Air Quality Sensor

-

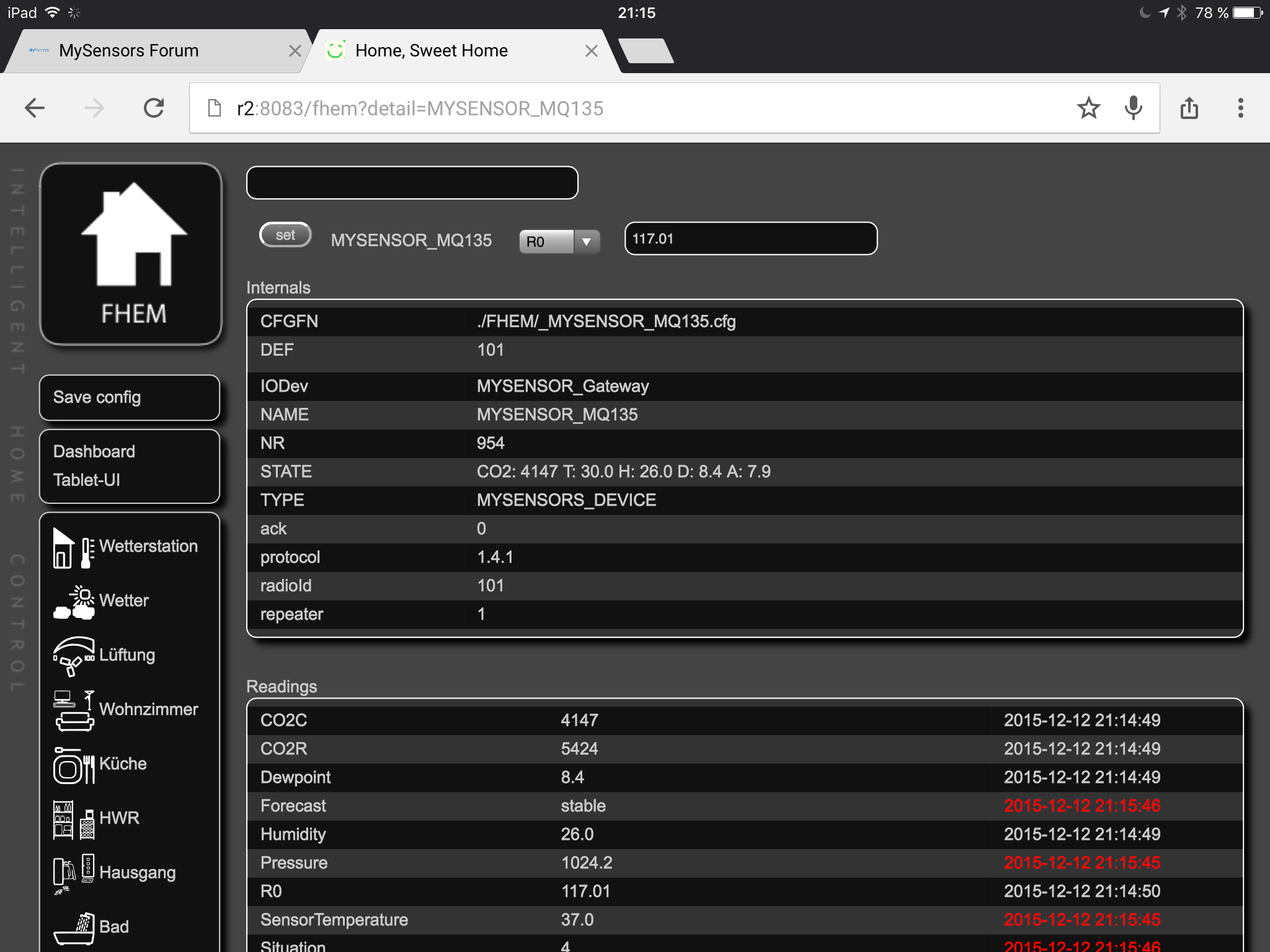

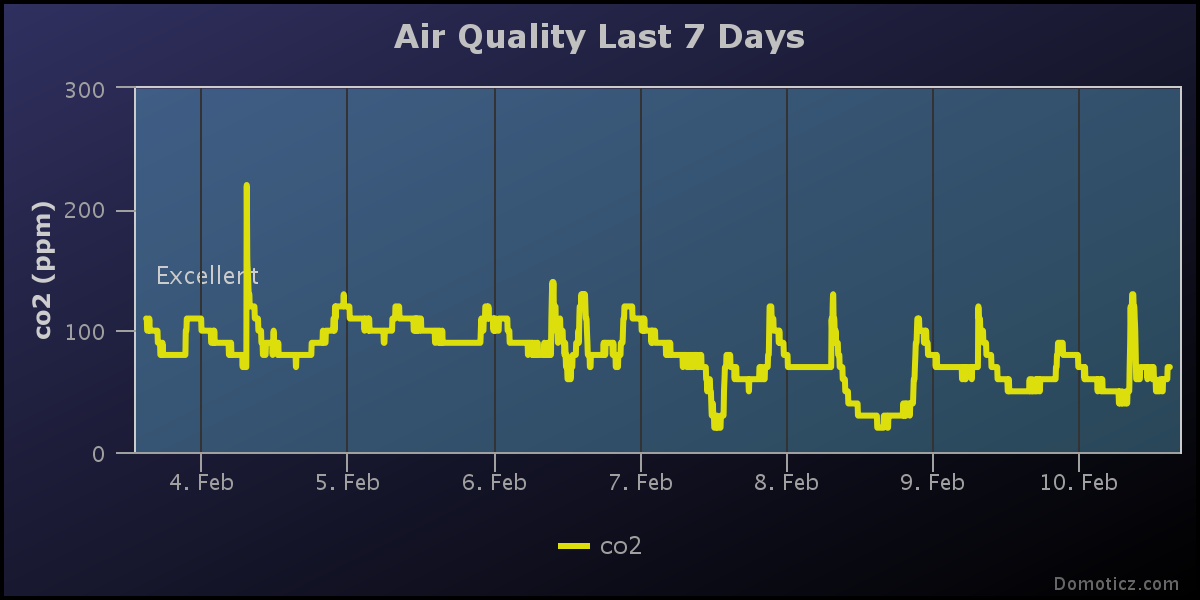

Adjusting my mq-135 sensor took several atempts as the CO2 value of the atmosphere is not a constant value of 399ppm.

This value is measured in Hawaii ( see http://co2now.org/ ) and is probably significantly lower than at your home. In germany for example you should calibrate your sensor when the wind comes from west over the atlantic which brings fresh air along. See http://www.donnerwetter.de/deutschland/co2.htmEverytime my sensor passed values below 400 I adjusted the R0 value. In the end I modified the sketch to be able to send this R0 value from FHEM to the sensor to avoid recompiling the sketch everytime.

See

https://github.com/windkh/mysensors/tree/master/CO2Sensor/CO2sensor.ino Line 440ff

-

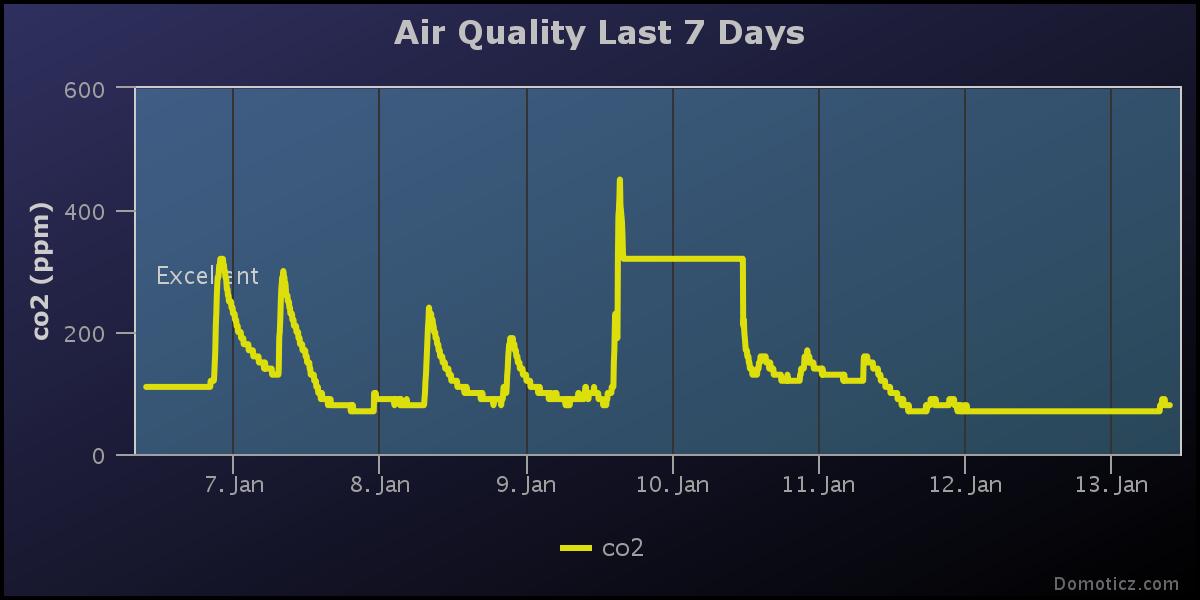

The sensor is in my kitchen. The value in the screenshot is very high as I made some french fries 2 hours ago.

