Air Quality Sensor

-

@jroseastro hello, first of all the MQ series are not so precise as that, use it for a test run, but for serious purpose please consider something better and with calibration.

Ozone is quite chalenging, if you go very high, since the MQ nead heating to work, it will drain fast your batteries.

For any sensor always refer to the datasheet.

MQ131 is given from 5 to 100 ppb (reason you get only a single value) if you use the provided calibration sheet. So the result is the one from the curve. We've had a discussion not yet settled with @hek about units and this is why I've not put it, but maybe I should uniformize everything in ppm since this is the most prevalent value used.

Also the datasheet says you need 6V to heat it, so you cannot heat it from the arduino except with a step up (not that good) or an external power source (best) with a voltage regulator.

-

I'm now testing the MICS-6814 (3 sensors in one) given for :

Carbon monoxide CO 1 -1000ppm

**Nitrogen dioxide NO2 0.05 –10ppm **

Ethanol C2H5OH 10 –500ppm

Hydrogen H2 1 –1000ppm

Ammonia NH3 1 –500ppm

Methane CH4 >1000ppm

Propane C3H8 >1000ppm

Iso-butane C4H10 >1000ppmDatasheet maionly speaks on CO, NO2 and NH3:

http://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdfHere is are scripts:

http://www.seeedstudio.com/wiki/Grove_-_Multichannel_Gas_Sensorhttp://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdf

Some readings:

The concentration of NH3 is 0.99 ppm The concentration of CO is 1.20 ppm The concentration of NO2 is 0.15 ppm The concentration of C3H8 is 1000.04 ppm The concentration of C4H10 is 999.98 ppm The concentration of CH4 is 2991.14 ppm The concentration of H2 is 1.09 ppm The concentration of C2H5OH is 1.40 ppmI guess I'll make a script soon...

-

I think MQ131 need 24 hours preheating time.Because of preheating time it will be costly. and for MiCS 6814 how do you calculate or measured other values of gases?? Because sensor's data sheet it hard to understand

@bhavika said:

I think MQ131 need 24 hours preheating time.Because of preheating time it will be costly.

no MQ is expected to run on battery for they always need pre-heating before getting a value.

and for MiCS 6814 how do you calculate or measured other values of gases?? Because sensor's data sheet it hard to understand

So fat I only use the provided library. Sensors are said to be factory calibrated, maybe a reason they are so costly. I'm not running it constantly at this time, but I saw no change in the few time I ran it so I'm still expecting to see something.

-

@bhavika said:

I think MQ131 need 24 hours preheating time.Because of preheating time it will be costly.

no MQ is expected to run on battery for they always need pre-heating before getting a value.

and for MiCS 6814 how do you calculate or measured other values of gases?? Because sensor's data sheet it hard to understand

So fat I only use the provided library. Sensors are said to be factory calibrated, maybe a reason they are so costly. I'm not running it constantly at this time, but I saw no change in the few time I ran it so I'm still expecting to see something.

@epierre Hi...it is ameasing your work :D

I am wondering about Mq-135. We have troubles with reading differents gases.

From the datasheet we read the slopes

Gas X" X0" "Rs/R0 "Rs/R0 pendiente (log y- log y0)/(log x-log x0)"

Air 200 10 3.6 3.6 0.00000

co 200 10 1.3 2.9 -0.26783

nh4 200 10 0.79 2.7 -0.41024

c02 200 10 0.8 2.4 -0.36673

3/4/ 200 10 0.72 1.9 -0.32391

1/4/ 200 10 0.64 1.5 -0.28432

+- 200 10 0.59 1.4 -0.28845the data are in the next worksheet https://docs.google.com/spreadsheets/d/18Z6XyxwXVsWdMIk9vbUuCucaLJDdmR0QUFSTYG79ftw/edit?usp=sharing

¿may you share with us your code for this sensor in order to see your slopes and Rs/R0 values ?

