector into the case and solder 2 wires to the board. Something like this http://www.ebay.de/itm/2-Pair-DC-Power-Female-Male-Connector-Cable-Pigtail-Plug-Wire-CCTV-camera-White-/252099946337?hash=item3ab253e761

Everything should stay "easy&simple" and i think, once installed, the sensor will "hang around" for a year or longer....

Sensors

I checked 3 properties to find the correct sensor:- minimum allowed voltage

- time for a measurement

- price

So, the htu21d was the winner for me - works great and fast after a little optimization of the arduino-library for this (replaced delay with gw.sleep)...

-

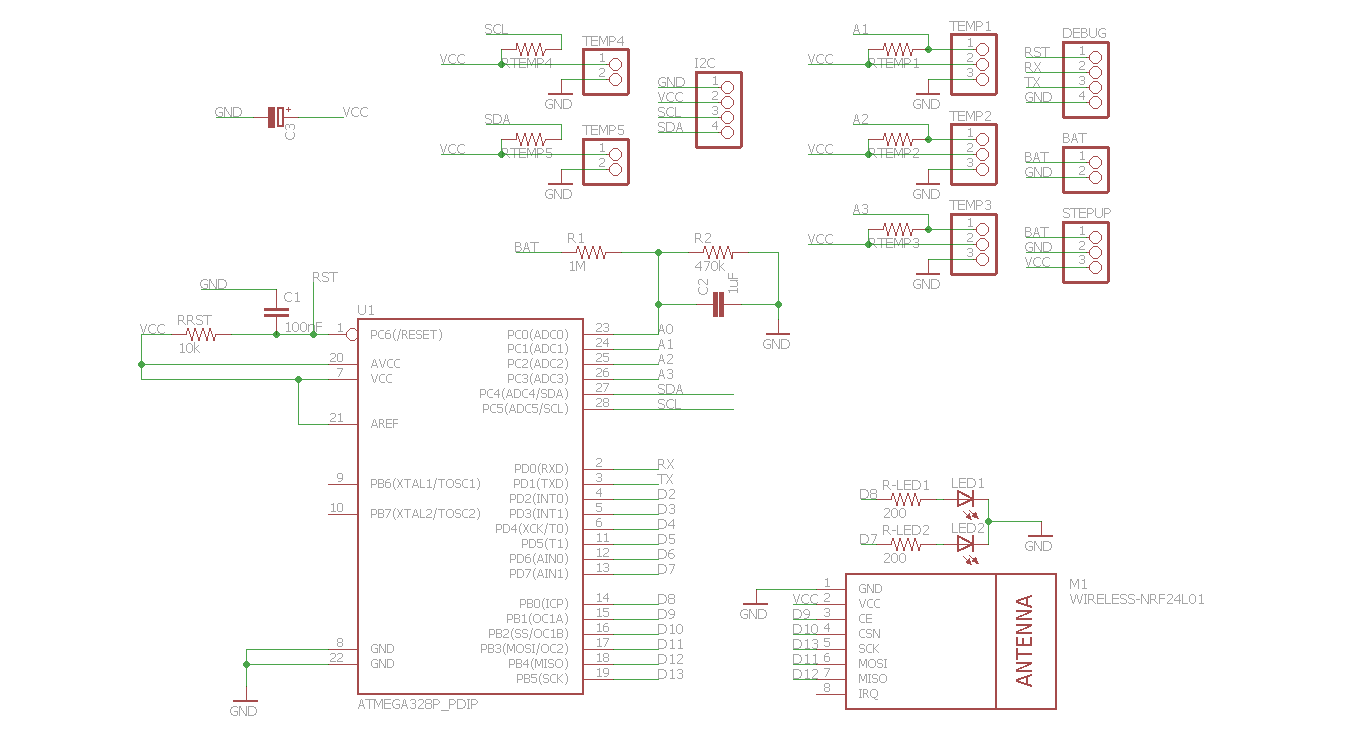

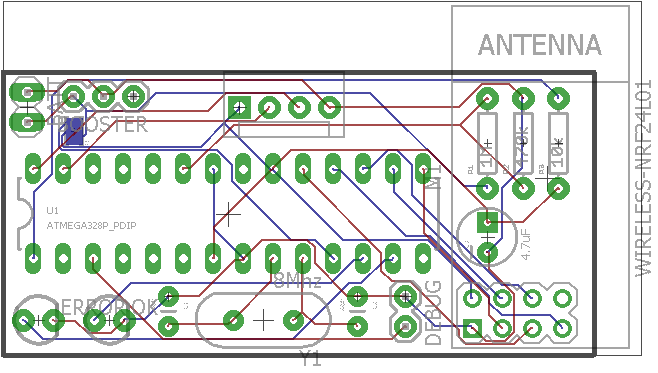

Next variant. Less flexible, but flexible enough. Boardsize now 50x30mm

It's only one pcb now and you can connect- 5x sensors (digital or analog)

- 1x I2C and 3x sensors (digital or analog)

Step-up can be soldered to the bottom.

What do you think?

-

hi Andreas,

What is the intention of TEMP4 and TEMP5 connectors ? I see that you pull up SCL and SDA, but all these connectors can do now is give VCC and GND on pin 1.

For TEMP1->3, it depends on how the sensor actually works. With Light Dependant resistor there is no issue. For other sensors (TMP36), a resistor pulling up to VCC would be a problem. A switch would be OK between pin 1 and 3 (GND) of those connectors. What is the usecase ?

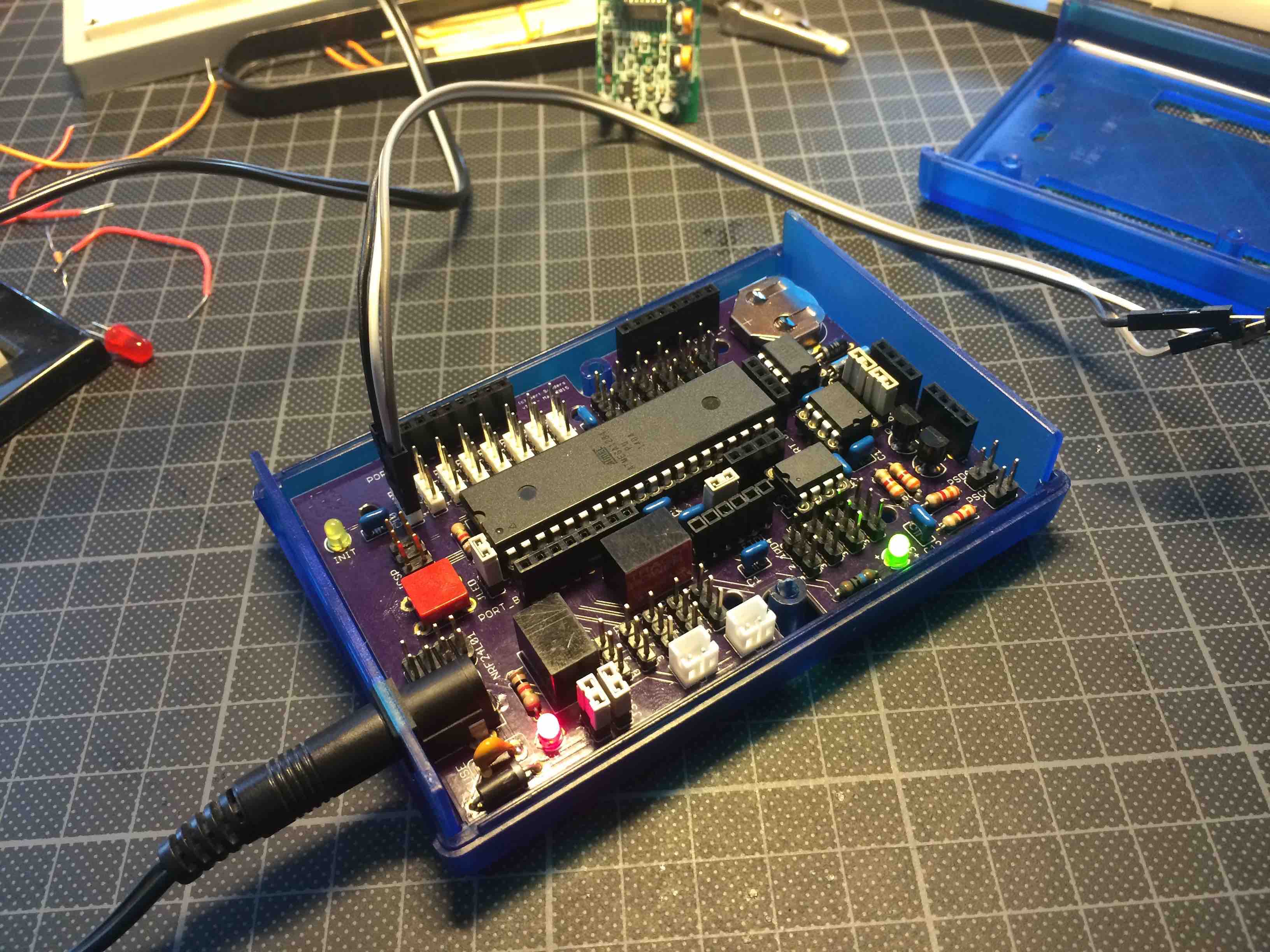

I have a atmega1284 based design, which is not yet shared on OSHPark. The version I made has the NRF24 connector in the wrong direction (but this is still useful). However, I can not close the case with the NRF24 in place. It was made for a Hammond 1593N case (the transparent blue type, very cool):

I used the case for the Arduino Due (bought this from Mouser).

I now corrected the orientation of the NRF24 connector but this not put this on OSHPark, because I can live with the mistake I made. Many ports on this one. But only works on 6-24V input. The power converters are from TRACO (1 for 5V, 1 for 3V3). It has 64KB EEPROM and RTC. Level converters for 5v->3V3 on I2C (so 2 I2C ports actually) and most pins are brought out together with 5V and GND.

The point here is that adding resistors to the three pin connectors is not really necessary. But it is nice to have signal-VCC-GND on three wires each time.

I think I will order the 1593K case next (to see what can be done with that), nice little box.

-

@Andreas: Very impressive CNC machine !!!

-

Hi Gert,

thx for the cnc-flowers

Sensors

I thougt about the different nodes i will have later. The biggest node will have 5x DS18B20 - so i really dont need more than 5 "ports" to connect sensors. I changed them to the analog-pins of the arduino, because i can use them as digital and analog ports too...

Temp4 and Temp5 can be used as I2C ("horizontal") OR as Temp4 and Temp5 for DS18B20 ("vertical"). See top left corner of the board. I think it is very flexbile to not solder the resistors (disconnect VCC) or to solder a wire instead of the resistor (vcc to pad). In this way i can connect PIRs, DS18B20, Analog-sensors and so on....i just solder the parts i need for the sensors...

Only thing: I cannot use I2C AND Temp4 / Temp5 at the same time, because A4 and A5 are SCL and SDA too....

I hope you understand what i mean and try to reach...Btw: Jumper-pins are not a must, if i want, i connect the sensors via wire to the pads, or solder them onto the pads directly....

Greetings

Andreas

-

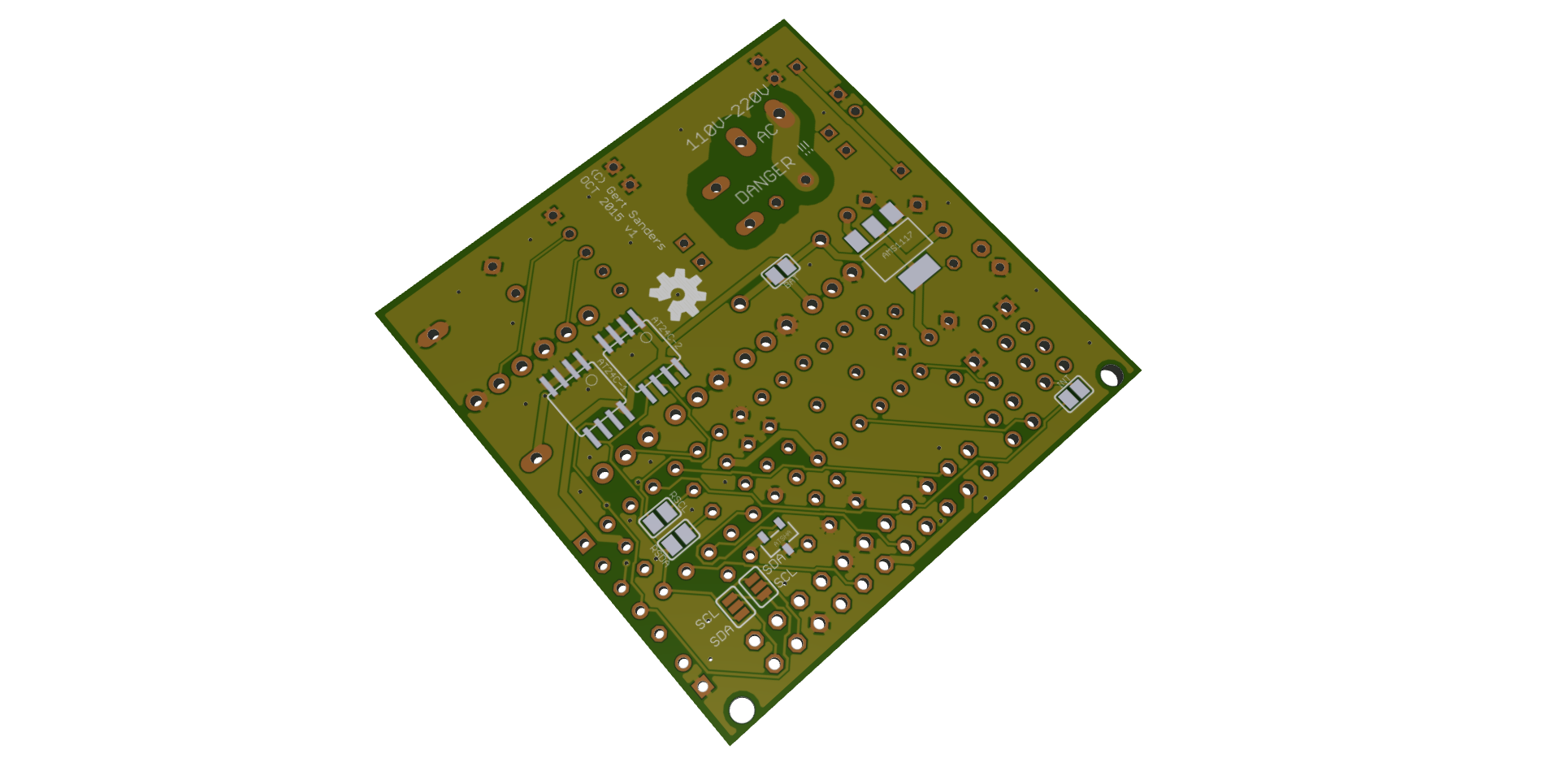

A 3D view of my lastest board

Tool used: http://mayhewlabs.com/3dpcb

So cool to see a 3D render, very fluid when moving around

-

Hi,

3d-view is really nice. I dont know why, but my gerber files dont work. Board is BIIIIIIIGGG and without holes

I asked in the hardware-forum, if there are any errors in my design. (http://forum.mysensors.org/topic/2042/errors-in-pcb-design)

I must finish this and order my boards now

Otherwise i will never find an end....

Otherwise i will never find an end....

-

Getting close to final layout myself ....

-

@ahhk said:

Hi,

i thougt a long time about placing such a booster on the pcb. Its quite difficult to find a good(!) booster. Lots of the cheaper booster draw a lot of current (quiescent current) - like the one behind your link. I tested only 2 until today.