-

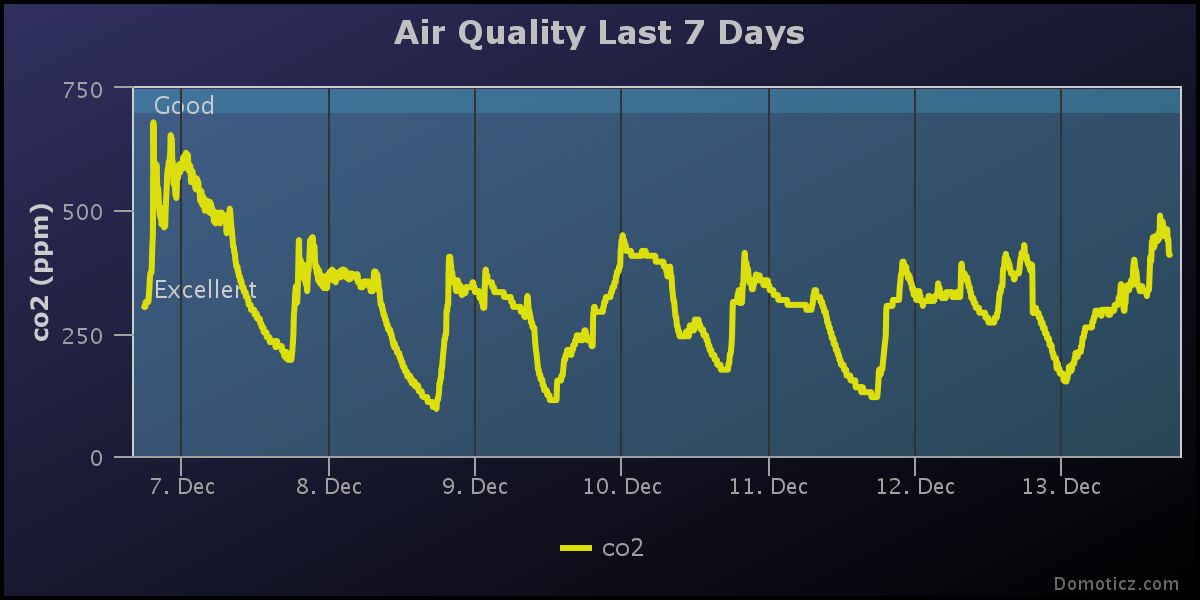

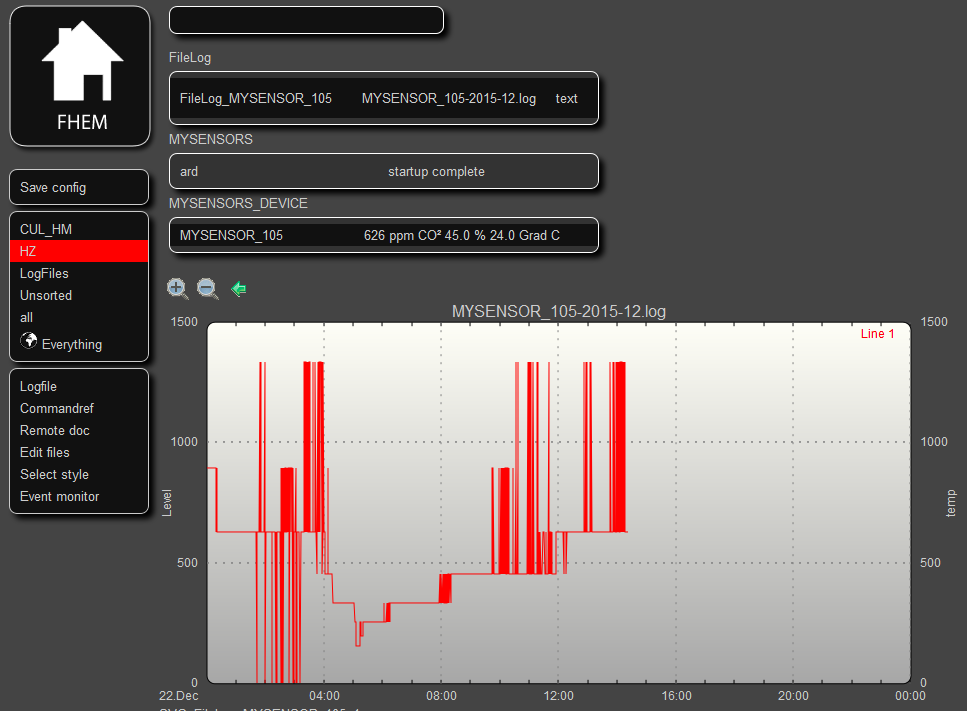

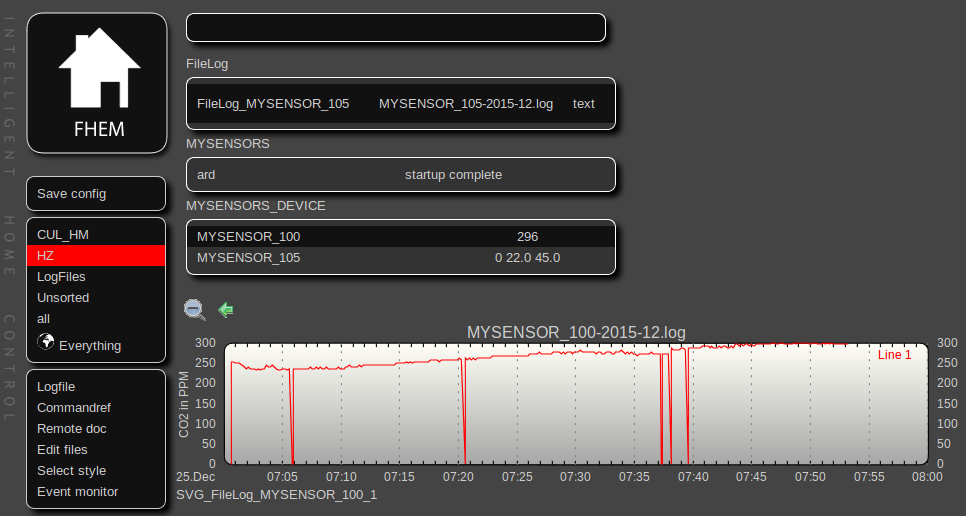

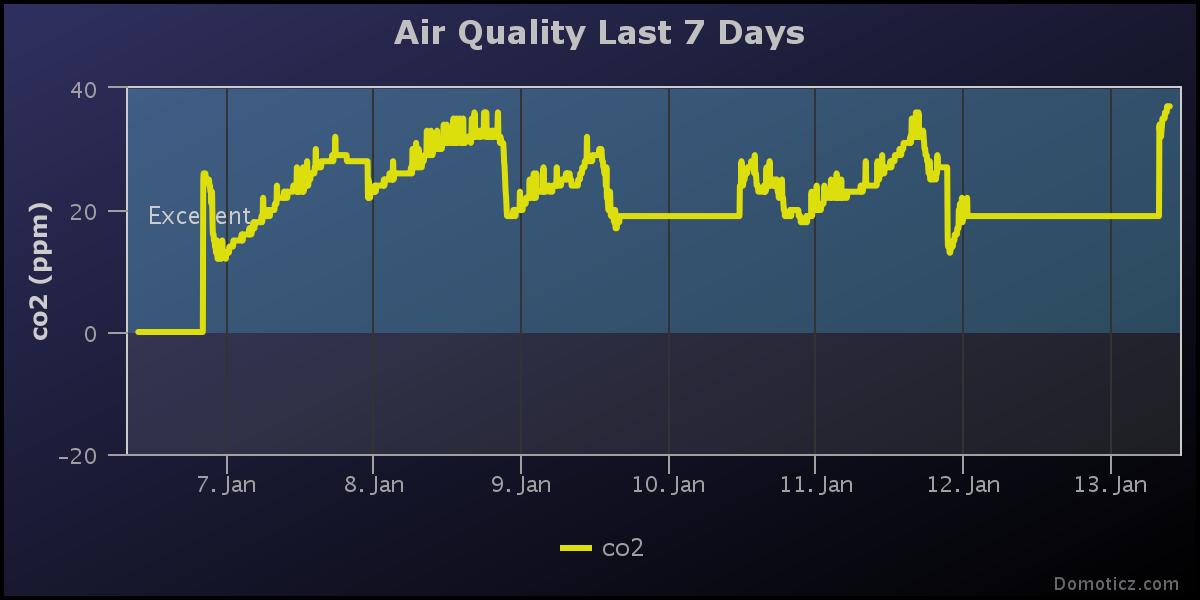

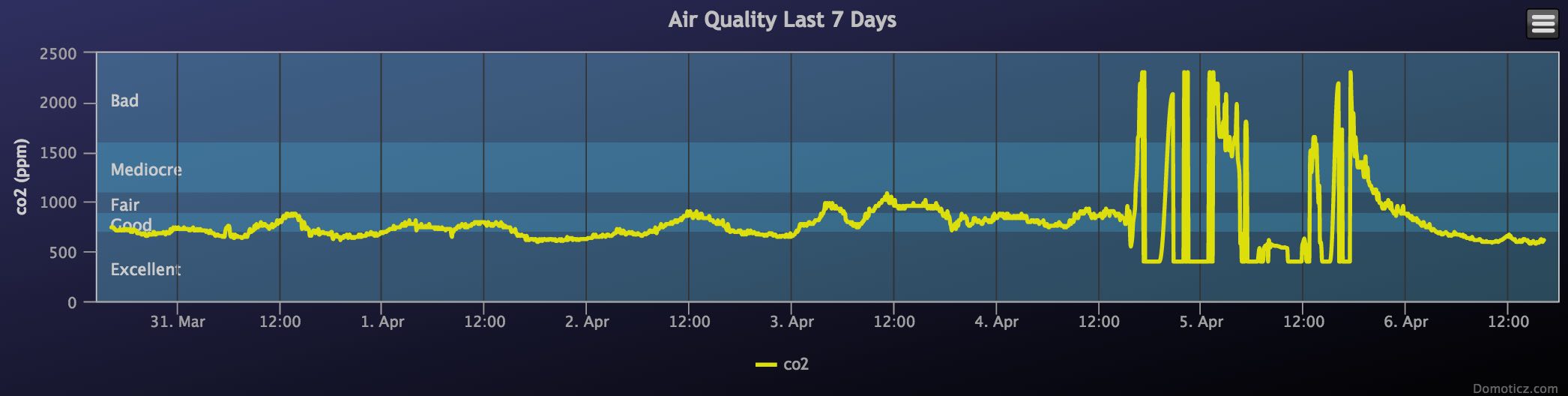

@Heinz so bad I don't have a MQ135 running anymore to compare, here are the MH-Z14 curves I have near my desk.

-

@bhavika said:

IN MiCS 2614 , sensitivity factor is defined by "Rs at 100 ppb of O3 divided by Rs at 50 ppb of O3". From where you measured Rs at 100 ppb or 50 ppb.???

this is just to tell you how much a double concentration scales up, here they just say it is somehow linear at ratio 2

-

@Heinz very nice work

(wie heisst du im FHEM Forum?)

(wie heisst du im FHEM Forum?)Does someone have the values a MQ-07 needs to perform properly? I rally don't know how to gather the right values from the description....

Thank you

-

@Rasenheizung if you base yourself on my template here https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino

H2

1.3 50

0.8 100

0.28 400

0.16 1000

0.05 4000y = 73.59123879 x-1.355617483

Residual Sum of Squares: rss = 87393.44418

H2Curve[3] = {73.5912, -1.355617};CO

1.6 50

1 100

0.39 400

0.21 1000

0.09 4000y = 99.27731641 x-1.513643469

Residual Sum of Squares: rss = 43168.87424

COCurve[3] = {99.27731, -1.51364};CO is a dangerous gas, the MQ7 is very sensitive to many things and no calibration too... for a serious work please think about using the MICS-6814 that is calibrated, includes 3 gases out of the box, and is very low consumption (can run on battery !)

https://github.com/empierre/arduino/blob/master/AirQuality-CO-NO2-NH3.ino

-

What is the pre-heating time for TGS2442???

-

@bhavika said:

What is the pre-heating time for TGS2442???

from datasheet: "the sensor’s resistance reaches to 90% of its final value in less than one minute"

-

So what is the conditioning period for testing in it??? It is two days.. What does it mean??

-

@bhavika said:

So what is the conditioning period for testing in it??? It is two days.. What does it mean??

on this kind maybe to have it powered for a full two days to burn out the production "dusts" that may remain in.

those sensors are not good science, see the correlation of gases they are reported for in the datasheet

-

Hello,

a very sensitive HCHO module you can see a demo here: http://www.seeedstudio.com/recipe/379-a-handheld-hcho-detector.html?utm_source=EDM&utm_medium=EDM&utm_campaign=EDM20150930

https://github.com/empierre/arduino/blob/master/AirQuality-HCHO.ino

-

I have a question for the MQ135. Do not always be above 500 ppm, the measured values? I also get values of 0. I suspect that it is due to the conversion. The values vary greatly. Is that normal? I get the values with an ordinary power supply.

-

This post is deleted!

-

Looks strange, could you supply your code?

Btw the sensor draws a lot of current, the power supply should be able to deliver 1A. Did you burn in the sensor for 12-24 hours?

-

I have used the code from epiere. Baking I have not done. I use different power supplies (USB, Samsung and a large controllable power supply). I sometimes feel that contacts do not function properly. But the sensor draws but only about 100 mA = 0.1 A? Then it seems to be on branding. I have three new sensors. Mostly we read that it is only an attempt here is to measure the CO2 content. When I check the values with a measuring instrument with which agree the details here https://olimex.wordpress.com/2015/05/26/experimenting-with-gas-sensors-and-arduino/ Branding should work outdoors? Can you show me a chart or values?

