Small wall outlet sensor node

-

I've created this to have easiest way to establish environment monitoring across the house

the idea is to have a wall outlet type plug with everything on board

and I like to do small things

The board is less than 50 x 50 mm

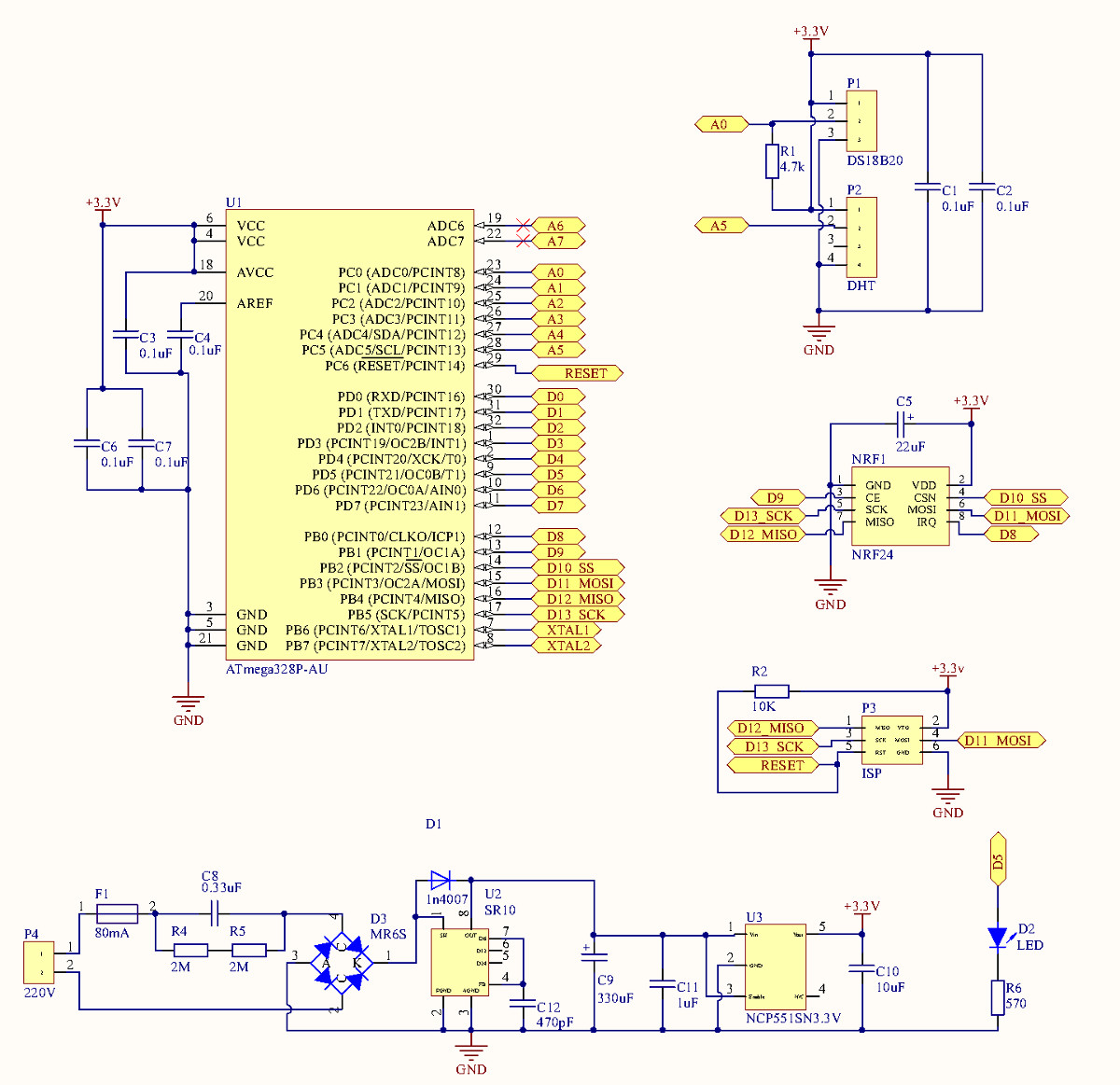

It contains AC-DC power supply with resettable fuse, 3.3V LDO, arduino based on atmega328, radio, LED, and two slots, one for DS18B20 and the second one is for DHT11/DHT22The real consumption measured by RMS wattmeter is just 0.3W

-

Really nice!

I guess the DHT11/22 pin could also be used for PIR sensor or drive a relay/actuator.

-

Cool!

@axillent, did you get a chance to test the MPL-03S-05E I sent you?

