What did you build today (Pictures) ?

-

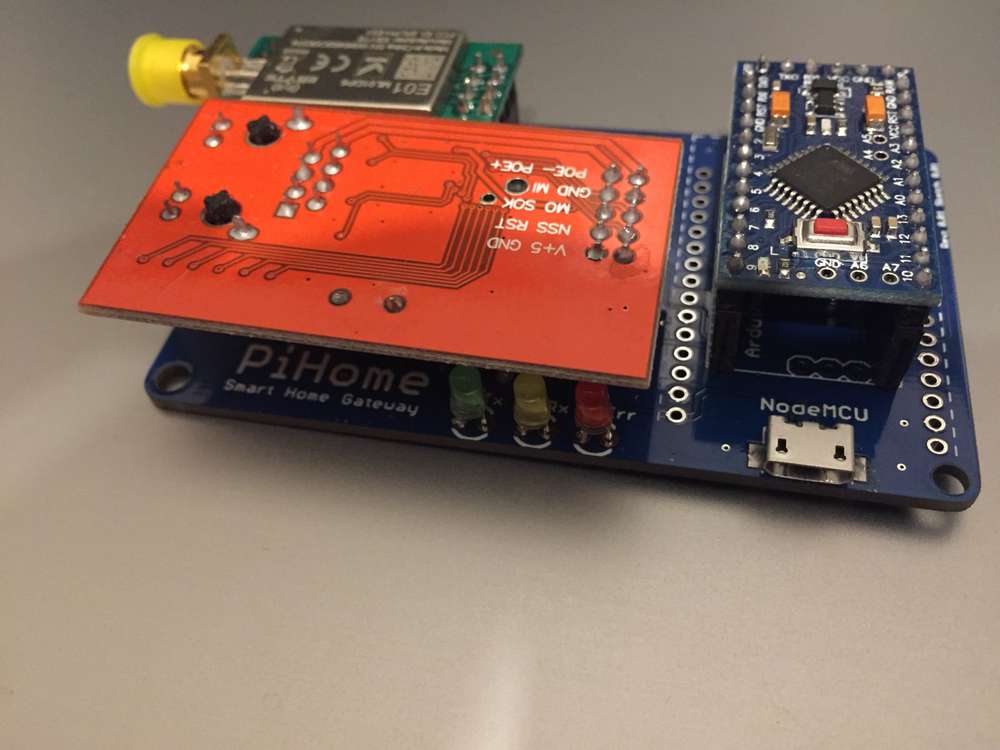

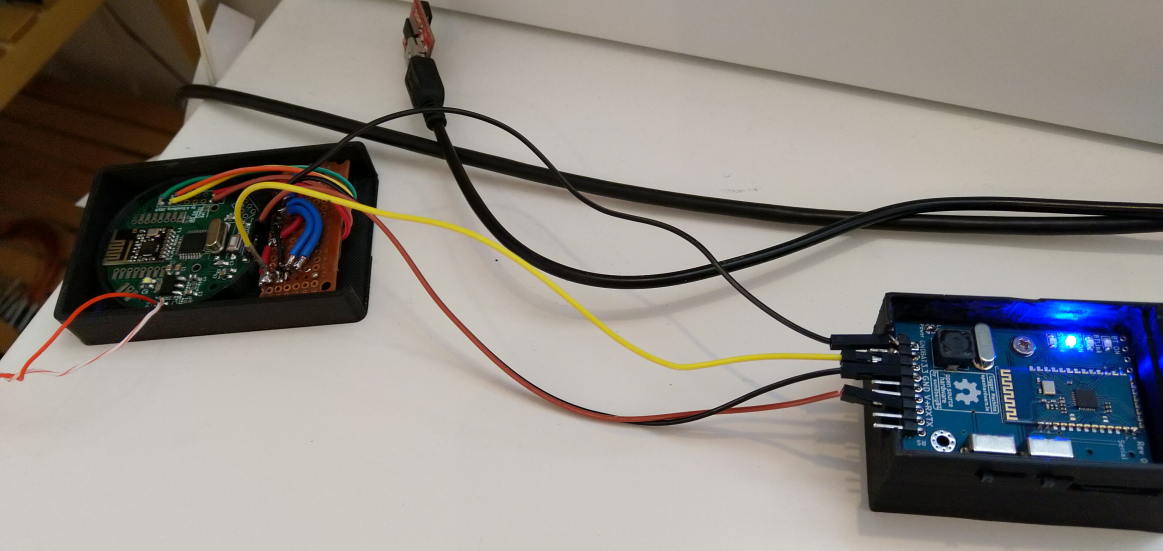

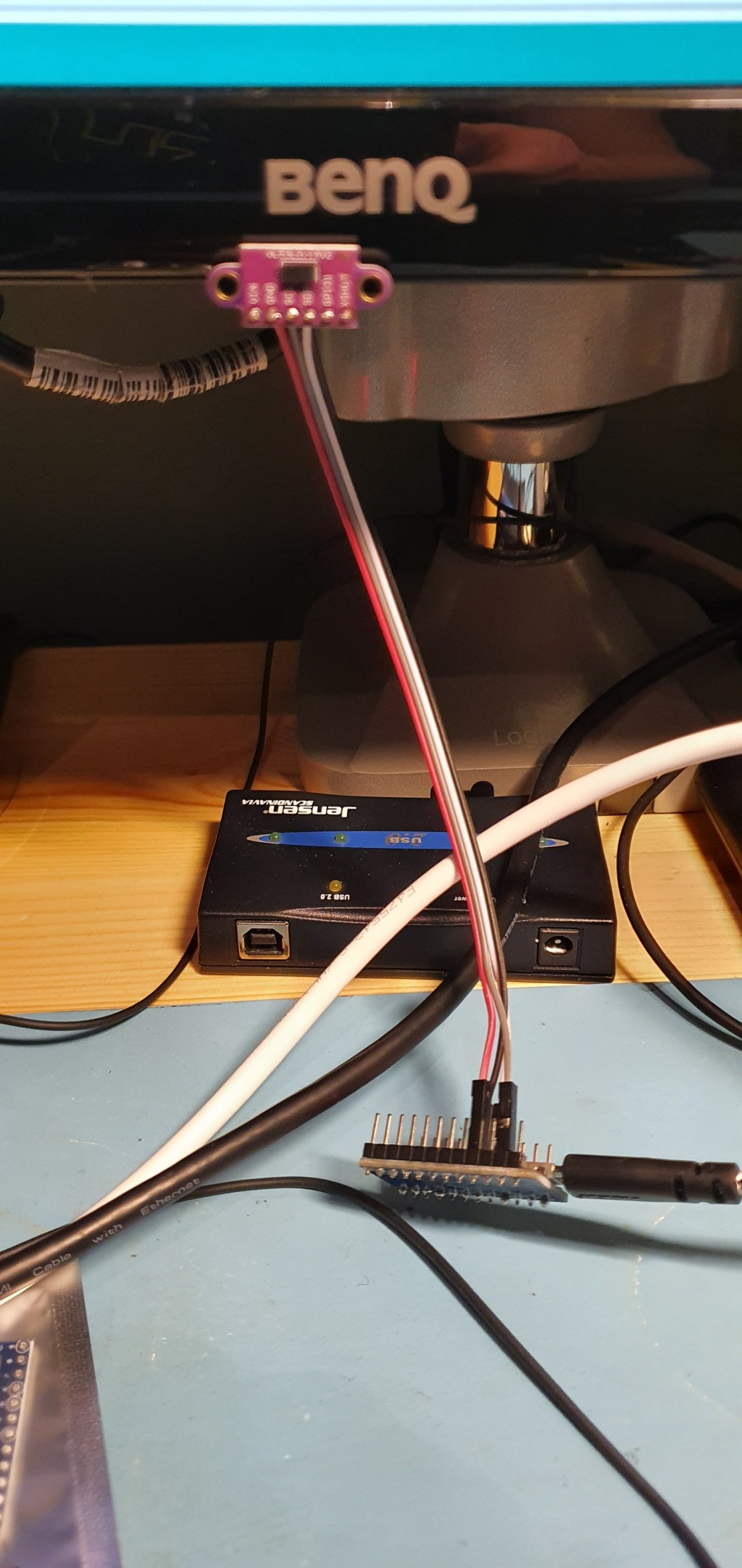

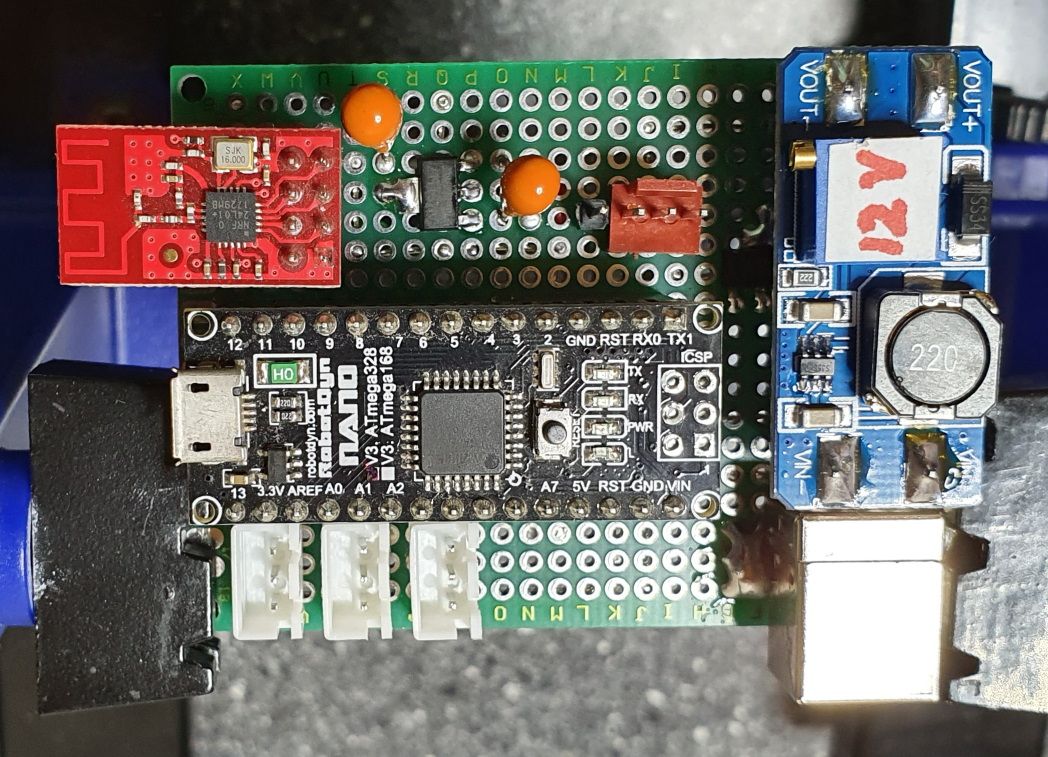

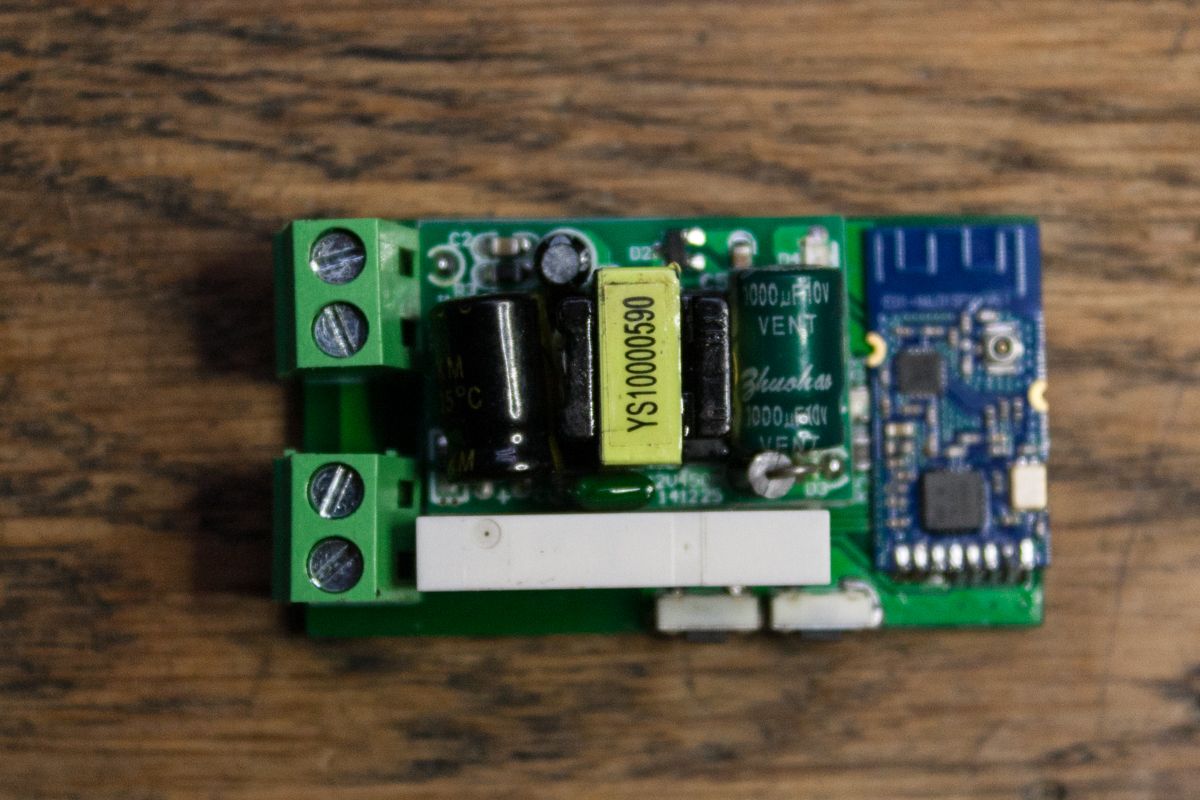

very first working Ethernet gateway

-

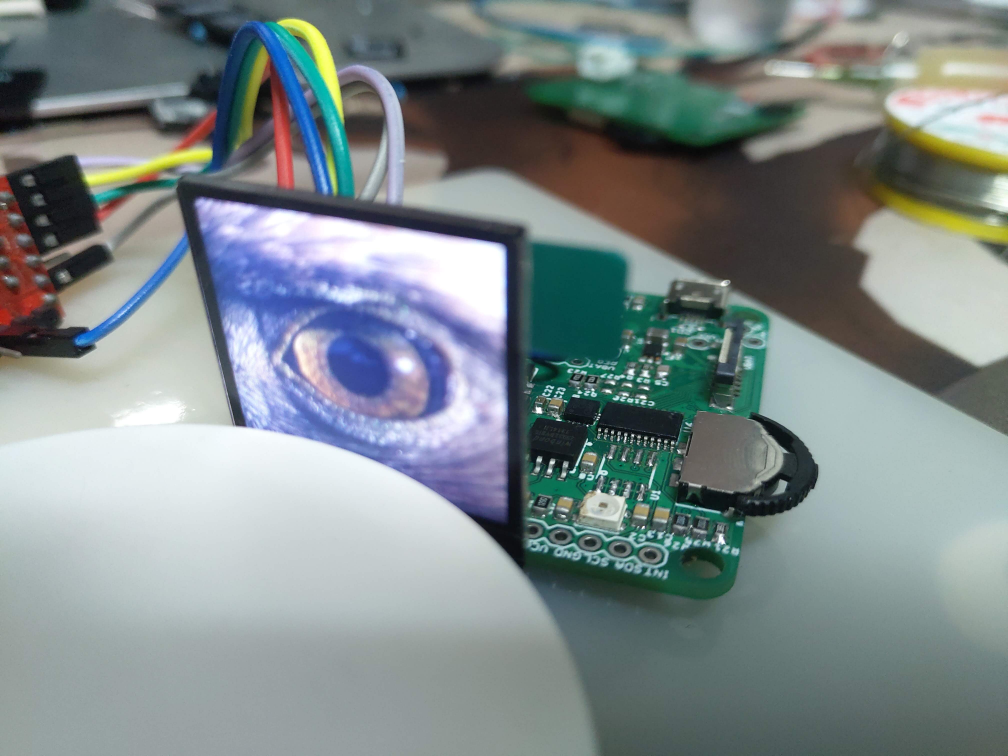

Today I finished to fix failed soldering (too old solder paste made a mess

) on the "motherboard" of my air quality sensor.

) on the "motherboard" of my air quality sensor.

It's based on ESP32, uses a charging IC with power path so it can run on batteries for around a day or stay plugged without destroying the battery, step down from USB/battery to get VCC, storage on I2C EEPROM, flash and/or µSD card (depending on use case), one SK6812 mini RGB led as indicator, a small 240*240 IPS LCD (backlight driven directly by ESP32 pin in high drive capability mode), a 3 way switch for basic user interface + footprint for PAJ7620 gesture recognition module, accelerometer and I2C IO expander to manage the 3 way switch and interrupts from sensor modules.

Sensor modules will be added on top, connected using an FPC connector. At the moment I made only one sensor PCB able to manage usual PM, CO2 and formaldehyde sensors. Only one sensor per sensor board where an attiny841 manages the UART sensor and convert it to I2C, it also manages the 5V step up to power the sensor.