This one: http://www.exp-tech.de/pololu-3-3v-step-up-spannungsregler-u1v10f3?gclid=CPmll6rH0ccCFRI6Gwod884Lxg

and this one: http://www.exp-tech.de/sparkfun-ncp1402-3-3v-step-up-breakout-prt-10967?gclid=CPCv55_H0ccCFUu6GwodKDUHwACurrent consumption differs approx 30uA between those 2 (red 70uA, green 100uA in sleepmode with sensors etc)...

Did you check current-consumption of your booster?Actually i am changing the board size to 50mmx24mm - its a lot cheaper to order from fusionpcb (seeedstudio)...

Thats a lot.

Greetings[▲QUICK EDIT]

Something like this? Booster soldered vertical....In this way you must select with the solder jumper how to power the board (battery direct or via booster)...

Hi ahhk,

Can You share brd files for this version? Thanks.

Maciej

-

Hi,

sure i will share the brd-file and schemativ. No problem. But let me first build one working sensor. I think i will order the pcbs this weekend, because this looks good too =>

-

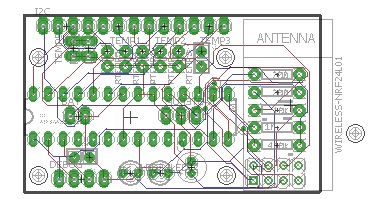

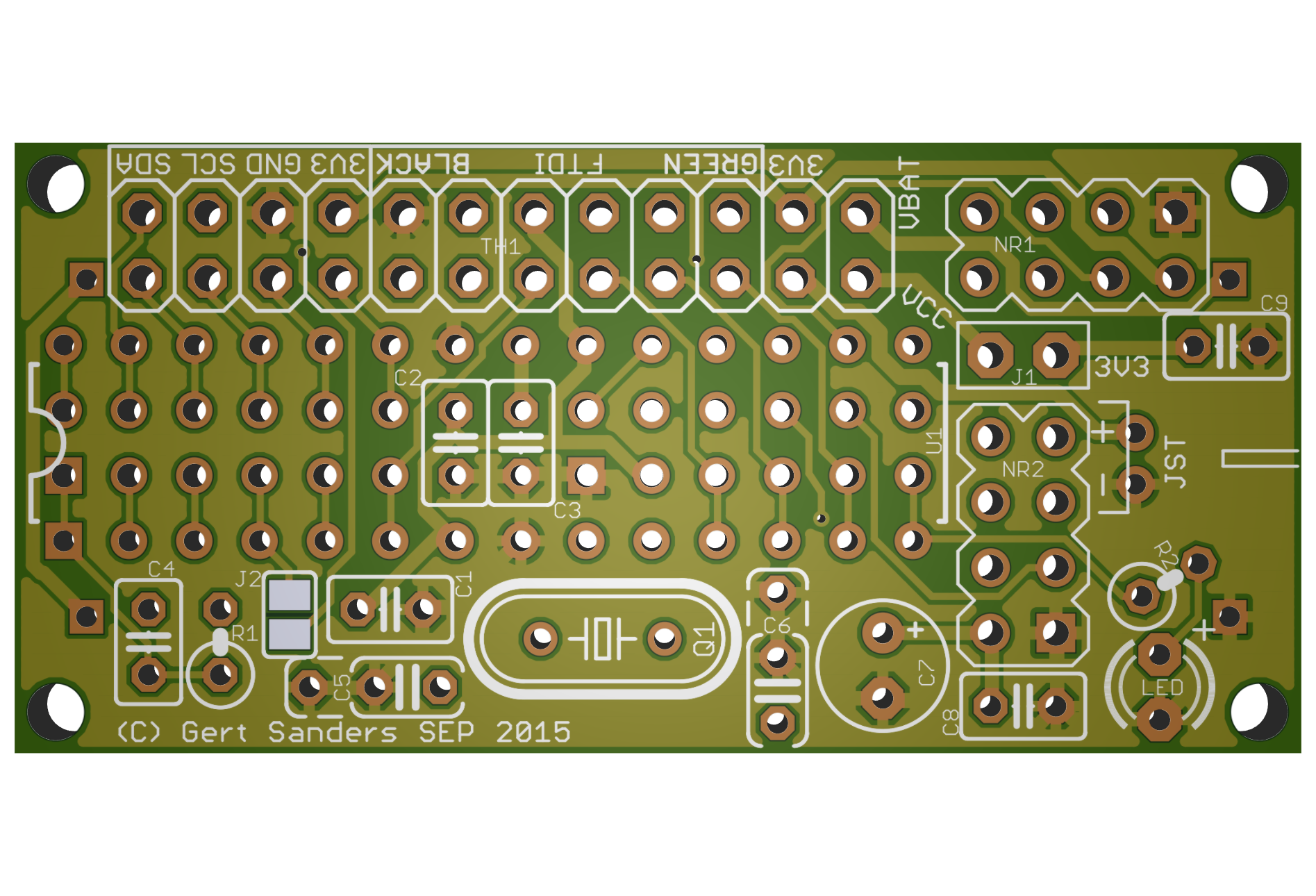

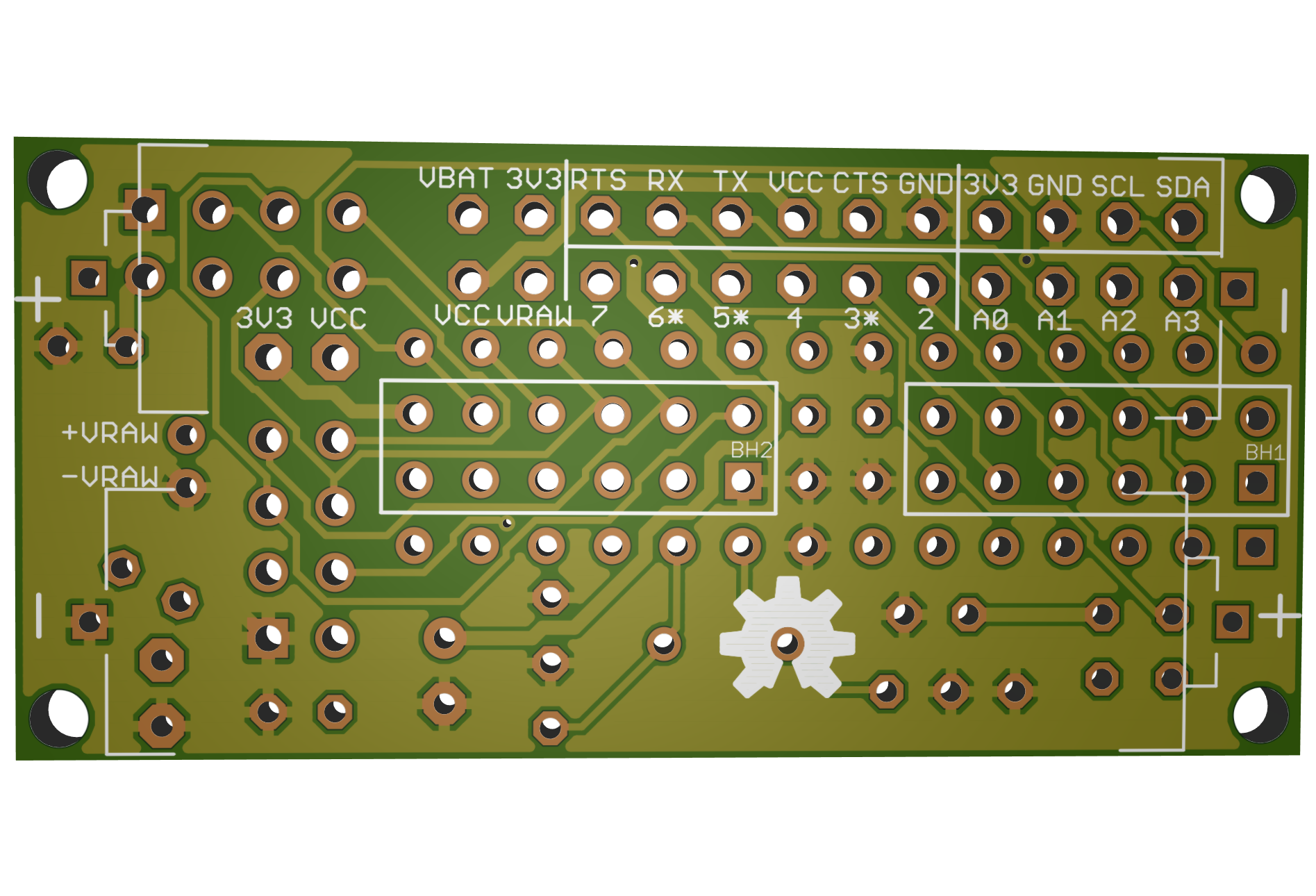

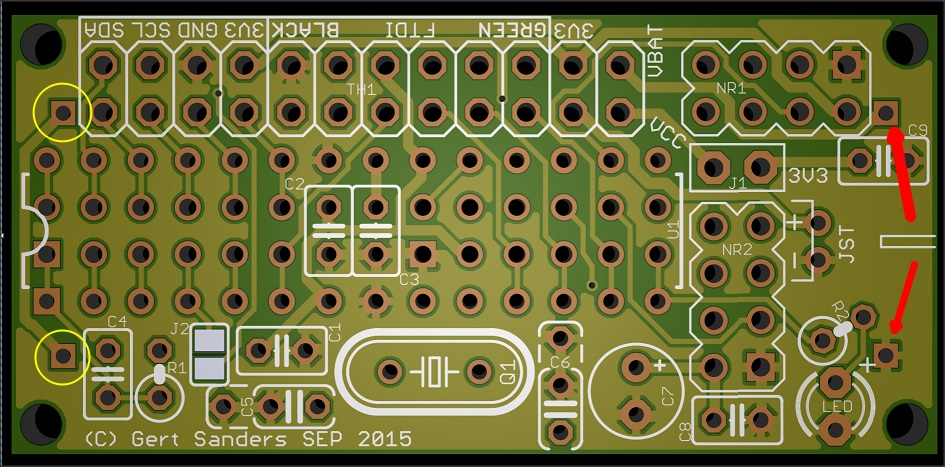

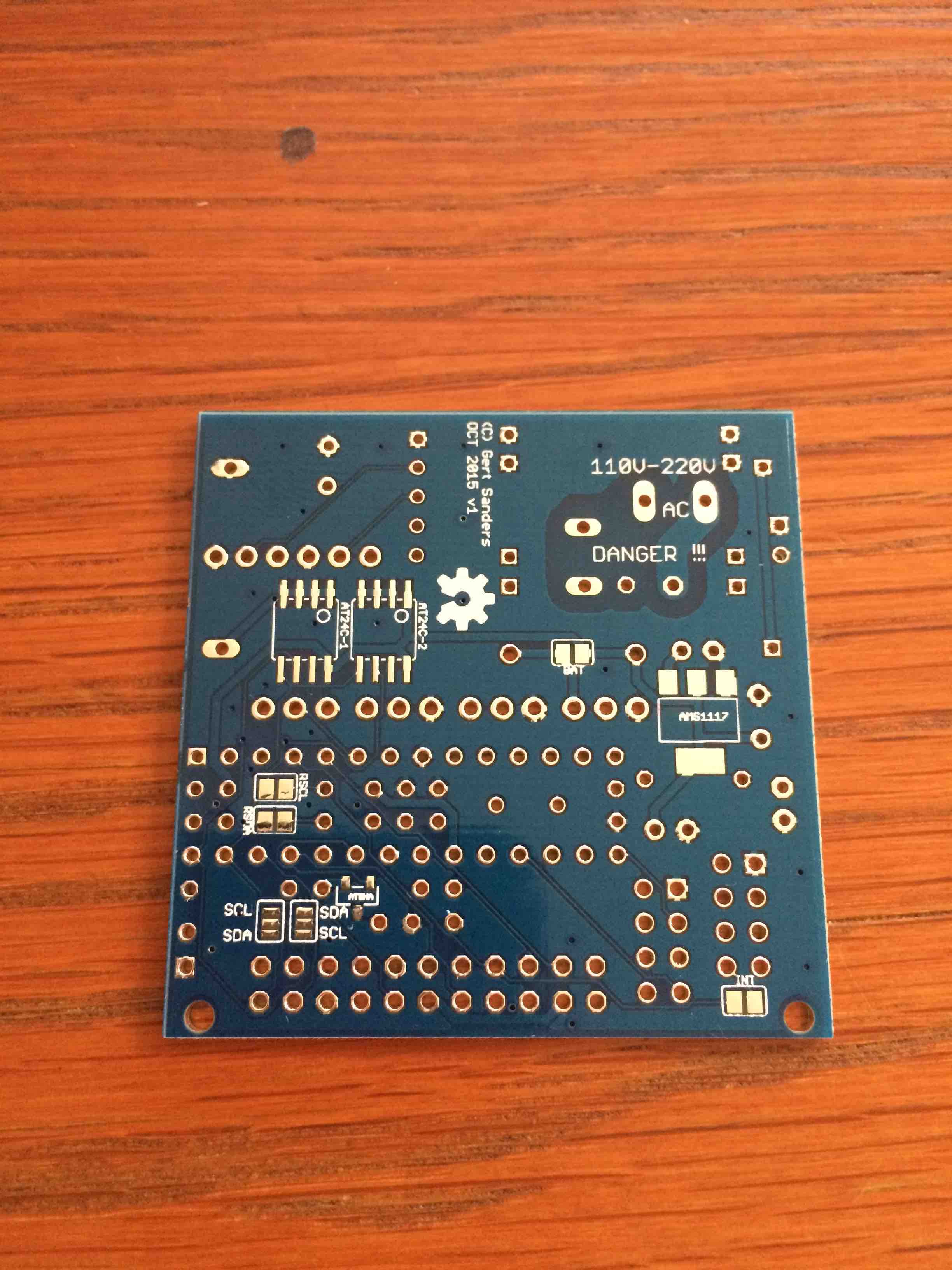

Done, this will be sent to the PCB makers:

Top:

Bottom:

-

each boards are nice, good work

-

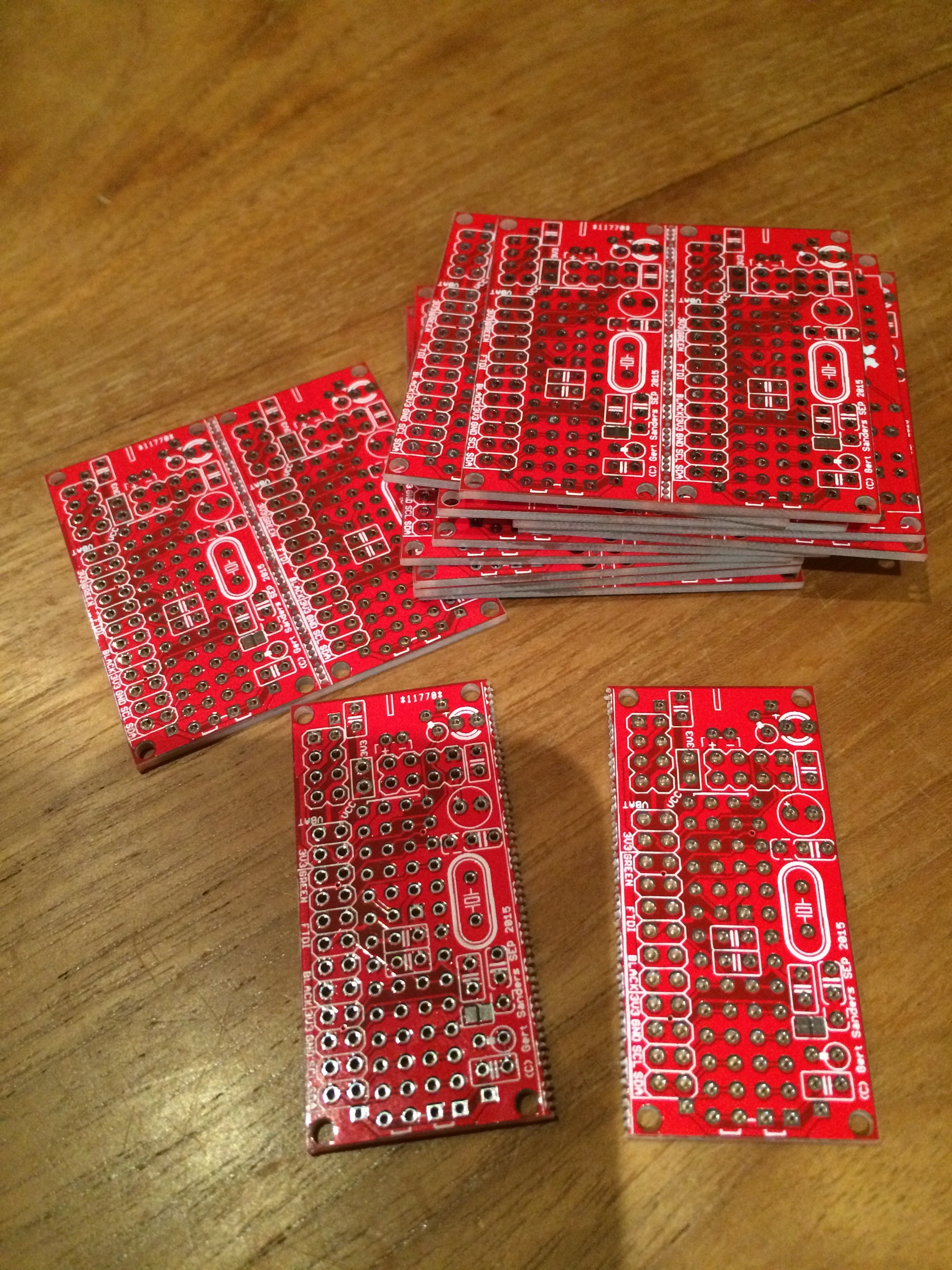

PCBs are ordered (shenzen2u)....i am very curious about it

-

Update: PCBs are shipped via express...