-

@axillent Very nice! How do you make the circuit board and the soldering of surface mounted components is quit advanced.

-

@gregl thanks, yes, the same board can be used for any simple 1-2 inputs or 1-2 channel actuator

I have a plan to create something similar for wall switch in 3-wire and 2-wire versions

-

@hek thanks

I read a datasheet and I doubt about where to use it

it requires quite a big external filter

the total size will be bigger than normal isolated AC-DCThe supply based on none-isoleted schema is interested in some projects where you need lower footprint.

If someone interested I will do a test

-

Here are a schematic and PCB prints

-

@olaeke thanks!

it is half-a-day project including a home-production of the PCB

but it is a 2-year experienceI also use a simplified approach for some PCBs, without drilling, using 0.5mm FR4 cut by office scissors and thermo-transfer technology. This one requires about 30-50 minutes for the production circle.depending on etching speed. For example this two side AC lamp off-timer:

http://radiokot.ru/circuit/digital/automat/81/04.jpg

http://radiokot.ru/circuit/digital/automat/81/05.jpg

-

Pictures bellow are virtual, under printing

-

It would be cool with a 90degree angled version as well

-

Excellent!

-

@axillent Your an evil genius!

-

@ServiceXp thanks)

all this is simple, just a patient workPrinted thing is a bit ugly comparing to the virtual one, but it's work is real

http://www.youtube.com/watch?v=JG7gutD1oo8

-

@axillent So very very cool!!

as @gadu commented, making one at 90 deg so its very low profile would be even better for places such as hallways where the sensor could be bumped....

Really nice!

-

@axillent - well done!

-

@axillent Very impressive! What is the total cost of the components involved?

-

@bjornhallberg it is hard to say

the BOM is simple and short

but the cost of a single component is dramatically depends on how many your purchase in a single order

for example atmega328 purchased in 10pcs will be US1.2 pcs while a single pcs will costs US3-4If it will be an interest I think in production this PCB can cost retail US8-12

-

@axillent

very very cool!!

-

Impressive!

-

made two more with modified box - it is a bit wider to hold DHT sensor inside

I made a new sketch as a combination of Dalas example and DHT. This new sketch able to detect automatically connected sensors and work according to detection.One problem I've got. I cannot get DHT working from AC plug. It is working fine been powered from DC and failed during startup been powered from AC

The most probably the reason is high pulsation (up to 440mV) coming from the supply based on SR10 chip.

The most probably the reason is high pulsation (up to 440mV) coming from the supply based on SR10 chip.

Dalas is fine with this but not DHT. Probably some code inside the library holds.Had to mark each sensor with radio channel because they will work with different gateways

-

really cool

what are u using to convert the AC-DC ? how u doing it ?

what are u using to convert the AC-DC ? how u doing it ?

-

@sharath-krishna thanks

yearly in this thread you can find a schematics.

I'm using here SR10. Many alternatives were discussed here http://forum.mysensors.org/topic/687/230v-power-supply-to-arduinoI've found a solution to my problem with DHT. I put delay(500) at the beginning of setup().

This is needed to stabilize DC before initializing DHT.

Alternatively a 4.7uF capacitor can be connected between RESET and GND

-

This is my combined sketch with automatic detection of connected many DS18B20 and DHT11/22