-

This post is deleted!

-

I used this library:

https://github.com/GeorgK/MQ135Together with this description:

https://hackaday.io/project/3475-sniffing-trinket/log/12363-mq135-arduino-librarySimple to use and very good explanations.

-

I've read about. It sounds interesting.

I stand a little hard with the development. Is there a skit for MQ135.h and MYSENSORS?

I will test this afternoon.

-

Hi @paqor,

I wrote a little sketch which you could use as a start, it uses the MQ135 library.

I also used a timer library, but this could be replaced by a simple sleep, too.RZERO should be changed when calibrating the sensor, this can be done at compile-time or during runtime by sending the value to the sensor via the gateway.

Unfortunately I could not test the sketch yet, but it should help you getting started.

If you have a second sensor which provides humidity and temperature then you can also get the corrected ppm from the library,...good luck!

/* MQ135 MySensor A0 white D0 black GND brown 5V red */ #include <SPI.h> #include <MySensor.h> #include <MQ135.h> #include "Timer.h" Timer timer; // 30 seconds #define TEMP_UPDATE_INTERVAL 30000 // MQ135 #define CHILD_ID_CO2 0 #define CHILD_ID_R0 1 #define CO2_SENSOR_ANALOG_PIN 0 /// Calibration resistance at atmospheric CO2 level #define RZERO 300.0 #define EEPROM_R0 0 MQ135 gasSensor = MQ135(CO2_SENSOR_ANALOG_PIN, RZERO); int lastC02; float lastR0; //----------------------------------------------------------------------------- // MySensor MySensor gw; MyMessage msgCO2(CHILD_ID_CO2, V_VAR1); MyMessage msgR0(CHILD_ID_R0, V_VAR1); //----------------------------------------------------------------------------- void setup() { gw.begin(incomingMessage, AUTO, true); gw.sendSketchInfo("MQ135 Sensor", "1.0"); gw.present(CHILD_ID_CO2, S_AIR_QUALITY); gw.present(CHILD_ID_R0, S_CUSTOM); uint8_t R02 = gw.loadState(EEPROM_R0); // get R0 from EEPROM float R0 = R02 * 2; // do a plausibility check if (R0 > 1.0 && R0 < 400.0) { Serial.print(F("Setting R0 from EEPROM: ")); } else { Serial.print(F("Setting default R0: ")); R0 = RZERO; } Serial.print(R0); Serial.println(F("")); gasSensor.setR0(R0); timer.every(TEMP_UPDATE_INTERVAL, timerHandler); } bool MQ135Changed() { bool changed = false; lastR0 = gasSensor.getRZero(); Serial.print(F("R0: ")); Serial.println(lastR0); { float ppm = gasSensor.getPPM(); Serial.print(F("CO2 ppm: ")); Serial.print(ppm); int roundedPpm = (int)ppm; Serial.print(F(" --> ")); Serial.println(roundedPpm); if (roundedPpm != lastC02) { lastC02 = roundedPpm; changed = true; } } return changed; } void timerHandler() { bool airQualityChanged = MQ135Changed(); if (airQualityChanged) { gw.send(msgCO2.set(lastC02)); gw.send(msgR0.set(lastR0, 2)); } } void loop() { gw.process(); timer.update(); } // Gets the R0 value from the gw passes ot to the lib and stores it into the EEPROM. void incomingMessage(const MyMessage& message) { Serial.println(F("Incoming Message:")); if (message.isAck()) { Serial.println(F("This is an ack from gateway")); } uint8_t sensor = message.sensor; if (sensor == CHILD_ID_R0) { float R0 = message.getFloat(); Serial.print(F("Incoming R0: ")); Serial.print(R0); Serial.println(F("")); gw.saveState(EEPROM_R0, (uint8_t)(R0/2)); gasSensor.setR0(R0); gw.send(msgR0.set(R0, 2)); } }

-

I have compiled from various sources themselves something. The result is https://gleisnetze.de/2015/12/25/das-erste-kleine-programm/ described herein. The most plausible values I received with the MQ135.h library. For that I have then added the transfer after MySensors / FHEM.