On the main board I also added an NRF24 footprint so with the same PCB I will be able to make a gateway with integrated battery backup.I'm pretty happy with the relatively well aligned components (no, I don't have OCD

) , too bad I had to unsolder, clean and re-solder each component as it now looks botched up. But at least everything (except a missing connection on µSD card, hence the blue wire) is working,

) , too bad I had to unsolder, clean and re-solder each component as it now looks botched up. But at least everything (except a missing connection on µSD card, hence the blue wire) is working,

LCD test showing jpgs from SD card

-

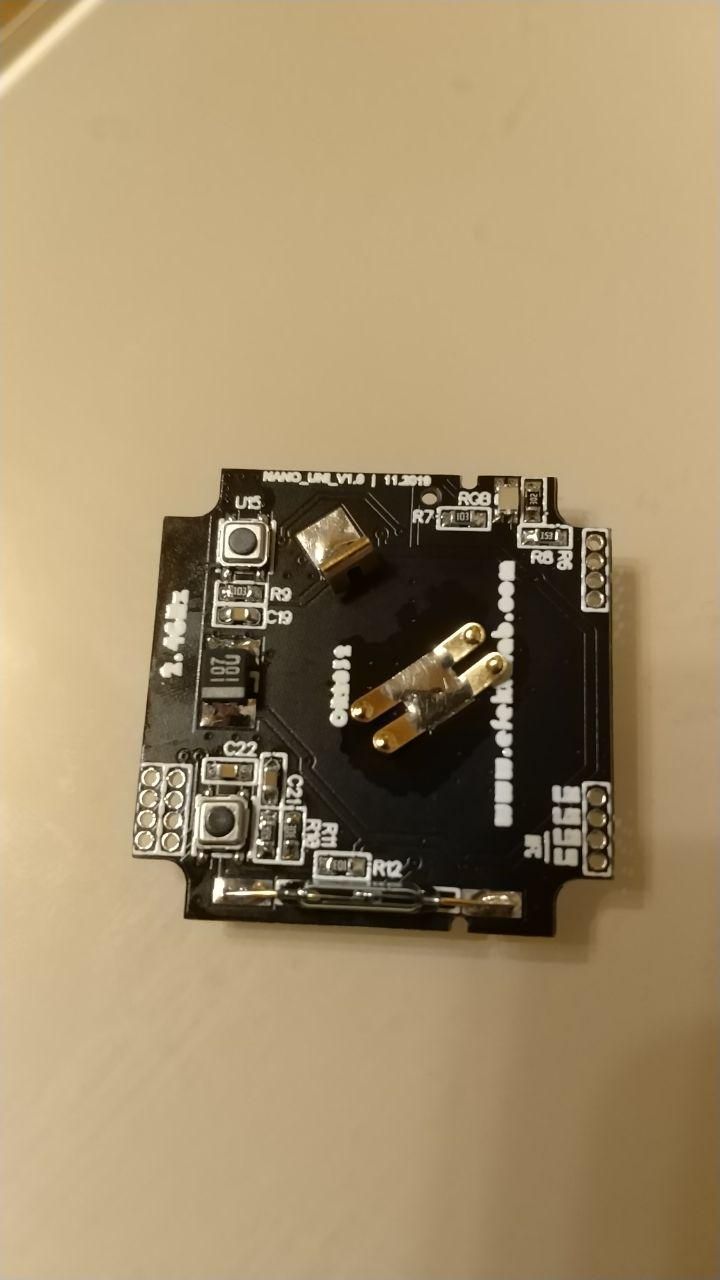

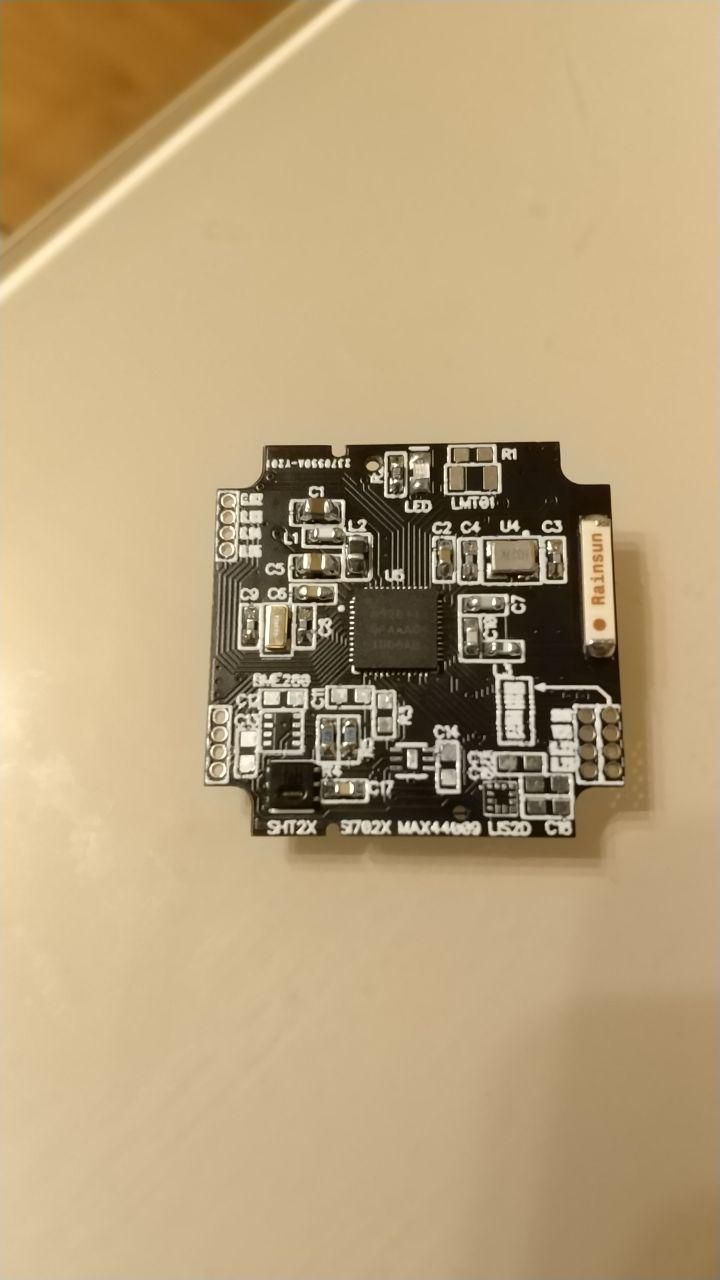

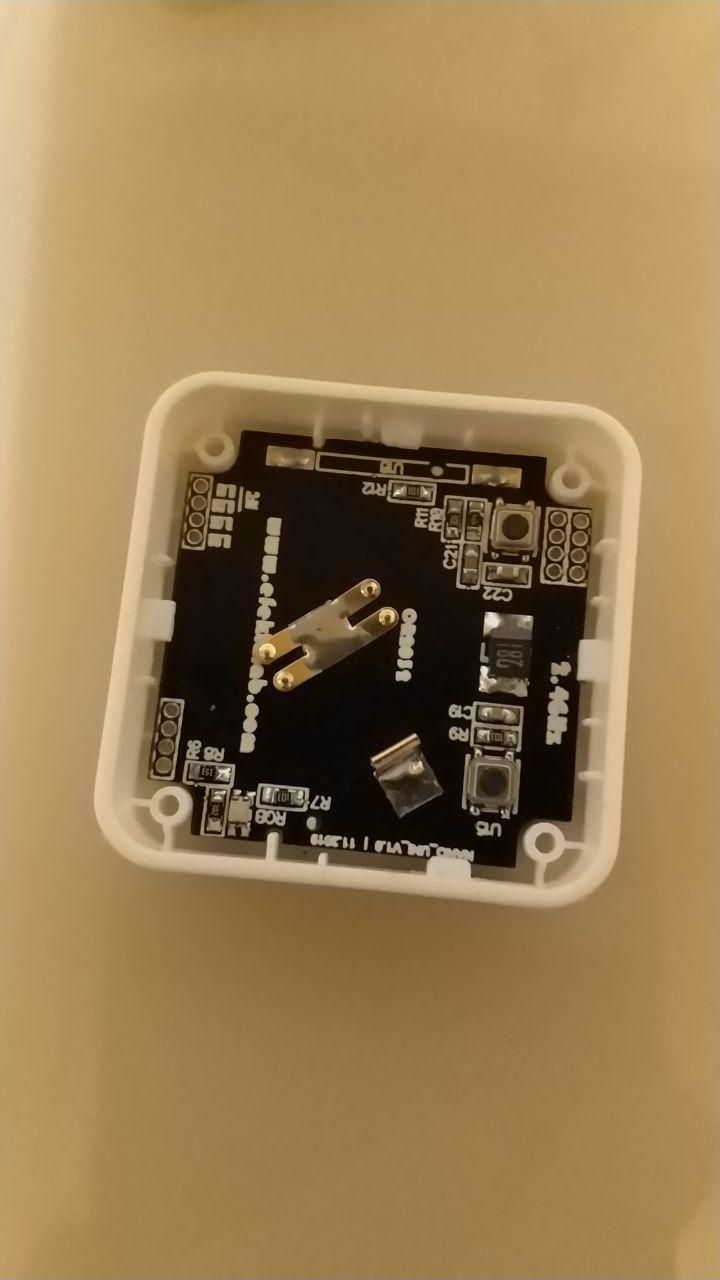

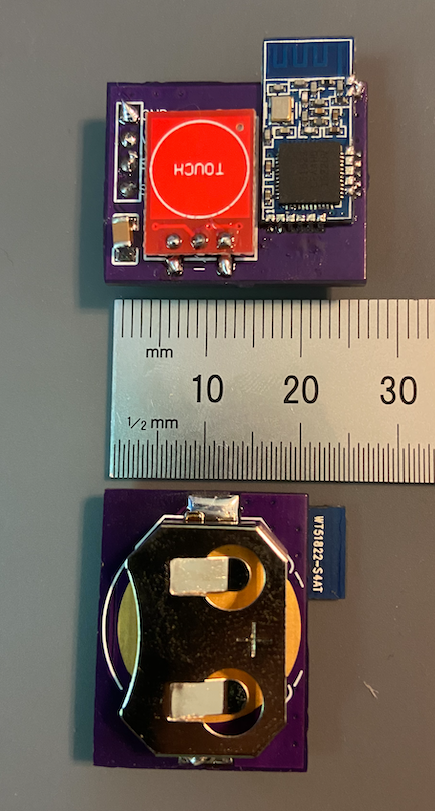

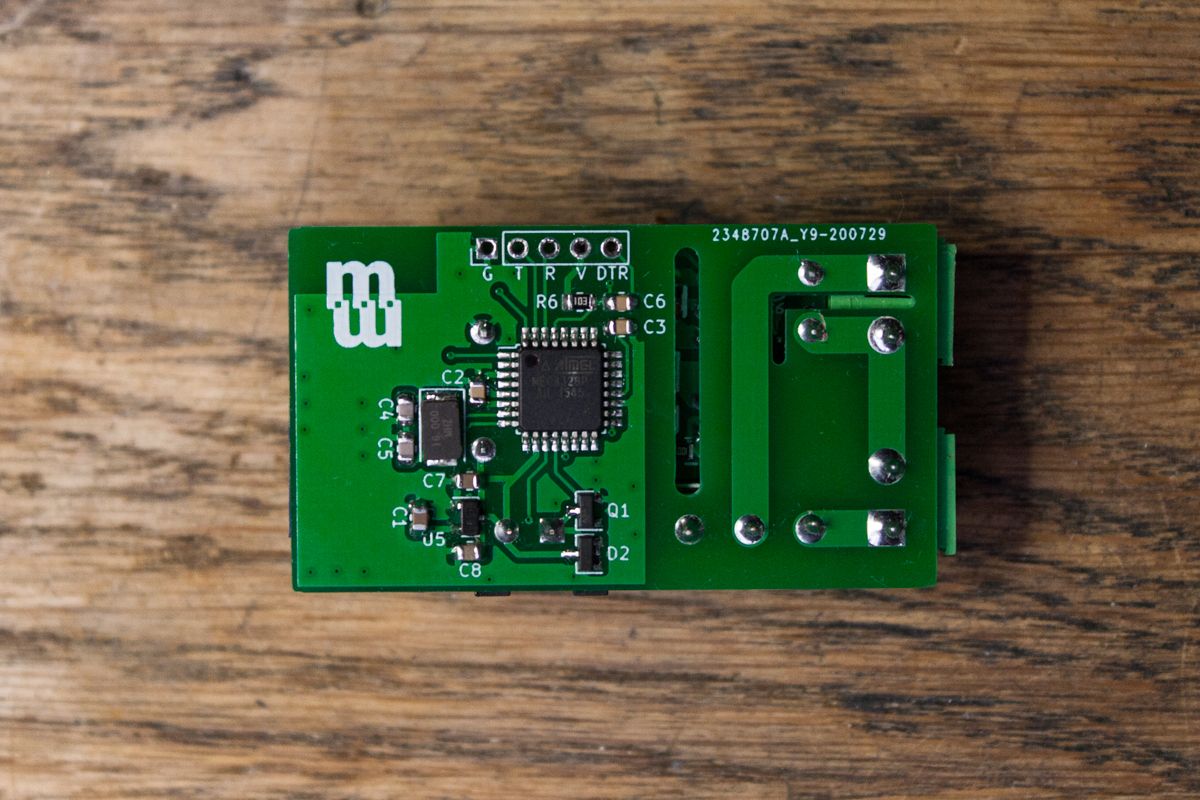

My new mini multi device on nRF52810, nRF52811, nRF52832 chips. Designed specifically for a very small case from Aliexpress. It works!!!

bme280, sht20/21, si7020/si7021, hdc1080, max40009, lis2dw12, lis2dh12, lmt01, reed switch, led + rgb led, user button and 6 analog pins, 6 digital pins with NFC.

VIDEO:

Mini multi-sensor in a small case. New Happy node mode test. nRF52 – 03:29

— Andrew EfektaSB

-

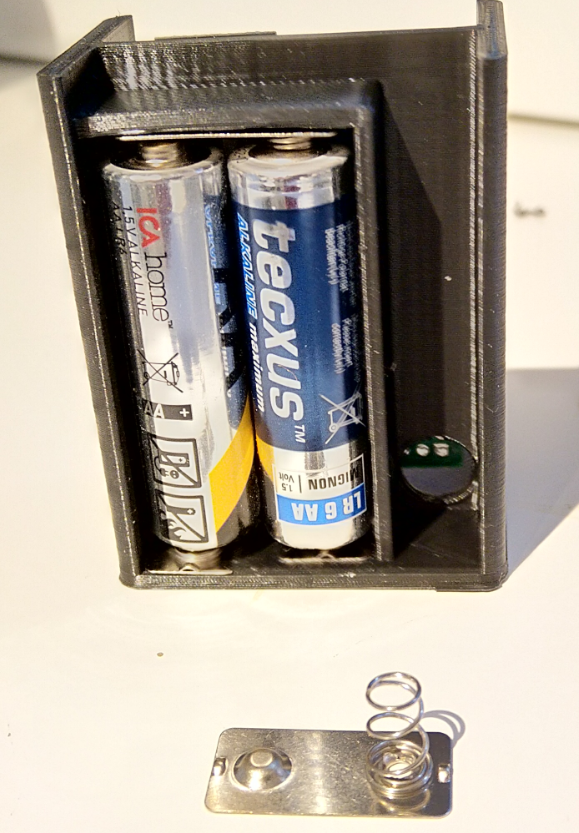

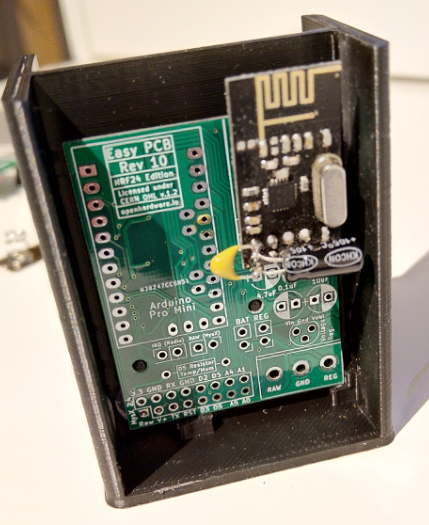

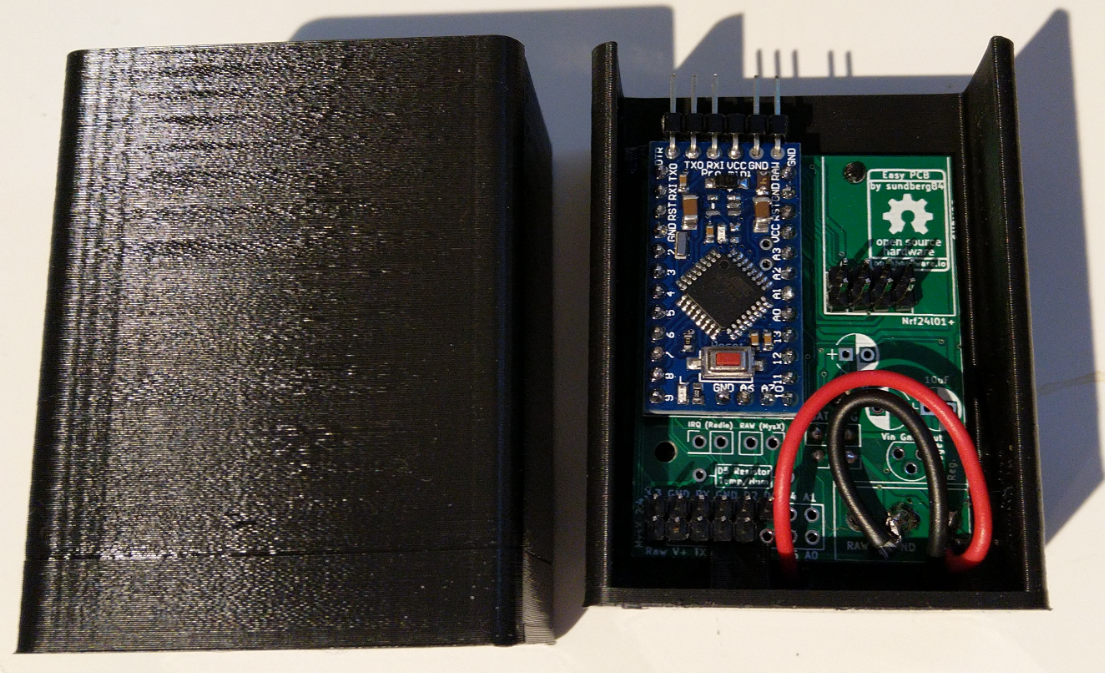

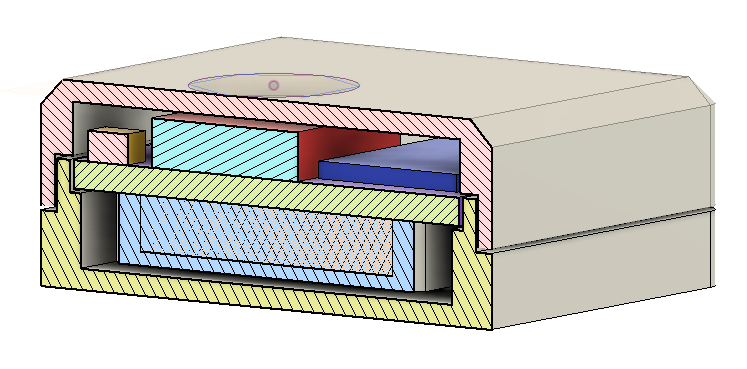

Today I designed a case for EasyPCB with 2xAA holder on the back.

and a case that slides just over.

It works with 3x5 version so for this you accually have to use the more advanced option and reflash the fuses on your pro mini to make it 3x5. The normal EasyPCB with booster is 5x5, but Im thinking of just stretching this for another version.

-

@sundberg84 just a suggestion; wouldn't it be good to move the batteries to the right (instead of the left) so they block the nrf antenna less?

-

@mfalkvidd - a great suggestion! It wont not block it completely but as you say, a little less.

-

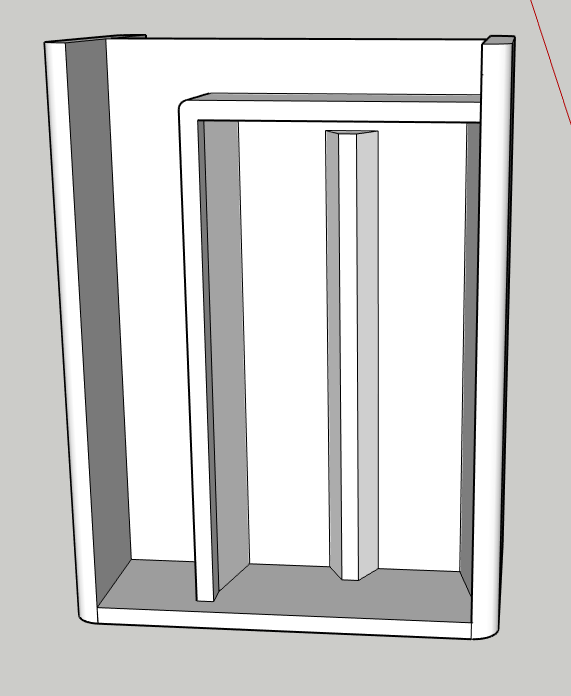

Here's another idea too: if you were to add a blank copper cladded FR4 between the batteries and the PCB above it, with a cut-out below where the antenna is, then maybe you'd have a much improved ground plane, making your radio awesome? You could have little drawer like grooves on the side of your case to slide the copper cladded FR4 into position, and, of course, you would want a ground connection to it.

-

Not sure about that groundplane @NeverDie - you are most probably right but I dont really understand the theory behind it but sounds really cool!

-

@sundberg84 Here's all the theory you need in one picture:

Most of the modules use a monopole antenna, and as near as I can tell, most of them, if not all of them, have insufficient ground plane. It still works, of course, but it's impaired over what it would be with a better ground plane. I think maybe that's why whenever someone switches to a dipole antenna they generally notice a huge improvement. So, there's always that, but your design is nice because it's so compact, and a dipole would spoil that.

-

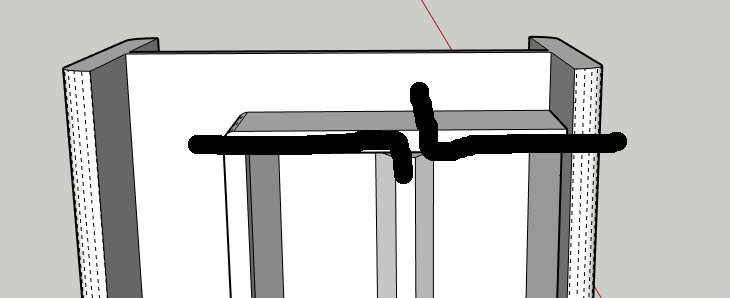

@NeverDie - so a ground plane like in here? Like that mod Pete did in his video but you inmplement it into the 3d case?