#define RADIO_CHANNEL 76 #define DS18B20_PIN A0 #define DS18B20_MAX_SENSORS 8 #define DHT_PIN A5 #define LED_PIN 5 #define SLEEP_TIME_SEC 60 #include <avr/wdt.h> #include <avr/interrupt.h> #include <avr/sleep.h> #include <MySensor.h> #include <SPI.h> #include <DallasTemperature.h> #include <OneWire.h> #include <DHT.h> // DS18B20 OneWire oneWire(DS18B20_PIN); DallasTemperature sensors(&oneWire); MyMessage msgHum(0, V_HUM); MyMessage msgTemp(0, V_TEMP); struct { struct { uint8_t count; float lastTemperature[DS18B20_MAX_SENSORS]; } ds18b20; struct { DHT sensor; uint8_t count; float lastTemp; float lastHum; } dht; MySensor gw; } var; ISR(WDT_vect) { } void setup() { wdt_disable(); //delay(500); pinMode(LED_PIN, OUTPUT); digitalWrite(LED_PIN, HIGH); // init mysensors var.gw.begin(NULL, AUTO, false, AUTO, RF24_PA_LEVEL,RADIO_CHANNEL); // init dalas sensors.begin(); var.ds18b20.count = sensors.getDeviceCount(); if(var.ds18b20.count > DS18B20_MAX_SENSORS) var.ds18b20.count = DS18B20_MAX_SENSORS; // init dht digitalWrite(LED_PIN, LOW); var.dht.sensor.setup(DHT_PIN); float temperature = var.dht.sensor.getTemperature(); var.dht.count = (isnan(temperature))?0:1; var.gw.sendSketchInfo("WallCombined", "1.0"); // present ds18b20 for (int i=0; i<var.ds18b20.count; i++) { var.gw.present(i+2, S_TEMP); } if(var.dht.count) { var.gw.present(0, S_HUM); var.gw.present(1, S_TEMP); } var.gw.debugPrint(PSTR("Init of combined sensor: %d ds18b20 sensors, %d dht sensors\n"), var.ds18b20.count, var.dht.count); for(int i=0; i < var.ds18b20.count + var.dht.count; i++) { digitalWrite(LED_PIN, LOW); delay(500); digitalWrite(LED_PIN, HIGH); delay(1000); } } void loop() { // Process incoming messages (like config from server) var.gw.process(); // Fetch temperatures from Dallas sensors if(var.ds18b20.count) sensors.requestTemperatures(); // Read temperatures and send them to controller for (int i=0; i<var.ds18b20.count; i++) { // Fetch and round temperature to one decimal float temperature = static_cast<float>(static_cast<int>((var.gw.getConfig().isMetric?sensors.getTempCByIndex(i):sensors.getTempFByIndex(i)) * 10.)) / 10.; // Only send data if temperature has changed and no error if (var.ds18b20.lastTemperature[i] != temperature && temperature != -127.00) { // Send in the new temperature var.gw.send(msgTemp.setSensor(i+2).set(temperature,1)); var.ds18b20.lastTemperature[i]=temperature; } } if(var.dht.count) { boolean metric = var.gw.getConfig().isMetric; float temperature = var.dht.sensor.getTemperature(); if (isnan(temperature)) { var.gw.debugPrint(PSTR("Failed reading temperature from DHT\n")); } else if (temperature != var.dht.lastTemp) { var.dht.lastTemp = temperature; if (!metric) { temperature = var.dht.sensor.toFahrenheit(temperature); } var.gw.send(msgTemp.setSensor(1).set(temperature, 1)); } float humidity = var.dht.sensor.getHumidity(); if (isnan(humidity)) { var.gw.debugPrint(PSTR("Failed reading humidity from DHT")); } else if (humidity != var.dht.lastHum) { var.dht.lastHum = humidity; var.gw.send(msgHum.setSensor(0).set(humidity, 1)); } } digitalWrite(LED_PIN, HIGH); delay(5000); digitalWrite(LED_PIN, LOW); delay(500); // sleep Serial.flush(); var.gw.powerDown(); for(int wdt_count=SLEEP_TIME_SEC; wdt_count > 0; wdt_count--) { wdt_enable(WDTO_1S); WDTCSR |= (1 << WDIE); set_sleep_mode(SLEEP_MODE_PWR_DOWN); sleep_enable(); sei(); sleep_cpu(); sleep_disable(); } wdt_disable(); }

-

3D models are published here http://www.thingiverse.com/thing:688442

-

@axillent said:

3D models are published here http://www.thingiverse.com/thing:688442

nice job

can you tell us what kind of 3D printer you are using, and if you are happy with it.

I have a lot of electronics, and not a lot of housings.... I'm thinking about jumping in!

-

@BulldogLowell I'm using Makerbot Replicator 2 for more than 2 years

I have nothing to compare with. But it gives the possibilities I never have.

From hardware side I had to fix some problems Replicator 2 is having. New models I hope is more sufficient.

Makerbot is progressing, at least an improvement on software side is essential.Today you will find many brands and many models to choose from.

-

@axillent How do you upload the sketch? Do you solder in a preprogrammed atmega or are there connectors on the board? The DHT needs only 1.5 mA. Wouldn't it be possible to supply this with an digital out pin of the atmega? This way you could delay the power up process.

-

Just a fair warning for anyone considering a new ("5th generation") Makerbot Replicator. Check up on some reviews before getting one. Things have apparently gone downhill since the good old days. Extruders don't last as long etc. If anyone is willing to pay the sort of price that Makerbot is asking there are better alternatives.

http://nicklievendag.com/makerbot-replicator-5th-generation-review/Also, the Makerbot software is painfully slow compared to most alternatives.

http://nicklievendag.com/simplify3d-vs-makerbot-desktop/

http://www.fabbaloo.com/blog/2014/7/20/hands-on-with-simplify3d

Not that I endorse Simplify3D. There are free / open-source alternatives that are just as fast.Finally, I'm skeptical about the legal details surrounding Thingiverse.