-

Hello

In MiCS 2614 or in any gas sensor. what should be the value of R0... Because in datasheet they mentioned that value is measured in ambient condition. Any default value for that??

-

@bhavika said:

Hello

In MiCS 2614 or in any gas sensor. what should be the value of R0... Because in datasheet they mentioned that value is measured in ambient condition. Any default value for that??

The datasheed propose the "clean air calibration": "Sensing resistance in air R0 is measured under controlled ambient conditions, i.e. synthetic air at 23 ±5°C and 50 ± 10% RH. Sampling test."

so you should go outside and mesure the defautl R0 value in your environment.

-

MQ-135 with 10k results in a R0 of around 360 in my environment. So you could start experimenting with values around 300-500. I had to use a voltage regulator to get reliable values from the sensor.

-

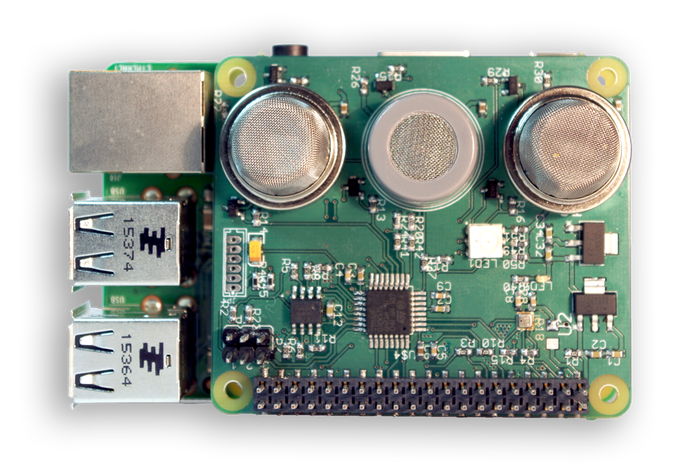

a little update on the MICS-6814:

NO2: sensible

CO: flat

NH3 flat

For the HCHO:

sorry for the flat part, some arduino issues at this time

-

Welcome @betthorn, great to have you here.

-

I have had some questions about converting from mg/m3 to ppm gases, here are the weight values and a proposed method:

NH3 17.03 g/mol

CO2 44.01

CO 28.01

H2S 34.08

NO2 46.01

NO 30.01

O3 48.00

C6H6 78.11

C7H8 92.14you have:

NO2 50 μg/m3 gives 26,5868821 ppm

O3 27 μg/m3 = 0.027 mg/m3 -> (8,31441298,15)/(48101,325)*27=13,7617025 ppmcorrect me if I'm wrong

-

2016 is where IoT for gas sensors are moving to more maturity, Cooking Hacks / Libellium proposed so far Fibaro sensors, but are now proposing more pricey one that are calibrated.

-

CO2 with MH-Z14

NO2 MICS-6814

HCHO sensor

-

In MQ135 sensor's datasheet , which line on the curve is used to find out the concentration of benzene?

-

@bhavika said:

In MQ135 sensor's datasheet , which line on the curve is used to find out the concentration of benzene?

MQ135 is sensitive to particle size, benzene is one of these. I rememer someone who used the chinese datasheet and found a chinese to translate it.

-

@epierre I am testing a stripped-down version of your code from your AirQuality-MQ135.ino. I stripped it to make it run just stand-alone.

What I don't understand is how to do the calibration. When I run it in outside environment (with 10k resistor), I get these values:valr 223 Vrl / Rs / ratio:13387 / 20875.00 / 0.00What would be the next step for calibration?

-

@supersjimmie replace MQ135_DEFAULTRO by your value 20875 in the sketch

-

@epierre Thanks, I thought it would be something like that, but that didn't work.

I then gotvalr 242 Vrl / Rs / ratio:5464 / 8520.00 / 0.00Nothing like around 400ppm.

-

yes for the code must be updated, the value is the CO2 (or something else) detected above the 399 in atmosphere

gw.send(msg.set(MQ135_DEFAULTPPM+(int)ceil(valAIQ)));

-

Thanks, but when calibrating something strange happens when I put the module outside:

valr 270 Vrl / Rs / ratio / ppm 61355 / 95673.00 / 0.00 / 399.00 valr 265 Vrl / Rs / ratio / ppm 62928 / 98126.00 / 0.00 / 399.00 valr 260 Vrl / Rs / ratio / ppm 64561 / 100673.00 / 0.00 / 399.00 valr 256 Vrl / Rs / ratio / ppm 378 / 589.00 / 0.00 / 399.00 valr 252 Vrl / Rs / ratio / ppm 1773 / 2764.00 / 0.00 / 399.00As you can see, the valr decreases slowly, but suddenly Vlr and Rs jump over.

Vlr is the value of 'val', which is: uint16_t val = ((float)22000*(1023-valr)/valr);

uint16_t is 16bit, so max 65535. It looks like my environment needs more than that?

(in fact, your code defines the defaultro as 68550, which is also too much for a uint16?)

-

@supersjimmie said:

Vlr is the value of 'val', which is: uint16_t val = ((float)22000*(1023-valr)/valr);

yes and this is why I did rewrite it to https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino but did not updated this one...

-

@epierre I striped-down that AirQuality-Multiple_Gas_Sensor1_4.ino to use only MQ135.

When used inside, the analogRead is 473, so a reasonble value.

But the MQCalibration function returns 0. Which means the MQResistanceCalculation also returns 0.MQResistenceCalculation only does one calc:

return (long)((long)(1024 * 1000 * (long)rl_value)/raw_adc-(long)rl_value);

rl_value = float RL4 = 0.990

raw_adc = 473 (measured as said above)

(1024 * 1000 * 0.990) / 473 - 0.990 = 2142.266

I checked that raw_adc is filled with the correct value (to be sure it is not lost somewhere).What looks to fix this, I changed everything to float . So:

return (float)((float)(1024 .* 1000. * (float)rl_value)/raw_adc-(float)rl_value);

Which can be simplyfied as:

return ((1024 * 1000*rl_value)/raw_adc-rl_value);

I went to float, because the function is created as float MQResistenceCalculation.This now gives some ppm values that are within a reasonable range (about 2000 here).

Now I have to figure out how to do calibration on this method again...

-

looks like I have to rework something... but not in the todo list right now... Imperihome is now back on top, and Particle on lipo/solar also...

-

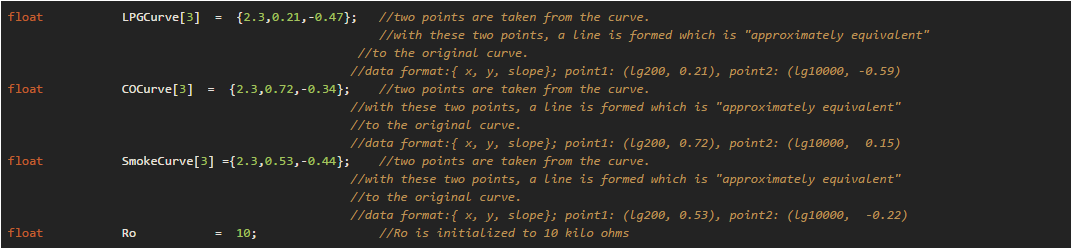

Hello,

I don't know how to calculate 3 numbers of LPGCurve[]. Can you explain clearly for me? Thank you so much !!!