¿do you know the meaning of the name of gases with 3/4 or 1/4 or +-thank you in advance

-

based on a datasheet, this one:

https://drive.google.com/file/d/0B8OvrwVDp8fCcWpHSjZNVzB1TjQ/viewI apply a power regression (tool: http://www.xuru.org/rt/PowR.as ) on the following points (I've not marked down values but theses are close match):

0.8 200 1 100 2.3 10Result: y = 103.6748512 x-2.81699418

Residual Sum of Squares: rss = 45.01031346¿do you know the meaning of the name of gases with 3/4 or 1/4 or +-looks like you had a chinese datasheet ;-) just remember those are correlated gases based on particle size for those captors, so it is not very accurate...

You can find many more sensors hare : https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino or simply in https://github.com/empierre/arduino/blob/master/

-

based on a datasheet, this one:

https://drive.google.com/file/d/0B8OvrwVDp8fCcWpHSjZNVzB1TjQ/viewI apply a power regression (tool: http://www.xuru.org/rt/PowR.as ) on the following points (I've not marked down values but theses are close match):

0.8 200 1 100 2.3 10Result: y = 103.6748512 x-2.81699418

Residual Sum of Squares: rss = 45.01031346¿do you know the meaning of the name of gases with 3/4 or 1/4 or +-looks like you had a chinese datasheet ;-) just remember those are correlated gases based on particle size for those captors, so it is not very accurate...

You can find many more sensors hare : https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino or simply in https://github.com/empierre/arduino/blob/master/

@epierre

Hi, May be I do not explain my point correctly (or maybe I misundertood ), let me try again.

We adopt a code, which is the next. The blue lines are the points (for each gas we need two points) that we need.

https://docs.google.com/document/d/1CevnhBLL9uoyZ31kkrMn-SXeOF_4e9YFGmchj46pGPY/edit?usp=sharingSpecifically we read from the datasheet the pairs of points for CO

point1 (lg200 , lg1.3)

Point2 (lg10, lg2.9)

then, we construct the data format:{ x, y, slope};

COCurve[3] = {1.0,0.462,-0.268};We are wondering about the pair of points for the others gases or the { x, y, slope} data for them, could you share them?.

and the other hand, the name of gases with 3/4 or 1/4 or +- appears as well in your datasheet (figure 3)... do you know why?

thank you so much

-

I prefer the power regression than the curves.

From your datapoints :

1.3 200

2.9 10I find:

y = 532.6744764 x-3.73371402

rss=0I don't remember where I found the datasheet with the chinese names that I translated through google.

-

I prefer the power regression than the curves.

From your datapoints :

1.3 200

2.9 10I find:

y = 532.6744764 x-3.73371402

rss=0I don't remember where I found the datasheet with the chinese names that I translated through google.

@epierre Now I see your point of view and of course it is better way to reduce the error.

in the other hand, I found the datasheet in chinese an then a friend translate it.

the meaning of the name of gases is for 3/4 (Alcohol), 1/4 (Tolueno) or +- (acetona)Thank you so much.

-

Hi,

I've started working with an MQ135 sensor, attached to a board like the disucssion you had from a year ago. I measured some of the resistances between the Aouts and the sensor pins and seems similar with the 1kohm resistance between AO and Gnd, and the pot not changing the output.

I was wondering if anyone managed to calibrate their board using the AO of this board, and if so how? I can't seem to get a good resolution, as it has noise of at least in the 10's of ppm.

I'm considering whether its simpler to by pass the board and its amplifier, and directly hook set up onto the sensor itself with the correct resistors.

-

Hi,

I've started working with an MQ135 sensor, attached to a board like the disucssion you had from a year ago. I measured some of the resistances between the Aouts and the sensor pins and seems similar with the 1kohm resistance between AO and Gnd, and the pot not changing the output.

I was wondering if anyone managed to calibrate their board using the AO of this board, and if so how? I can't seem to get a good resolution, as it has noise of at least in the 10's of ppm.

I'm considering whether its simpler to by pass the board and its amplifier, and directly hook set up onto the sensor itself with the correct resistors.