-

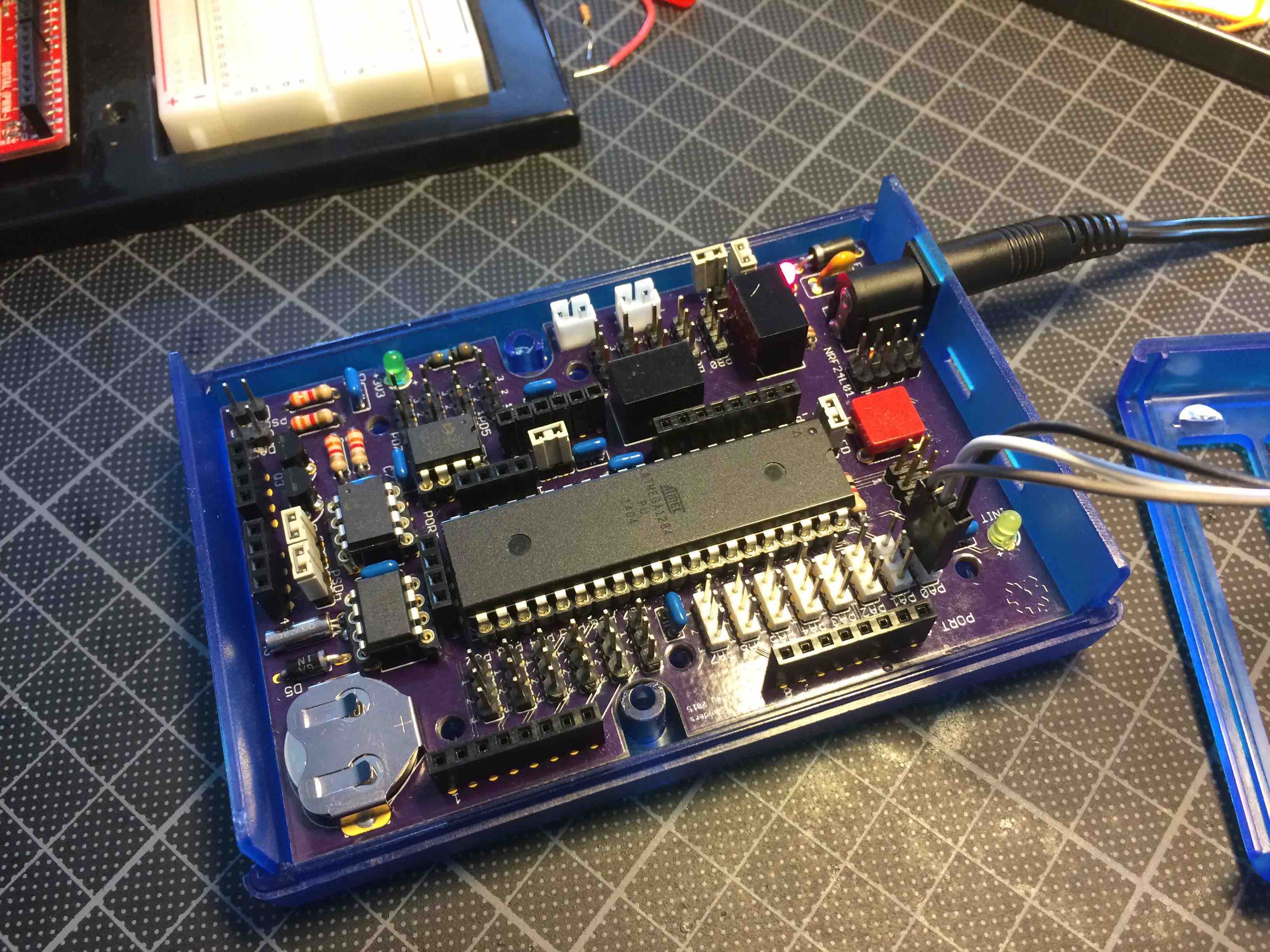

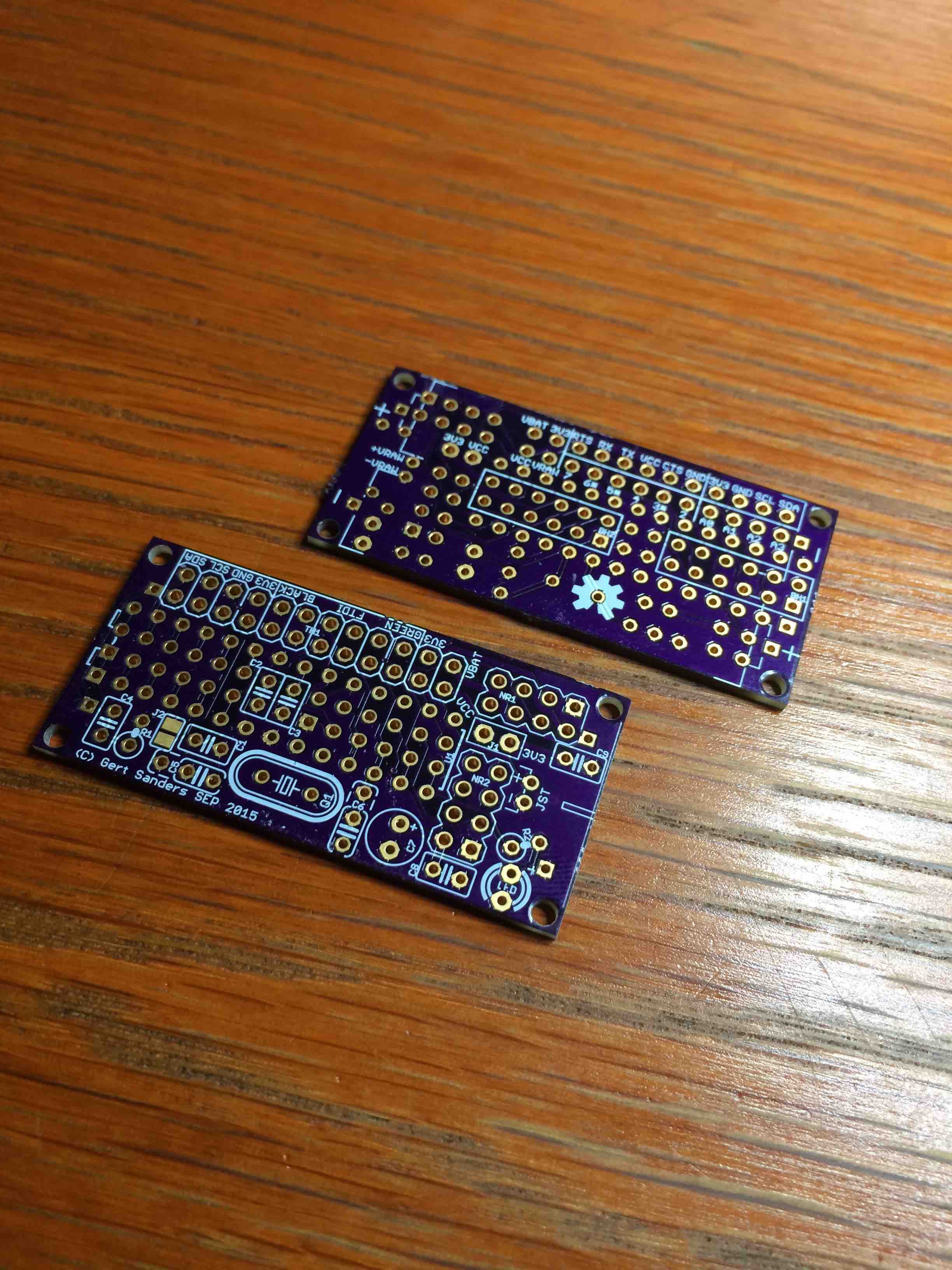

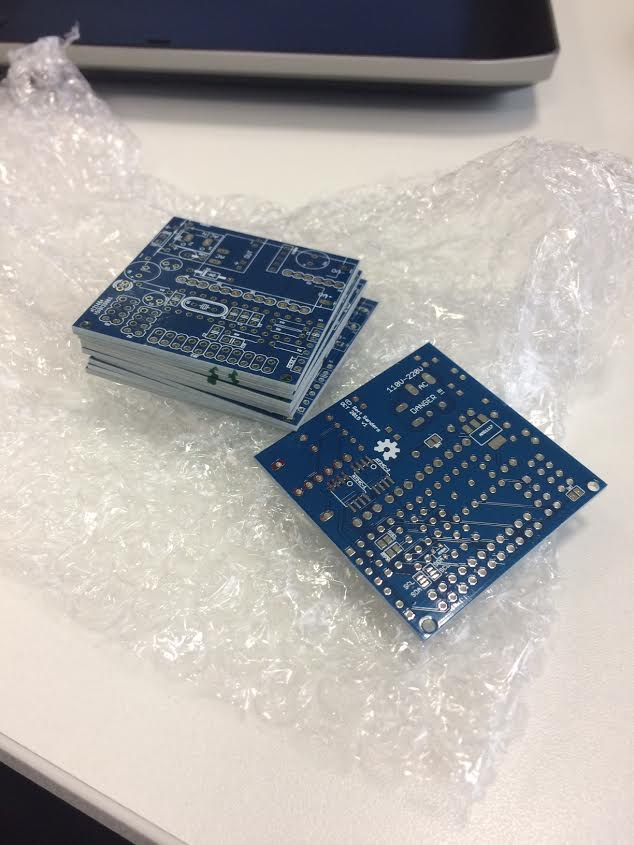

Update: this arrived in my mail today:

I also ordered a set from DirtyPcbs, which were ready lastweek monday, but are still on their way to me.

Assembly starts tomorrow

-

ok, great

Lets how they look ready....

Lets how they look ready....