-

@tantt2810 as explained above, if the datasheet has a logarithmic scale, you can use the power regression to approximate the curve. One tool for example to do this calculus:http://www.xuru.org/rt/powr.asp

for a sensor discussed above I read this on the datasheet:

H2

1.3 50

0.8 100

0.28 400

0.16 1000

0.05 4000The xuru website gives me this:

y = 73.59123879 x-1.355617483

Residual Sum of Squares: rss = 87393.44418and thus I have::

H2Curve[3] = {73.5912, -1.355617};

-

@epierre Thank you so much !!!

Have a nice day =)) !!!

-

hi

i am new here.

sorry i am a little confused by with these new formulate.

is it the key for module?

-

Hello,

I'm don't understand the recipe below. Why RL_Value(Load Resistance)(1023-raw_adc)/raw_adc)? Can you explain for me?

Thank you so much !!!

/***************** MQResistanceCalculation ****************************************

Input: raw_adc - raw value read from adc, which represents the voltage

Output: the calculated sensor resistance

Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage

across the load resistor and its resistance, the resistance of the sensor

could be derived.

***********************************************************************************/

float MQ2::MQResistanceCalculation(int raw_adc)

{

return ( ((float)RL_VALUE(1023-raw_adc)/raw_adc));

}

-

@jenbaker said:

sorry i am a little confused by with these new formulate.

is it the key for module?

if you have a module the datasheet gives you the values, yes. Remember this is their """""generic"""" calibration, in fact they all copy the other so don't expect your MQ** would follow this by the letter...

-

@tantt2810 said:

Hello,

I'm don't understand the recipe below. Why RL_Value(Load Resistance)(1023-raw_adc)/raw_adc)? Can you explain for me?

Thank you so much !!!

Input: raw_adc - raw value read from adc, which represents the voltage

Output: the calculated sensor resistance

Remarks: The sensor and the load resistor forms a voltage divider. Given the voltage

across the load resistor and its resistance, the resistance of the sensor

could be derived.

float MQ2::MQResistanceCalculation(int raw_adc)

RL_VALUE(1023-raw_adc)/raw_adc));in fact it is above described, you have a voltage, you want a resistance.

https://learn.sparkfun.com/tutorials/voltage-dividersdatasheet needs a value which is the Rs/Ro (called here RL) where

Ro: sensor resistance at 100ppm of NH3 in the clean air.

Rs:sensor resistance at various concentrations of gaseshere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178);

-

@epierre Hi you,

I think the Rs/Ro is not RL. In the datasheet RL=5kOhm. As I know it is a resistance on board Arduino, and we set it 5kOhm. Is it right? I also don't know why we set it equal 5kOhm. =))

And why 20000 is in "float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm" ?

Please help me clearly. Thank you so much !!!

-

Hello,

I have read the sensitivity characteristics curve in datasheet of MQ135 and I don't know AL R, 3/4, 1/4* and +- mean? Can you help me, please !!!

NH4 represent for NH3, doesn't it ?

Thank you so much !!!

-

Hi everyone,

I have an CO2 MG811 sensor. I don't know where tcm pin connect with ?

Please help me. Thank you so much !!!!

-

Hello, I'm working with an MQ-136 sensor, and am interested in measuring H2S and/or SO2 concentrations. I've got a simple sketch written which gives me a fairly consistent value on the serial monitor, but I've tried to run the multiple gas sensor sketch both complete and I also tried picking apart the sketch just to include MQ-136 related variables and algorithms, but I can't get it to work. It's showing too many errors to list here. Does anyone have simple conversions from the serial outputs to usable values for various gases that this sensor can measure?

-

hello, how i read co2 ppm with my mq135?

helpme please

-

@tantt2810 said:

Hi everyone,

I have an CO2 MG811 sensor. I don't know where tcm pin connect with ?

Please help me. Thank you so much !!!!this is an analogic sensor, so VCC/Gnd to power it, and readings on analogic Aout

-

@tantt2810 sorry for not being more responsive, I left MQ/TGS behind me but I've not kept all my notes on mesuring this and that, that would require me to search for it again. But I appreciate if you can spot me some float/type error conversion in sketches !

-

I was a bit disappointed when a project I contributed to on Kickstarter showed the inside of their boxes, I wonder how they will manage to satisfy customers with calibration... or their home made index as netatmo did

-

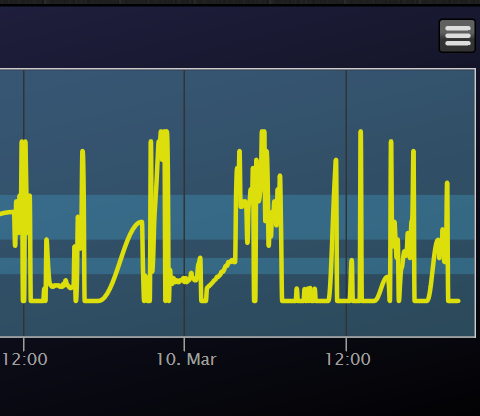

Used the air quality script for MQ7 but throwed out all the conversions and calibrations. Just reading the plain input from the analogue pin.

I targeted this as a smoke detector but it seems this sensor highly depends on the humidity of the surrounding air. Are there any existing formulas to correct for the humidity of the surounding air?And on one sensor i have some irratical data as shown below (blue). I wonder if it's a power supply (black and green is DHT) or a broken sensor?

-

@moskovskiy82 well looks like a strange sensor... try averaging several samples/// always remember to have it running several days before measuring for there are chemical left from china factories...

-

Hey all,

I've got a question regarding the calibration function in https://github.com/empierre/arduino/blob/master/AirQuality-Multiple_Gas_Sensor1_4.ino :

$ grep MQCalibr * AirQuality-Multiple_Gas_Sensor1_4.ino: Ro0 = MQCalibration(MQ2_SENSOR,10,RL0,SmokeCurve); AirQuality-Multiple_Gas_Sensor1_4.ino: Ro1 = MQCalibration(MQ6_SENSOR,10,RL1,LPGCurve); AirQuality-Multiple_Gas_Sensor1_4.ino: Ro2 = MQCalibration(MQ131_SENSOR,10,RL2,O3Curve); AirQuality-Multiple_Gas_Sensor1_4.ino: Ro3 = MQCalibration(TGS2600_SENSOR,10,RL3,C2H5OH_terCurve); AirQuality-Multiple_Gas_Sensor1_4.ino: Ro4 = MQCalibration(MQ135_SENSOR,10,RL4,CO_secCurve); AirQuality-Multiple_Gas_Sensor1_4.ino: Ro6 = MQCalibration(TGS2602_SENSOR,1,RL6,C7H8Curve); .... AirQuality-Multiple_Gas_Sensor1_4.ino:float MQCalibration(int mq_pin, double ppm, double rl_value,float *pcurve )Th function MQCalibration should calibrate the sensor in clean air, the calibration function uses the PPM concentration of the gas in a clean air environment.

You already use the appropriate value for i.e. CO2 (around 399 PPM) in the MQ135 sketch - but why are you using those obscure values in the calibration (1, 10) here?Thanks in advance!

-

@wreiner said:

Th function MQCalibration should calibrate the sensor in clean air, the calibration function uses the PPM concentration of the gas in a clean air environment.

You already use the appropriate value for i.e. CO2 (around 399 PPM) in the MQ135 sketch - but why are you using those obscure values in the calibration (1, 10) here?Well, I didn't know the concentration in clean air so I had to put in a value even random... I took the hypothesis there are very few in the air so low value.

-

@epierre

Thank you. Your mean is Vcc->5V, GND->GND, Dout->Digital pin, Aout->Analog pin. Is it right?

But I don't know the tcm pin connect with ? I have read datasheet but I don't find any info about tcm pin. Please help me. Thank you so much !!!

-

Readings of my MQ135 are going up and down like a yo-yo. Not sure how to read them really?

What do you think?

-

I am confused with MiCS 4514 sensor. What I had done is :

using MiCS quick start evaluation board, measured ADC value

calculated Vout and from that calculated R0.

Rs/R0 concentration gives me high value, which is not possible, My data is as follows

clean air file is used for the purpose of R0 value

https://drive.google.com/file/d/0B8sF8a6FHoseWjhWOHRoYzIxakk/view?usp=sharing

and Polluted file is used to calculate the actual pollution

https://drive.google.com/file/d/0B8sF8a6FHoseR1BnclhCUHdibEU/view?usp=sharingI am confused. Please help me

-

@tantt2810 said:

@epierre

Thank you. Your mean is Vcc->5V, GND->GND, Dout->Digital pin, Aout->Analog pin. Is it right?

But I don't know the tcm pin connect with ? I have read datasheet but I don't find any info about tcm pin. Please help me. Thank you so much !!!do not use the digital pin !!! it only reacts with the potentiometer in on/off mode, so useless... you need to power the device with Vcc/Gnd, and read the output with Aout (A stands for analog). The last one forget it.