-

Yeah, the flat piece that the red line points to. I'm not sure what those black spray painted things are, so I'm ignoring those.

-

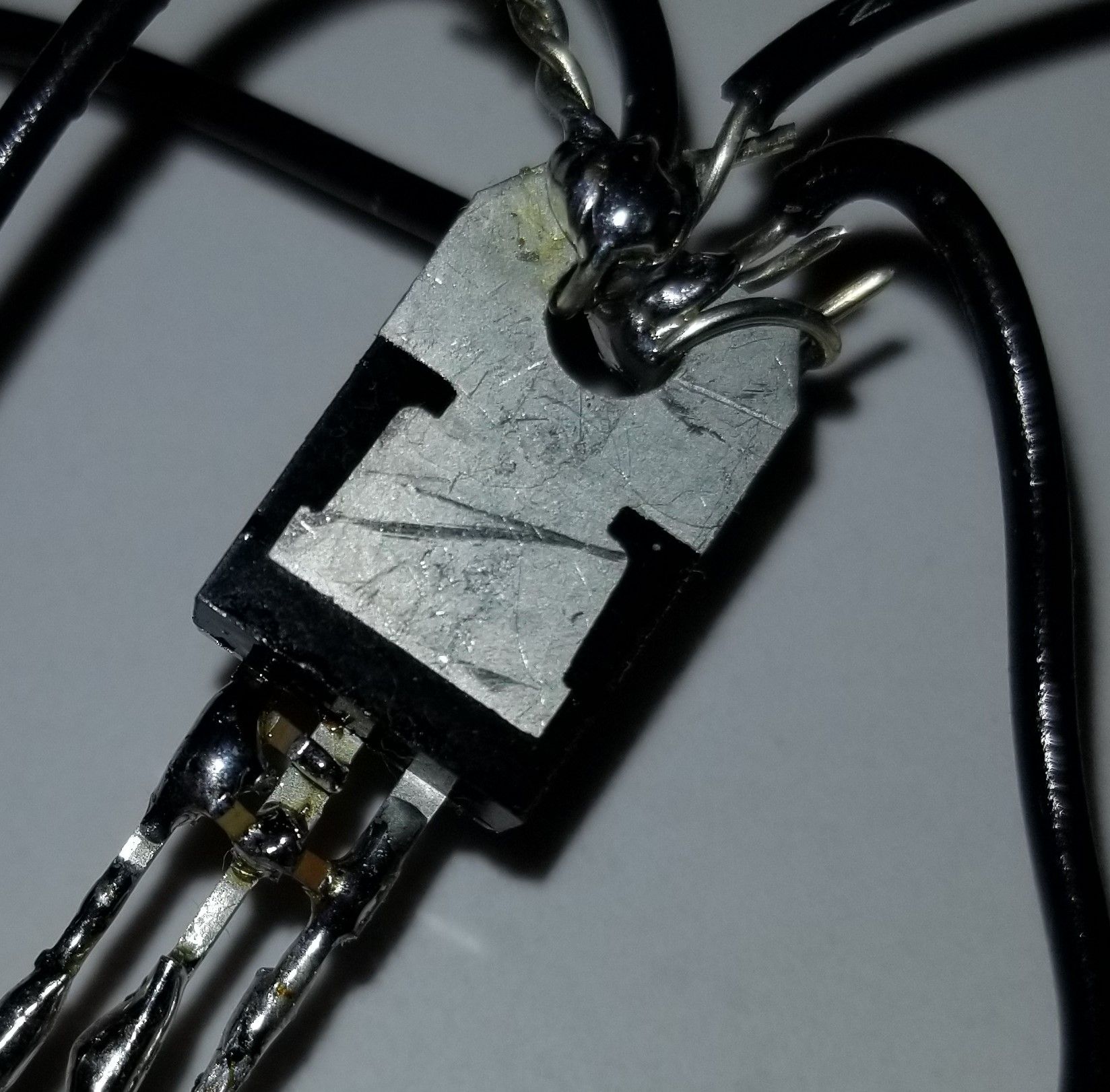

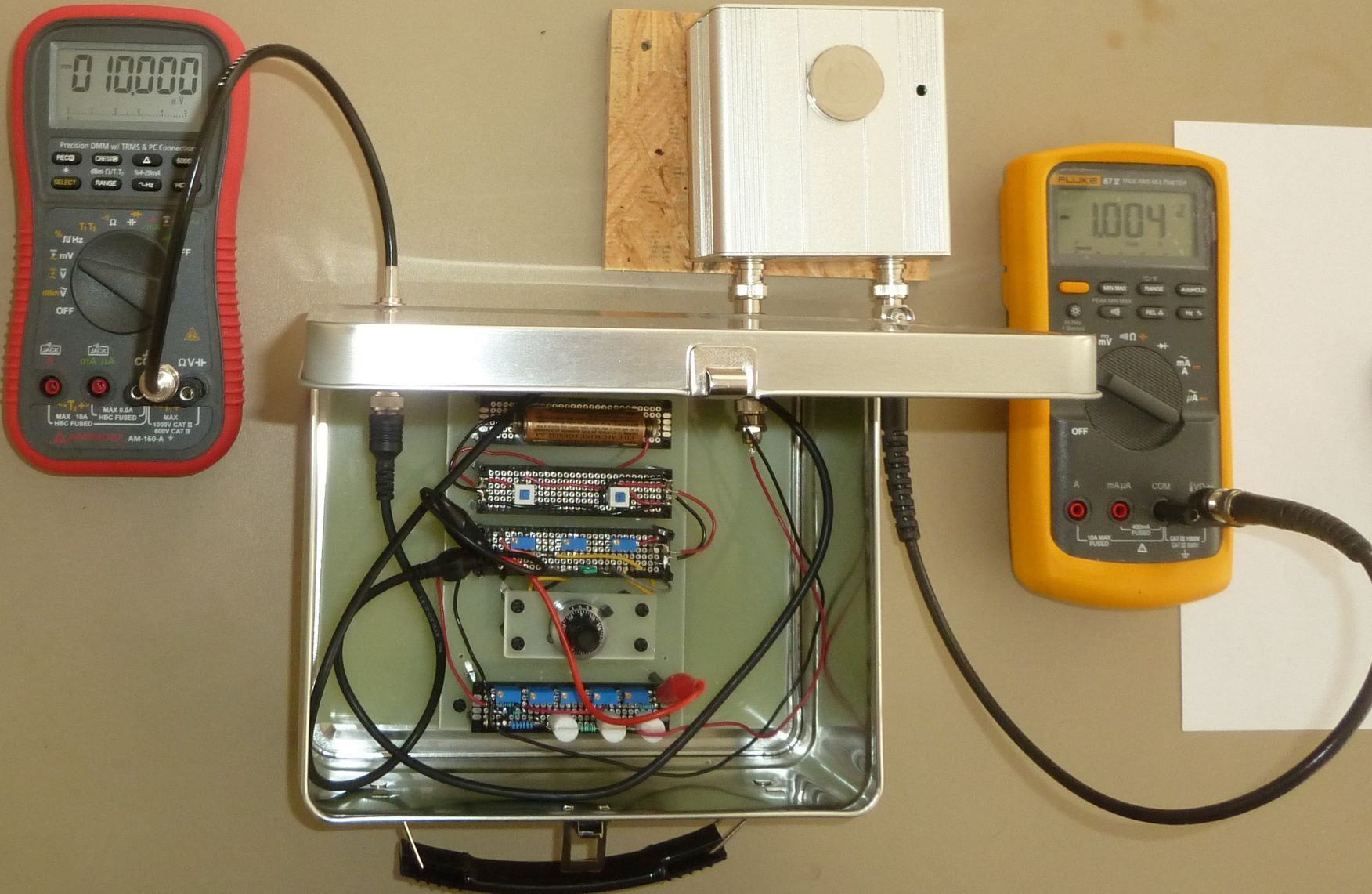

Made a dead-bug op-amp circuit to help measure open-circuit voltages created by nano-amp currents generated by a solar cell illuminated by just 1 lux of very dim light:

This picture is actually just the LDO part of the op-amp circuit, where I was able to solder the prescribed surface mount capacitors directly between its pins. The larger circuit is described on this thread: https://forum.mysensors.org/topic/10812/the-harvester-ultimate-power-supply-for-the-raybeacon-dk/122

Why dead-bug you ask? Since the circuit depends on the correct measurement of the effects of mere nanoamps, I didn't want any leakage currents that might happen on a protoboard, which can be significant when it's just a small number of nanoamps and their effects that's under scrutiny.

-

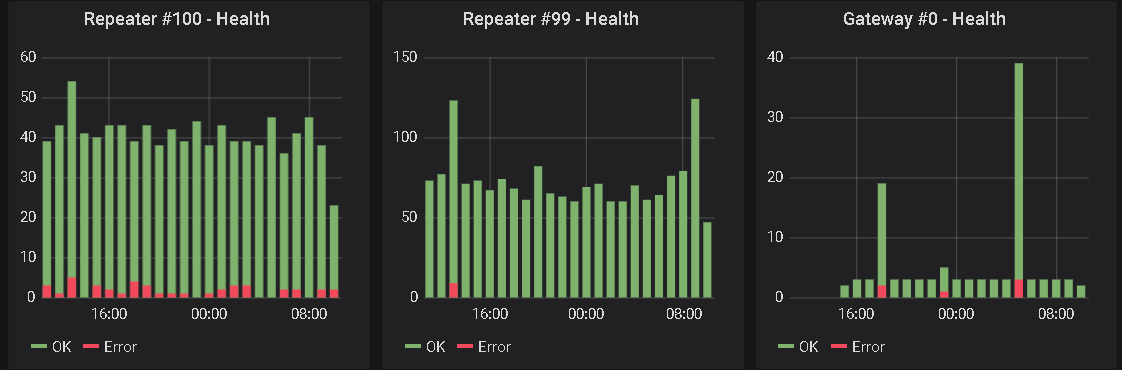

Updated my GW with the code @mfalkvidd provided to monitor OK and NACK

-

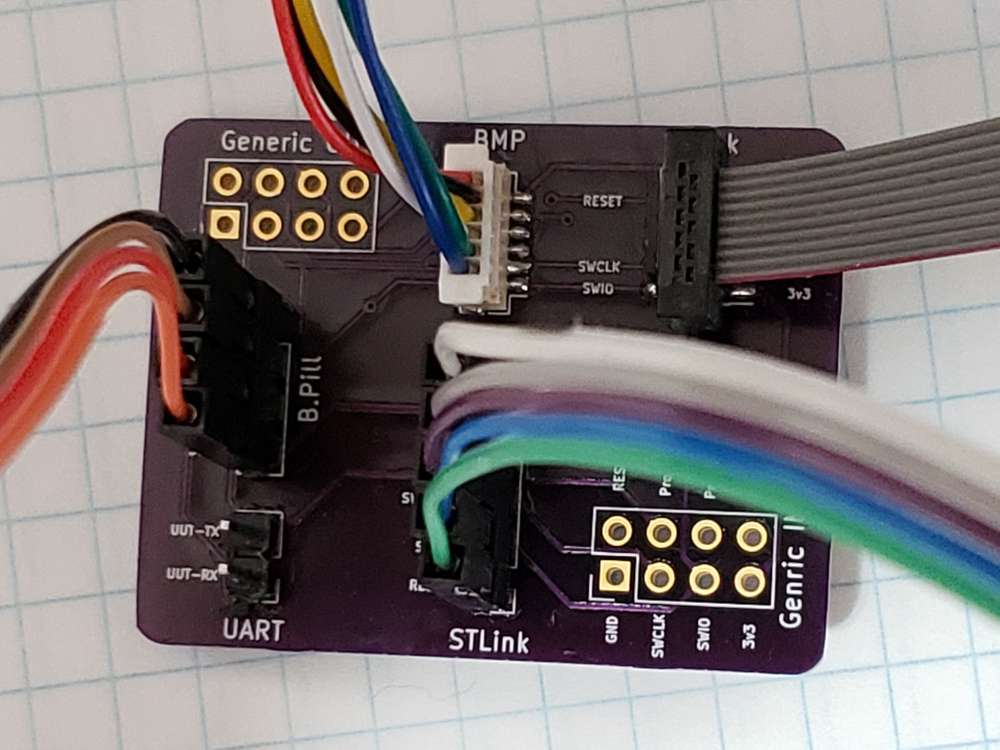

I got tired of twisting DuPont cabels to get from different programmers to different boards.

This is an adapter that lets me connect the programmers I commonly use (Jlink-mini, BMP, STLink clone) with the boards I commonly program with straight through wires. I left a couple unpopulated for future in and out.

-

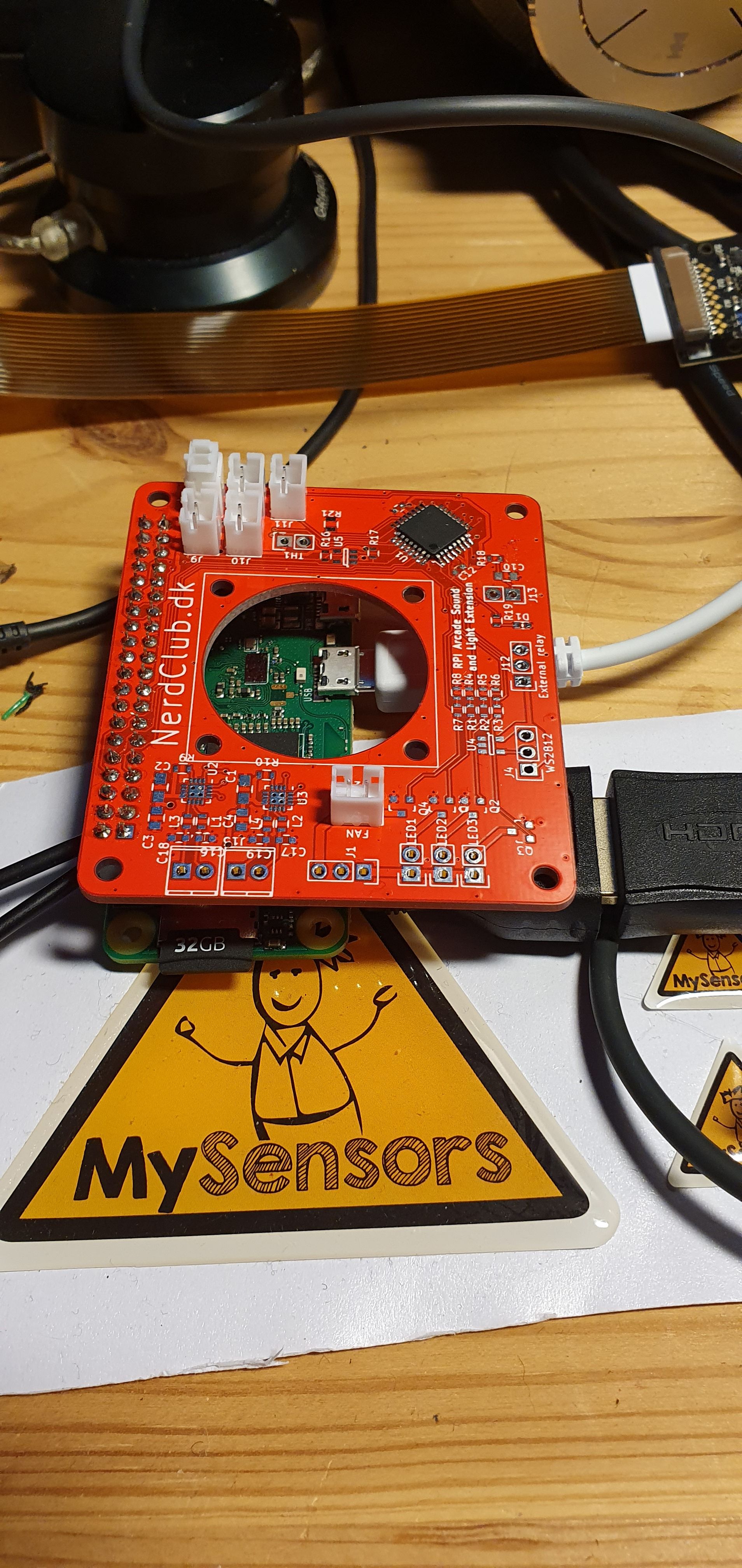

Finally I am starting to do a little electronics again.. First thing is a prototype assembly of RASLE (Rpi Arcade Sound and Light Extension). It's a custom made arduino "coprocessor" for a raspberry pi, built into retropie arcade cabinets. It's a joint project with a couple of friends that are building arcade cabinets (I built mine a couple of years ago, I think that there is pictures earlier in this thread).

Features:

- stereo 3W class-d amplifier

- atmega328p

- 3 pwm channels for LED strips

- a port for WS2812 type led strips

- pwm channel for fan

- output for a relay to control mains input for the box (let the rpi shutdown cleanly, before disconnecting power)

- 5 button inputs (shared between rpi and atmega)

-

Hi, finished two nodes based on the same multi-purpose battery powered pcb (all the documentation here)

One is a door / window sensor based on a Reed switch.

If someone is interested, the dedicated wiki page contains the detailed build instructions.

The other is a soil moisture sensor.

For this one, the wiki page is here.

Happy Easter, even if at home!

-

Anyone know or have experience with how well the underlying capacitive soil moisture sensors hold up over the long term? Clearly they're better than the cheap conductive electrode kind, which for most people don't last very long at all, but I recollect reading that water ultimately invades the PCB enough on even the capacitive designs that it goes kaput. Maybe they've been improved since then or maybe there are now known tricks for how to fortify them against that happening?

-

@NeverDie Good question. My is too young (2 days) to say something.

Here a possible solution. See at about 9:50

-

@NeverDie The guy with the swiss accent once said that you can coat the capacitive soil moisture sensors with a water resistant varnish or put it inside a waterproof shell.

https://www.youtube.com/watch?v=udmJyncDvw0

starting at ~7 mins.@franz-unix Ha, Great minds think alike.

-

@BearWithBeard

I love the video of the swiss guy!

I love the video of the swiss guy!

-

@BearWithBeard ah, now I know who 'the guy with the Swiss accent' is

-

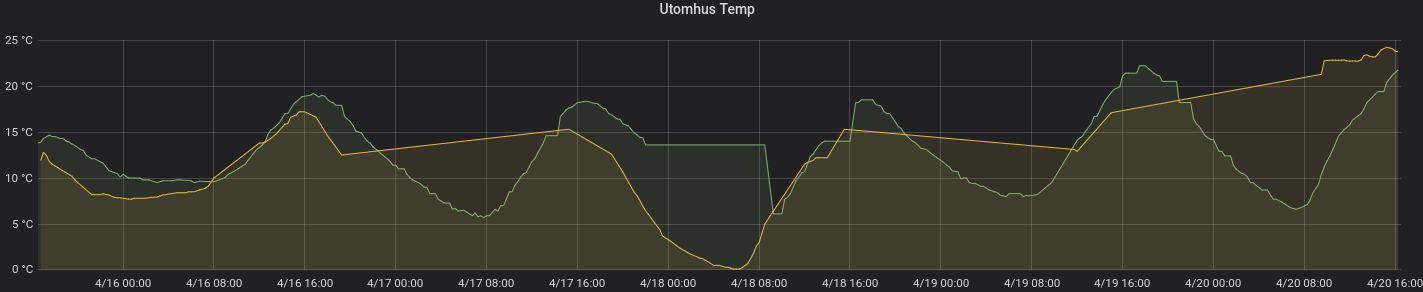

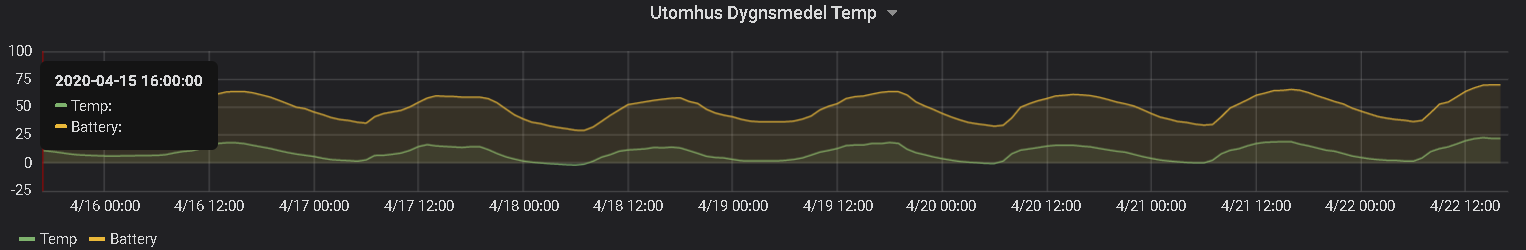

Today I have a very strange problem. I have created a new outdoor sensor which is powered by a 240v-5v HLK module. Its working VERY intermittent and should send data every 5 minutes (no exceptions).