@Yuki-M said:

Hi,

I've started working with an MQ135 sensor, attached to a board like the disucssion you had from a year ago. I measured some of the resistances between the Aouts and the sensor pins and seems similar with the 1kohm resistance between AO and Gnd, and the pot not changing the output.

I was wondering if anyone managed to calibrate their board using the AO of this board, and if so how? I can't seem to get a good resolution, as it has noise of at least in the 10's of ppm.

I'm considering whether its simpler to by pass the board and its amplifier, and directly hook set up onto the sensor itself with the correct resistors.

Calibration is not possible as it varies between the same sensors of this construction class. Check datasheet on minimal sensibility also on low and max values.

Also without a gas concentration it is not possible to calibrate it. The best guess is that co2now.org gives you that outside (aka clean air) it is 399 for CO2, but that would be only for CO2 and not the other gases !

-

@epierre Thanks for a rapid response!

Yes I've been trying to calibrate it assuming out door air is at 399ppm. I understand each one has variances but would like to know how you guys worked it out.

I'm using

ppm = 116.6020682 (Rs/Ro)^-2.769034857

from davide's blog http://davidegironi.blogspot.ch/2014/01/cheap-co2-meter-using-mq135-sensor-with.html#.VinvWX4rIuUSince the board show RL, I took that to calculate Rs. This lets me calculate Ro, thus calibrate it.

Not quite sure where I'm going wrong. I had it working 8 months ago, and came back to it and couldn't figure out how i had it working so well.. I was able to get pretty nice graphs and now its very unstable.

I'm having a play around with it, you can see my current points here https://thingspeak.com/channels/31162

-

@epierre Thanks for a rapid response!

Yes I've been trying to calibrate it assuming out door air is at 399ppm. I understand each one has variances but would like to know how you guys worked it out.

I'm using

ppm = 116.6020682 (Rs/Ro)^-2.769034857

from davide's blog http://davidegironi.blogspot.ch/2014/01/cheap-co2-meter-using-mq135-sensor-with.html#.VinvWX4rIuUSince the board show RL, I took that to calculate Rs. This lets me calculate Ro, thus calibrate it.

Not quite sure where I'm going wrong. I had it working 8 months ago, and came back to it and couldn't figure out how i had it working so well.. I was able to get pretty nice graphs and now its very unstable.

I'm having a play around with it, you can see my current points here https://thingspeak.com/channels/31162

@Yuki-M said:

@epierre Thanks for a rapid response!

Yes I've been trying to calibrate it assuming out door air is at 399ppm. I understand each one has variances but would like to know how you guys worked it out.

I'm using

ppm = 116.6020682 (Rs/Ro)^-2.769034857

from davide's blog http://davidegironi.blogspot.ch/2014/01/cheap-co2-meter-using-mq135-sensor-with.html#.VinvWX4rIuUSince the board show RL, I took that to calculate Rs. This lets me calculate Ro, thus calibrate it.

Not quite sure where I'm going wrong. I had it working 8 months ago, and came back to it and couldn't figure out how i had it working so well.. I was able to get pretty nice graphs and now its very unstable.

would say: let it burn for 24/48 hours to leave it clean itself ;-)