-

@alexsh1 is that raw ADC output or with a calculation ? normaly this should go up or down but not in sucha drastic way

-

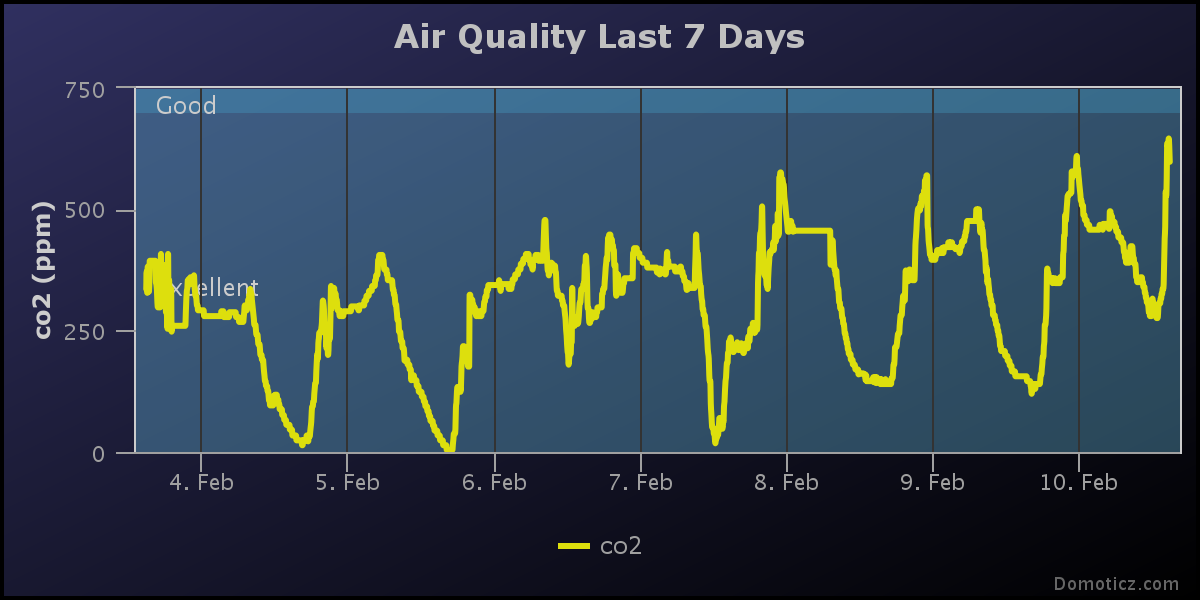

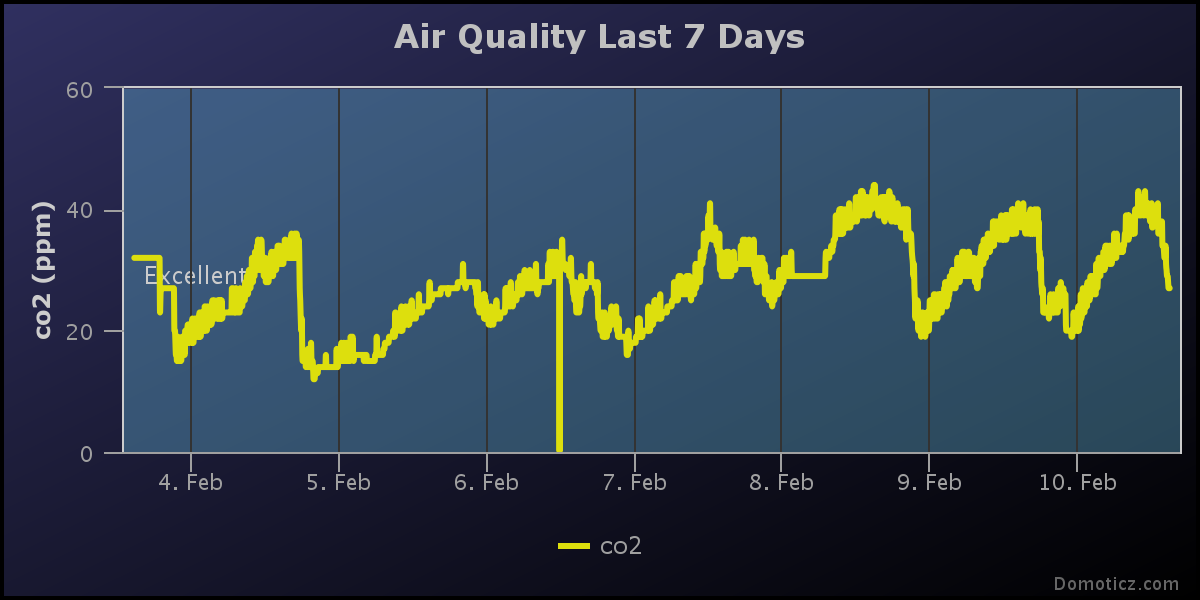

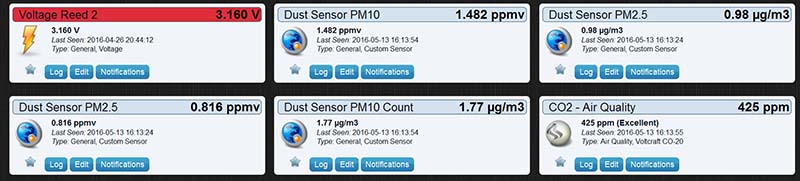

This is a value gw.send(msg.set(MQ135_DEFAULTPPM+(int)ceil(valAIQ))) reported to Domoticz.

It does not make any sense to me at all.

-

@epierre

Thanks you so much !!! Good job, Good boy =)).

-

@alexsh1 said:

This is a value gw.send(msg.set(MQ135_DEFAULTPPM+(int)ceil(valAIQ))) reported to Domoticz.

It does not make any sense to me at all.same for mle, sometime it is good to have two piece to compare their behavior... I have 3 o them ...

-

@epierre do you think it is a faulty sensor though?

-

Hello,

Can I use pinMode(digitalpin, OUTPUT) to turn off sensor? Or Is there any way to wirte a function that turn off sensor?

I want to remote it on web to turn on or off it.

Thank you so much !!!

-

For those who are trying to use an MQ135 module from e-bay or other sellers, on a small pcb with a chip, LED and potmeter:

It took me a while until I figured out that the little chip has a very big influence on the value that you read on the A-out pin.

Only after removing the connection between the A-out pin and the little chip, I got normal measurements.I also replaced the small resistor marked "102" with a 10k resistor, to make measurements more compatible with code that uses a 10k pull down resistor. But that was already a known issue, found on many other places.

-

@tantt2810 said:

Hello,

Can I use pinMode(digitalpin, OUTPUT) to turn off sensor? Or Is there any way to wirte a function that turn off sensor?

I want to remote it on web to turn on or off it.

Thank you so much !!!

well no, powering is through Vcc/GND, so you whould use a switch on this. Digital pins do not gives enough power for such sensors.

-

@alexsh1 said:

@epierre do you think it is a faulty sensor though?

coud be, hard to know without possibility to compare to another one.

-

This is what I discovered. When nobody is around the sensor 'settles' on a particular value. However, when there is anyone around in the room, the sensor reading goes up and down - see the snapshot attached. Any idea what the problem may be?

-

@alexsh1 hard to say, could be something moving inside if someone makes vibration around and thus this strange reaction... the down curve at the end is correct, the in between not

-

Hi,

Can you check the reception level?

I had same behaviour with an old temperature/humidity module; need to move it to another place in the room, and works perfectly now

-

@Elfnoir said:

; need to move it to another place in the room, and works perfectly now

temp/hum are "less" sensitive on environment, here the sensors heats up to 40-60° (or more) so temp/hum is not the most impacting (I can be wrong anyway

-

@epierre I wonder if you looked at this sensor Figaro TGS8100:

http://www.figarosensor.com/products/entry/tgs8100.html

Looks like it is perfect for a low-powered platform.

-

@alexsh1 said:

@epierre I wonder if you looked at this sensor Figaro TGS8100:

http://www.figarosensor.com/products/entry/tgs8100.html

Looks like it is perfect for a low-powered platform.

as a replacement for MQ in low power yes could be... the bad part is how to get one ?

-

@epierre said:

the bad part is how to get one ?How about http://www.soselectronic.com/?str=371&artnum=170939&name=figaro-tgs8100 ?