Whats even more strange is that, when my outside node (called multi) is working, I have a battery powered node (sleep 15 min - send - sleep) that seems to go down, and the other way around (not always, but quite frequent - could be very unrelated but I have notised it a couple of times now).

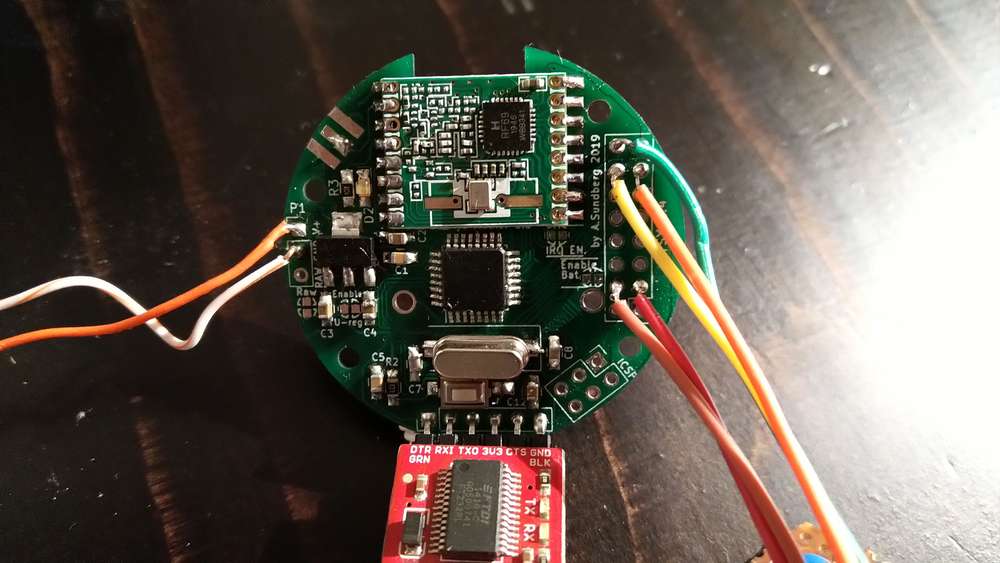

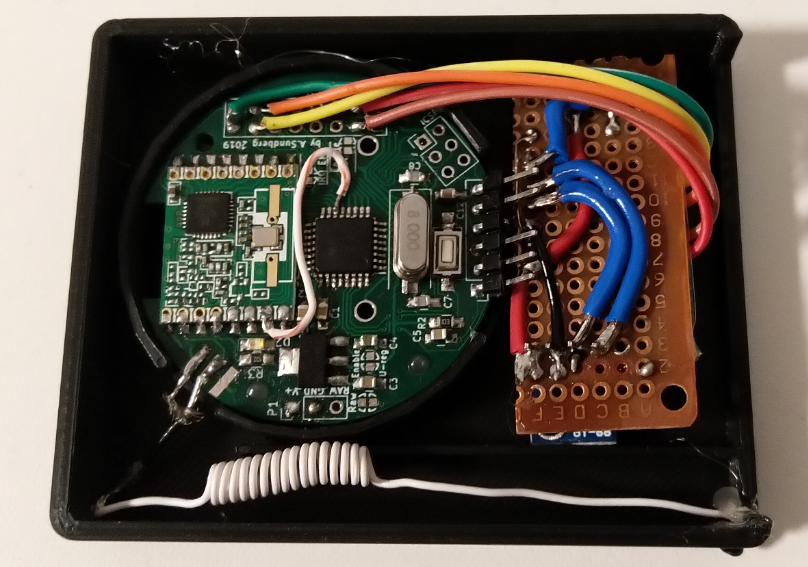

Anyhow, Im very glad i build my logger node - works great once more. I use this so often and really recommend all with a bigger network to have some sort of mobile debugger. Most of the times I use the bluetooth module (2xAA powered) but at this point I have my node on my workbench powered by a USB adapter (orange wires). I then parasite power from the node to run the debugger and is now logging everything to a sd-card.

-

In case anyone hasn't seen the logger before, it is available at https://www.openhardware.io/view/532/The-Logger-Machine-Short-and-long-term-serial-logging

-

Another picture from today:

Just started working with coincells - CR2032 to be exact. Anyone knows why the battery % varies with the given temperature? Are those coincells very temp. dependent or I have made a misstake somewhere... ???

-

@sundberg84 said in What did you build today (Pictures) ?:

Anyone knows why the battery % varies with the given temperature

They don't like it when it's too cold. Check page 4 :

https://data.energizer.com/pdfs/lithiumcoin_appman.pdf

-

@sundberg84 looks like you can ditch the temperarure sensor and just use the battery voltage to measure the temperature

-

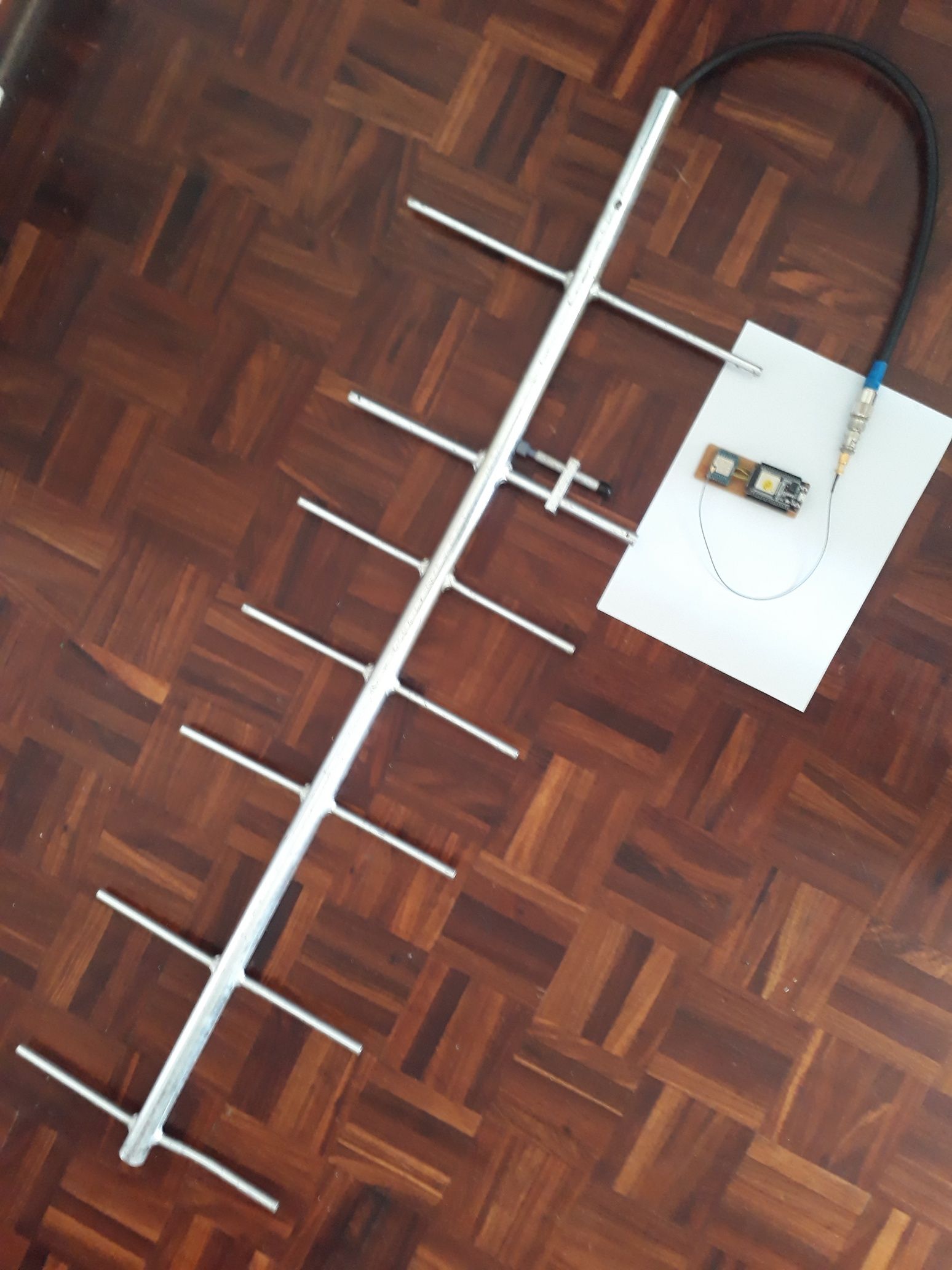

433 MHz ESP 32 MQTT Gateway with proper antenna

-

@Nca78 - Well, its been around 14-17dgr C today, so almost room temp. Strange

@Yveaux - hahaha, best answer! Saving uA!

-

@NeverDie sorry if it's a bit off topic, but I see that 10 pin ARM box connector you use in several of your designs, and I was wondering if it offers anything extra in addition to the regular 6 pin programming pins. I'm asking specifically because I want to try some of your nrf52832 designs, but would like to avoid spending extra money on special connectors and cables. Thanks!

-

@idanronen No, nothing extra. It just conveniently and transparently interfaces to the ribbon adapter cable used by the Nordic nrf52 dev kits for programming external nRF52 MCU's. If you want to roll-your-own, you can do away with most of the pins. I myself migrated to a smaller connector in later designs.

-

@NeverDie thanks for clarifying!

So for example in the mini breakout board (https://www.openhardware.io/view/471/Ebyte-nRF52832-Small-Breakout-Board) I could just align the 6 pads and use a standard 6 pin pogo programmer right?

-

@idanronen Yup. If you have more questions, you should probably ask them on a different thread than this one, as it's off topic here.

-

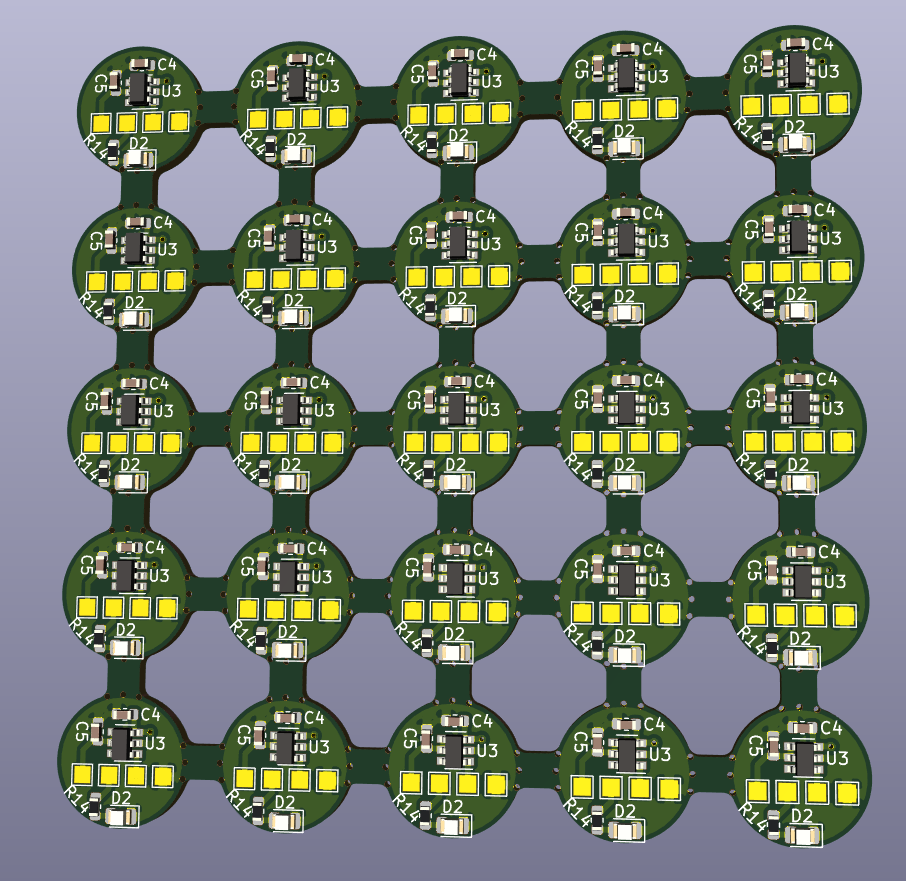

Offtopic in terms of mysensors platform, but somehow tangent to a home automation. I've made a batch of concrete switches/push buttons which are in this case simple buttons with led backlight and all the logic is located centrally in distribution box, based on KNX ABB module. But I am planning on making smarter and more complex version which could use Mysensors as its transport.

and a photo of insides of one of the prototypes at first stages of development

-

@monte Nice work! I love the looks of the concrete switches, do you have some links or useful information on how you did it.

I have a project of a doorbell that could use such a switch.Thanks!

-

@monte It's a real pleasure to see such professional looking design!

I'm curious though: the button in your teardown looks clear:

so how does it turn black and give the solar eclipse effect? I mean, I can see the 4 LED's that comprise the "sun," but how does the button (the "moon" in this analogy) go from clear to black?

-

@NeverDie tanks for describing it as "professional":)

The clear button on the last photo was one of prototypes as I've mentioned, frankly process of refining the button part to make it work as it should was the longest part of the development. Now it is made in two stages: at first the transparent acrylic part is cut on laser machine, then it placed into a mold with curing mix of resin and concrete, which makes it's black top layer that blocks the light from below. 3mm acrylic base and 2mm resin top layer.

But I have to say that next batches will be made the other way, which is already in my mind:)@MatiasV thanks! Well, I coluld describe the whole process of making, but it requires a lot of work like making propper mold, the process of trial and error while trying to achieve consistant pour and at last the complex process of making a button that would work without sticking.

Frankly I don't think it's worth time and effort if you plan tho do only one switch for yourself. But I can give you hints about concrete mixture and other stuff, if you're just interested in it's concrete part.

-

@monte Now that you've mastered the medium you can cast your own tile to texture a wall:

I met a local architect who did such a thing for her own home. She only had to create a handful of different molds, and then random placement gave the illusion of more than that. Maybe they could be secret panels for hiding all your home automation control equipment behind. High WAF that would be.

-

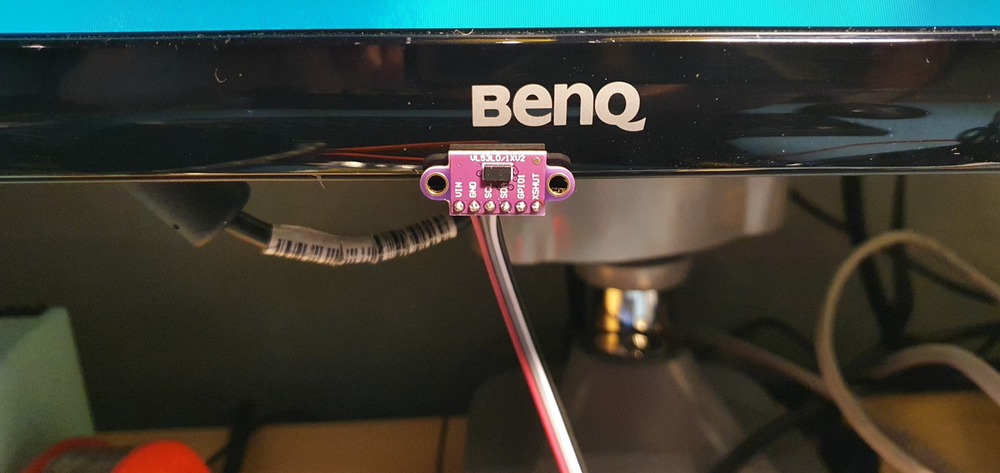

Just made a fun (and useful) sensor / device, using a arduino pro-micro (atmega32u4), and VL53L01 TOF distance sensor.

It's an auto lock device for my pc, I have mounted the VL53L01 to the bottom of my center monitor, and then have it measure the distance to my body, whenever it exceeds 1m (or is out of range), I increase a counter. When the counter reaches 20 (seconds) I send keypress GUI+L, to lock the screen (works equally well on ubuntu and windows).

When I return to the desk again, it is detected by the arduino (distance is now under 1m again). And it then sends CTRL+ALT+DEL to start login procedure.

The arduino sketch is available on https://gist.github.com/tbowmo/7e9934796d47566dc09e7b3bc5b2f208

next project should probably be to find a better enclosure, and build one for when I return to the office in a month or two, when the corona lockdown is lifted more

-

I finished my fully functional panel for domoticz, using Display Nextion ...

I don't know where to post, sorry !!! lol

-

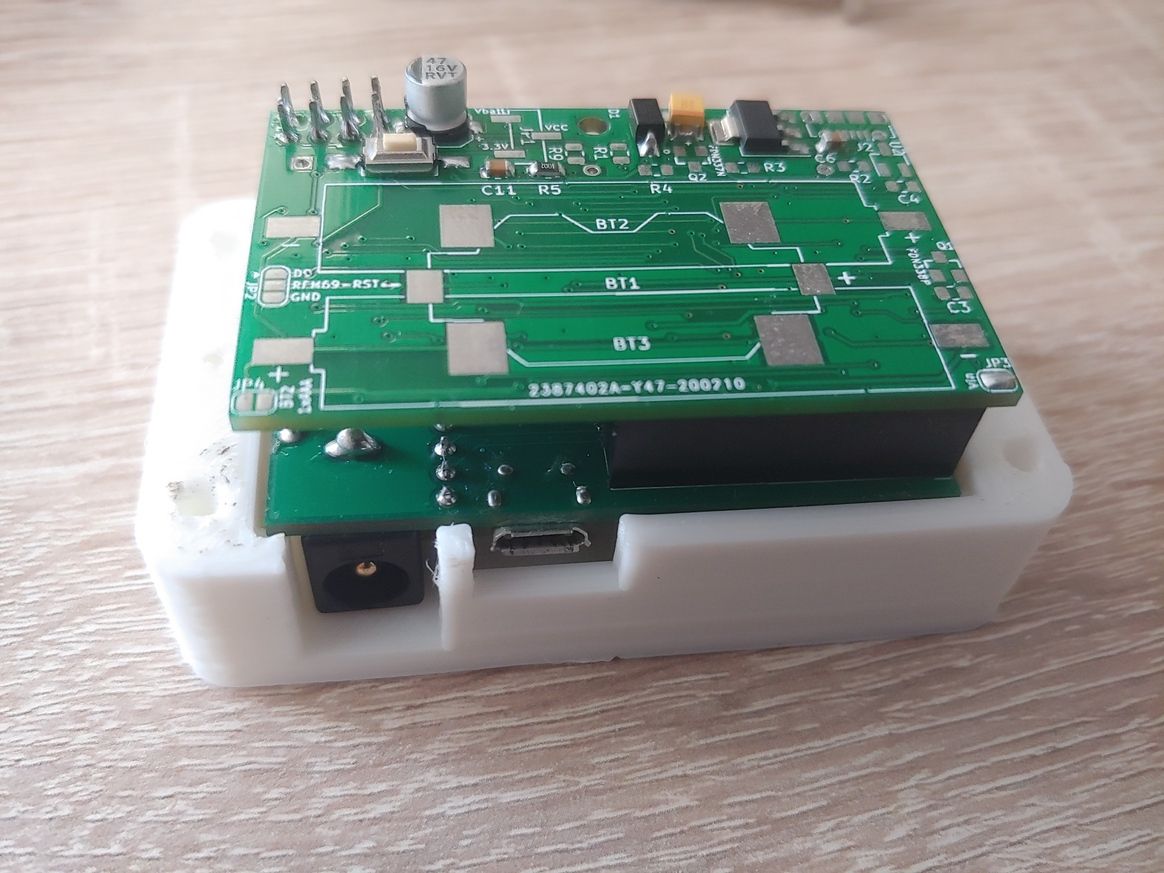

Interupted by our first "Summer" lightning, but in replacing my old Rfm69 gateway (old one works, but uses a ftdi adapter for Serial communication and i have another need for the adapter). In the same time im taking up signing. The node has a atsha chip but I never used it properly which im going to try to fix.