-

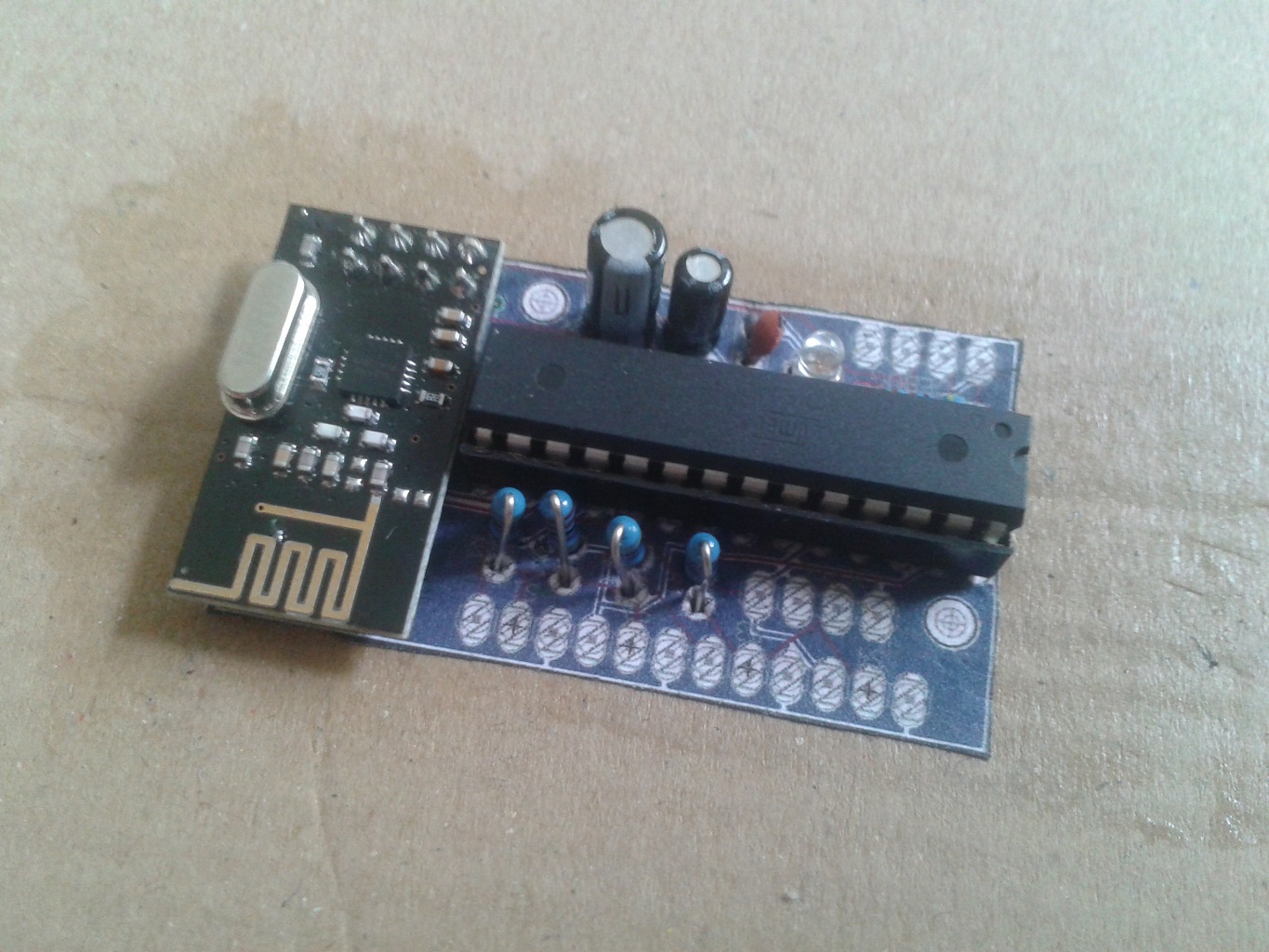

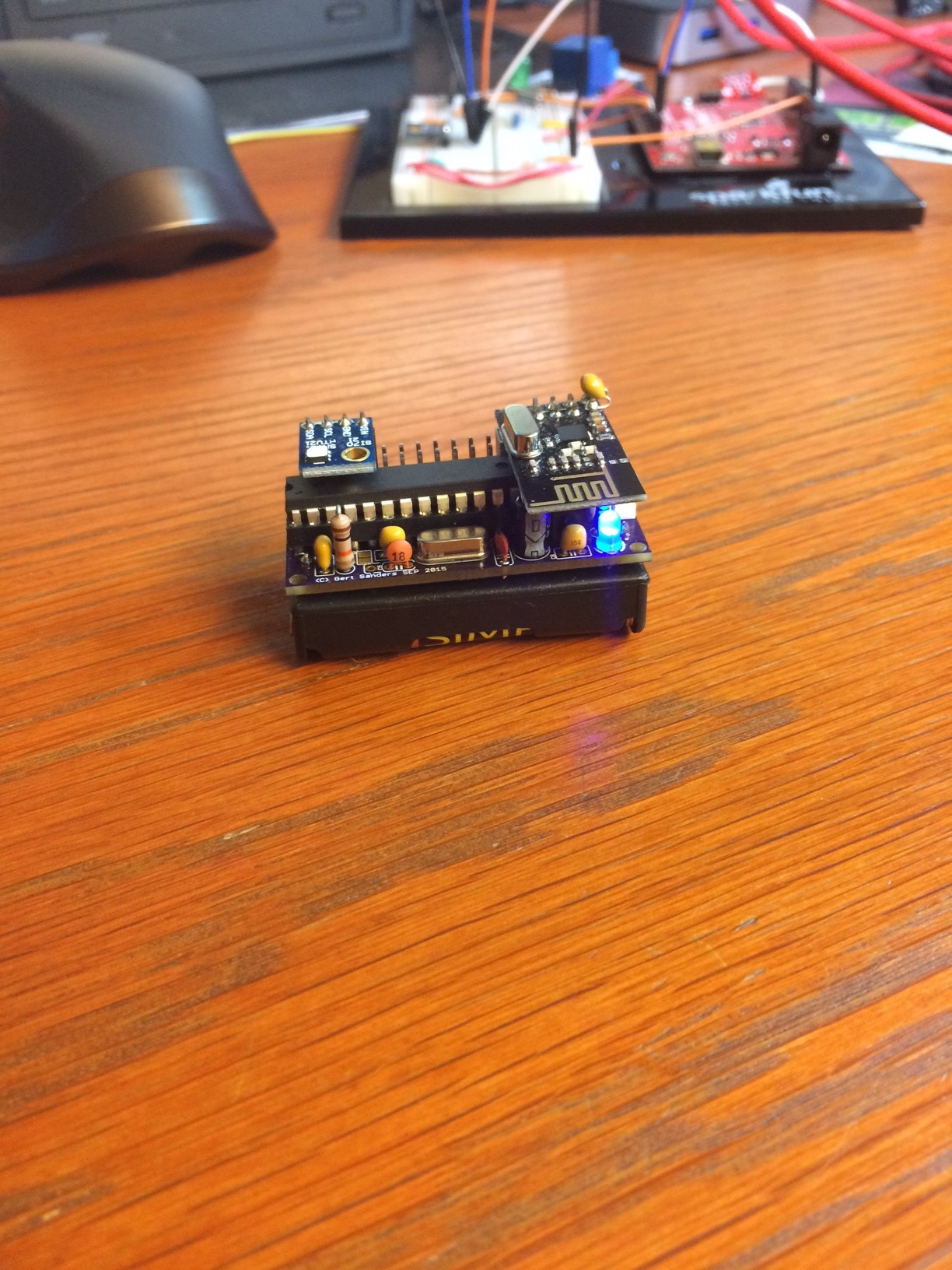

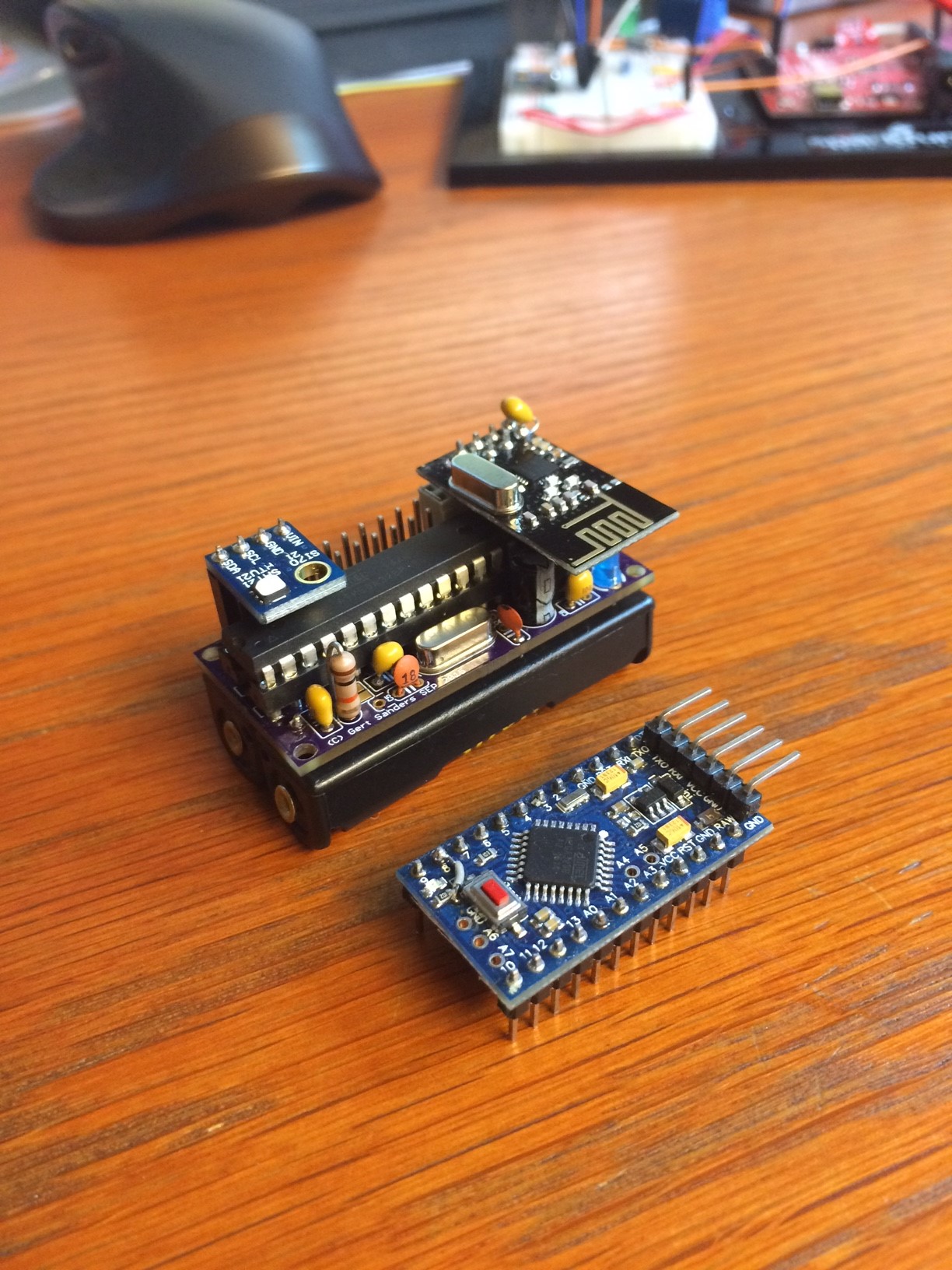

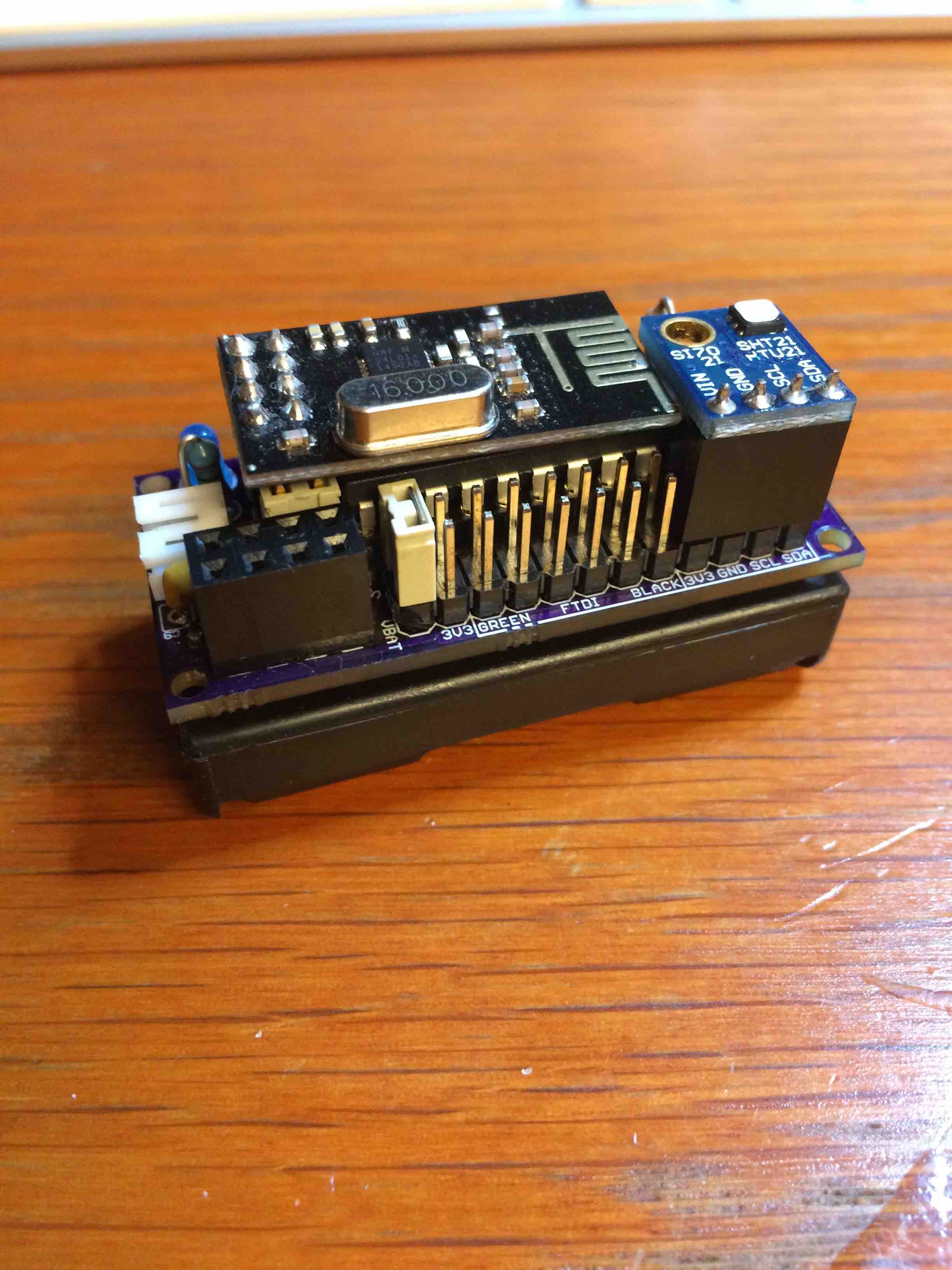

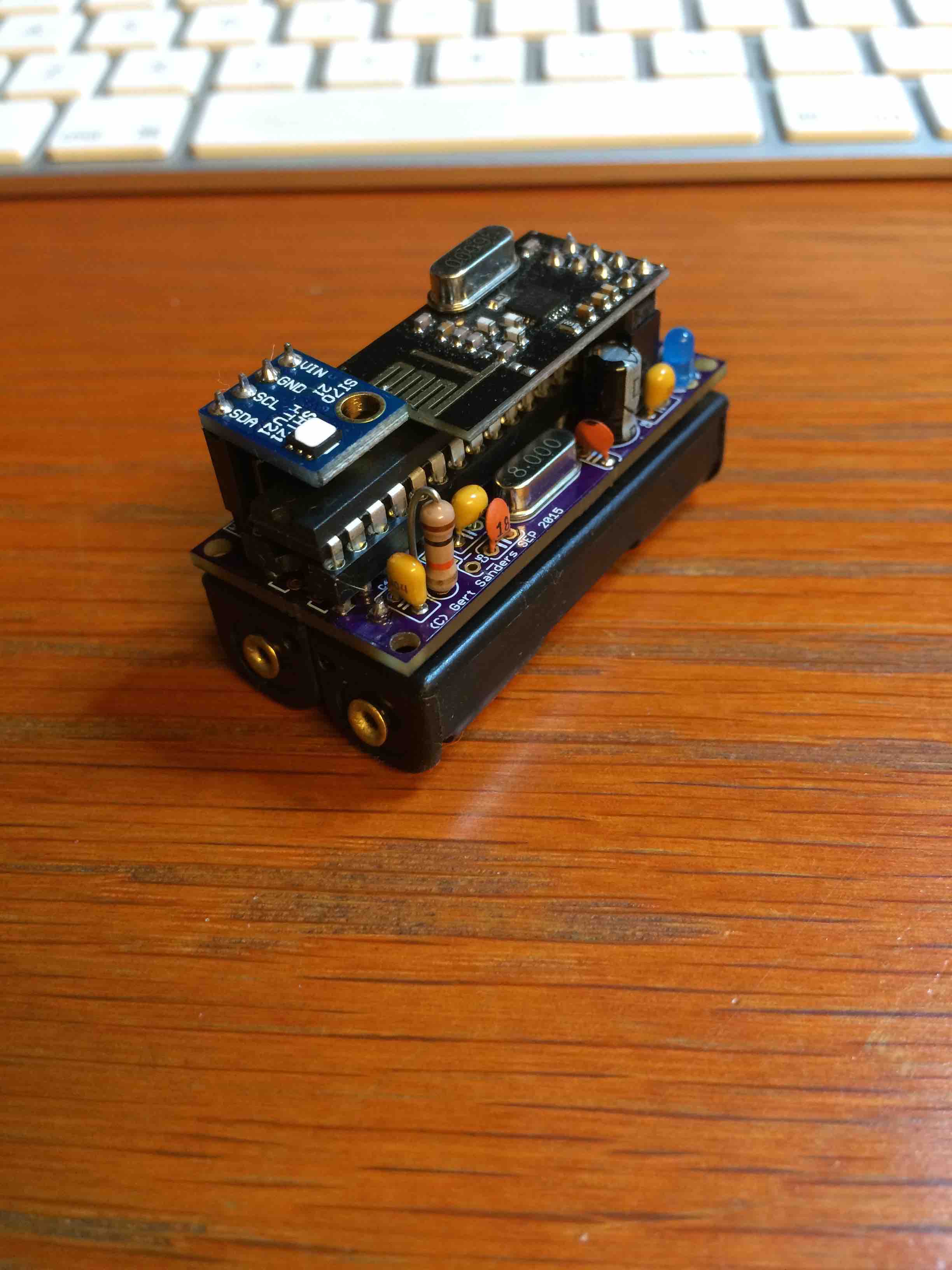

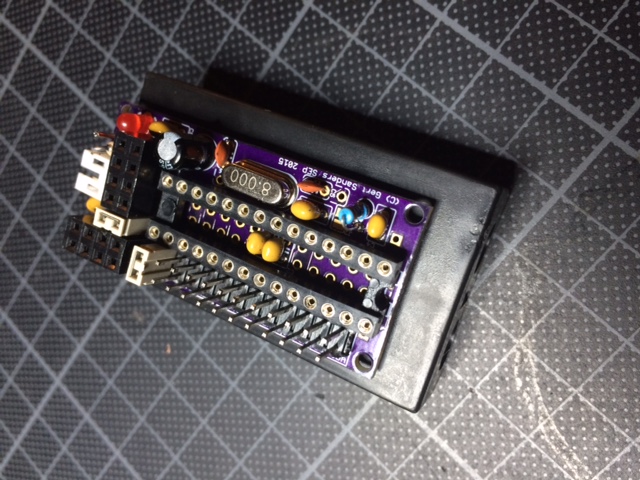

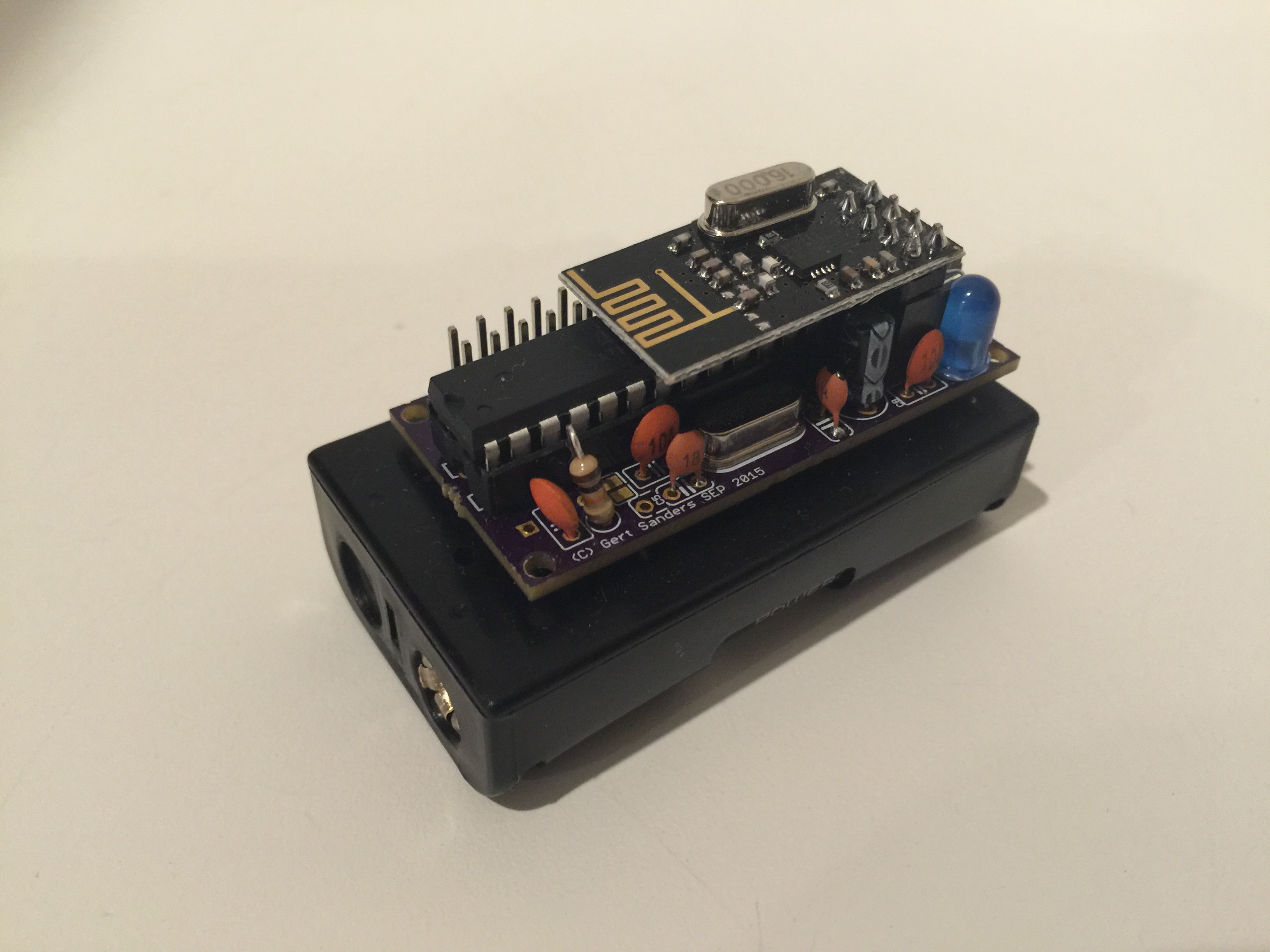

Here is version 2 of my sensor:

-

This post is deleted!

-

Maybe its better to open a new thread for this question?

-

Just realised this. Indeed, I will start a new topic.

-

Second variant with the same board. This one actually sends it's messages better (no more st:fail's):

And it's nice and compact. Now I need to find a nice ventilated little box to protect them from dust.

This board is now tested and shared on OSHPark: https://oshpark.com/shared_projects/unP8BmuI

Component values are mentioned in the brd file. I will add a BOM in Excel format later.

-

Really great job!!!

-

@GertSanders said:

Now I need to find a nice ventilated little box to protect them from dust.

This might work - it's well ventilated; width & depth OK, but don't know about height.

http://www.ebay.co.uk/itm/291147751395?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

