@neverdie

Is it working correctly if you just issue a G0 x10 then x-10?

did you switch to the jpadie workspace for v1.1?

sounds like you have a short on pin 5

rmtucker

Posts

-

CNC PCB milling -

Atmega 328p memory@mfalkvidd said in Atmega 328p memory:

@dbemowsk I like this device because it has headers so no soldering strictly required. Note that the distance is smaller than the "standard" 2.4mm.

The 2mm pitch is a pain if you do not use the BLE400 motherboard that goes with it.

It took me ages to source a 2mm pitch protoboard then sockets to plug it into.

But it is easy to use.:relaxed: -

CNC PCB milling@neverdie

What if you have broken .048 off the end of the tool during autolevel?

So run some g-code above the job then re-probe so you know you have not twatted the tool.:relaxed: -

CNC PCB milling@neverdie

Maybe run step 1

Then run some g-code but above the job.(for a few mins).

Then run step 3.

This could be an autolevel problem. -

CNC PCB milling@neverdie

Forget using probe to begin with as this would show lost steps but also any mechanical inaccuracy.

Just concentrate on the motors to begin with. -

CNC PCB milling@neverdie

Hmmm how long is a piece of string.:grinning:

My machine is on a much larger scale but the principal is the same.

Is this a mechanical inaccuracy or lost steps?

Make yourself a small program that rapids each axis in turn from one end of the axis to

the other.

On my own machine the motors are running pulleys to the leadscrews/ballscrews.

I place a mark on the pulleys and a pointer (pin and blue tac) when the machine is at 0,0,0.

I run the program and adjust the accel and velocity returning to 0,0,0 every time and checking the marks always line up.(If they don't lowering the settings 10% and running again).

Which eventually proves it is not lost steps. -

CNC PCB millingNormally i would turn one up at a time until the motors lose steps,then pull them back 20%.

-

CNC PCB milling@neverdie

Yes or use bCNC to set them. -

CNC PCB milling@neverdie

I think you should start by altering the acceleration/Max velocity settings etc in grbl.

Slow them down a little:grinning: -

CNC PCB milling@andrew said in CNC PCB milling:

to make the isolation routing width larger, you should use multiple passes. this is necessary to create a large enough isolation width. to be sure that all copper will be removed between the different passes (e.g. due to cnc inaccuracy or backlash) you should use overlapping. see http://flatcam.org/manual/procedures.html#wide-isolation-routing

Just to clarify that what andrew is talking about is multiple radial passes with an offset further away from the track/pads each time.

Not multiple passes in the depth.:confused: -

CNC PCB milling@neverdie said in CNC PCB milling:

Actually, I'm not even sure what the dimensions were on the freebie. It wasn't labeled. Perhaps it was too wide to begin with.

Maybe this is where your problem lies.

How did you write the g-code without knowing?

Too many variables here wich could give you these results.

The bigger tracks,Are they measuring the correct width with a vernier after you have cut them? -

CNC PCB milling@neverdie

Yes sorry a used one:wink: -

CNC PCB milling@neverdie

Just for future reference i would use a duff cutter for autolevelling then change to a good cutter to cut the job after resetting the z0.

It is so easy to smash the front of an engraving cutter when using this method for autolevelling as the machine takes a little time to stop after touching the pcb.

Just my advice anyway:relaxed: -

CNC PCB milling@neverdie

The last photo looks like the tip is missing from the cutter? -

CNC PCB milling@neverdie

Linux for me too.Never used windows in years:relaxed: -

CNC PCB milling@neverdie said in CNC PCB milling:

@rmtucker Which g-code sender is it that you like best?

I am not using a g-code sender,i am using mach3.

But i have just started playing with grbl and bCNC seems to do most things. -

CNC PCB milling@neverdie

Stick some g-code in and press cycle start:grin: -

CNC PCB milling@rmtucker

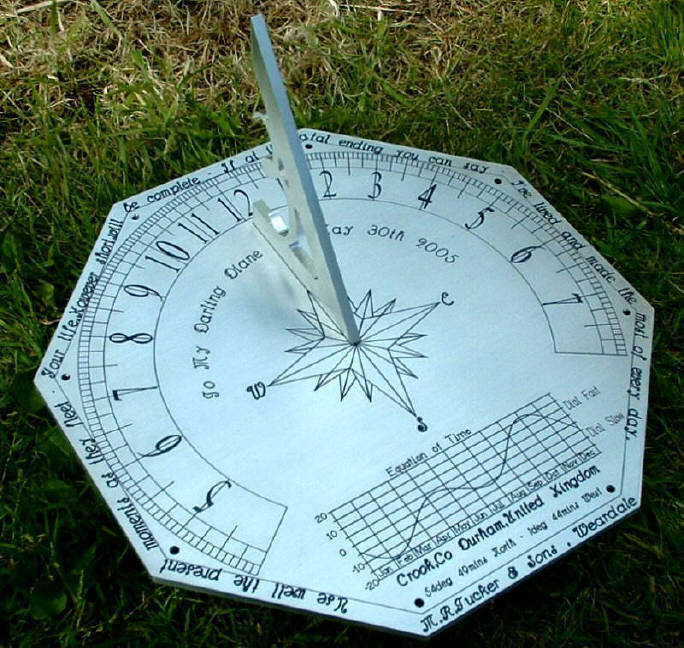

And this for our lass

-

CNC PCB millingCarved this on my home made cnc router recently.

Bit off topic but good fun.

It is about 2ft diameter and 8" thick(old millstone)

-

CNC PCB milling@neverdie

You have gone quiet:relaxed:

Must be beavering away cutting pcb's?