Double Micro (nano) Ampere meter

-

A very low current (double) stand alone uA meter to tune MySensors battery nodes..

I de' MySensor'ized this project because it is more usefull on the workbench for measuring the very low currents of MySensors battery nodes. I own several Ampere meters including the famous µCurrent. Many of these are not accurate enough or need a lot of wiring and additional equipment (µCurrent). I just wanted something simple and stand alone

Using the low cost HX711 weight scale 24 bit AD converter a sub 10€ cost double µA meter was born. Some characteristics to fit MySensors projects:- range channel A: ± 20mA 5½-6½ digit µA

- range channel B: ±40mA 5½-6½ digit µA

- burden voltage 1µV/1µA (internal resistance 1Ω)

- 'patch panel' on the connectors.

- easy calibration.

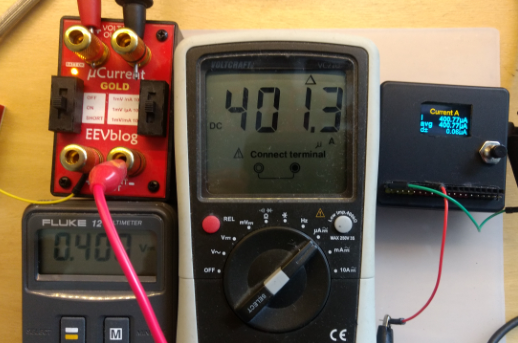

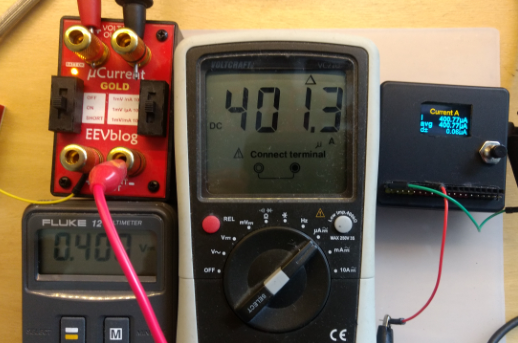

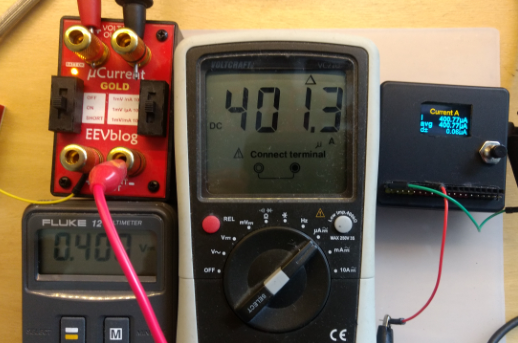

In comparison with the µCurrent and a standard multimeter in uA range

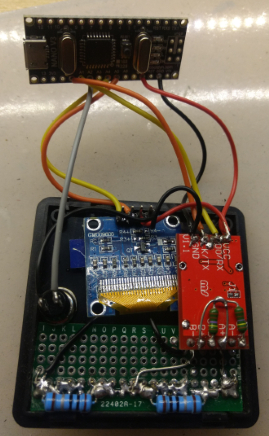

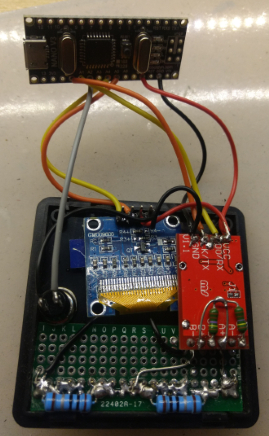

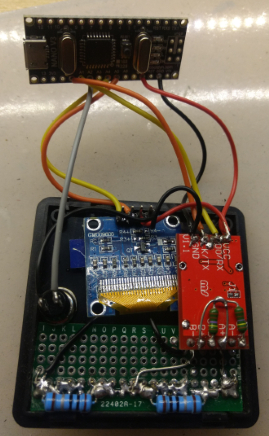

The internals:

Although it cannot compare in accuracy with the µCurrent (in combination with a good multimeter) it is more than useable and accurate to do some serious MySensors tuning.

If there is some interest I will try to publish a decent built instruction on Openhardware.io.

-

A very low current (double) stand alone uA meter to tune MySensors battery nodes..

I de' MySensor'ized this project because it is more usefull on the workbench for measuring the very low currents of MySensors battery nodes. I own several Ampere meters including the famous µCurrent. Many of these are not accurate enough or need a lot of wiring and additional equipment (µCurrent). I just wanted something simple and stand alone

Using the low cost HX711 weight scale 24 bit AD converter a sub 10€ cost double µA meter was born. Some characteristics to fit MySensors projects:- range channel A: ± 20mA 5½-6½ digit µA

- range channel B: ±40mA 5½-6½ digit µA

- burden voltage 1µV/1µA (internal resistance 1Ω)

- 'patch panel' on the connectors.