My dirty dirty boards have arrived today

I actually received 12 boards, so I can make 24 sensors, great succes !!!

!!!

-

@GertSanders

Please post the BOM.

-

@Didi Here is the BOM and EAGLE files.

selfcontained low power node v1.csv

selfcontained low power node v1.brd

selfcontained low power node v1.sch

-

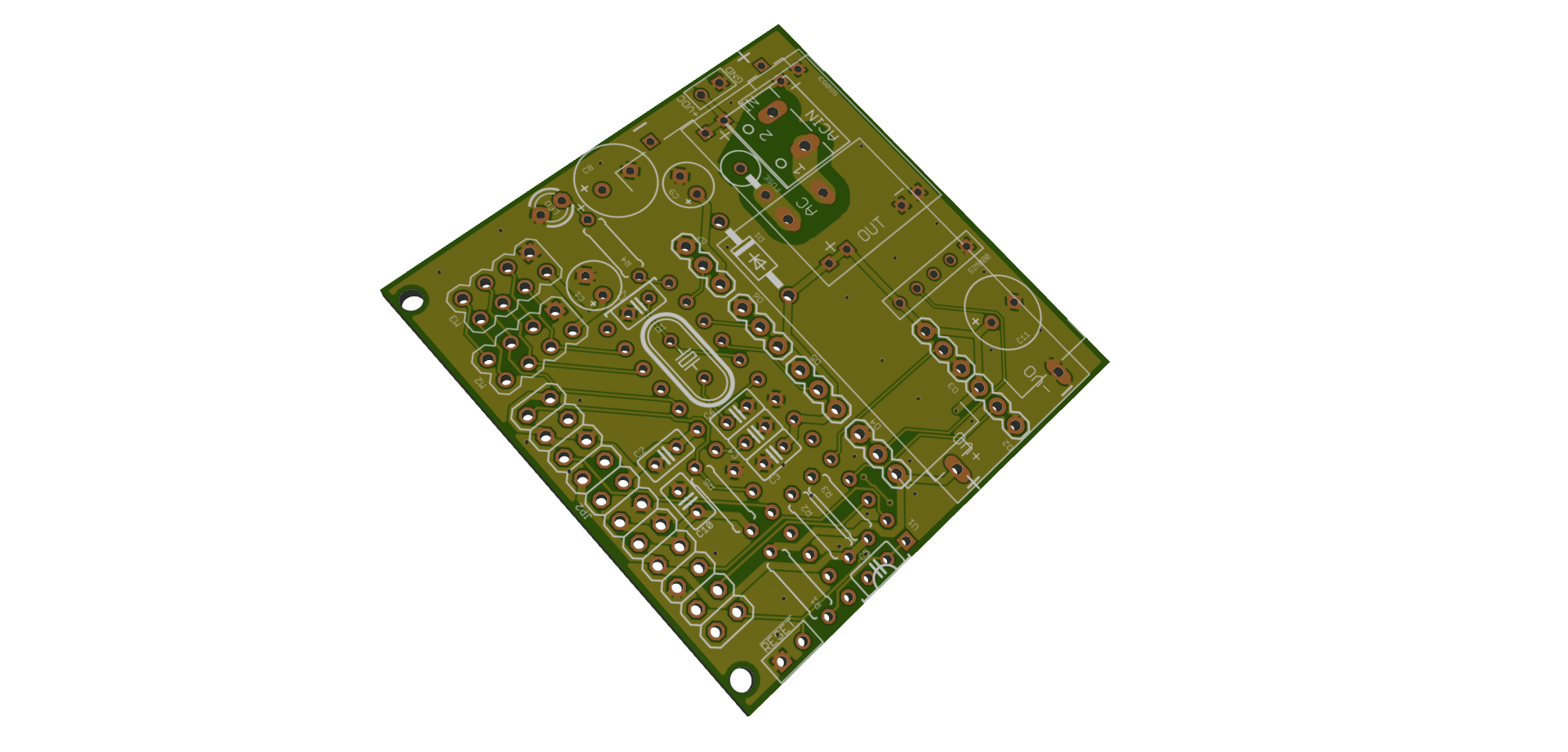

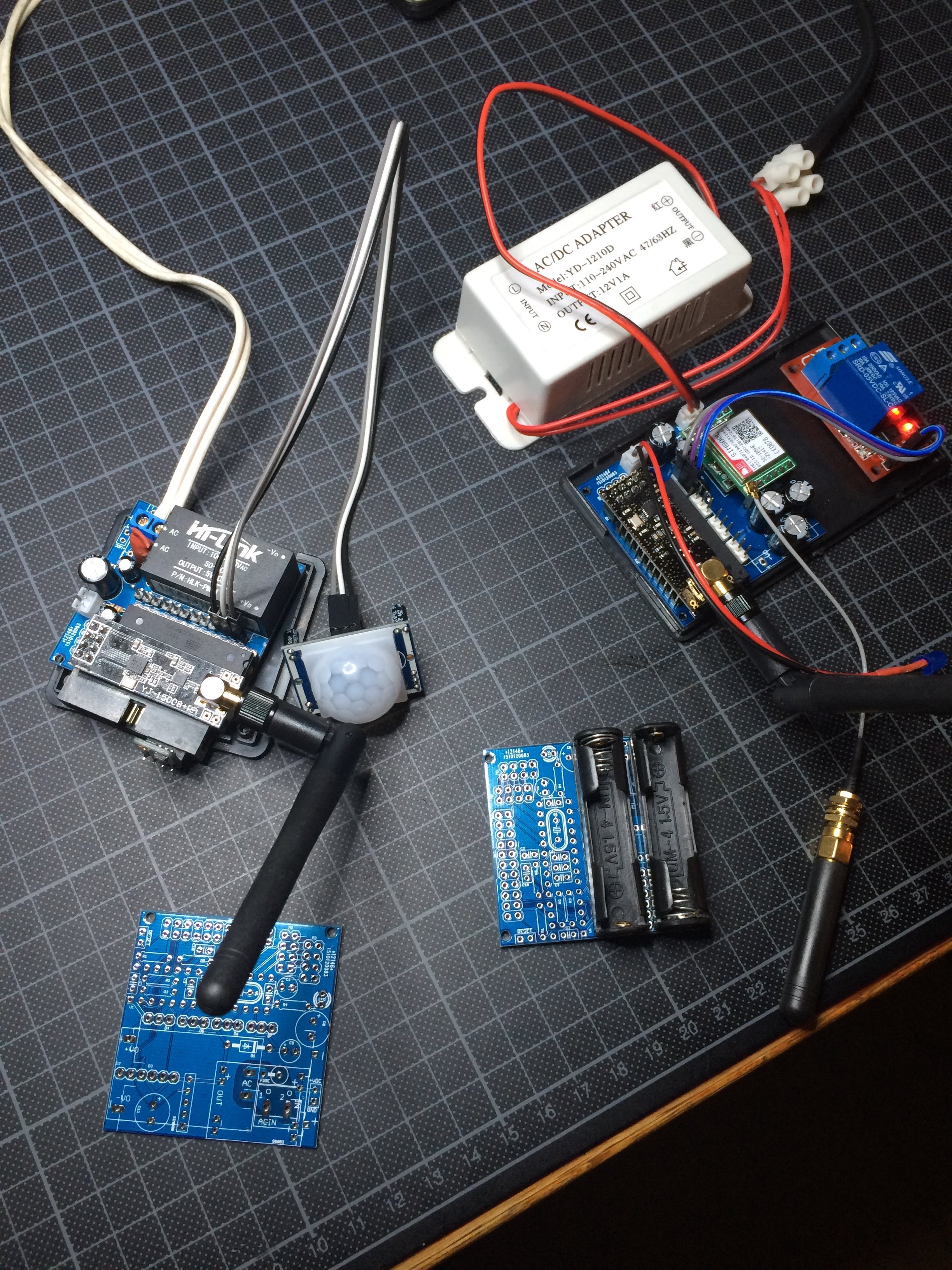

Preview of my latest board, waiting for prototypes to test this ....

This is a 50x50mm board with multiple powering options (AA or AAA batteries, direct 3.3 or 5V DC, 4.5-20V DC in, 220V AC) and can fit a GSM module at the same time as the NRF24 radio. Allows 2 variants of I2C connection (SDA and SCL on IO header can be swapped via soldering pads). Room for signing chip and some I2C based EEPROM or FRAM memory. Several connectors for digital pins with power.

Fits into this box:

http://www.aliexpress.com/item/Free-shipping-2-pcs-lot-60-58-28mm-plastic-housing-DIY-project-box-ABS-junction-box/2039860908.html

-

-

@GertSanders Hi Gert, on the small board, did you soldered C2 and C3 on the bottom or on top just under/in the IC socket?