-

Hi guys,

today I have finished the 3d printable case of the d-diot hub.

The hub basically is a Raspberry Pi 3 with the d-diot board (see this topic) that offers the following functionalities:

-

IR Gateway (blaster and receiver) to control every device that has a dummy infrared remote.

-

433 Mhz Gateway with the RFLink firmware running on the on-board ATMega2560 microcontroller

-

Dual MySensors Gateway: NRF24 (2.4 Ghz) and RFM69 (868 Mhz).

-

Latch circuit to power-on and safely power-off your Pi with a simple button press.

-

SSD1306 I2C Oled display controllable in Home Assistant

-

Radio activity LEDs for IR and Mysensors gateways

-

Nice and powerful web interface thanks to Home Assistant

-

Easy setup and configuration with the d-diot image

If someone is interested, here the detailed build instructions.

-

-

@NeverDie My experience shows that the Chinese sensors that are sold on Aliexpress have a low quality printed circuit Board. When used outdoors, they may deteriorate within 1-2 seasons. Inside the house, in a flower pot, the service life is much longer. As for such sensors developed independently, the quality of printed circuit boards that are ordered through the services of jlcpcb, pcbway... very high.

-

@NeverDie I personally took a bottle of nail polish and coated every sensor I had. I had a hunch that moisture seeping might affect the capacitive sensors so I took precautions. They've lasted a year now with no sign of deteriorating.

-

Thanks! Earlier in 2020 I started a shoot-out of different weatherproofing coatings, and I can already see that Spray Max 680061 is by far performing the best out of all the hard coatings that I tried: https://www.spraymax.com/en/products/product/clear-coats-and-spot-blender/2k-clear-coat/ So, for that reason, I suspect it would also perform very well at moisture proofing capacitive PCB soil probes.

-

I built a picoamp current source and tested a picoammeter that I built from Gyro's design that was posted on the EEVblog forum. It turns out it can measure even single digit picoamps to an accuracy of less than a picoamp (i.e. less than one trillionth of an amp!)

-

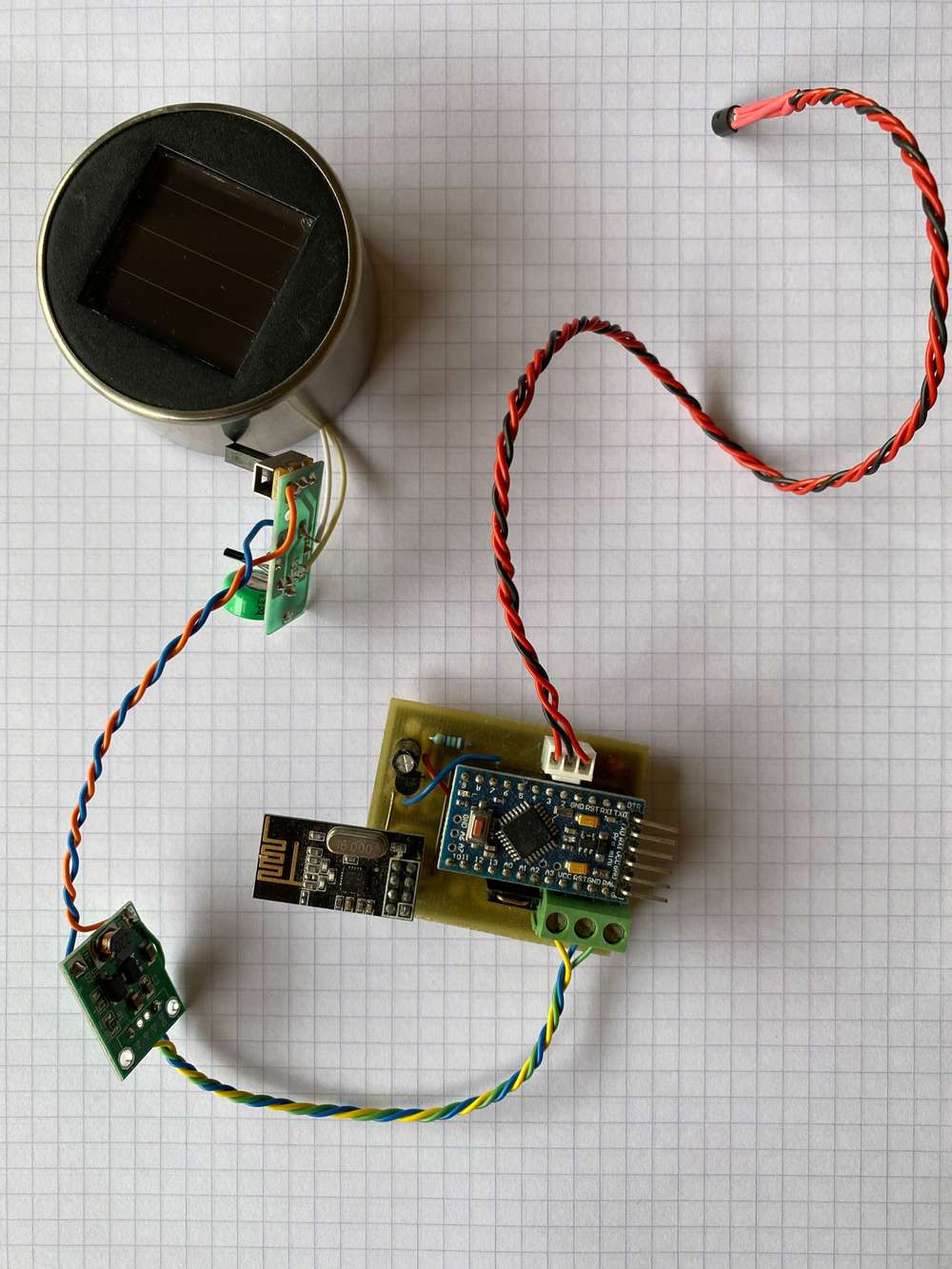

Today I finally found some time to put a few modules together.

A cheap solar cell (€1.35 a piece) with recharcheable battery which feeds via a step-up converter (€0.70 /pc) a pro-mini (5VDC). The DS18B20 is read every 5 minutes.

Now I’m Interested how long this sensor will do its job.

-

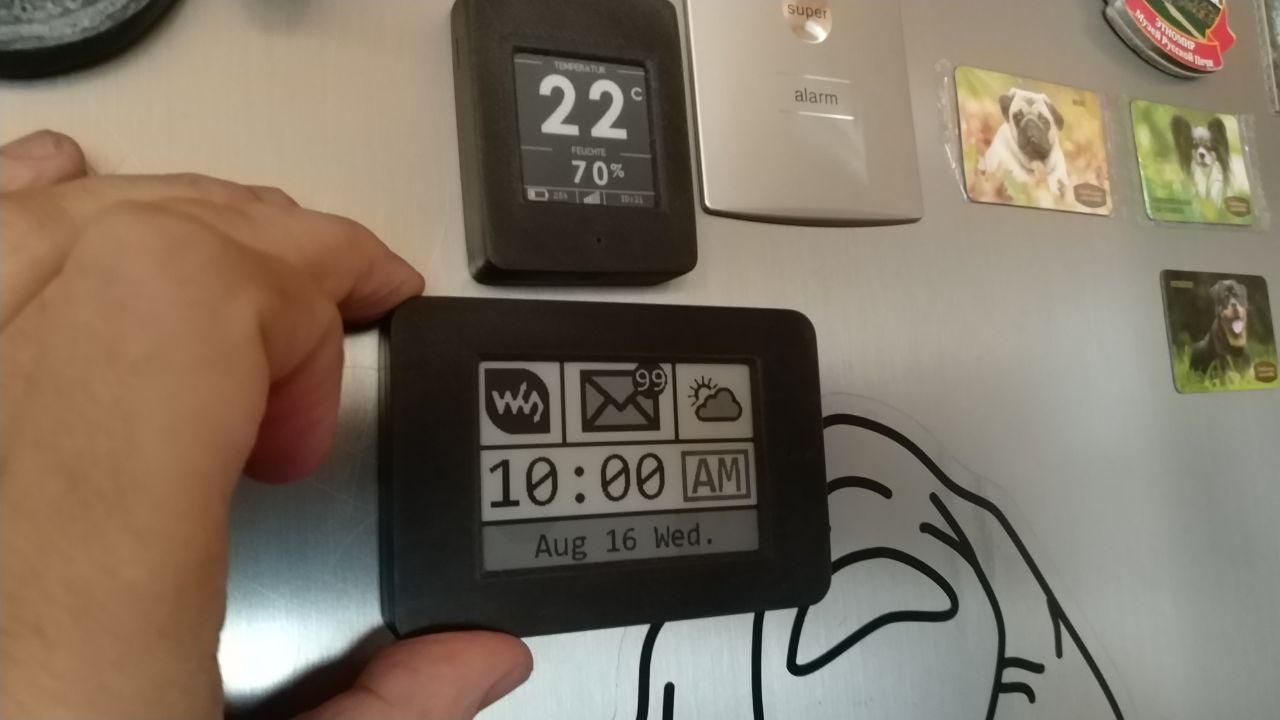

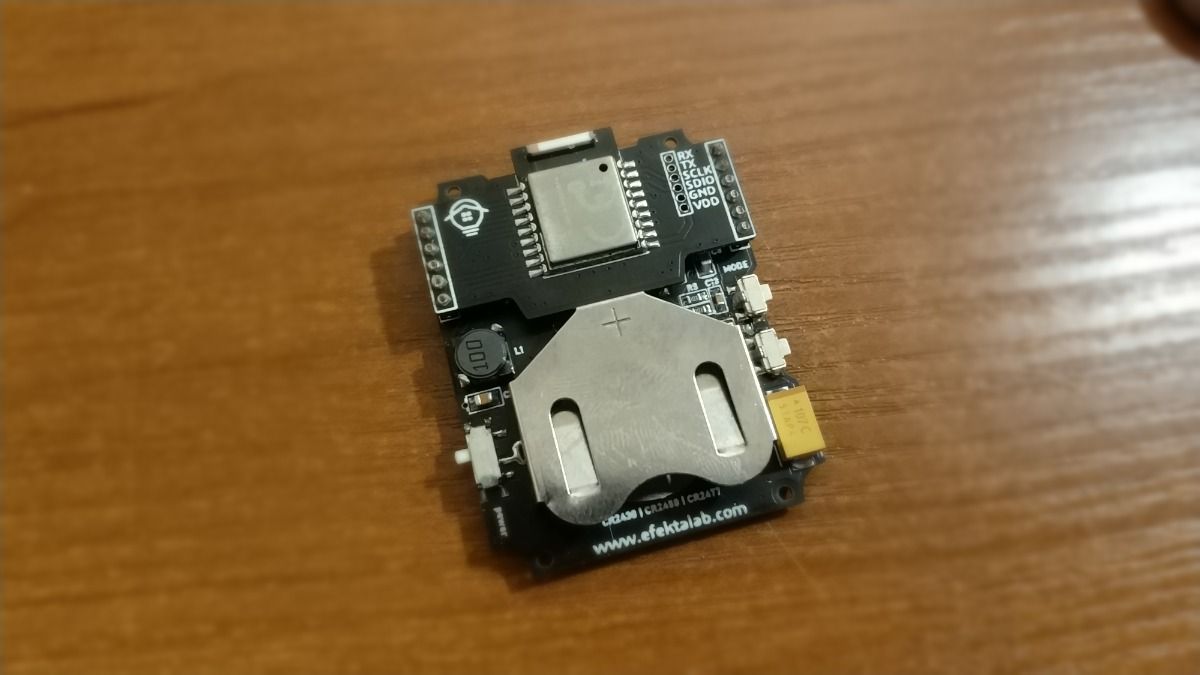

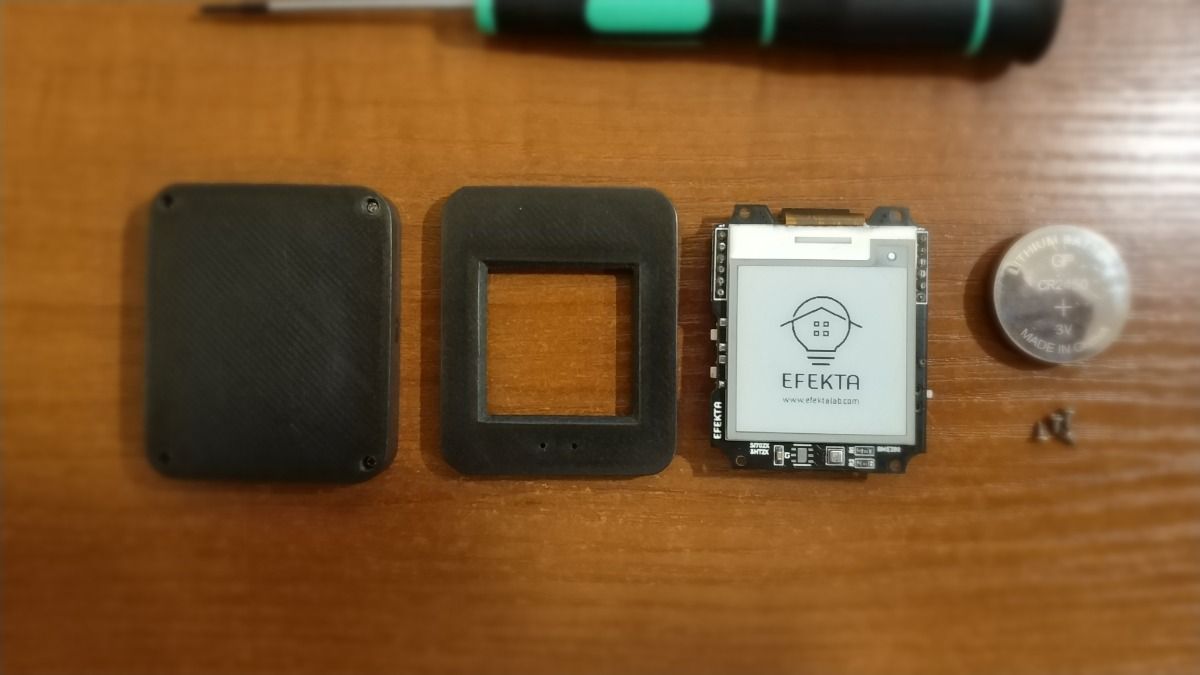

Hi, everybody. Yesterday I made a case for my new device with an e-ink display 2.7. the Case turned out to be quite thin. The dimensions of the device in the case are 86.5 mm X 59.5 mm X 11.5 mm. The new device is a continuation of the project - https://www.openhardware.io/view/629/EFEKTA-TempandHum-sensorver-nRF52-E-Ink-display

-

Man, things are starting to look very professional around here.

-

Made a prototype board for writing a software for one of my projects. Goal was to have everything needed on a board no bigger then a 1.54" eink display, and to make it doable at home by my own.

I was gladly surprised that everything worked (after a sleepless night of fighting through-layer connections, and soldering/desoldering FPC connectors) The only I've messed up is order of connector pins, so the display is connected the wrong way...

The only I've messed up is order of connector pins, so the display is connected the wrong way...

It also has pads for SHT30 sensor so it may be somehow useful after development is done.

-

@monte said in What did you build today (Pictures) ?:

FPC

Excellent handwork. I also dealt with such FPC conectors :), here are the correct FPC conectors - https://aliexpress.ru/item/32794813863.html

-

@berkseo Thanks!

Link doesn't open. I have the right ones, I've just messed up PCB layout. Somehow pins on the board goes in the wrong direction, so the most left pin is #24 instead of #1

-

@monte fixed the link, html.... not htm

-

@monte By the way, this version of screens is discontinued, it is better to develop software for new versions

-

@berkseo thanks for mentioning that. But as I understand the change in software would be just including another header file, if I'm using GxEPD library. There is a mention on github that there is GDEH0154D67 model as a replacement for GDEP015OC. Or do you mean that they are discontinuing 1.54" displays completely?

-

@monte said in What did you build today (Pictures) ?:

Or do you mean that they are discontinuing 1.54" displays completely?

Yes, I mean that these displays are no longer produced. And it is better to focus on new ones.

-

@berkseo well, that's a shame. They are the perfect size for my purpose. I guess I need to stock few of them, while I can

Thanks for the tip!

Thanks for the tip!

-

@berkseo said in What did you build today (Pictures) ?:

@monte said in What did you build today (Pictures) ?:

Or do you mean that they are discontinuing 1.54" displays completely?

Yes, I mean that these displays are no longer produced. And it is better to focus on new ones.

Just to clear up a potential misunderstanding: The 1.54" EPDs aren't going to vanish anytime soon. Only the GDEP015OC1 has been discontinued and the GDEH0154D67 may follow, too at some point.

But Dalian Good Display has just launched the GDEW0154M09 this month, which seems to be the successor of the GDEH0154D67 at first sight. There is also the GDEW0154M10, which supposedly has a better contrast due to a new manufacturing process. Waveshare seems to be still selling their version of the GDEH0154D67, but not any of the new ones.

I don't think you need to hoard them like other poeple hoard their live-long stock of toilet paper these days.

-

My super simple NRF51 touch buttons. I mostly use these to toggle overhead lights that I've converted to Tasmota.

-

@ncollins Elegant. Does it talk to a gateway, which then talks to your Tasmota, or does it somehow talk directly to the Tasmota? So many things now have Bluetooth as part of them that the possibility of direct communication sometimes exists.

-

@NeverDie Buttons -> Mysensors Gateway -> OpenHab Rules -> Tasmota Switches / Outlets / Extension cords.

I am tempted to explore the BLE route. It seems to support a majority of my sensor use cases, I like the idea of standardizing on the GATT protocol, and there are already a ton of tools and connectors in place.

-

@ncollins And this is my simple capacitive button, just a button:). Beginning of this story was like this:... once I bought a Chinese capacitive button and was very upset with the quality...

-

-

@berkseo said in What did you build today (Pictures) ?:

Сapacitive touch button - V1.0 – 02:09

— Andrew EfektaSBLooks really good! I like the LED bridge.

-

@tbowmo said in What did you build today (Pictures) ?:

atmega32u4

Next step: build an entire keyboard and flash QMK to it!

Nice project, I thought about something similar but to operate a fan, which is way harder than communicating with a computer, I should have started with that.

Very little nice sensor that one...

-

@monte Where do you buy that e-ink displays? they look awesome

-

@berkseo nice! Just today, I've ordered something similar but with an led mounted sideway, to make more diffused glow of the opaque resin that will cover these:

@Danielo-Rodríguez I've bought mine on aliexpress, but you can find them at several different places. They are produced by a company named Good Display (Dalian Good Display Co., Ltd to be precise). They have different sizes and colors with different price and performace too. Also they are sold by Waveshare, but the displays are the same, I believe.

-

The other day I received PCB of a long-awaited project. Yesterday and today, I soldered the device, designed and printed the case of the device. It works, wow!!!

-

I'm surprised no one here has built anything Covid19 related--even something as basic as a handwashing timer or something like that. I, for one, am tired of singing songs to time myself, and getting kids to handwash for the full recommended duration is, well, something I'd rather let automation enforce instead of me!

-

@NeverDie From these things, which are in the photo above, can make an informant COVID-19. Show the trend, the number of infected people to date in your location, and so on.