-

Hi, It all make sense, I am just confused that in your code once your multiply and once you divide...

case CO:

{

if(ratio1 < 0.01) ratio1 = 0.01;

if(ratio1 > 3) ratio1 = 3;

//c = pow(10, 0.6) / pow(ratio1, 1.2);

** c = pow(ratio1, -1.179)4.385; //mod by jack*

break;

}

case NO2:

{

if(ratio2 < 0.07) ratio2 = 0.07;

if(ratio2 > 40) ratio2 = 40;

//c = ratio2 / pow(10, 0.8);

** c = pow(ratio2, 1.007)/6.855; //mod by jack**

break;

}

SO, what is the actual formula?Vir

@epierre said:

I'm now testing the MICS-6814 (3 sensors in one) given for :

Carbon monoxide CO 1 -1000ppm

**Nitrogen dioxide NO2 0.05 –10ppm **

Ethanol C2H5OH 10 –500ppm

Hydrogen H2 1 –1000ppm

Ammonia NH3 1 –500ppm

Methane CH4 >1000ppm

Propane C3H8 >1000ppm

Iso-butane C4H10 >1000ppmDatasheet maionly speaks on CO, NO2 and NH3:

http://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdfHere is are scripts:

http://www.seeedstudio.com/wiki/Grove_-_Multichannel_Gas_Sensorhttp://www.seeedstudio.com/wiki/images/1/10/MiCS-6814_Datasheet.pdf

Some readings:

The concentration of NH3 is 0.99 ppm The concentration of CO is 1.20 ppm The concentration of NO2 is 0.15 ppm The concentration of C3H8 is 1000.04 ppm The concentration of C4H10 is 999.98 ppm The concentration of CH4 is 2991.14 ppm The concentration of H2 is 1.09 ppm The concentration of C2H5OH is 1.40 ppmI guess I'll make a script soon...

-

What does 37143 represents, Rs? and -3.178 is a second value from your regression method, but what about the first value?

Can you elaborate on ppm line, please

Virhere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178);

-

@bhavika said:

I am confused with MiCS 4514 sensor. What I had done is :

using MiCS quick start evaluation board, measured ADC value

calculated Vout and from that calculated R0.

Rs/R0 concentration gives me high value, which is not possible, My data is as follows

clean air file is used for the purpose of R0 value

https://drive.google.com/file/d/0B8sF8a6FHoseWjhWOHRoYzIxakk/view?usp=sharing

and Polluted file is used to calculate the actual pollution

https://drive.google.com/file/d/0B8sF8a6FHoseR1BnclhCUHdibEU/view?usp=sharingI am confused. Please help me

I am confused by the formula you are using, could you please explain?

Pollution NO2 = (POWER((RS/R0)*(1/POWER(10,0.8068)),(1/1.01)))Pollution CO = POWER((RS/R0)*(1/POWER(10 , 0.5476)),(1/-0.8497)))

is the actual formula like this?:

pollution = POWER((ratio *(1/POWER(10, curve[0])),(1/[curve[1])))

This is different than any other formulas discussed in this thread...

Vir

-

so does 37164 represents the scaling factor and -3.178 the exponent?

Vir

@Vir said:What does 37143 represents, Rs? and -3.178 is a second value from your regression method, but what about the first value?

Can you elaborate on ppm line, please

Virhere the formula is a simplification of this:

float Vrl = val * ( 5.00 / 1024.0 ); // V

float Rs = 20000 * ( 5.00 - Vrl) / Vrl ; // Ohm

int ratio = Rs/Ro;

ppm = 37143 * pow (ratio, -3.178);

-

@epierre I have the problem with the dust sketch (shinyei ppd42ns). The following code does not work in MySensors 1.5

... gw.send(msgPM10.set("ppm")); ... gw.send(msgPM25.set("ppm")); ...2016-04-24 14:44:19.438 Error: MySensors: Unknown/Invalid sensor type (43) 2016-04-24 14:44:19.438 Error: MySensors: Unknown/Invalid sensor type (43)So far both PM10 and PM25 are showing zero. However, if I upload the following code, it works fine (one channel though):

// Watch video here: https://www.youtube.com/watch?v=a8r4CeQopfY /* Connection: JST Pin 1 (Black Wire) => Arduino GND JST Pin 3 (Red wire) => Arduino 5VDC JST Pin 4 (Yellow wire) => Arduino Digital Pin 8 Green Led connected to Arduino D7 Yellow Led connected to Arduino D6 Red Led connected to Arduino D5 Dust Sensor possible application: - Applications of customer - Air quality sensor - Dustlessness workshop - Cigarette detector */ /* Sensor is to create Digital (Lo Pulse) output to Particulate Matters (PM). Lo Pulse Occupancy time (LPO time) is in proportion to PM concentration. The output is for PM whose size is around 1 micro meter or larger. We can use the sensor to detect the dust in clean room. Minimum detect particle: 1um http://www.seeedstudio.com/wiki/Grove_-_Dust_Sensor Grove - Dust Sensor Demo v1.0 Interface to Shinyei Model PPD42NS Particle Sensor Program by Christopher Nafis Written April 2012 http://www.seeedstudio.com/depot/grove-dust-sensor-p-1050.html http://www.sca-shinyei.com/pdf/PPD42NS.pdf */ int pin = 8; unsigned long duration; unsigned long starttime; unsigned long sampletime_ms = 1000;//sampe 1s ; unsigned long lowpulseoccupancy = 0; float ratio = 0; float concentration = 0; int gLed = 7; int yLed = 6; int rLed = 5; void setup() { Serial.begin(9600); pinMode(8,INPUT); pinMode(gLed,OUTPUT); pinMode(yLed,OUTPUT); pinMode(rLed,OUTPUT); starttime = millis();//get the current time; } void loop() { duration = pulseIn(pin, LOW); lowpulseoccupancy = lowpulseoccupancy+duration; if ((millis()-starttime) > sampletime_ms)//if the sampel time == 30s { ratio = lowpulseoccupancy/(sampletime_ms*10.0); // Integer percentage 0=>100 concentration = 1.1*pow(ratio,3)-3.8*pow(ratio,2)+520*ratio+0.62; // using spec sheet curve Serial.print("concentration = "); Serial.print(concentration); Serial.print(" pcs/0.01cf - "); if (concentration < 1.0) { Serial.println("It's a smokeless and dustless environment"); digitalWrite(gLed, HIGH); digitalWrite(yLed, LOW); digitalWrite(rLed, LOW); } if (concentration > 1.0 && concentration < 20000) { Serial.println("It's probably only you blowing air to the sensor :)"); digitalWrite(gLed, HIGH); digitalWrite(yLed, LOW); digitalWrite(rLed, LOW); } if (concentration > 20000 && concentration < 315000) { Serial.println("Smokes from matches detected!"); digitalWrite(gLed, LOW); digitalWrite(yLed, HIGH); digitalWrite(rLed, LOW); } if (concentration > 315000) { Serial.println("Smokes from cigarettes detected! Or It might be a huge fire! Beware!"); digitalWrite(gLed, LOW); digitalWrite(yLed, LOW); digitalWrite(rLed, HIGH); } lowpulseoccupancy = 0; starttime = millis(); } }

-

@epierre hi, could remove some doubts regarding the mq131 sensor?

thanks,

Anne

-

@alexsh1 said:

(shinyei ppd42ns)

I corrected the following sketch which had bad yg/m3 to ppm conversion thanks to LouiS22 from Domoticz forum remark (type conversion errors leading to 0 values).

https://github.com/empierre/arduino/blob/master/DustSensor_SamYoung_DSM501.ino

I guess I'll have to do the same here (but I lack time...):

DustSensor_Shinyei_PPD42NS.ino

-

@epierre Thanks - I'll have another go at Shinyei PPD42NS sketch once I have time. Ideally, I'd like to combine it with MH-Z14A sketch.

-

@alexsh1 which is a good idea, also a temp/him is quite usefull though I didn't added the impact in the formulas so far.

-

@epierre I have combined the two sketches - works just fine, but need to find a spare temp sensor.The hardware setup looks messy so adding an extra i2c sensor will complicate it even more. I'll come back with the combined three-in-one sketch shortly.

BTW, this

gw.send(msgPM25.set("ppm"));still throws the following error. What version MySensors are you using?

MySensors: Unknown/Invalid sensor type (43)

-

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

The ppmv equation is:

ppmv = mg/m^3 * (0.08205*T)/MT = atmospheric temperature in kelvins = 273.15 + °C

M = molecular weight of the air pollutant = 28.97

(http://www.engineeringtoolbox.com/molecular-mass-air-d_679.html - this is a good link)

0.08205 = Universal Gas Law constant in atm·l/(mol·K)Your code for this equation is:

ppmv=(float)(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/0.01))/1000;Now, I think it should be as follows:

- temp = °C + 273.15

int temp=273.15 + 22;22C - is a typical temp inside though the intention is to use a sensor

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM25*0.0283168)/100) * ((0.08205*temp)/28.97))/1000;I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?