-

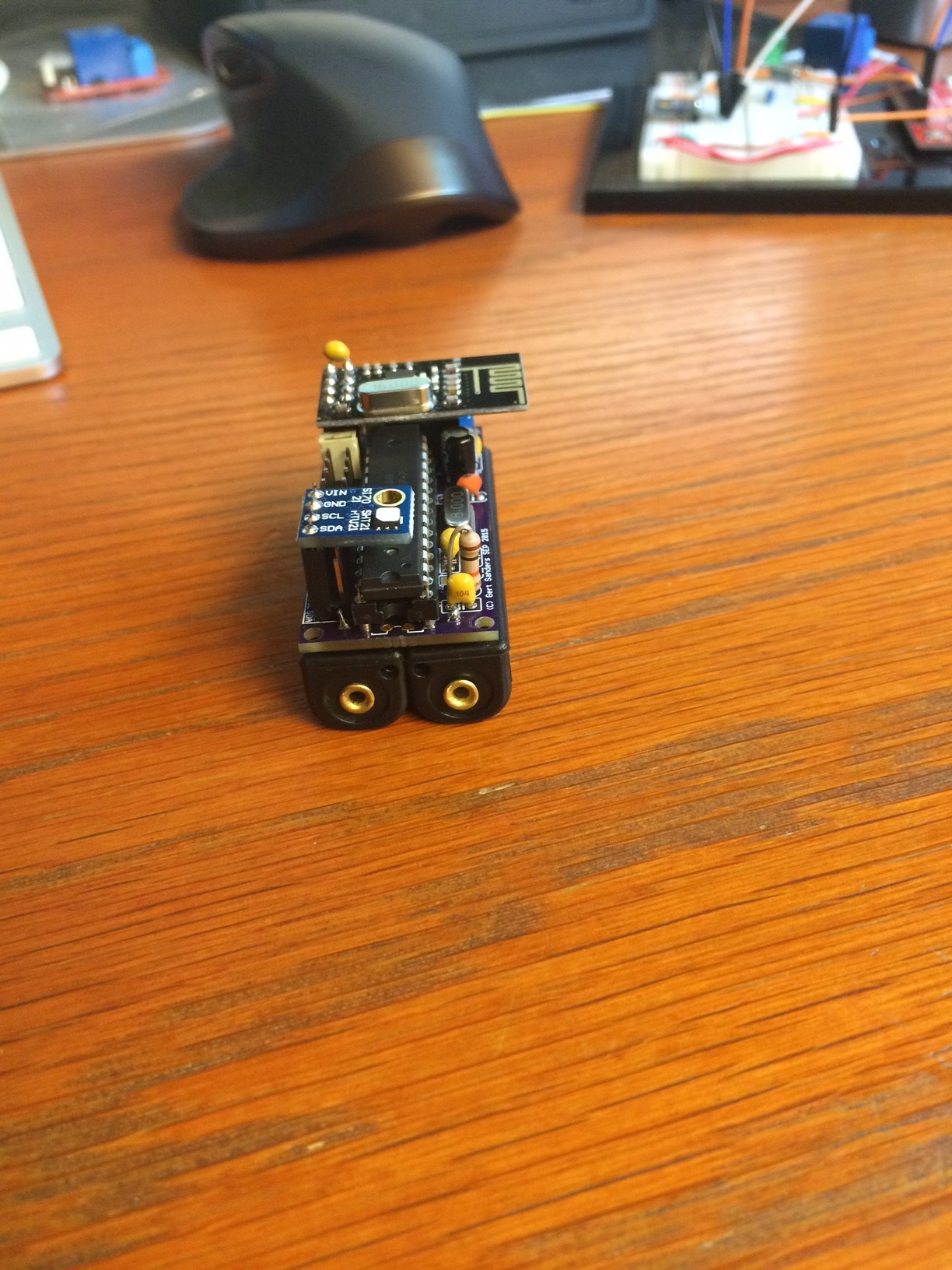

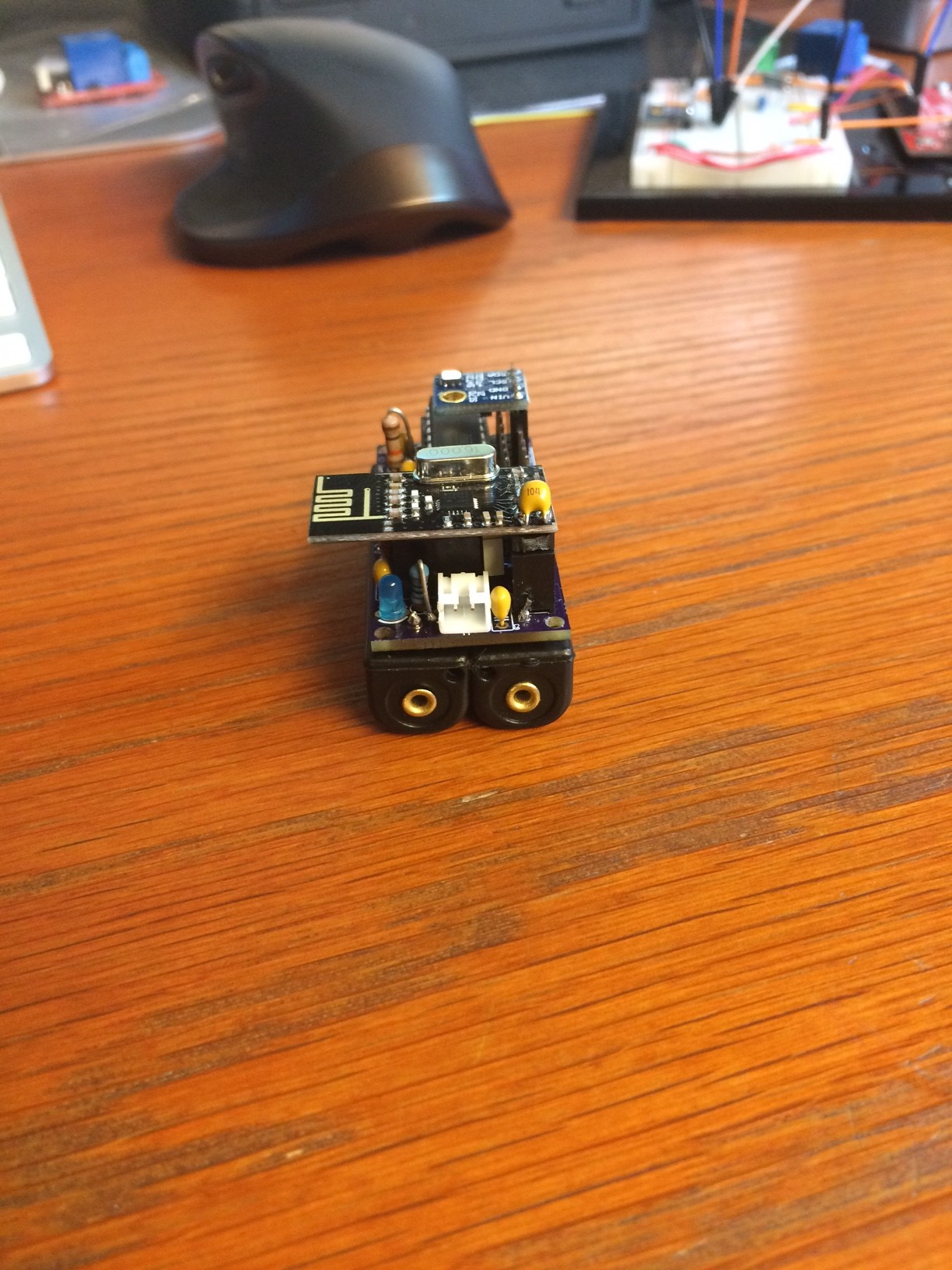

@pjeterinfo On one of the sensors I soldered it on the bottom between the two connectors on the bottom.

For the sensors where I add the batteryholder on the bottom, I do indeed solder these capacitors on topside between the legs of the chip. Later this evening I will make a photo of such a setup.

-

This is the small board on an AA batteryholder.

-

very good job, i'm very interested to try your board. Did you try to order from

dirtypcbs.com vs oshpark for the price?

-

I ordered from both. From OSHPark because they have a 10-12 days turnaroundtime for me (to Belgium) so I could test faster and Dirtypcb because of price (quality is as good, only ENIG is missing). The boards are shared on both manufacturers websites.

More details here:

http://forum.mysensors.org/topic/595/pcb-boards-for-mysensors/30

-

My AC capable boards have arrived in the mail today, some of these will become repeaters, some will be GSM nodes, I know what to do the coming days

-

I did also order your red board now and will try it. Do you have a wiring diagram that I can open with adobe reader or something else.

-

@gloob Here is the diagram: GSRedboard schematic.pdf

This is the same schematic as "selfcontained low power node v1.sch"

Since a Redboard already exists (Sparkfun makes them), I added the GS prefix, but I like the name suggestion

-

@GertSanders I don't understand the shipping price on dirtypcb. They say "10 each 5x5cm PCBs $14" so that mean that 10 pcbs boards, each are 5x5 cms will cost 14$, right ?

but when I choose buy, I get confused. In the quantity selection there is protpack +-10 which is 14$, and another option to set the quantity to 10, 20 or 30, it increases the price to 28$Can you please clarify this ? Thanks

-

http://dirtypcbs.com/about.php

If you need a specific quantity of boards the use a more expensive board house. The proto pack will be 10 +/- 1 boards.

-

@mountainman Thanks. Strange offer to have expect 9 or 12 boards

-

@ahmedadelhosni It probably depends on the other boards put on the same panel. A boardhouse makes PCB's in large panels. They fit as much designs as they can on these boards. If you need exactly 10, they will give priority to your design (and it costs more); if not needed, they can add your design to a board and if that means 9 PCB's only, that would be acceptable. For my blue board design I received 11 PCB's, for the red board I received 12, but I would have been OK with 9 or 10 also (given the low price and good quality).

For prototyping I think this is a very good deal. The only minor point: transport time is VERY long, in my case it is 4 weeks between notification that the PCB's are shipped to me and actual delivery to my mailbox. Production is about 1 week. So if you have time (count 5-6 weeks) to get your boards, then DirtyPCB is very good value. If you need prototypes faster (at a little higher expense) I suggest you use OSHPark. You will only get 3 PCB's, but they will be delivered faster (about 3 weeks in my case).

-

@GertSanders

I did now receive the PCBs and ordered the other components via Reichelt.de

I hope to start soldering next week.Do you have any tips to flash the Atmega?

Did you use the normal Arduino IDE?

Do I have to check something special?

-

@GertSanders just to let you known i did plat around a little bit with your PCB design and i found a way to use is with-out the crystal by using the ATmega's internal 8 MHz clock

See the results here: http://forum.mysensors.org/topic/2484/running-atmega328p-on-internal-8mhz-clock

The free PCB space (where the clock Cap's and crystal was designed) i now use for the big transmitter capacitor to lay down.

-

@BartE Excellent, of course you can use this without the crystal, depends on your fuse settings

-

@gloob I made my own version of the Optiboot bootloader to flash led on pin 8. I will add the hex file to the site later. To flash the atmega328 I made an extension to the bootloader programmer sketch by Gammon, I will post that as well. It is a translation of my version into his sketch format.

-

Hello,

I have now soldered everything on the board and want to burn the bootloader now.

I have included the bootloader HEX file in the bootloaders folder and modified the boards.txt file.

How do I now burn the bootloader with the Arduino IDE?I have a FDTI programmer but I'm not sure if this is the correct device to burn the bootloader or if I need something different.

-

Is it possible to order the AC boards from your last picture?

-

I order from OSHpark the v2 of your own board and I have a question, if I run it with 2AA battery for example, I put jumpers (marked red on the picture) and it is working.

But if I want to try with 5v input, like from usb charger, do I need to have a 3.3v regulator for the NRF24+ ? And if yes, do I need other pcb to complete this?

Other question, what is the use of the jumper J1? I'm not sure...

Thanks again !!

-

hi @Carl-H By adding the two jumpers as you do, indeed it wil work with a set of batteries.

J1 connects the VCC circuit with the 3V3 circuit.

3V3 circuit connects to the NRF24. Vcc circuit connects to the power (Vcc and AVcc) of the atmega328.

The jumper you put on the left arrow, is to connect the VRaw input with 3V3 (above).

So by adding the two jumpers you get battery voltage on VCC and on 3V3 circuit, through the JST connector (which is connected to VRaw).

If you want to use 5V, you will need to add a 3V3 regulator. This can be through a companion board like I published on OSHPark (https://oshpark.com/shared_projects/IOHUNYT2), or you could make your own board. You could take the VRaw input and bring to down to 3V3 and connect to the 3V3 circuit. If you put a jumper between Vraw pin and VCC pin instead of between VRaw and 3V3, then VCC will have the 5V.

If you use the companion board, you should not bridge the Vcc and 3V3 circuits or the Vcc and 3V3 circuits.As you guessed, to get 3V3 from a 5V input you need more then just this board.

There are also two pins for a battery holder. One is visible above C9, this is the + side and connected to VBat. The other is right of the LED and R2 and is negative side and connected to GND circuit.

More info on this board I will keep adding here: http://forum.mysensors.org/topic/595/pcb-boards-for-mysensors/30

-

@Cliff-Karlsson The blue board (AC capable) can be ordered from Dirtypcb's:

http://dirtypcbs.com/view.php?share=12146&accesskey=c3a217d7f31434a5565ecf9bdf3f7dc6

There is no BOM for the moment. I built several variants, and they all work. But I do not consider this my final version of this type of board. The above link points to my first spin of the PCB (first version). There is no v2 right now, but I have some ideas to improve it, and I'm open to suggestions.

I will add the EAGLE files also to the message thread where we collect all the hardware.

Fo the moment most info (images) is only here:

http://forum.mysensors.org/topic/2374/50mm-x-50mm-board-with-different-powering-options/10

-

Just got the board v2 from OSHpark and I would to ask a few questions:

- Can I replace R2 with 220Ohm one?

- I have 16Mhz crystal - hopefully this is not a problem?

I fired the board, but cannot connect it to the Arduino IDE 1.6.5 via the FTDI USB-TTL. I checked the voltage and it is 3V from the battery pack with two jumpers J1 and VBAT to VCC in place. I have used a standard ATMEGA328P_PDIP with an Arduino Uno bootloader I got from the Ebay. Do you think this may be an issue?

Regards

Alex

-

@alexsh1 I think running at 16Mhz in 3V is asking too much from the processor. The boot loader for Arduino Uno assumes 16Mhz, and communication with the processor at a much higher speed then I use on my board. That is why I compiled my own boot loader (for 8MHz and serial communications at 36K baud instead of 115K baud).

Also, the boot loader for Arduino Uno assumes there is a LED on pin 13. In my board I moved this to pin 8. This should not block the processor. Having it at 16Mhz while powering it with 3V is more the issue here I think.

If you have an Arduino Uno available, you can burn your own boatloader. The HEX file is added in the topic:

http://forum.mysensors.org/topic/595/pcb-boards-for-mysensors/31

The how to here is:

http://www.gammon.com.au/bootloaderUsing 220 Ohm for R2 should be OK, the led will get a bit more current, but should handle it fine. The port can give 20mA. With 220 Ohm you pull 13mA, so within limits.

-

From another board:

The most common non-5v voltage is of course 3v3 and as you can see at 3v3 the chip is only spec'd at just over 13MHz, people do often run them at 16MHz but that is well out of spec. That's ok if you are playing around, making a widget for yourself etc, but it's not ok for a commercial product, especially if it will be subject to large temperature variations.

Source: http://forum.arduino.cc/index.php?topic=213105.0

At 3V (or thereabouts when using g a set of batteries) you are well under specification. 12MHz would be OK, 16MHz is a bit much.

-

@GertSanders said:

@alexsh1 I think running at 16Mhz in 3V is asking too much from the processor. The boot loader for Arduino Uno assumes 16Mhz, and communication with the processor at a much higher speed then I use on my board. That is why I compiled my own boot loader (for 8MHz and serial communications at 36K baud instead of 115K baud).

Also, the boot loader for Arduino Uno assumes there is a LED on pin 13. In my board I moved this to pin 8. This should not block the processor. Having it at 16Mhz while powering it with 3V is more the issue here I think.

If you have an Arduino Uno available, you can burn your own boatloader. The HEX file is added in the topic:

http://forum.mysensors.org/topic/595/pcb-boards-for-mysensors/31

The how to here is:

http://www.gammon.com.au/bootloaderUsing 220 Ohm for R2 should be OK, the led will get a bit more current, but should handle it fine. The port can give 20mA. With 220 Ohm you pull 13mA, so within limits.

@GertSanders - thanks very much for your comprehensive and quick reply.

OK, this is what I thought. Will have to change crystal to 8Mhz and burn a new bootloader.

Interesting info I found on Nick's web-site regarding my issue:For running at 16 MHz you need at least 3.78V and at 8 MHz you need at least 2.40V. (Caveat: under testing I found that it did not seem to work reliably much under 2.8V at 8 MHz).

[EDIT] That unreliability would have been because of the brown-out reset kicking in at 2.7V. If you are using lower voltages you need to adjust or disable the brown-out detection.

I am planning to run at 8 MHz using the internal oscillator, to save parts and space. Thus you could conceivably run the whole thing off 2 x 1.5V batteries, giving around 3V nominally. However 3 x 1.5V batteries would be OK, and let you run it at 16 MHz.

Taken from here: http://www.gammon.com.au/forum/?id=11637 (Power Supply)

-

@alexsh1 I completely switched off the BoD in my fuse settings, this saves the battery even more. I found that the processor kept working down to around 1,64V. Even my NRF24 worked to that low level, because the last message I received in my Domoticz from that node gave a battery voltage of 1.64V

Anyway, since I monitor all battery levels via a script in Domoticz, there is no need for BoD.

-

@gloob To burn a boatloader with Arduino IDE, you will need a second Arduino or working atmega328 onto which you can load a sketch.

I have an older Arduino board (the one I bought when I first started exploring this new hobby), and I use the setup as described in this article: http://www.gammon.com.au/bootloader

-

@GertSanders said:

@alexsh1 I completely switched off the BoD in my fuse settings, this saves the battery even more. I found that the processor kept working down to around 1,64V. Even my NRF24 worked to that low level, because the last message I received in my Domoticz from that node gave a battery voltage of 1.64V

Anyway, since I monitor all battery levels via a script in Domoticz, there is no need for BoD.Yes, I noticed that you have atmega328pO4M8i.bootloader.extended_fuses=0x07 which is as you said switches off all BoD levels.