-

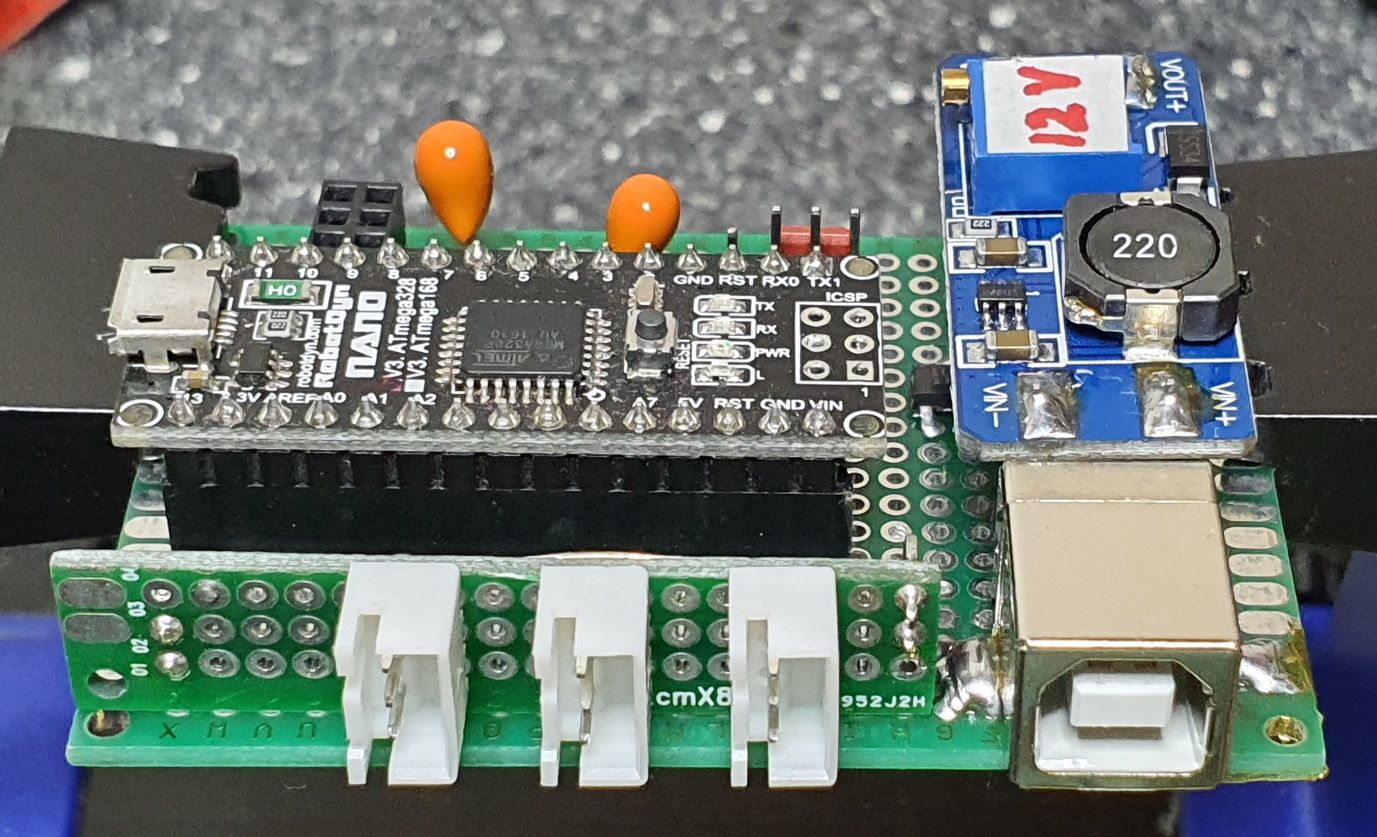

A MySensor'ed temperature controller for my utility cabinet, which runs too hot due to all the electronics in there (cable modem, router, switch, etc.)

In its current version it is able to control a 12V 120mm PWM fan, and reads the temperature from 3 DS18B20 temp sensors (inlet, 'ambient' and router).

Later I might add a temperature controller to keep the ambient temperature stable at a a few degrees above inlet, by controlling the fan's dutycycle.As all sensors in my utility cabinet are powered from 5V USB, I used a step-up converter to generate the 12V required by the fan.

After soldering everything together I wasn't happy with the orientation of the JST headers for the temp sensors, so a small PCB was added to mount them under 90 degrees:

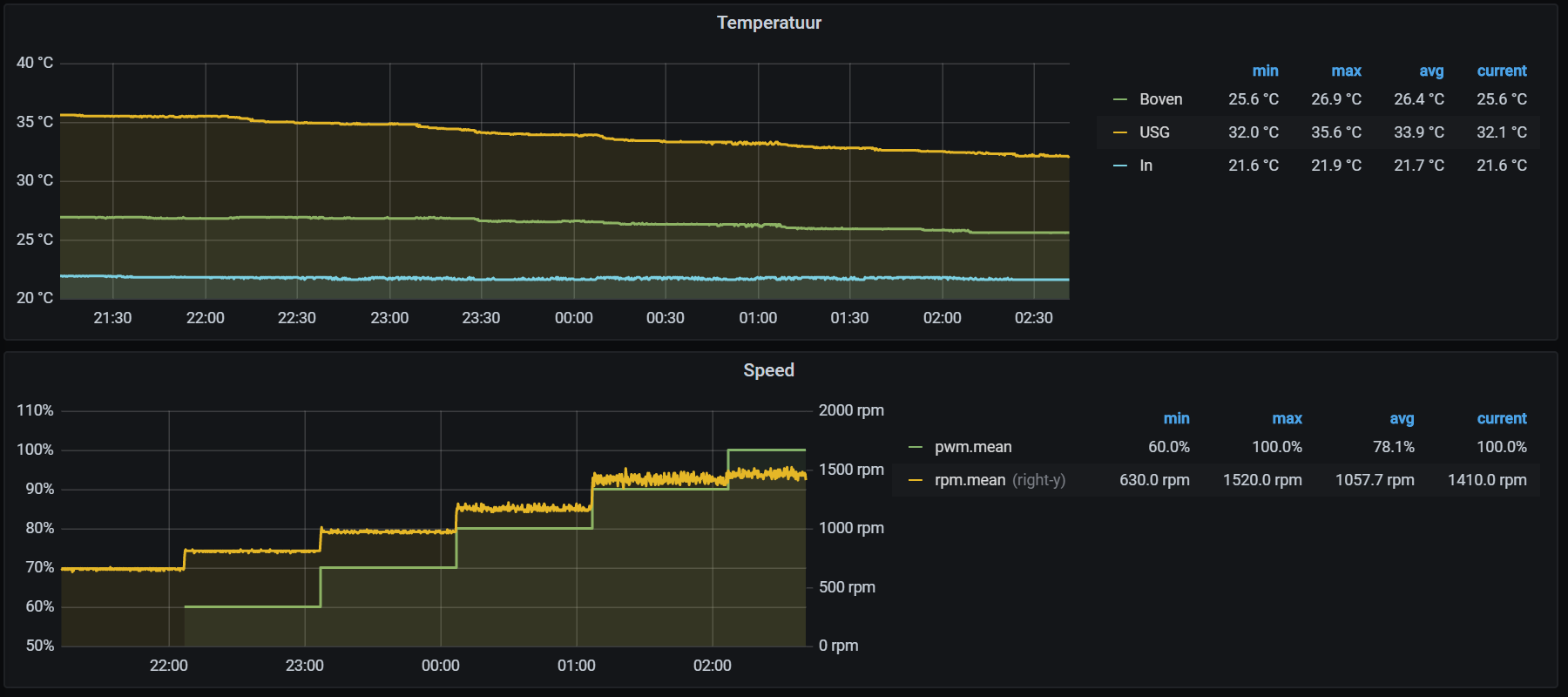

All data and control is routed to Node-red, stored in InfluxDB and graphed in Grafana:

You can see the temperature of the router ('USG') go down with increasing fan rotational speed (lower chart, 'rpm.mean').

Temperature decrease is not as big as I hoped for, so I might need to install a fan with a bigger airflow.

-

My new gateway with leds for state and the only node I have: A wireless arcade button controller

-

@Danielo-Rodríguez you might already be aware of this, but all that metal close to the nrf24 antenna will probably block some signal.

-

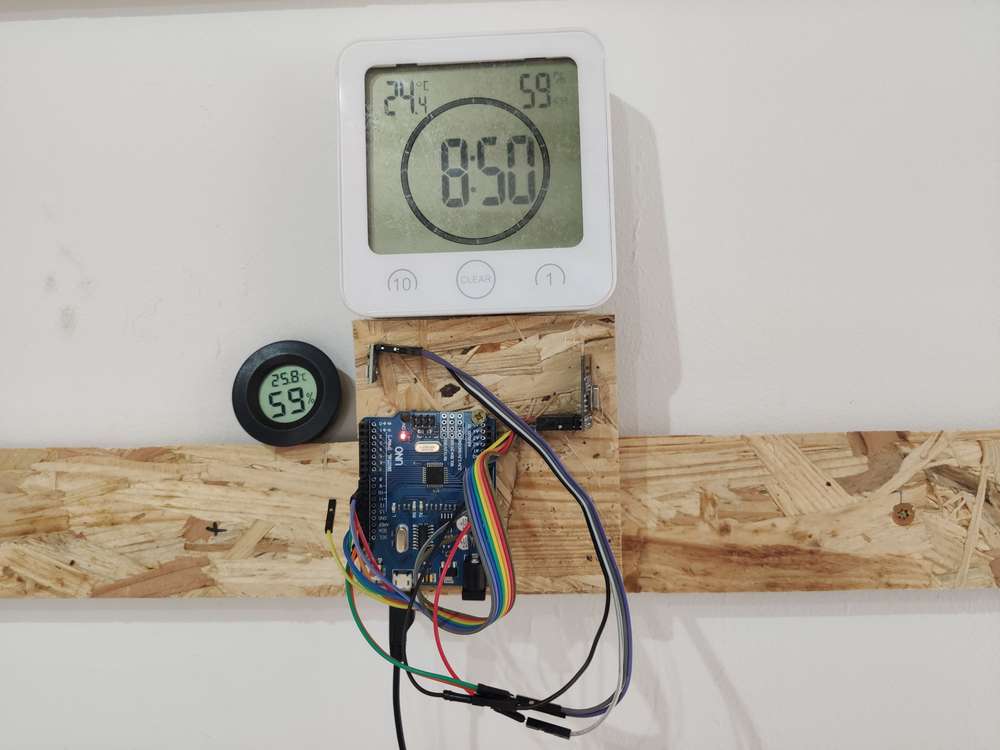

Well, it not really a build I plugged in wires, and copied code. Found a random usb charger and put it all in my workspace to be.

And I absolutely love this thing. Maximum of 3 hours work. I was having fun, so it could be more.

I considered that there could and should be a display on this thing, but not for now. I made this, because I have never experimented with temperature sensors and I just received a few. Now I can just see what happens with the temperature in there.

sensor is a AHT10 temperature and humidity.

http://www.aosong.com/m/en/products-40.html

I used this library: https://github.com/enjoyneering/AHT10

I repurposed Hek's DHT code, and swapped the readings with the AHT's

shed before

workspace after but still filling it.

-

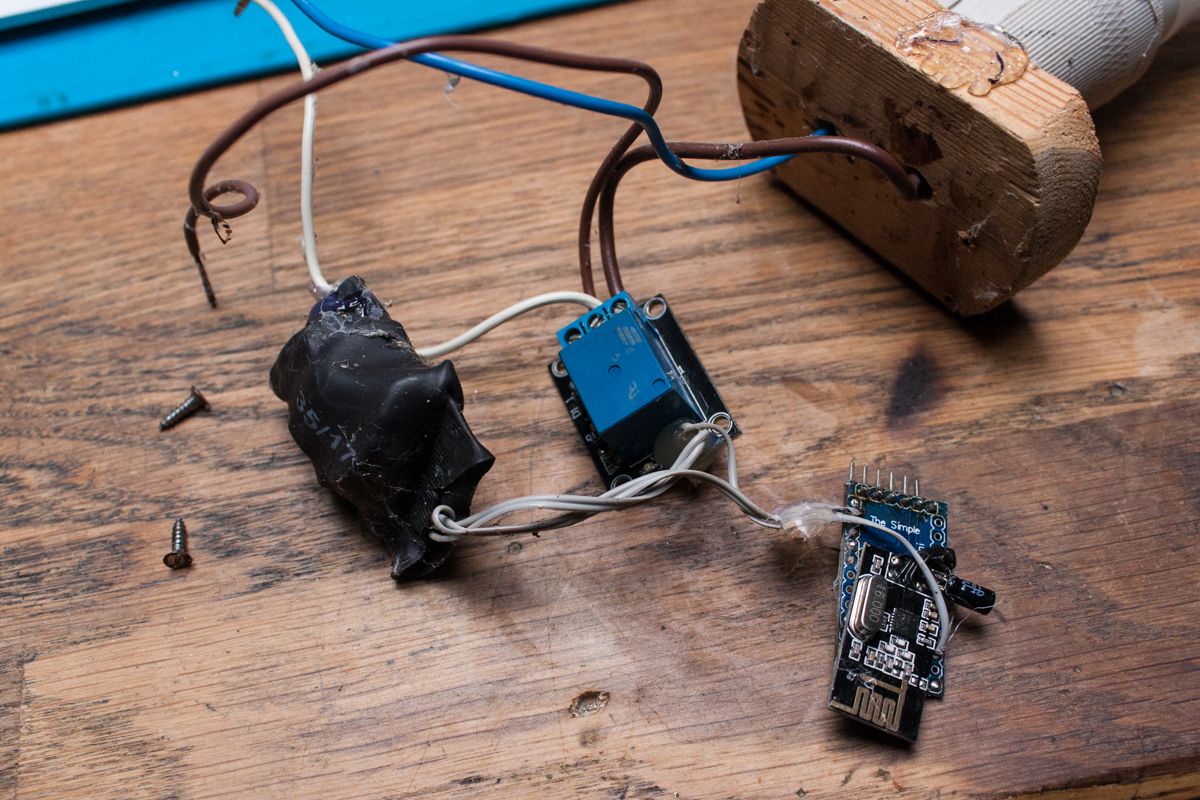

Today I've finally swapped my outdoor relay node with something descent.

This was my very first mysensors node that I've built when I was only starting to mess with arduino, probably around four years ago.

This board uses cheap 5v power supply and an amplified version of NRF24 module from Ebyte. It supposed to be poured with silicone ore resin, but I am yet to find suitable box, the size of this board appeared to be bigger then most of such cases designed for compound pouring. But I'm planning on making next version, with non-isolated power supply, which will help to achieve smaller size.

-

My new project of a temperature and humidity sensor with an electronic ink display 1.02 Inch ( GDEW0102T4 ), very low power consumption, very small device.

-

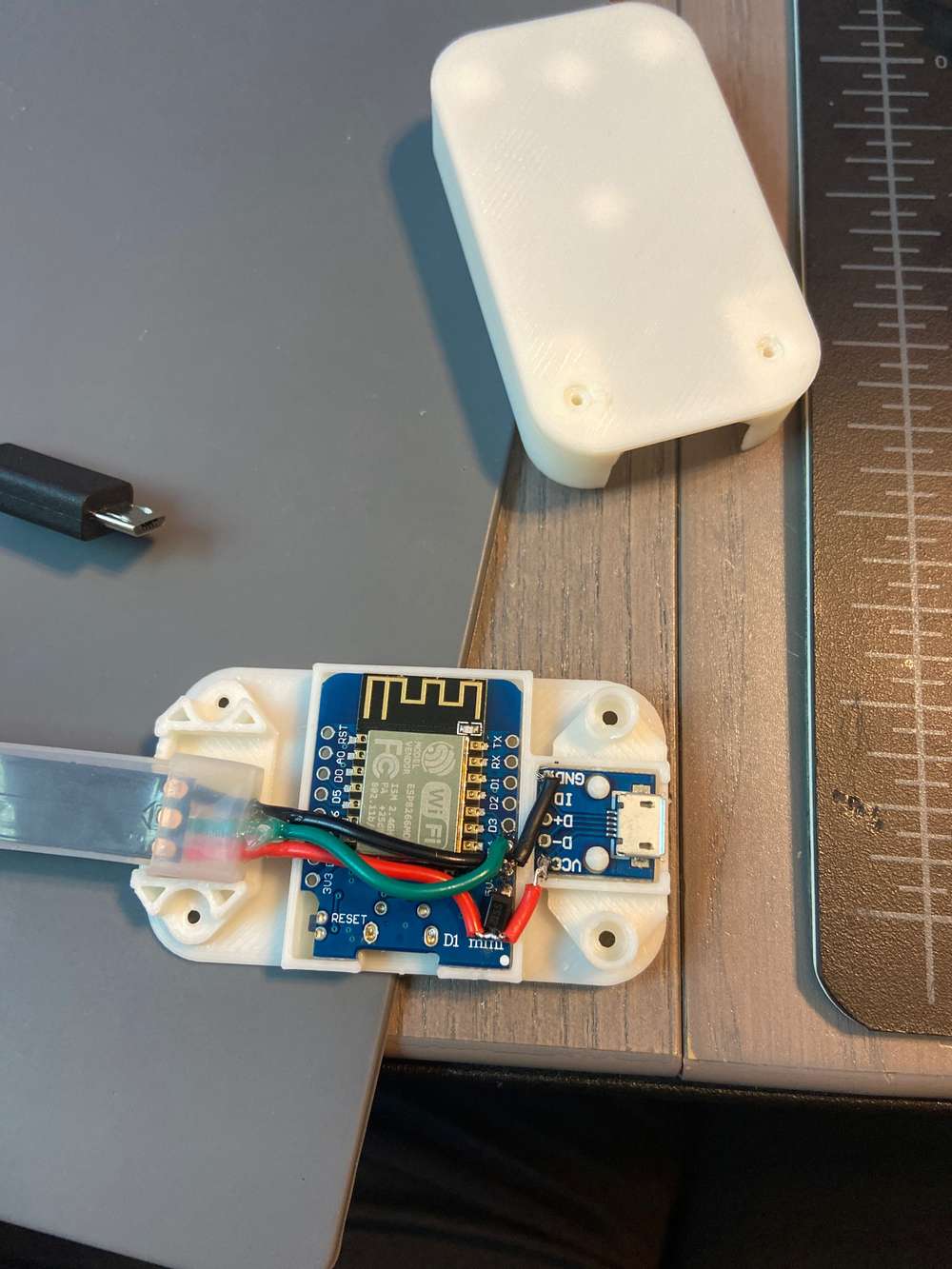

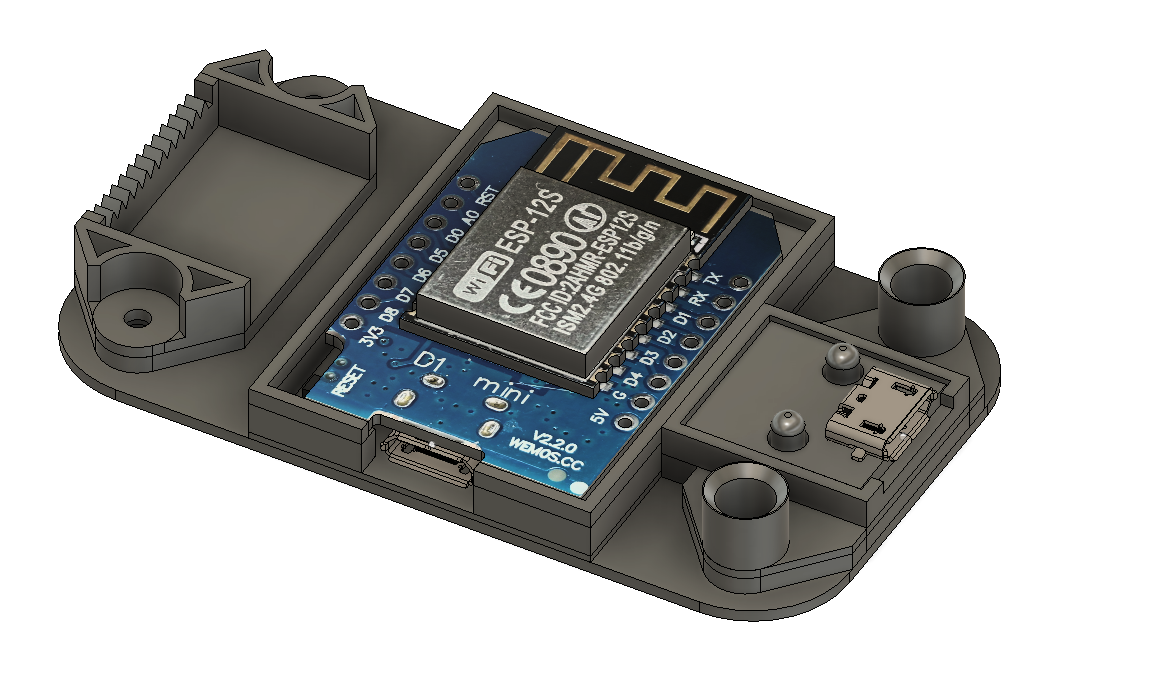

USB + ESP8266 adapter for W2812B LED strip.