-

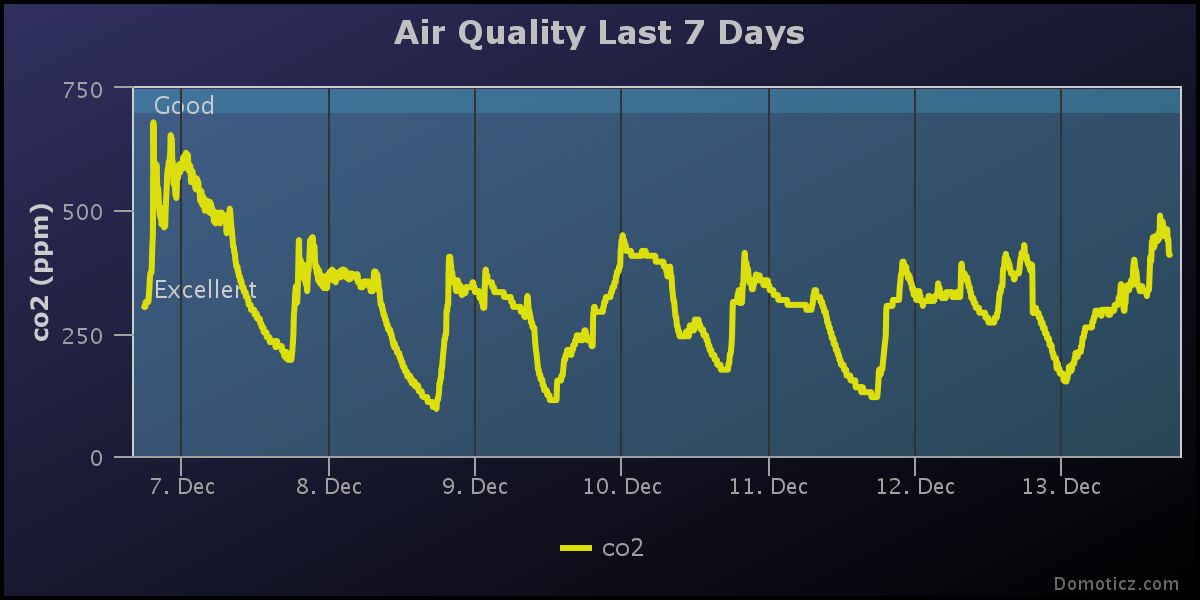

Adjusting my mq-135 sensor took several atempts as the CO2 value of the atmosphere is not a constant value of 399ppm.

This value is measured in Hawaii ( see http://co2now.org/ ) and is probably significantly lower than at your home. In germany for example you should calibrate your sensor when the wind comes from west over the atlantic which brings fresh air along. See http://www.donnerwetter.de/deutschland/co2.htmEverytime my sensor passed values below 400 I adjusted the R0 value. In the end I modified the sketch to be able to send this R0 value from FHEM to the sensor to avoid recompiling the sketch everytime.

See

https://github.com/windkh/mysensors/tree/master/CO2Sensor/CO2sensor.ino Line 440ff