Thanks for an interesting info regarding the voltage. This is a very good news. I guess you are getting a notification in Domoticz if a battery level goes down to 1.64V?

I'am going to setup a programmer on mega 2560 tonight, but meantime ordered one of the programming shields to streamline the process - http://www.boardstuff.co.uk/

-

@alexsh1 I actually set up a notification on each Voltage sensor within Domoticz, so that I get a prowl message when the voltage drops below 2V. This then gives me some time to replace the batteries. The 1.64V was when I intentionally let a sensornode die out, just to see what would happen. I never let the voltage drop that low now. All my nodes now have batteries that should last at least 9-12 months (depends on the sensor and it's activities).

-

@GertSanders

Thanks for your help. I was now able to burn the bootloader and will start testing the board tomorrow when I have a valid 3,3V source to power the radio.

Can I power the radio from an FTDI programmer if the programmer is set to 3,3V power? If yes, how to set the two jumpers?

-

@gloob if you power via a 3V3 FTDI interface, then you only need to close jumper 1 to connect the Vcc corcuit with the 3V3 circuit.

-

@GertSanders

Thanks for your support. I have now the serial gateway sketch running and output of the arduino seems good:0;0;3;0;9;gateway started, id=0, parent=0, distance=0 0;0;3;0;14;Gateway startup complete.I will now order some Si7021 sensors and continue my testing.

Can I use the following sensors:

Si7021 Industrial High Precision Humidity Sensor I2C Interface for Arduino

-

@gloob I'm using the same sensors for Temperature and Humidity. The pinout of these boards is what I based my pinout on my red board on. (3V3, GND, SCL, SDA). I'm using now 5 of these.

-

Ok, after a few long days I managed to burn the bootloader. For those who are struggling with the same problem please note the following:

- Use Nick Gammon's website and optiboot bootloader (512kb only). I had a standard ATmegaBOOT_168_atmega328_pro_8MHz_hex (Lilypad 8 MHz loader) and could not make it work with 3.3.v.

- Important: the 2048kb bootloader's (Lilypad 8MHz) address is 0x7800. For the optiboot (512Kb) you need to change it for 0x7E00. Now everything works fine - I just need now to change fuses to make sure the voltage can go down below 2V.

@GertSanders I wonder what sketches do you use with this board? it is nice to have Si7021 (it is pin-for-pin for your board) for temp and humidity.

-

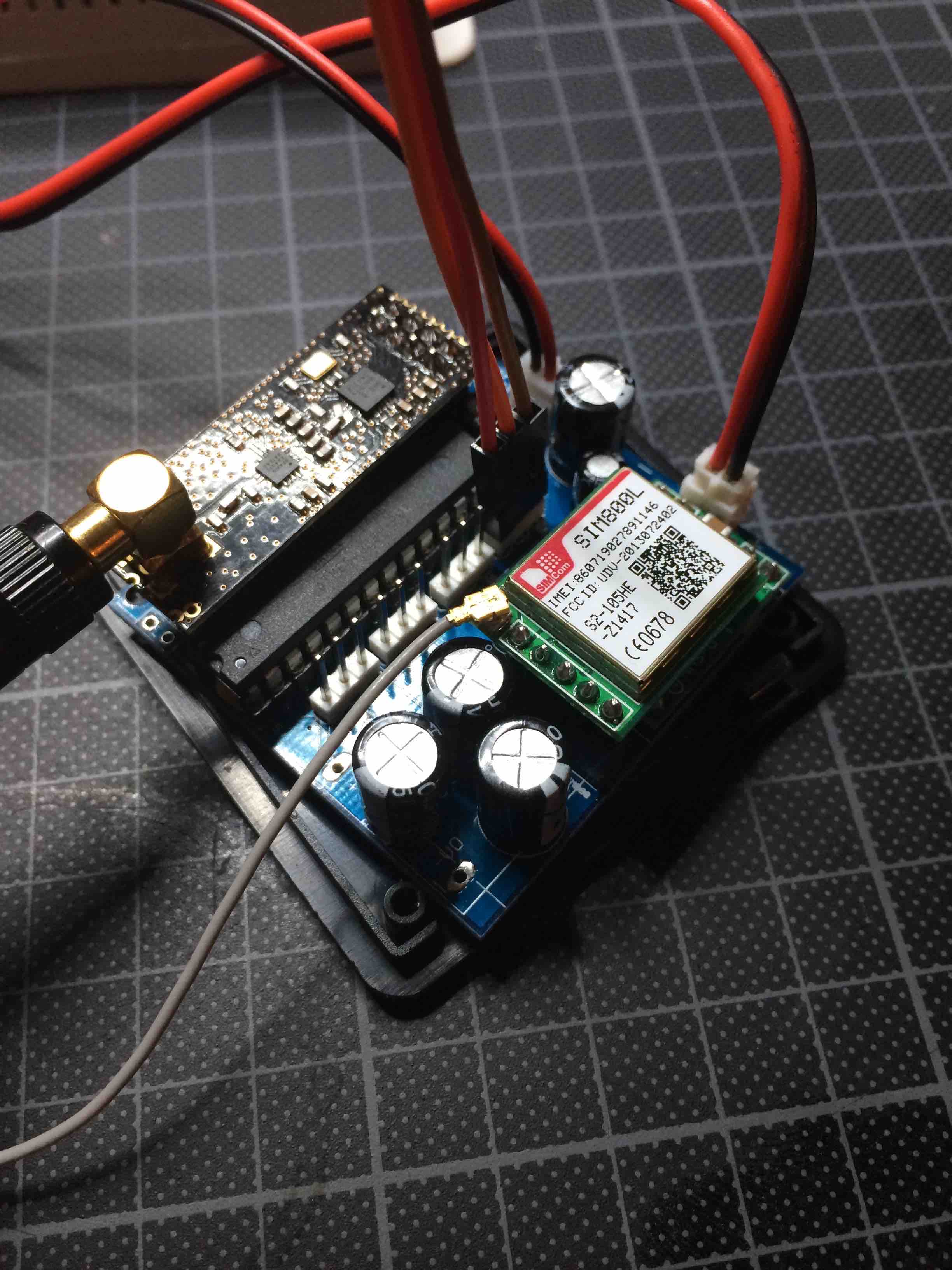

@alexsh1 I make my own sketches, the one for my board with SI7021 is used most in my house. I also have a repeater, a GSM node, a sleeper node which wakes up when switches are tripped (basis for upcoming door sensor node). I work with the development version of the library (1.6.0-beta) of Mysensors

I added my Temp/Hum sketch as inspiration: TEMPNODESI7021.ino

-

Interesting

@GertSanders GSM node? is it a standalone or you have it hooked up to this node?

I have a GSM node connected to a couple of SSRs to control water heating - sadly this is not connected to MySensors

-

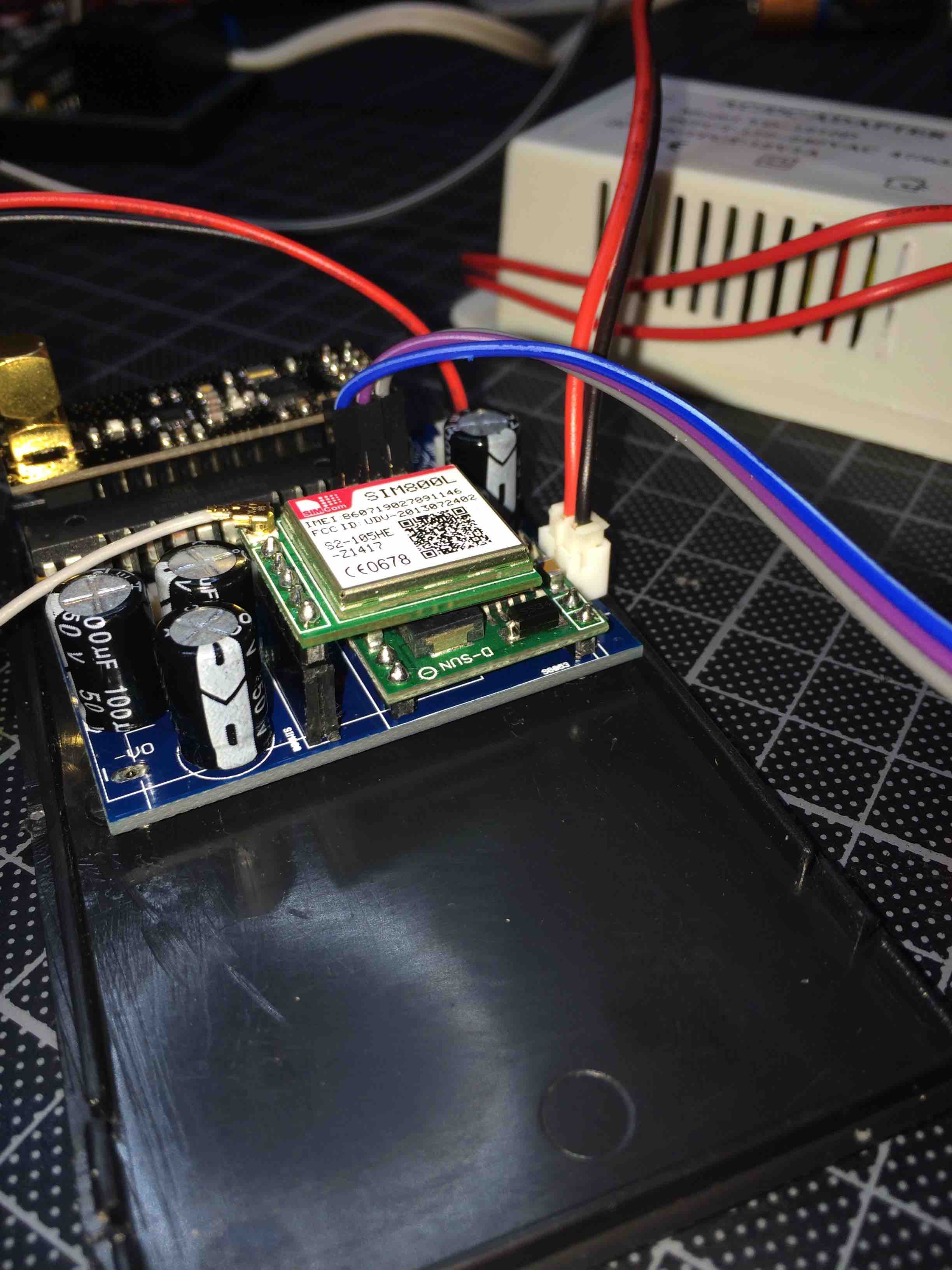

@alexsh1 It is based on my AC capable board, is a normal atmega328p board, but with a SIM800L mounted on it. This module allows me to send and receive SMS's, and I use one of the digital output pins to control a waterpump. I have a second AC based board ready which will be my MySensors SMS gateway. This means it will be able to receive V_TEXT and send that to the default GSM number as a SMS. It should be possible to receive SMS and send that as V_TEXT to other nodes, but so far I have not started the design of the second sketch yet.

You see it here also (top right) with the relay module and the white AC-DC converter connected.

Side view:

-

@GertSanders

Do you have a source or shop for the AAA battery holder with solder pins? I did only find some for AA batteries.

-

@GertSanders said:

@alexsh1 It is based on my AC capable board, is a normal atmega328p board, but with a SIM800L mounted on it. This module allows me to send and receive SMS's, and I use one of the digital output pins to control a waterpump. I have a second AC based board ready which will be my MySensors SMS gateway. This means it will be able to receive V_TEXT and send that to the default GSM number as a SMS. It should be possible to receive SMS and send that as V_TEXT to other nodes, but so far I have not started the design of the second sketch yet.

I only have 1-2 high current (3kWh at 240V resistive load) devices at home and I am already controlling them as well my internet router (remote reboot if no internet) via SMS. At this stage I need a larger property to expand my home automation lol

-

@gloob said:

@GertSanders

Do you have a source or shop for the AAA battery holder with solder pins? I did only find some for AA batteries.Would you mind me asking why you'd need AAA batteries? Much less capacity and the holder is not much smaller. I have been using Eneloop AA rechargable lithium batteries (http://www.ebay.co.uk/itm/4pcs-1-5V-AA-2200mWh-Lithium-li-ion-Rechargeble-Battery-4-PORTS-AA-charger-/272027421169?hash=item3f561909f1:g:r9AAAOSwMTZWSFHz) and they are holding up really well. The advantage is that they hold 1.5V almost until they are discharged unlike NiMh

-

@gloob I got my AAA holders from Aliexpress.

-

@GertSanders said:

AAA holders

-

Indeed, those

-

Do you have an idea how long a temperature sensor will run on 2 AAA batteries?

-

@gloob Not yet, some of mine have been running for 2months with a voltage drop of less then 1%

-

My board waiting for a sensor from China

-

@alexsh1

How did you connect the battery? Did you solder it directly to the board?

-

@gloob There are two connections on the board to allow soldering the battery holder. Both the AA and AAA versions I use have the same pin spacing (seems standard), so you can use an AA battery holder as @alexsh1 does, or an AAA as I have.

http://forum.mysensors.org/uploads/files/1446751714416-image.jpeg

The red arrows show where the batteryholder pins should go. If you have individual AAA battery holders, then the pins surrounded by yellow circle are also used to connect the batteries in series. If the battery holder holds 2 batteries, then only the pins pointed to by red arrows are used.

The PLUS sign next the the pin on the lower right of the above image is for the LED, the polarity of the pins from the battery is marked on the silkscreen of the bottom side. Looking at it from the top side, the pin above right is for Positive, the pin on below right is for Negative (or GND).

Jumper J2 is to connect the IRQ pin from the NRF24 to pin 2 (INT0) of the atmega328. You could also use that to connect a switch between the top jumper pad (connected to pin 2) and the extra ground pin of C5, to use with a doorswitch. I have used this with the internal pull up, but that would not be very good for the battery-use. It is better to use a 1MOhm pull up resistor wich can also be connected using the extra hole connected to pin 2 and Vcc

-

@gloob @GertSanders is spot on! I only have 1.5V AA rechargeable lithium batteries so the choice of the battery holder is obvious.

-

Just ordered a batch from DirtyPcb so the journey is just beginning!.

Doubt i will need a whole batch so if anyone requires a couple in the uk let me know.

-

@GertSanders said:

@alexsh1 I completely switched off the BoD in my fuse settings, this saves the battery even more. I found that the processor kept working down to around 1,64V. Even my NRF24 worked to that low level, because the last message I received in my Domoticz from that node gave a battery voltage of 1.64V

Anyway, since I monitor all battery levels via a script in Domoticz, there is no need for BoD.How is 1.64v possible,It was my understanding that 8Mhz requires a minimum of 2.4v?

-

The processor is guaranteed to work within the specified limits. Outside the specified limits, no guarantees are made. It might work, it might not work or it might work slightly with strange glitches.

-

I see now.Thank you

Has anyone modified Gertsanders Firmware to run at 1Mhz?

That would give reasonably stable results down to 1.8v.

I don't have the skills to compile from scratch and cater for the led on pin8 etc.

-

@rmtucker The firmware itself does not need to be changed to use the internal oscillator. You accomplish that by using a different set of fuse values:

atmega328pO4M8i.bootloader.low_fuses=0xE2

atmega328pO4M8i.bootloader.high_fuses=0xDE

atmega328pO4M8i.bootloader.extended_fuses=0x07This sets the processor to a mode using the internal oscillator.

Add the call to divide the frequency by 8 (can be done in the sketch itself) and you have a 1MHz internal clock.

-

@GertSanders So have you never found it a problem running at 8Mhz?

Do most of your sensors work ok below the 2.4v threshold?