Well, this is actually a Tasmota + Openhab build, but could easily be MySensors.

Also worth noting, this 5m 150 led strip draws too much current to reliably use with a USB wall adapter.

-

Very nice renderings.

W2812B uses about 50mA at full brightness, so you'd need a power supply that can deliver 7,500mA if you run the entire strip at maximum.

-

@mfalkvidd Yeah, I realize I can only use a portion of the strip, or keep it very dim. I actually bought this with the hopes of flashing with Tuya Convert, but turns out they switched to non ESP modules. So, I figured I would make my own.

-

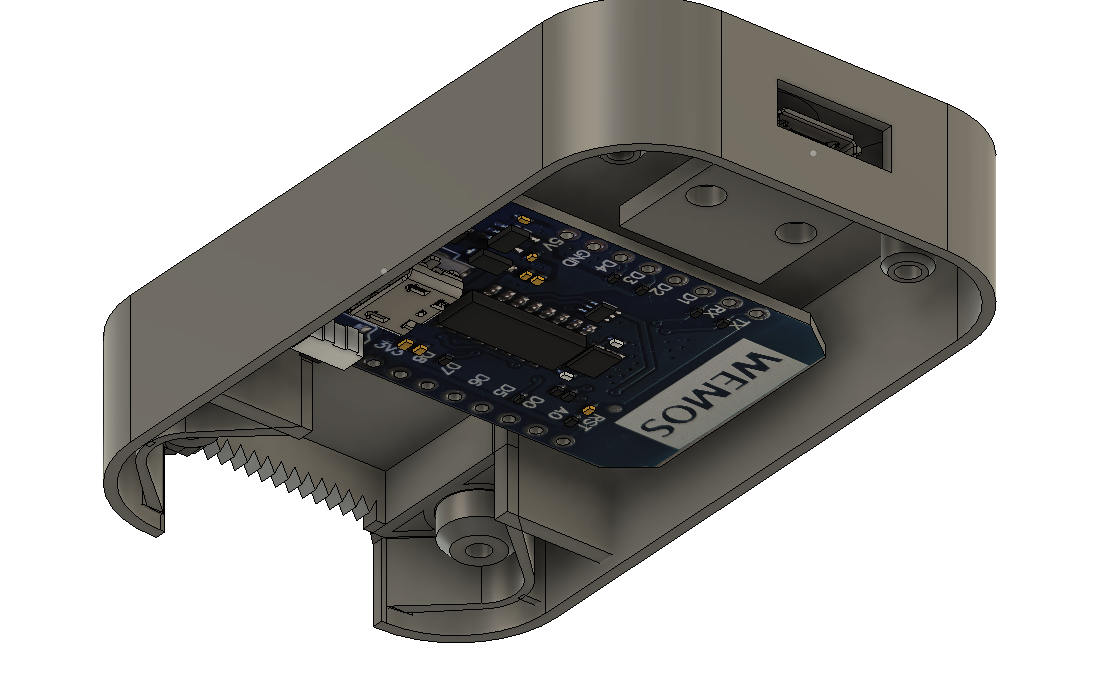

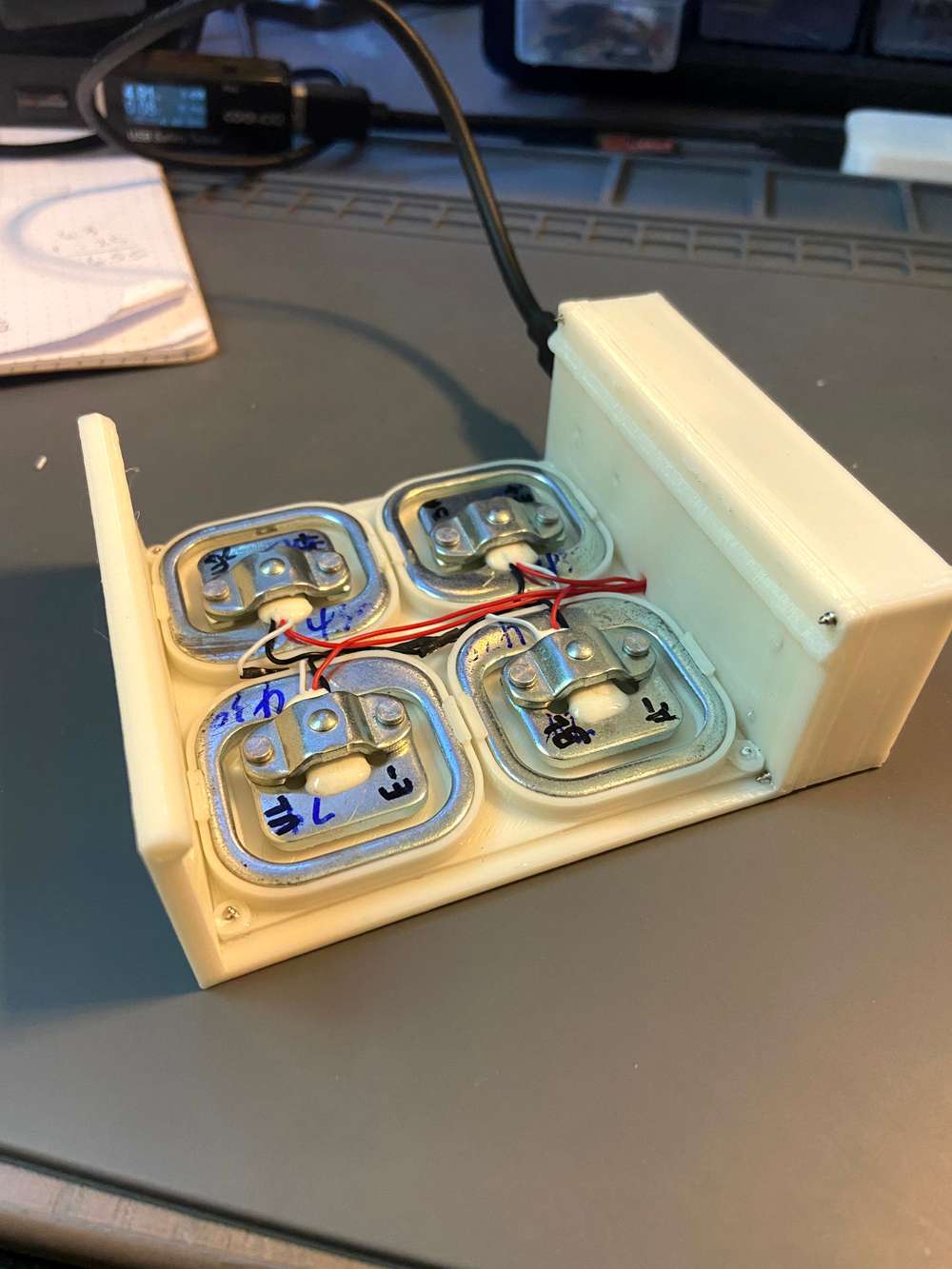

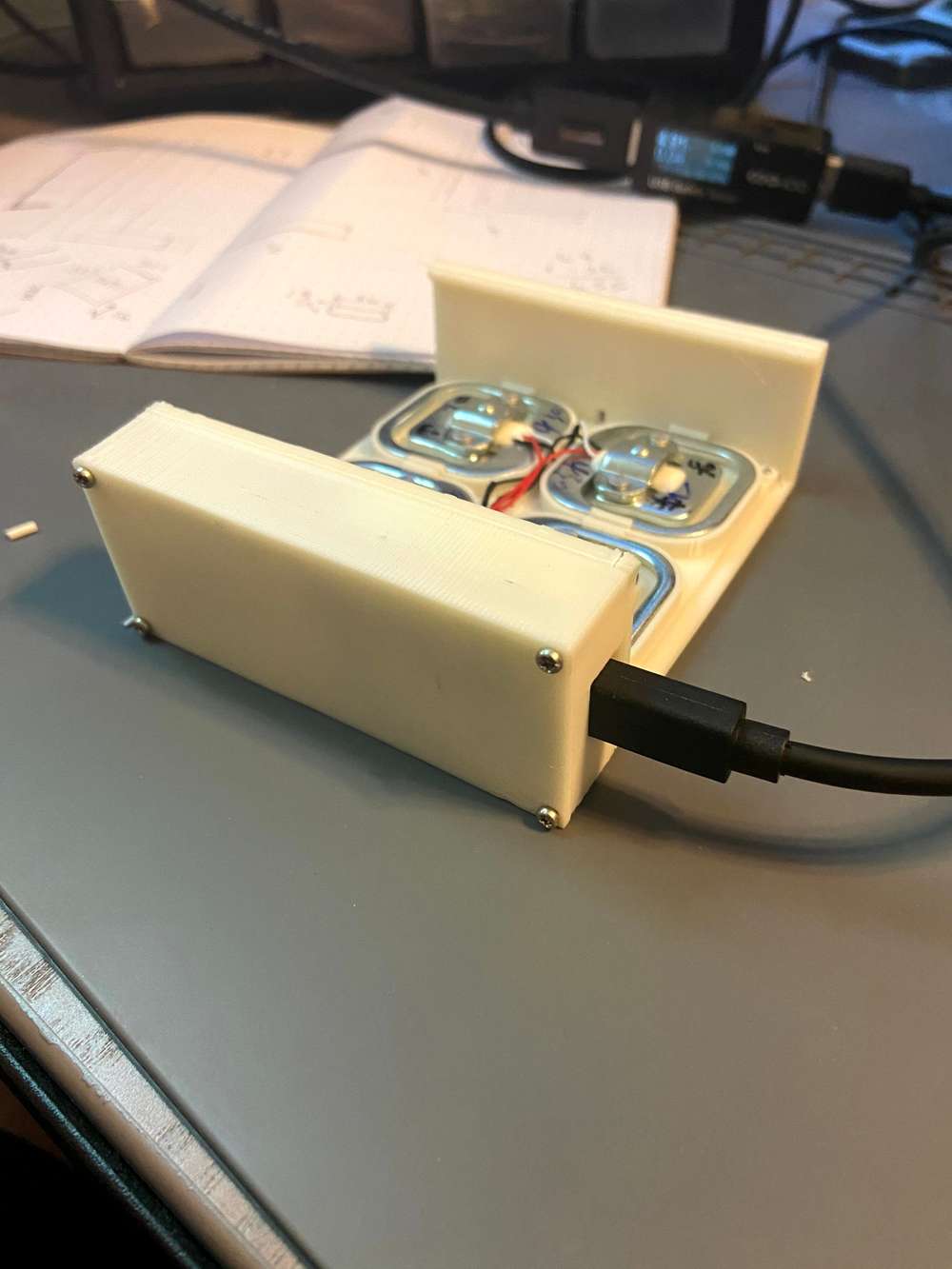

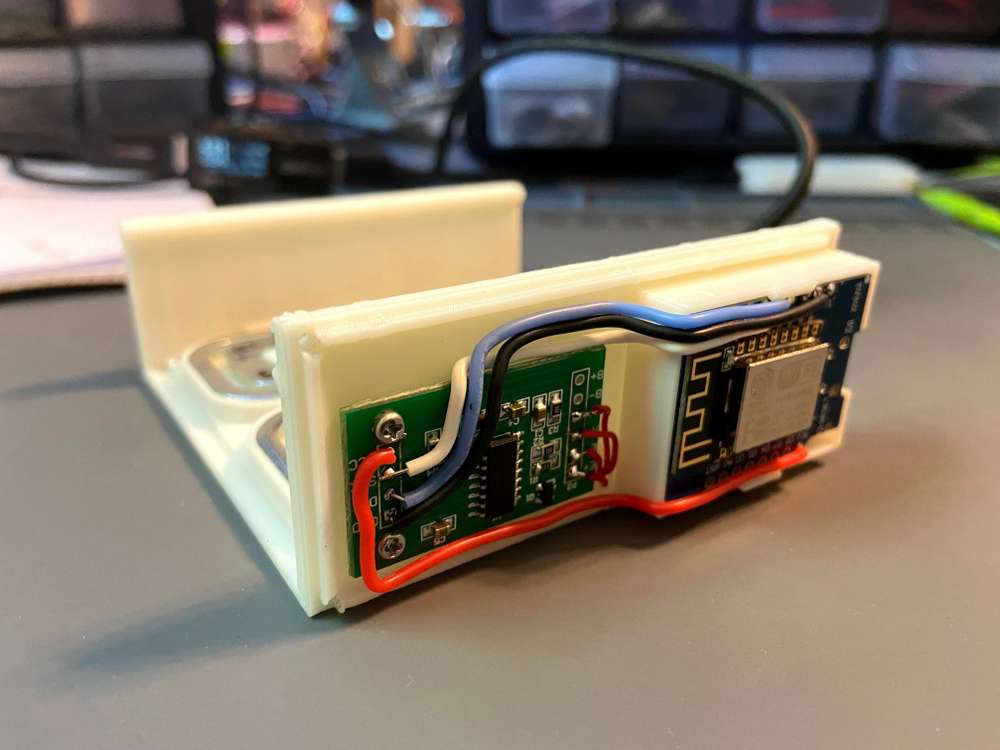

A bed occupancy sensor. 4 50kg load cells, an HX711, and a Wemos D1 to make a wifi scale that rests on a bed slat under the boxspring.

Given the placement and weight distribution it doesn't turn the bed into a huge bath scale, but definitely accurate enough to use the deltas to estimate if there is someone in the bed. I can also tell when our 12lb (5.5kg) dog is on the bed.

I have rules in openhab to turn the overhead fan on and off. Also disables some TTS notifications if somebody is in bed.

-

thanks to assistance of some of the people here i now have up and running a front gate controller for my double front gates (Solar powered)

now have a node that monitors the batteries, knows if the gate is open or closed and has a relay for activating the gate

-

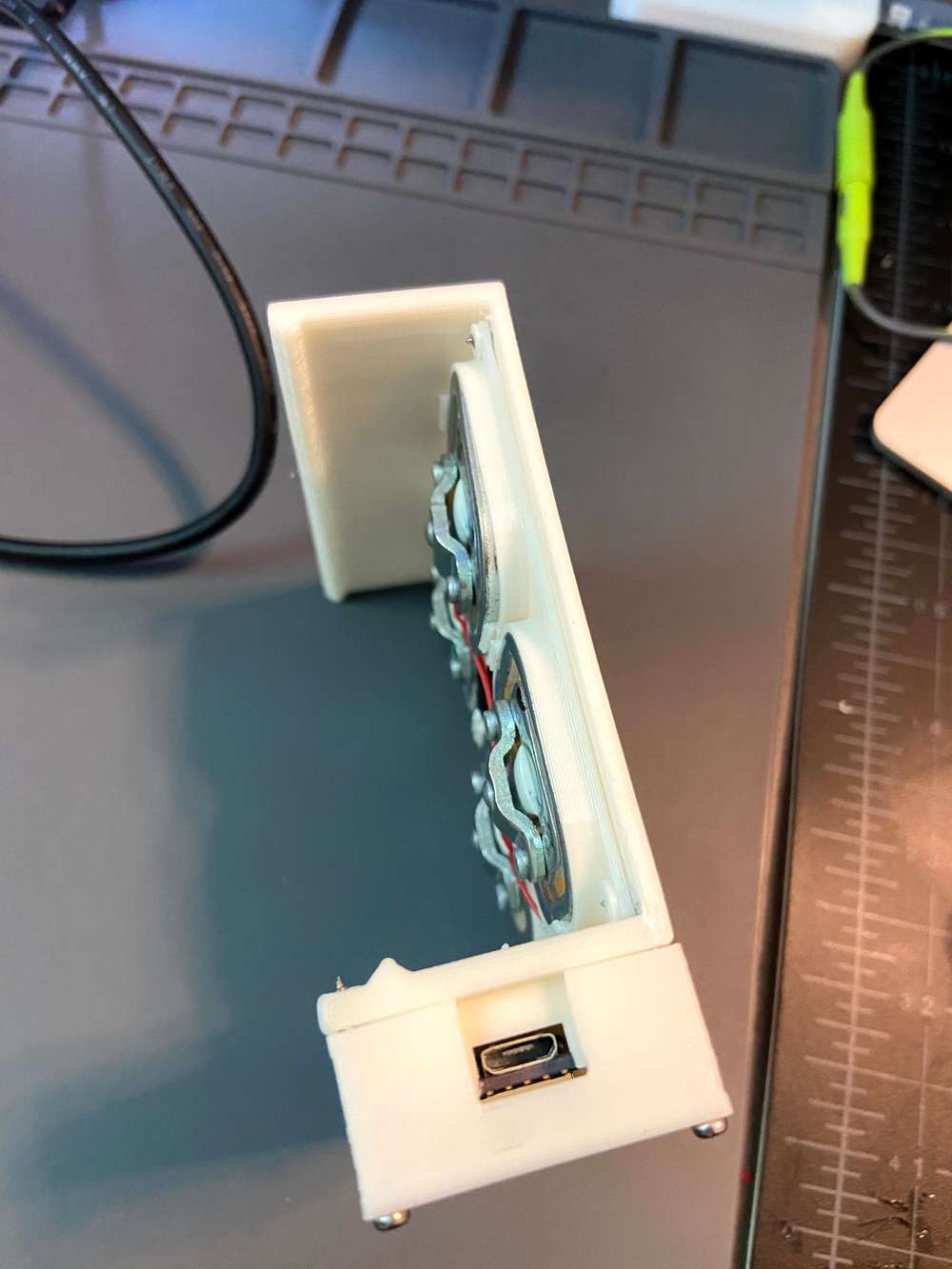

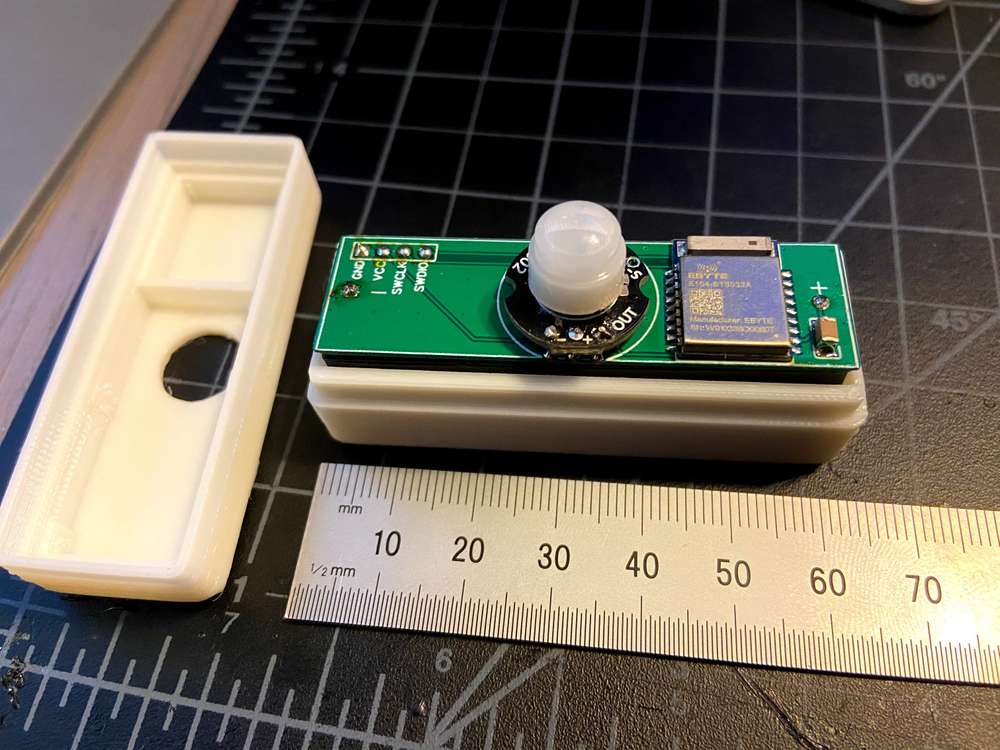

Compact, simple NRF52 motion sensor

Ebyte E104-BT5032A NRF52832 module

MH-SR602 Motion Sensor

LiFePO4 AA Battery

-

MYS PoE MQTT Gateway with 868Mhz LoRa radio in IP55 85mm x 85mm box

- arduino pro mini 3.3V clone

- SX1276 with spring antenna

- W5500 lite

- 5V 802.3at power over ethernet splitter (gutted)