IMPORTANT UPDATE:

I have just received the following result:

PM10: 7373 send: 11-11-0-0 s=0,c=1,t=37,pt=7,l=5,sg=0,st=ok:1.744If I use the following web-site http://www.herramientasingenieria.com/onlinecalc/ppm-mg_m3.php and the result is

mg/m3 = 7373 * 0.283168/100 = 2.08 mg/m3

The molecular weight is 28.97 for dry air2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

Now I have found a spare BMP280 (temp and pressure sensor) which I can use here.

Additionally, I need to use 24-h and 1 year averages - https://www3.epa.gov/airquality/particlepollution/2012/decfsstandards.pdfStay tuned!

-

@alexsh1 said:

@epierre I started looking at the formula you have used in ppmv calculation. Why do you need ppmv? All values in EPA or Europe are in μg/m3.

because domoticz only knows ppm... and many AIQ like use only that except for particles.

- temp = °C + 273.15

int temp=273.15 + 22;

22C - is a typical temp inside though the intention is to use a sensor

not for me

- The amended ppmv equation is going to be:

ppmv=(((concentrationPM250.0283168)/100) * ((0.08205temp)/28.97))/1000;

I have not changed 0.0283168 /100 - not sure that this is. And the whole thing is divided by 1000? why?was a volume conversion

The molecular weight is 28.97 for dry air

2.08 mg/m3 is equivalent to 1.74ppm for a gas with molecular weight=28.97 Pressure=1013.25, Temperature=22CSuccess!

success for the mysensors value ?

MySensors: Unknown/Invalid sensor type (43)Domoticz doesn't recognize this command... I use 1.5.x but I have my own gateway to domoticz

- temp = °C + 273.15

-

@epierre Yes, all works fine now. I modified the combined sketch and here is the final result.

-

Which one to use for detection of fire smoke? Currently have got several MQ-7 but they don't seem so good at it

-

@moskovskiy82 said:

Which one to use for detection of fire smoke? Currently have got several MQ-7 but they don't seem so good at it

as discussed just above, a particle sensor could be good for smoke is a particle concentration, coupled with heat this would be a good indicator

if (concentration > 315000) { Serial.println("Smokes from cigarettes detected! Or It might be a huge fire! Beware!");

-

What about mq2 or mq135? Any experience? As a gas sensor will be more suitable detecting early fire

-

@moskovskiy82 said:

What about mq2 or mq135? Any experience? As a gas sensor will be more suitable detecting early fire

please see what it does, this is not a gas sensor this only detect particle size whatever the gas...

-

@epierre

It still detects concentration. Both state CO detection. So in case of fire won't they detect the increase in concentration much faster that the particle sensor like Sharp’s GP2Y1010AU0F or alternative?

-

@moskovskiy82 For a fire smoke, you can use pretty much any gas or particle sensor - there are a quite few gases formed during the burning process. MQ2 is highly sensitivity and has a fast response time. I can recommend it for a fire detection usage. However, I have been disappointed in MQ* sensors in general - there are not accurate, require 24h heat-up time, consume a lot of power etc. The only advantage is the price.

To detect fire to can use a flame sensor - http://www.instructables.com/id/Flame-detection-using-Arduino-and-flame-sensor/

-

Can someone tell me how to read this line?

float mq135_ro = 10000.0; // this has to be tuned 10K OhmDo I have to messure the sensor and adjust the variable or do I have to tune the resistance? If I have to do the first thing, when do I have to messure it? In warm state and clean air with a multimeter?

-

@epierre Did you check out the airbeam, which is based on a more expensive sensor Shinyei PPD60PV?

http://www.takingspace.org/airbeam-technical-specifications-operation-performance/They made a step-by-step manual about building the same on Shinyei PPD42NS. I took their code and stripped a few parts and this is what I am left with:

#include <SoftwareSerial.h> #include <FlexiTimer2.h> int pin = 3; volatile double rawParticalCount; volatile double totalParticles = 0; volatile double particleCountToDisplay = 0; volatile double ratio = 0; volatile uint16_t timeCounter = 0; #define numberOfPeaksRecording 5 volatile uint32_t previousPeaks[numberOfPeaksRecording]; volatile uint32_t sumOfPreviousPeaks = 0; volatile uint32_t instantGoal = 0; volatile int32_t delta = 0; volatile uint32_t slowMovingAverage = 0; volatile boolean readyToSendData = false; void setup() { Serial.begin(115200); pinMode(pin,INPUT); FlexiTimer2::set(1,1.0/10000,readPin); FlexiTimer2::start(); } void loop() { if(readyToSendData){ Serial.print(rawParticalCount, DEC); Serial.print(" Raw Particle Count (0-10000) "); Serial.print(ratio, DEC); Serial.print(" Ratio (0-100%) "); Serial.print(particleCountToDisplay, DEC); Serial.print(" Particle Count"); Serial.println(""); readyToSendData = false; } } void readPin(){ if(digitalRead(pin) == LOW){ rawParticalCount++; } timeCounter++; if (timeCounter == 10000) { timeCounter=0; //Changes are made here based on Chris Nafis's code: http://www.howmuchsnow.com/arduino/airquality/grovedust/ ratio = rawParticalCount/100.0; //Convert to percentage, the shinyei reads 10milliseconds to 90milliseconds duration for particles. Basing on 10milliseconds, smallest particle assumingly from specification sheet. //FlexiTimer2, reads 10,000 readings per second, which would be 1 reading per 100 microseconds. 100 readings would be 10 milliseconds. Since Shinyei runs at minimal 10 millisecond range. I divided 10,000 readings by 100 to get 100. //Good example would be rawPArticalCount is 5000 half of the 10,000 readings were active. 5000/100 would be 50 which translate to 50% low pulse occupancy. totalParticles = (1.1*pow(ratio,3)-3.8*pow(ratio,2)+520*ratio+0.62); rawParticalCount = 0; // shift counters over, code adapted from template provided by Mike Taylor and Joshua Schapiro from Carnegie Mellon University's CREATE Lab for (uint8_t i = 0; i < (numberOfPeaksRecording-1); i++) { previousPeaks[i] = previousPeaks[i+1]; } previousPeaks[numberOfPeaksRecording - 1] = totalParticles; sumOfPreviousPeaks = 0; for (uint8_t i = 0; i < numberOfPeaksRecording; i++) { sumOfPreviousPeaks += previousPeaks[i]; } instantGoal = 2*sumOfPreviousPeaks; delta = instantGoal - slowMovingAverage; if (delta < -5000){ slowMovingAverage = slowMovingAverage - 250; } else if (delta < -2500){ slowMovingAverage = slowMovingAverage - 120; } else if(delta < -1200){ slowMovingAverage = slowMovingAverage - 60; } else if(delta < -500){ slowMovingAverage = slowMovingAverage - 25; } else if(delta < -5){ slowMovingAverage = slowMovingAverage - 5; } else if(delta < -1){ slowMovingAverage = slowMovingAverage - 1; } else if(delta > 5000) { slowMovingAverage = slowMovingAverage + 500; } else if(delta > 2500){ slowMovingAverage = slowMovingAverage + 250; } else if(delta > 1200){ slowMovingAverage = slowMovingAverage + 120; } else if(delta > 500){ slowMovingAverage = slowMovingAverage + 50; } else if(delta > 5){ slowMovingAverage = slowMovingAverage + 5; } else if(delta > 1){ slowMovingAverage = slowMovingAverage + 1; } particleCountToDisplay = slowMovingAverage; readyToSendData = true; } }I have not adopted it for MySensors yet.

I like moving average they use, but the values do not make sense to me:0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 53470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 27.0000000000 Ratio (0-100%) 53970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 54470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 21.6200008392 Ratio (0-100%) 54970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 55470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 24.2800006866 Ratio (0-100%) 55970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 56470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 24.1200008392 Ratio (0-100%) 56970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 57470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 22.3199996948 Ratio (0-100%) 57970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 58470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 20.3600006103 Ratio (0-100%) 58970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 59470.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 17.6299991607 Ratio (0-100%) 59970.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 60220.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 19.0499992370 Ratio (0-100%) 60720.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 0.0000000000 Ratio (0-100%) 60715.0000000000 Particle Count 0.0000000000 Raw Particle Count (0-10000) 20.6599998474 Ratio (0-100%) 61215.0000000000 Particle Count

-

@alexsh1 said:

I took their code and stripped a few parts and this is what I am left with:

@alexsh1 the PPDN42 is for 1 micron and 2.5 micron , this one is for 0.5 micron

airbeam has standard code: https://github.com/HabitatMap/AirCastingAndroidClient/blob/master/arduino/aircasting/aircasting_shinyeiPPD42NS.ino

or I've not seen ?

-

@epierre this is not the air beam code. They introduced "do it yourself" consept similar to the airbeam but with a different sensor (shinyei ppd42ns)