Guess i will find out when the pcb boards arrive

-

@rmtucker Short answer: yes. So far most my sensors are working fine and all sit above 2.4V but I have not had problems when they do below 2.4V

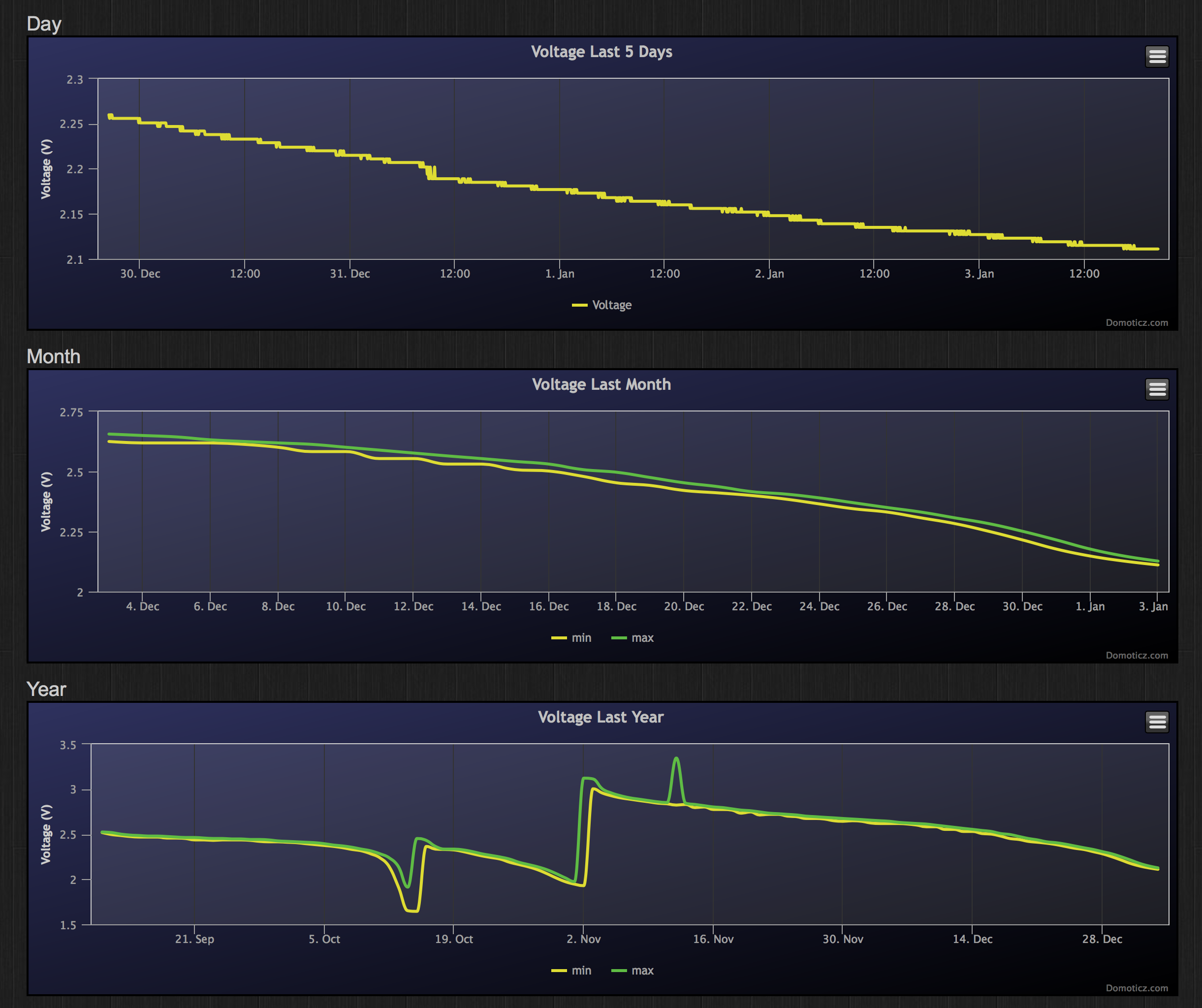

There is one sensor now that has a battery in decline. This sensor uses a lot of power and goes through it's batteries very fast. So it is a good test for this low voltage work. It is now at 2.11V and still sends messages every 5 minutes. On the first graph you can see it is still working fine wel below 2.4V and it is clocked at 8MHz with a crystal.

I have a notification on all my sensors so that when the battery voltage goes below 2V I get a Prowl from Domoticz. This has only happened on this sensor (twice so far), because I was using NiMH batteries (which discharge faster than alkaline). Around 2 november I put in 2 alkaline batteries (AAA), but these were not brand new.

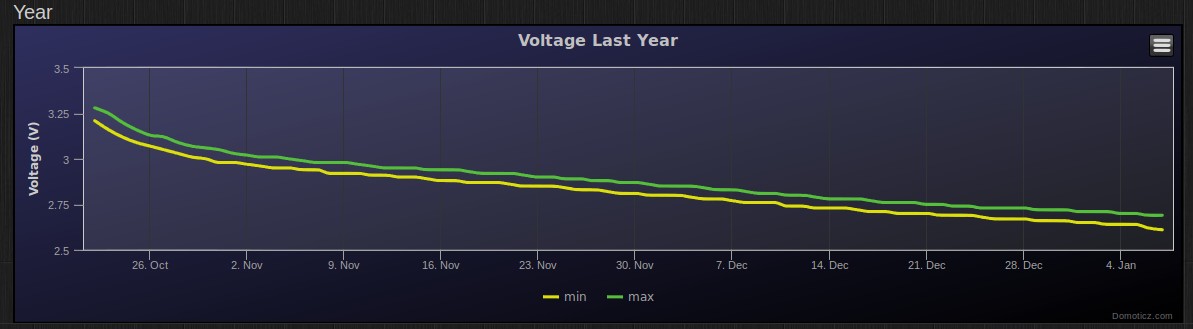

Most of my sensors have a discharge pattern as here below:

-

@GertSanders What rate is the sensor in the very bottom graph sending messages?

That discharge rate looks very nice.@GertSanders said:

@rmtucker The firmware itself does not need to be changed to use the internal oscillator. You accomplish that by using a different set of fuse values:

atmega328pO4M8i.bootloader.low_fuses=0xE2

atmega328pO4M8i.bootloader.high_fuses=0xDE

atmega328pO4M8i.bootloader.extended_fuses=0x07This sets the processor to a mode using the internal oscillator.

Add the call to divide the frequency by 8 (can be done in the sketch itself) and you have a 1MHz internal clock.

Problem with using div/8 in the sketch and not altering the bootloader is that all the timings are off for baud rates and pwm etc.

Where if it is altered in the bootloader it all works as it should.Last question i promise

I currently use the arduino mini pro and when uploading sketches to it using ftdi,i have to press the reset button to get the upload to work.

Will i have the same problem with your boards?

-

@rmtucker On my board I do not need to press a reset to be able to upload sketches, since I connected the RESET pin to the FTDI header via a capacitor.

So if the FTDI interface does the reset via RTS pin, then it will reset the board and you can upload sketches.

The sensor in the last graph sends it's voltage and temperature every 5 minutes, even if the value is sometimes the same as the previous one. It also sends it's battery voltage every 5 minutes.

In my last version of the sketch I have now added a change based on the Sensebender sketch. That sketch sends it's temperature or humidity only if the change is a minimal difference with the previously sent temperature or humidity. It always sends it's battery level every half hour. That should make it last minimum a year on 2 AAA batteries.

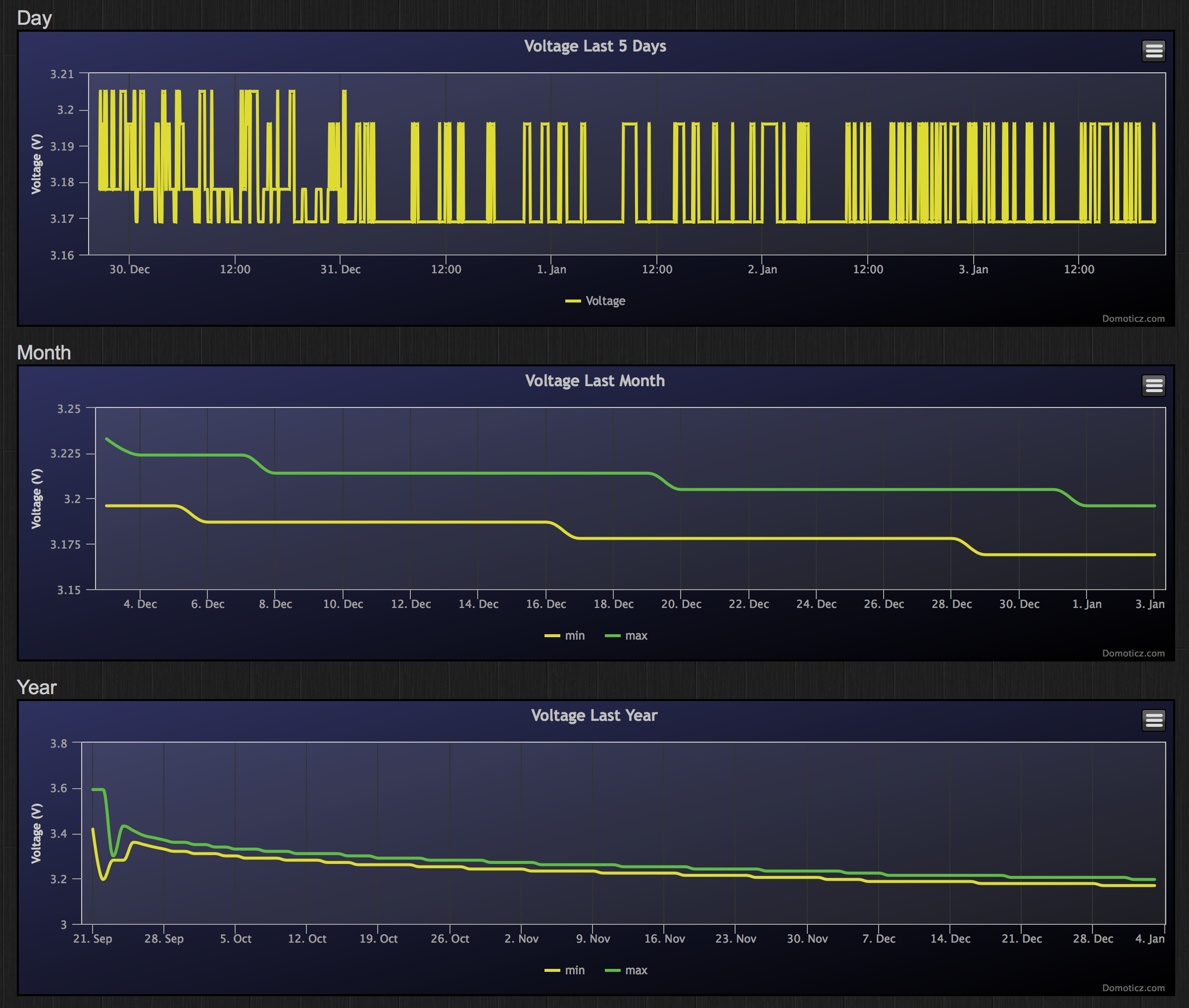

Below is a graph of another sensor sending data every 5 minutes.

-

In comparison here is an ESP8266 doing the same job every 5mins

But that is 4 AA Alkaline batteries.

And by the look of todays voltage it is on it's way out.

-

@GertSanders said:

It seems you have removed the crystal and capacitors and plan to use the internal oscillator, I did this as well. Works most of the time, but uploading of sketches can give transmission errors of you go above 57K6 baud. Better to transmit at 36Kbit then (needs a change in the BOARDS.TXT file of Arduino IDE)

76K8 baud works better than 57K6 (division from 8 MHz has less error), and there are Optiboot variants which support it (with theBOARDS.TXT change you mention). Or 38K4 baud (half that) as you suggest, which is no more timing accurate than 76K8 but by being slower still may give more margin for sloppy edges or the like - if needed.

-

Hi GertSanders,

After ordered and make 3 of 50mm x 30mm board with success. Now I ordered the AC Capable 50mm x 50mm board. I try to read the schema and I have some question. If I want to use this board with only 2 AAA battery, Do I need to use AMS1117? and witch jumper do I need to close? It is optional to use AT24C ?

Thank you for your help

-

@Carl-H To use the board with AA batteries you do NOT need to place the AMS1117. But you will need to short the jumper "BAT" which you will find on the same surface as the AMS1117 if you want to feed the NRF24 with the same power.

The batteries are connected to the Vcc power line. The NRF24 is connected to the 3V3 power line. There is no interconnection, unless you use the AMS1117 or you short the jumper "BAT".The AT24C's are optional. If you do plan to use them, you will also need to place the I2C pull resistors and you will need to short the jumpers RSCL and RSDA. These two jumpers connect the pull-up resistors to the SCL and SDA lines.

If you use a sensor connected to the pins SCL/SDA of the extension connector you sometimes have no need for pull-ups as the sensor itself has them.

The jumpers SCL-SDA and SDA-SCL are there to allow switching the signals of the SCL/SDA pins on the extension connector. The jumper closest to the board edge is for the pin on the very edge of the connector, the jumper close to the ATSHA is for the second pin. Without shorting these two jumpers, the pins on the extension connector have no function.

Some sensor-boards have a SDA-SCL-GND-3V3 connector, others have a SCL-SDA-GND-3V3 pattern. The jumpers are there to be able to use both types.

-

Thanks for your clear explication! I have another question, where is the FTDI port ?

-

@Carl-H It is part of the expansion connector.

I added more info on the OpenHardware.io site.

-

Ok my boards arrived from DirtyPCB.

A couple of questions:-1.I am not using NR2 (The radio socket that protrudes),Also i am using the internal osc and not the xtal.

So can i leave out C9,NR2 Socket,C5,C6,Xtal ?

2.What are C2,C3 doing.

The socket for the cpu i have fitted will not let me squeeze them in.Should i solder them in underneath or can they be left out?

-

@mtucker

-

Yes you are right about leaving out these components, but if you use NR1 i should leave out C8 and keep C9 (mount the decouple C's as close to the decouple component as possible)

-

these components are for decoupling the uP. You can mount them at the bottom, do not leave the out.

I used a tip from earlier in this forum thread for gaining a little bit more space when using these

Cheerz

-

-

@BartE answered perfectly. You can leave out C5,C6 and XTAL if you use the internal oscillator. C9 is for the NRF24, no matter if you use NR1 or nR2 socket. And yes, you only need 1 socket, so if you use NR1, no need to add NR2 (and vice versa).

Socket NR2 is for the longer (and power amplified) radio with external antenna, NR1 was intended for the standard NRF24L01+ with PCB antenna.

C2 decouples AVCC (the analog power input), just as C1 decouples the VCC (digital) power input. C3 stabilises the analog reference input. If you do not use the analog->digital conversion, you could skip C3 as well.I also do not use standard 28 pin sockets, but strip sockets just like BartE.

In the image here I used a standard socket, but cut away the middle "bridge" to allow mounting the decoupling capacitors.https://www.openhardware.io/uploads/568faa0cbaba42246aa57103/image/IMG_7527.jpg

In the image below I use the strips BartE mentioned:

https://www.openhardware.io/uploads/568faa0cbaba42246aa57103/image/IMG_7686.jpg

More images and details are here:

https://www.openhardware.io/view/5/Battery-based-atmega328p-sensor-no-SMD

-

I am pulling out what hair i have left.

All i am getting is this:-

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

Init complete, id=253, parent=255, distance=255

Battery:3.161 Batt%:90 Temperature:21.73C Humidity:56%

find parent

send: 253-253-255-255 s=255,c=3,t=7,pt=0,l=0,sg=0,st=bc:

-

Node 253 tries to connect and fint its way to the gateway (find parent) but doesnt get any respons.

Do you have a working gateway - what does the gateway log looks like?

Suggested Topics

-

Welcome

Announcements • • hek