-

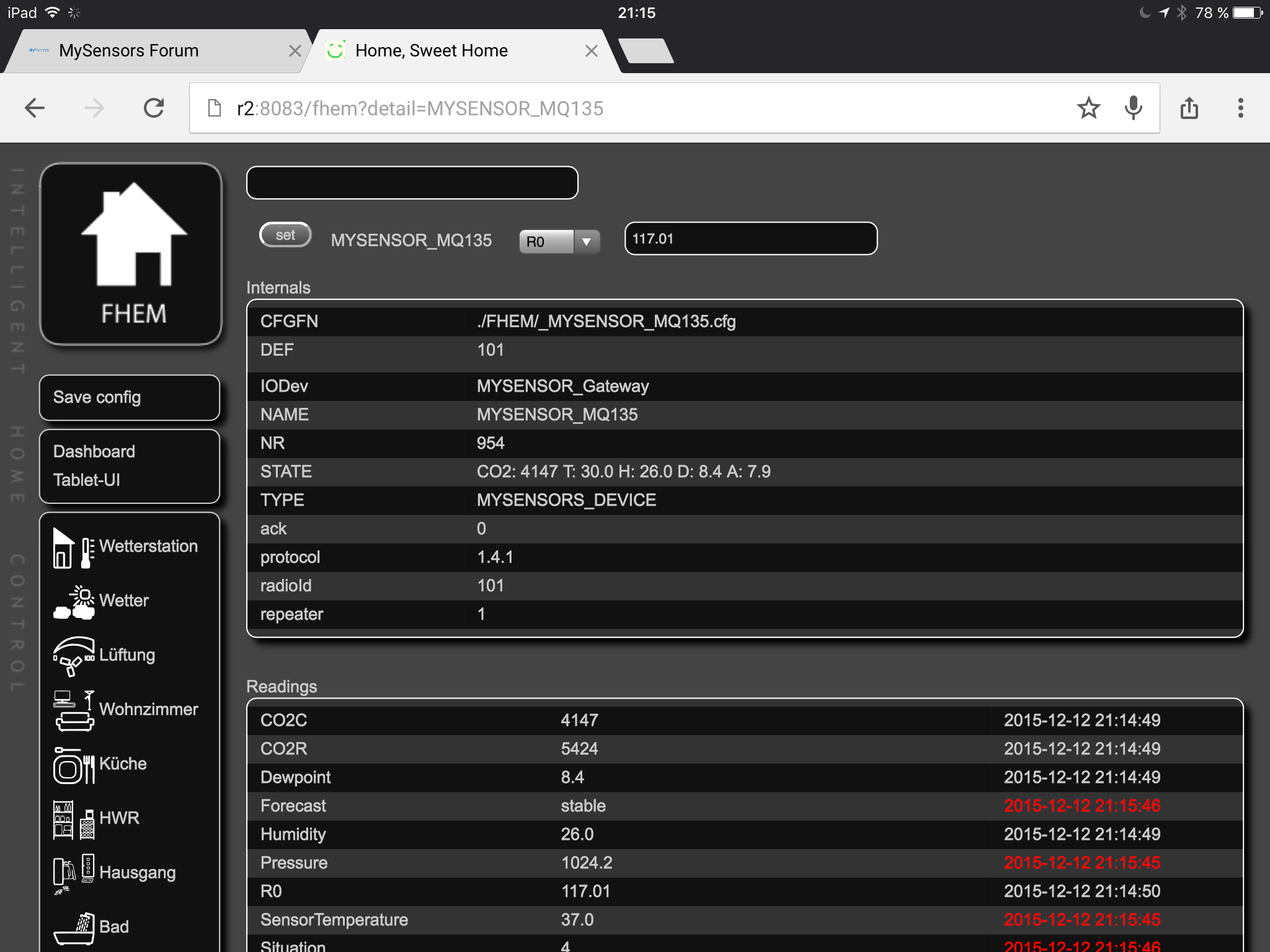

The sensor is in my kitchen. The value in the screenshot is very high as I made some french fries 2 hours ago.

-

IN MiCS 2614 , sensitivity factor is defined by "Rs at 100 ppb of O3 divided by Rs at 50 ppb of O3". From where you measured Rs at 100 ppb or 50 ppb.???

@bhavika said:

IN MiCS 2614 , sensitivity factor is defined by "Rs at 100 ppb of O3 divided by Rs at 50 ppb of O3". From where you measured Rs at 100 ppb or 50 ppb.???

this is just to tell you how much a double concentration scales up, here they just say it is somehow linear at ratio 2

-

@Heinz very nice work :+1: (wie heisst du im FHEM Forum?)

Does someone have the values a MQ-07 needs to perform properly? I rally don't know how to gather the right values from the description.... :)

Thank you

-

@Rasenheizung if you base yourself on my template here https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino

H2

1.3 50

0.8 100

0.28 400

0.16 1000

0.05 4000y = 73.59123879 x-1.355617483

Residual Sum of Squares: rss = 87393.44418

H2Curve[3] = {73.5912, -1.355617};CO

1.6 50

1 100

0.39 400

0.21 1000

0.09 4000y = 99.27731641 x-1.513643469

Residual Sum of Squares: rss = 43168.87424

COCurve[3] = {99.27731, -1.51364};CO is a dangerous gas, the MQ7 is very sensitive to many things and no calibration too... for a serious work please think about using the MICS-6814 that is calibrated, includes 3 gases out of the box, and is very low consumption (can run on battery !)

https://github.com/empierre/arduino/blob/master/AirQuality-CO-NO2-NH3.ino