-

@Jan-Gatzke originally a pre-loaded MCU were soldered but later I solder on top of the PCB a 6 pin ISP connectors

There is no need to source DHT from the MCU pin, it is simple to put delay at the beginning of setup or use highest startup time by fuses (my choice)the original idea is to use pogopin connector, but I've just ordered them and not yet received. I need a very small footprint ISP connector for Mysensors devices

@bjornhallberg said:

Just a fair warning for anyone considering a new ("5th generation") Makerbot Replicator. Check up on some reviews before getting one.

have no experience with 5th generation but fully agree with you that there are many alternatives

Also, the Makerbot software is painfully slow compared to most alternatives.

it is not true. I'm very satisfied with the performance of the software.

I do not believe that someone can be faster than instantaneousFinally, I'm skeptical about the legal details surrounding Thingiverse.

what kind of issues?

-

@axillent said:

Also, the Makerbot software is painfully slow compared to most alternatives.

it is not true. I'm very satisfied with the performance of the software.

I do not believe that someone can be faster than instantaneousI meant slicing speeds on very complex models specifically. But it would not surprise me if the print quality / toolpaths created are better with competing software as well.

Finally, I'm skeptical about the legal details surrounding Thingiverse.

what kind of issues?

Like Facebook and other big corporations where they basically own the data you upload and store on their servers.

Oh, also, bonus points to Makerbot / Stratasys for actually stealing technology and incorporating it into their own designs:

http://3dprintingindustry.com/2014/05/28/makerbot-become-takerbot/Bottom line, your Replicator 2 is in many ways better than the current line-up from Makerbot. Mostly because the extruder will last you many thousands of hours and not just 200-500 or whatever they guarantee these days when people come complaining.

The biggest joke is perhaps their massive Z18 printer, which costs a fortune, puts out dismal results (at least without a ton of tweaking if at all possible), can't handle ABS and is really slow. Plus having the same lousy extruder. I mean, 200 hours on the Z18 could translate into just 10 reasonably big print jobs. They actually got one at my local Makerspace.

They could have gotten two ordinary printers for the price of that one ...

They could have gotten two ordinary printers for the price of that one ...

-

@bjornhallberg bad to know that new models are worse

actually had no plans to upgrade. For the nearest feature I'm fine with Repl2.

it is also important that I made a required tuning and able to recover many things by myself

already have an experience and know what to expectI do not think my models complicated but the slicing speed was improved by handred times in the first year of the purchase

today i have to wait almost none before printing startswhat is even more important - raft support was improved revolutionary. Before it was sucks to print surface on the raft - it became ugly and unacceptable as a from panel. Now all are very different

-

Great project axillent +1

-

@Johnny-B-Good thanks!

-

very nice

-

@Jan-Gatzke said:

@axillent How do you upload the sketch?

do you mean a .zip file or the inline source?

for inline I have to add leading spaces to all lines (it is simple to to in Atmel Studio) and than just past it here

-

@axillent i wanted some more information along with the schematics.. like the wattage of the resistors used and also the type and voltage rating of the capacitors . Please could you provide the same ?

-

@sharath-krishna no problem

all resistors except R4 & R5 are SMD 0603, R4 & R5 are SMD 1206

C8 is 0.47-0.68uF @ 400V for 220V input, or 0.68-1uF @ 250V for 110Vall other capacitors need a rate for 10V and above

-

@axillent thanks for the values but what are the wattage of the resistors?

-

@axillent : thanks

and @Tibus i think all only 45 and r4 would be like 0.5w else all 0.25 may be

and @Tibus i think all only 45 and r4 would be like 0.5w else all 0.25 may be  i have not worked much with smd tough.

i have not worked much with smd tough.

-

@Tibus I gave you the footprints, for SMD it is equivalent of the wattage)

actually only R4 & R5 a sensitive to the footprints. An even more sensitive to a maximum rating voltage than to the wattage.

I'm using two 1206 in series to be sure that they will hold up to 400V. I made a check of different brands, usually the maximum rated voltage for 1206 is not bellow 200-300V, that means that in series of equal resistors the maximum rated voltage will be 400-600Vall other resistors are under low voltage and very low power dissipation

but if you need wattage just for learning curve, usually 0601 is 0.1W, 1206 is 0.25W

Suggested Topics

-

Welcome

Announcements • • hek