- easy calibration.

In comparison with the µCurrent and a standard multimeter in uA range

The internals:

Although it cannot compare in accuracy with the µCurrent (in combination with a good multimeter) it is more than useable and accurate to do some serious MySensors tuning.

If there is some interest I will try to publish a decent built instruction on Openhardware.io.

@AWI Impressive!

-

I need this! Please publish instructions ;)

-

Wow, that looks nice, I'm stucked with my multimeter and couldn't find the parts avaiable for delivery here to build a µcurrent gold.

Please publish the build instructions !

(Maybe if you could give use the BOM first, then you'll have plenty of time to publish build instruction before we get delivered ;)) -

Awsome!

I'd like to compare your impressive array of measurement devices against my Agilent U1273A. Actually to decide if I need a µCurrent.... Maybe in an upcoming meetup in NL or BE this summer?

-

There it is Micro (nano) ampere meter (double). I need to add a schematic drawing. Any suggestions/ questions are welcome.

-

Parts ordered :D

-

@gohan As mentioned in the description: I use it as a "patch panel" to distribute the power and ground to different devices. Wiring tends to get messy on my workbench...

Not mine but similar ;-)@AWI - did you steal my image on my workbench ;) j/k.

We need to revive the old workbench topic again! -

@gohan No special tolerance resistors needed. The only reason for choosing metal film resistors is that their temperature coefficient is better than carbon types (typical 50ppm/°C compared to 200-500ppm/°C).

As you will be calibrating the circuit you can choose from a large range (0.1 Ohm - 100 Ohm) for the shunt. This will only influence the burden voltage / sensitivity and range (Ohm's laws). -

@DavidZH Impressive only by numbers ;-) I am prepared to trade my µCurrent for the Agilent :blush:

A meetup sounds good..any specific plans yet? -

A very low current (double) stand alone uA meter to tune MySensors battery nodes..

I de' MySensor'ized this project because it is more usefull on the workbench for measuring the very low currents of MySensors battery nodes. I own several Ampere meters including the famous µCurrent. Many of these are not accurate enough or need a lot of wiring and additional equipment (µCurrent). I just wanted something simple and stand alone

Using the low cost HX711 weight scale 24 bit AD converter a sub 10€ cost double µA meter was born. Some characteristics to fit MySensors projects:- range channel A: ± 20mA 5½-6½ digit µA

- range channel B: ±40mA 5½-6½ digit µA

- burden voltage 1µV/1µA (internal resistance 1Ω)

- 'patch panel' on the connectors.

- easy calibration.

In comparison with the µCurrent and a standard multimeter in uA range

The internals:

Although it cannot compare in accuracy with the µCurrent (in combination with a good multimeter) it is more than useable and accurate to do some serious MySensors tuning.

If there is some interest I will try to publish a decent built instruction on Openhardware.io.

If there is some interest I will try to publish a decent built instruction on Openhardware.io.

I'm interested.

-

If there is some interest I will try to publish a decent built instruction on Openhardware.io.

I'm interested.

@NeverDie said in Double Micro (nano) Ampere meter:

I'm interested.

In case you haven't seen it, it's here :

https://forum.mysensors.org/topic/6723/micro-nano-ampere-meter-double/5 -

@NeverDie said in Double Micro (nano) Ampere meter:

I'm interested.

In case you haven't seen it, it's here :

https://forum.mysensors.org/topic/6723/micro-nano-ampere-meter-double/5@Nca78 said in Double Micro (nano) Ampere meter:

@NeverDie said in Double Micro (nano) Ampere meter:

I'm interested.

In case you haven't seen it, it's here :

https://forum.mysensors.org/topic/6723/micro-nano-ampere-meter-double/5Thanks! It looks a bit complicated to me. I've used one of these breakout boards (https://www.amazon.com/gp/product/B00OPVBEQO/ref=oh_aui_search_detailpage?ie=UTF8&psc=1) as a way to measure 24-bit voltage on capacitors, and it works really well. As you can perhaps tell from the photo:

the chip is fairly simple to use. What I especially liked is that there was already a demo arduino sketch for interfacing with it. That was a real time saver. If I were to build something, I might try that first, if only because it seems like it might be easier (though perhaps, in part, because I'm already comfortable with it). Would using it in conjunction with a sense resistor be all it would take to make an accurate, high resolution current sensor?