- SPELSBERG IP55 box

-

My new arduino project wireless weather mini station with electronic ink display 2.9 inches (GDEH029A1), very low power consumption,compact size, housing with magnets. The device can use si7020 / 21, sht20 / 21, HTU20/21D or BME280 sensors. Use the MINEW MS50SFA RF module with nRF5210, nRF52811, nRF52832 chips, or the EBYTE E73 module with nRF52840 and nRF52833 chips. Soon to be available on openhardware.io

Video: DIY Mini Weather station with an electronic ink display 2.9 Inch ( GDEH029A1 )

-

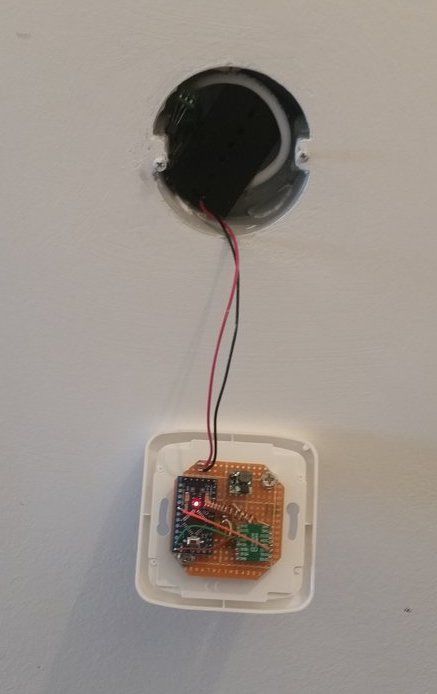

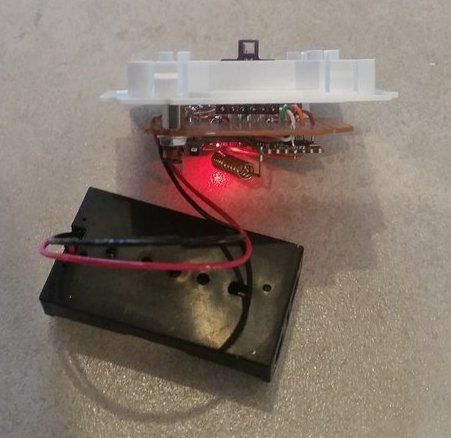

Prototype of room sensor for stardard electric box

- arduino pro mini 3.3V

- sx1276 radio

- bme680

- 2x1.5V AA battery holder

- battery measuring circuit according to https://www.mysensors.org/build/battery

- ABB Tango cover (drilled)

Cover is not fully closed to allow air circulation. But I would preffer some method to drill holes/grill into it - any tips to get decent looking result?

-

@tssk said in What did you build today (Pictures) ?:

any tips to get decent looking result?

- Drill at low RPM so you don't melt the plastic.

- If you're going to drill a bunch of holes to make a kind of grill, then preferably use a CNC (even a cheap one!) to drill them so that they don't look hodgepodge.

-

@tssk - really like your design! Well done.

-

@sundberg84 thanks for creating this thread btw. You got the 1st and 1001st post

-

Today im testing and outdoor node in a new PCB, but I had mixed csk and ce on the radio (it's a dual radio PCB).

-

@ncollins Just wondering: why 4 load cells per sensor instead of only one?

-

- At 50kg per cell, 4 would allow me to actually turn the bed into a huge scale if I decided to go down that route

- I don't believe these are intended to support a significant load for extended periods of time, they can permanently deflect. Given they always have the weight of a king size mattress + boxspring, I wanted to distribute that as much as possible

-

Current issue: outdoor nodes random stops/disappears - maybe during the time when its high humidity, so trying to try some different approaches i read - this multisensor is getting painted with clear nail polish. Also this PCB is a new board im testing, that Im hoping to be the base for my "final" home automation nodes. Still in dev. but great possibilities!

-

@sundberg84 Gaskets that are held under tight compression seem to work well at holding out moisture. I've seen a number of commercial products that rely on that and only that for in-ground radio sensors.

-

Here's an example from the new Flume (version 2) water meter monitor:

It gets strapped to your water meter, typically in the ground. All it has is one gasket to seal out everything. This particular box just snaps closed. No screws! Quite a difference from Version 1, which also used a gasket, but had 12 screws holding it snug.

-

@sundberg84 Really like the shape and look of the PCB! I hope I can achieve similar result for my room sensor.

-

And another of my completed projects is a mini weather station running on nRF52832 and nRF52840, you can install bme280 or si7021, htu21d. Powered by a single cr2450 battery. As always soon to be on openhardware.io

Video: https://youtu.be/HNjYtKyh8zo

-

@berkseo By calling it a mini weather station now you'll need to add an anemometer and rain gauge...

-

@NeverDie Sorry, I didn't know there were rules like that now :), then it would just be a temperature, humidity and pressure gauge with weather forecasting, okay?

-

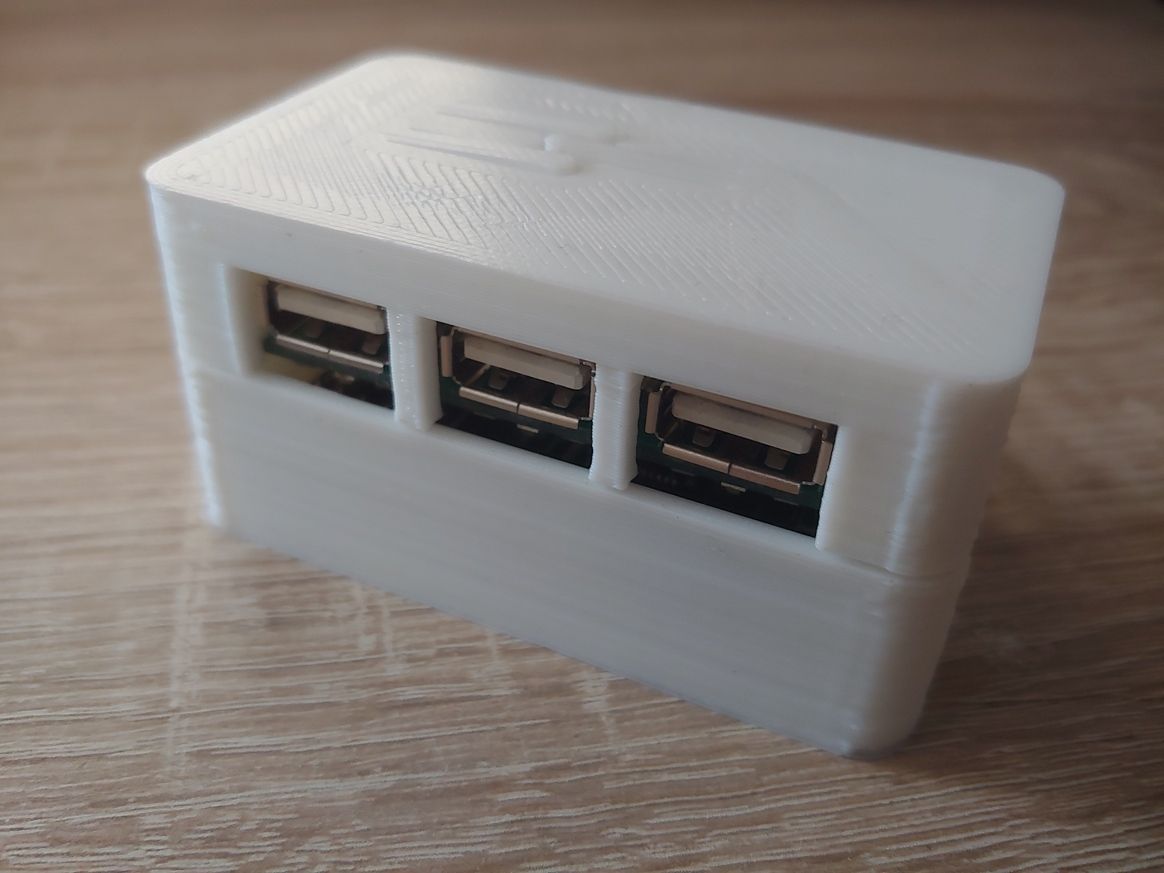

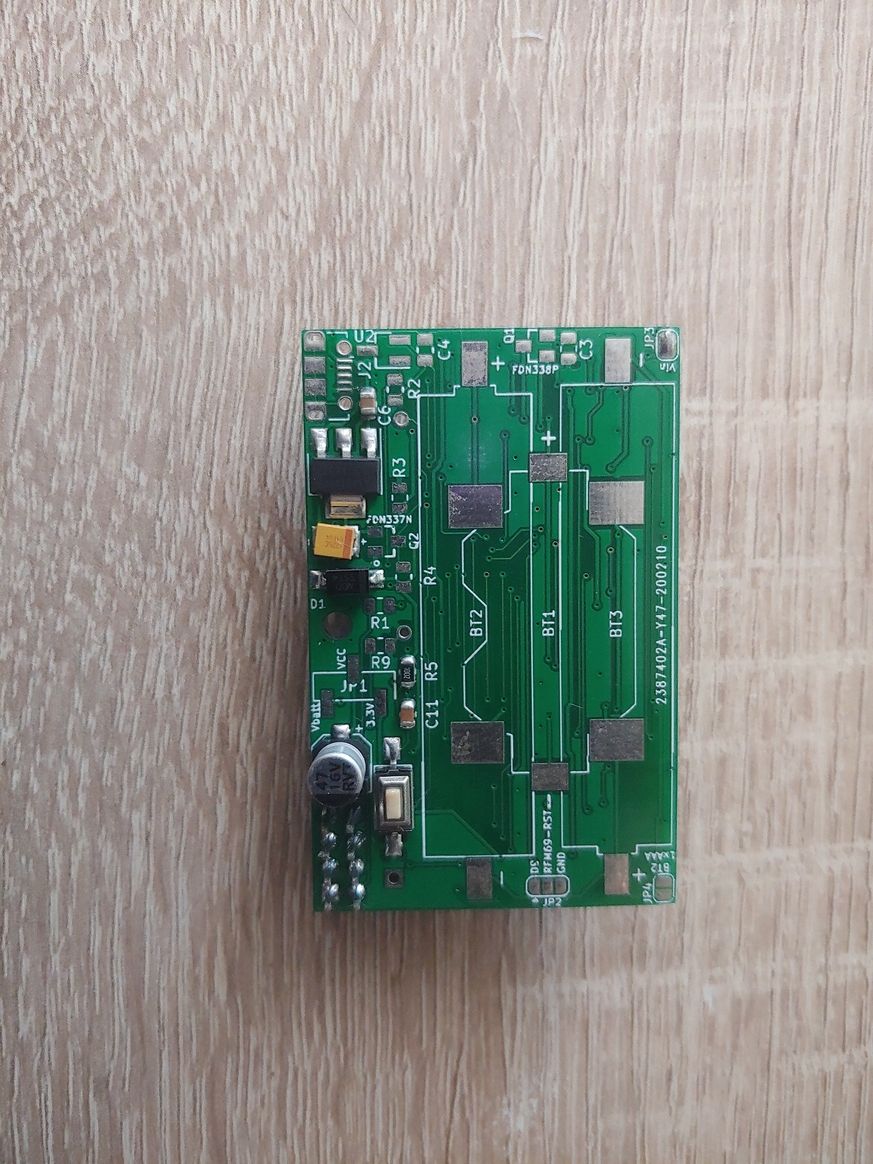

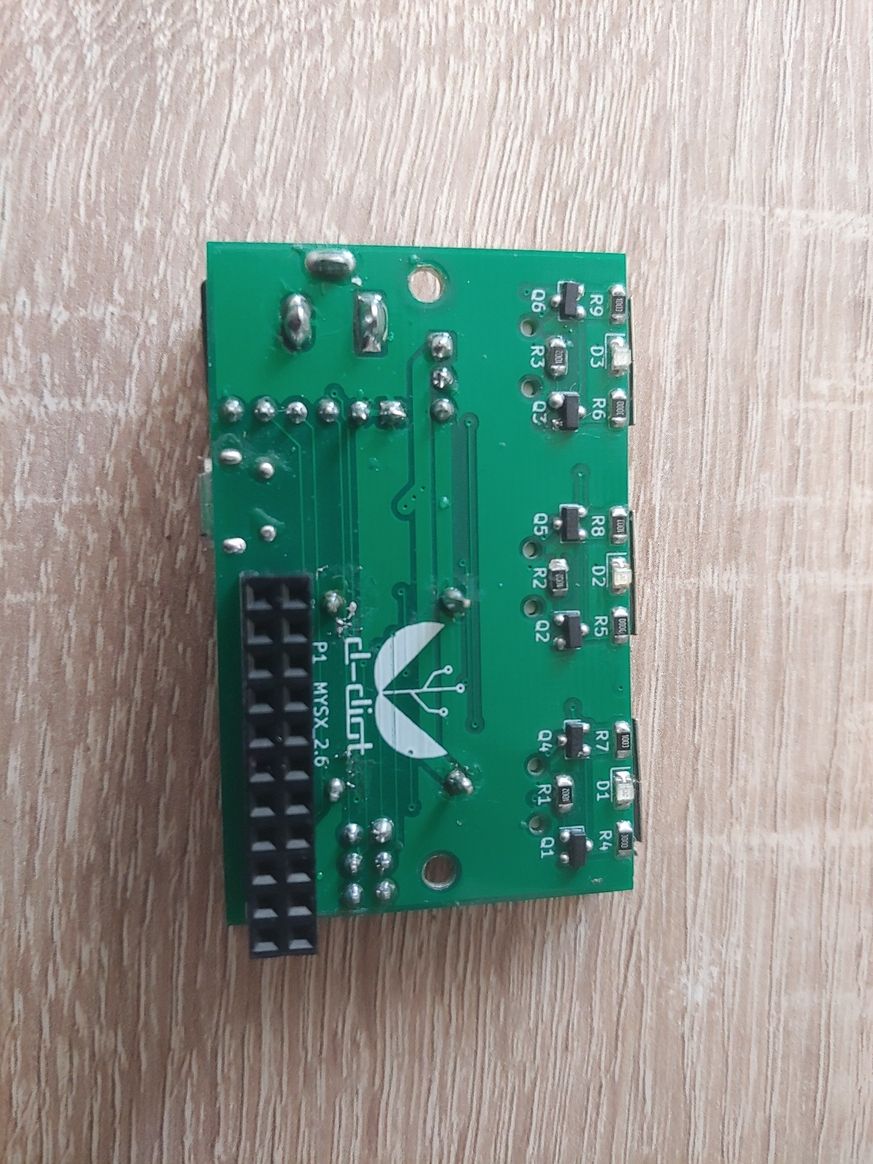

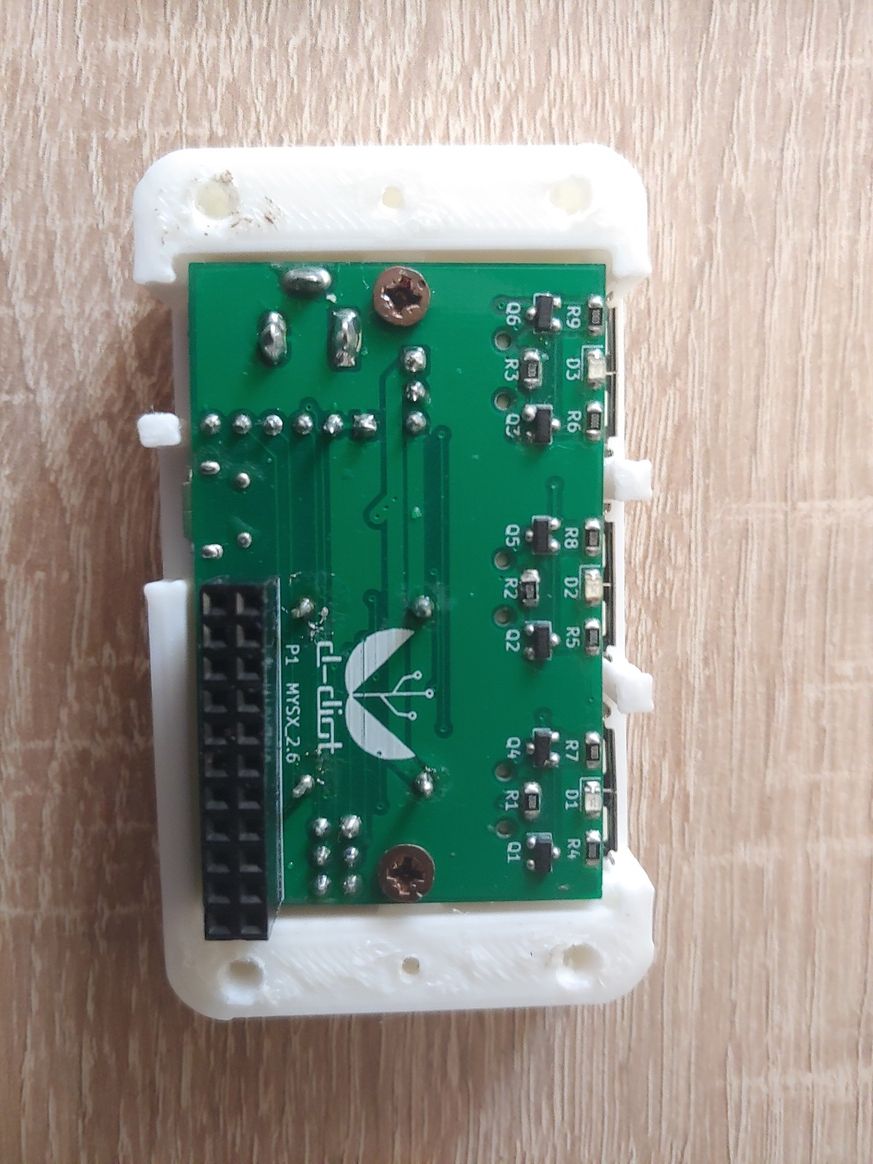

Hi guys,

this is my last node. A 3d printable smart USB power hub.

If someone is interested, here all the details.

-

I am testing a node with a DigiPyro, PYD 1598 motion detector. It is advertised to be low power and runs from 1.8 to 3.6 volts, so should run well with a coin cell. They have to be programmed with several options and I have not found a lot of documentation. I went with what seemed like the most sensitive choices and it seems to work so far. More research needed . ...

https://www.excelitas.com/product/pyd-1588-pyd-1598-low-power-digipyrosI bought a couple of these from DigiKey for around $4 each. Now they are more than $12 each and there is no stock. So, these may not be as good a choice as they seemed at first. We'll see . ...

-

The milling topic got my interest and I have been working on getting a machine for myself.

So far I have just assembled the machine and realised milling is a bit more difficult to start then 3d printing.

anyway, I would like to share my progress. I am building video's now

No circuitsboards yet, but here is a introduction of my way to victory.

Unboxing the Genmitsu Prover 3018 cnc mill from sainsmart – 03:09

— Joeri de Man